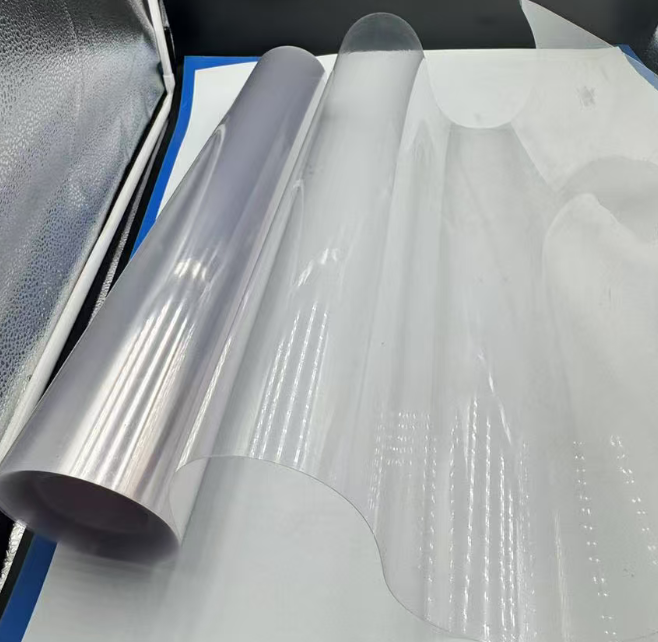

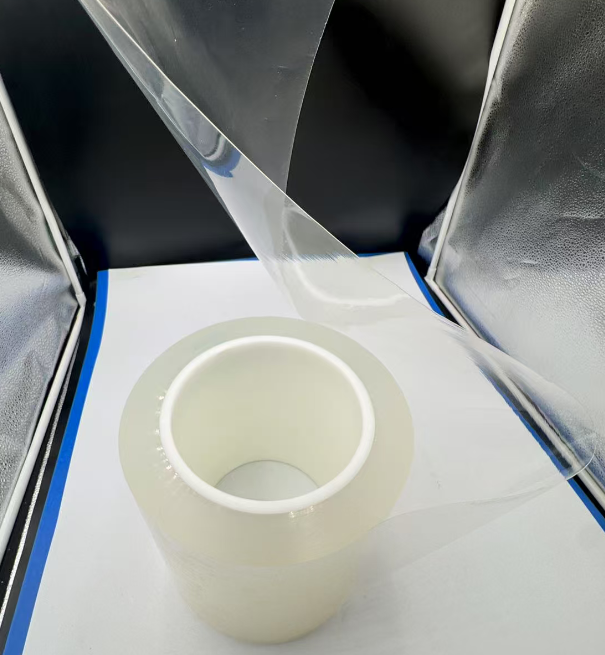

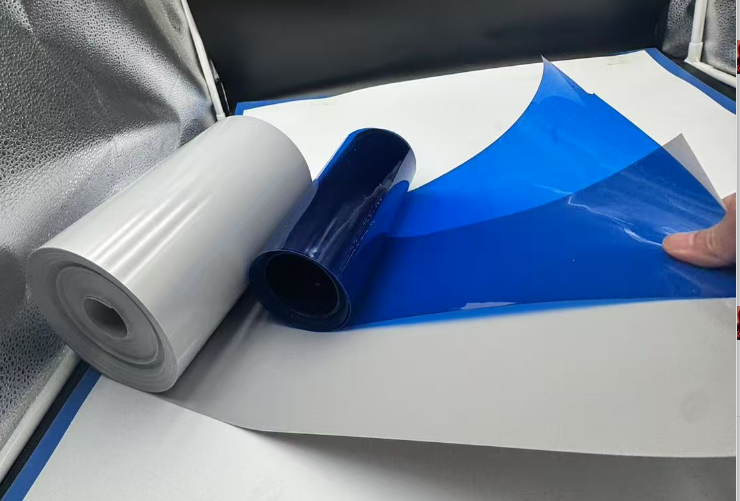

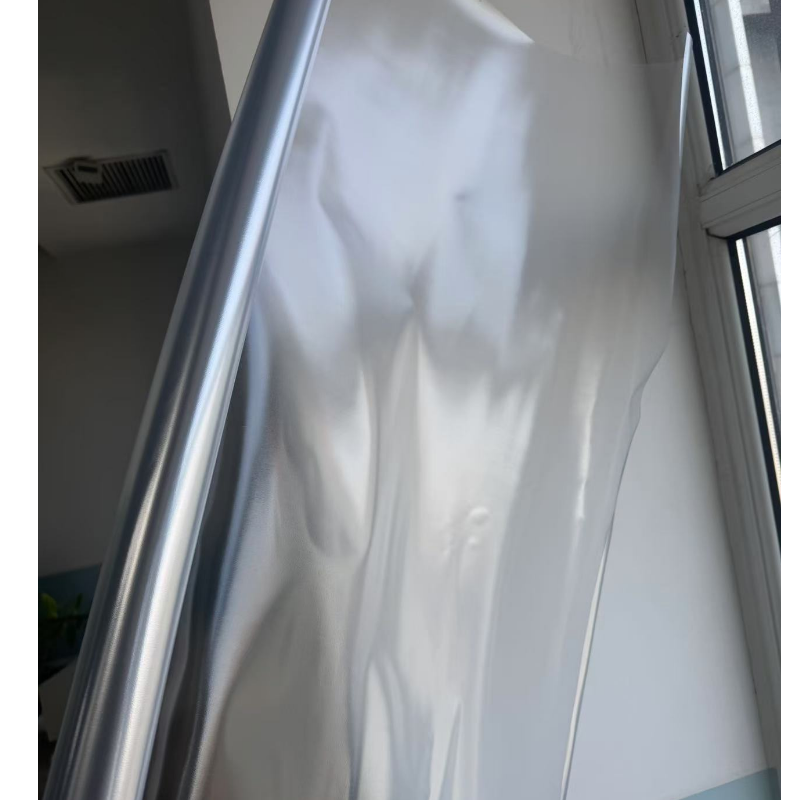

White opaque high barrier PVDC hard sheet

White opaque high barrier PVDC hard sheet

Usually, it is a composite hard sheet made of polyvinyl chloride (PVC) as the substrate and coated with polyvinylidene chloride (PVDC) latex and other processes. It is widely used in the field of pharmaceutical packaging.

- top leader plastic

- China

- 19 business days

- 200 tons/month

- Information

White opaque high barrier PVDC hard sheet

Usually, it is a composite hard sheet made of polyvinyl chloride (PVC) as the substrate and coated with polyvinylidene chloride (PVDC) latex and other processes. It is widely used in the field of pharmaceutical packaging.

Appearance: It is white and opaque, with a flat and smooth surface and no obvious defects, such as cracks, scars, bumps and wrinkles, perforations, precipitation, missing edges, oil stains, etc.

High barrier properties: PVDC molecular chains contain a large number of polar chlorine atoms, which makes it difficult for oxygen molecules and water molecules to move in them. It has excellent barrier properties for oxygen, water vapor, etc., and can effectively prevent the deliquescence, oxidation and deterioration of drugs, and extend the shelf life of drugs. Its oxygen barrier performance is 10 times higher than that of PVC of the same thickness, and its water vapor barrier performance is 5-10 times higher.

Good mechanical properties: It has certain rigidity and flexibility, and is impact-resistant, corrosion-resistant, aging-resistant, UV-resistant, and radiation-resistant. It can better protect drugs during packaging, transportation and storage, and is not easy to break or damage.

