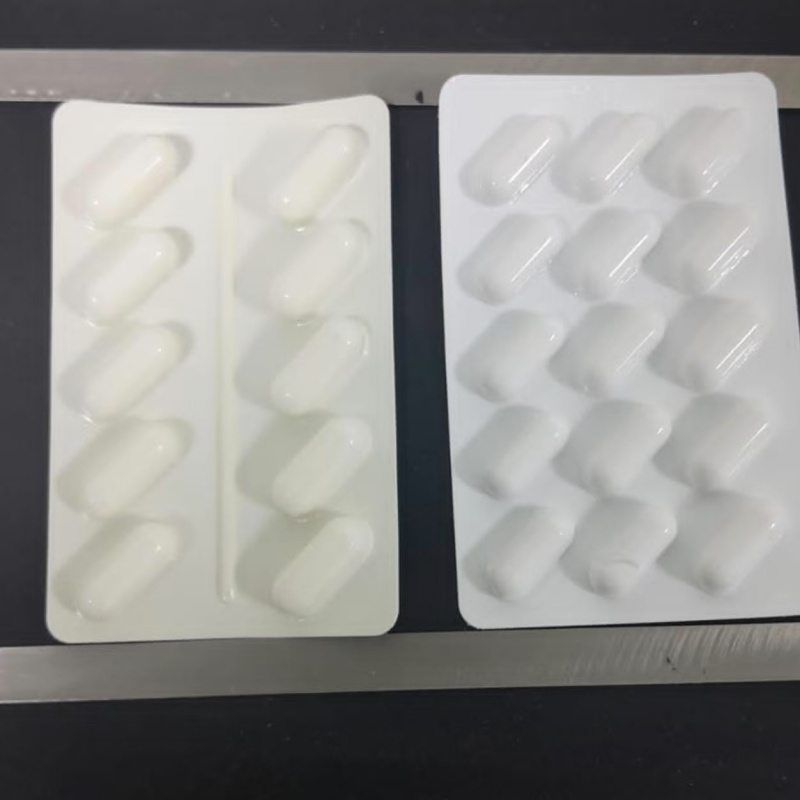

0.25mm white opaque PVC film for blister packaging of tablets and capsules

0.25mm white opaque PVC film for blister packaging of tablets and capsules.

Good barrier properties: can effectively block the influence of external factors such as moisture, oxygen, light on tablets and capsules, prevent drugs from getting damp, oxidized or deteriorating, and extend the shelf life of drugs.

- top leader plastic

- China

- 15 business days

- 1500 tons/month

- Information

0.25mm white opaque PVC film for blister packaging of tablets and capsules.

Good barrier properties: can effectively block the influence of external factors such as moisture, oxygen, light on tablets and capsules, prevent drugs from getting damp, oxidized or deteriorating, and extend the shelf life of drugs.

Opacity can better protect drugs from light exposure, especially light-sensitive drugs;

Good heat sealing performance: can be closely combined with PTP aluminum foil and other materials through heat sealing process to form a good sealing effect, ensuring that the drugs in the package are in a closed environment to prevent leakage and contamination.

Easy to process and shape: can be softened by heating, and quickly and accurately formed into blisters of various shapes and sizes on the blister packaging machine to meet the packaging needs of tablets and capsules of different specifications.

Production process

Raw material preparation: select polyvinyl chloride resin particles that meet the pharmaceutical packaging standards, as well as appropriate amounts of plasticizers, stabilizers, lubricants and other additives to ensure that the quality and performance of the film meet the requirements.

Mixing and stirring: add the raw materials to the mixer in a certain proportion, stir and mix them thoroughly, and make the additives evenly dispersed in the polyvinyl chloride resin.

Extrusion molding: The mixed raw materials are heated and melted by an extruder, and then extruded into sheets through a die. During the extrusion process, the temperature, pressure, extrusion speed and other parameters are controlled to ensure the thickness uniformity and quality stability of the film.

Calendering treatment: For some films that require higher flatness and finish, the calendering process can be further adopted to calender the extruded sheet film through multiple rollers of the calender to make its surface smoother and the thickness more precise.

Cooling and shaping: The film after extrusion or calendering needs to be cooled and shaped by a cooling device to solidify it into a film with a certain strength and hardness. The cooling speed and temperature control have an important influence on the performance of the film.

Slitting and packaging: The cooled and shaped film is cut into appropriate widths and lengths as needed, and then packaged for easy transportation and storage.

Within 15-20 days after received payment...more