Easy to process and shape: It has similar flexibility and rigidity to PVC hard sheets, is easy to shape and heat-seal quickly, and is suitable for ordinary blister aluminum-plastic packaging machines. It can be processed by blister molding and other processing operations. The processing parameters and methods are similar to those of PVC hard sheets, and it can be easily made into blister packages of various shapes to meet the packaging needs of different medicines.

Chemical stability: Low content of vinyl chloride monomer and low index of easy oxidation, safe and non-toxic, will not react chemically with medicines, ensuring the quality and safety of medicines.

Production process

Coating method: First, the PVC hard sheet is surface treated, then coated with water-based polyurethane (PU) adhesive, and then the PVDC emulsion is evenly coated on the PU adhesive layer. After drying, curing and other process steps, the PVDC layer is firmly attached to the PVC substrate. The performance of the composite hard sheet can be adjusted by controlling the process parameters such as coating amount, coating times, drying temperature and time.

Co-extrusion method: Add PVC raw materials and PVDC raw materials to different extruders respectively, and after heating, melting, extrusion and other processes, the two materials are compounded together in the mold to form a PVC/PVDC composite hard sheet. The composite hard sheet produced by the co-extrusion method has tight bonding between the layers and stable barrier properties.

Application field

Pharmaceutical packaging: Mainly used for blister packaging of pharmaceutical tablets, capsules, etc., which can provide good protection for drugs and ensure the stable quality of drugs within the validity period. It is especially suitable for drugs with high requirements for moisture resistance and antioxidant, such as antibiotics, cardiovascular and cerebrovascular drugs, biological agents, etc.

Within 15-20 days after received payment...more