The Versatile Properties of Natural PP Film in Tableware and Cold Drink Packaging

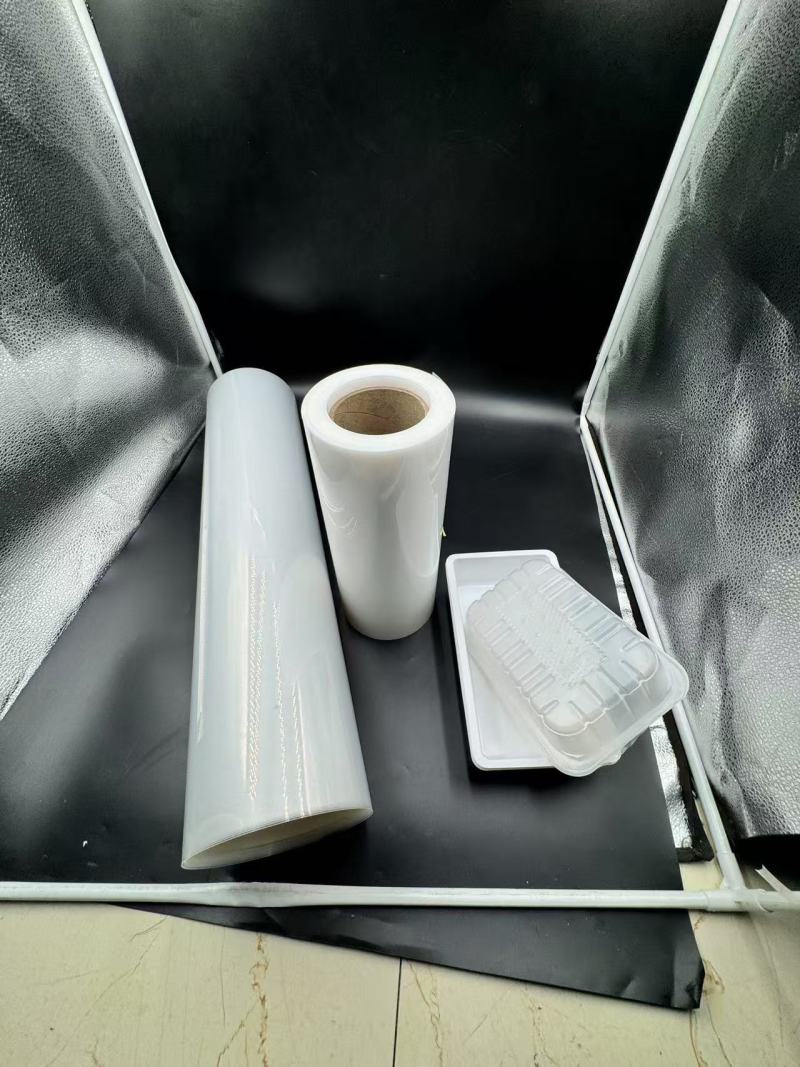

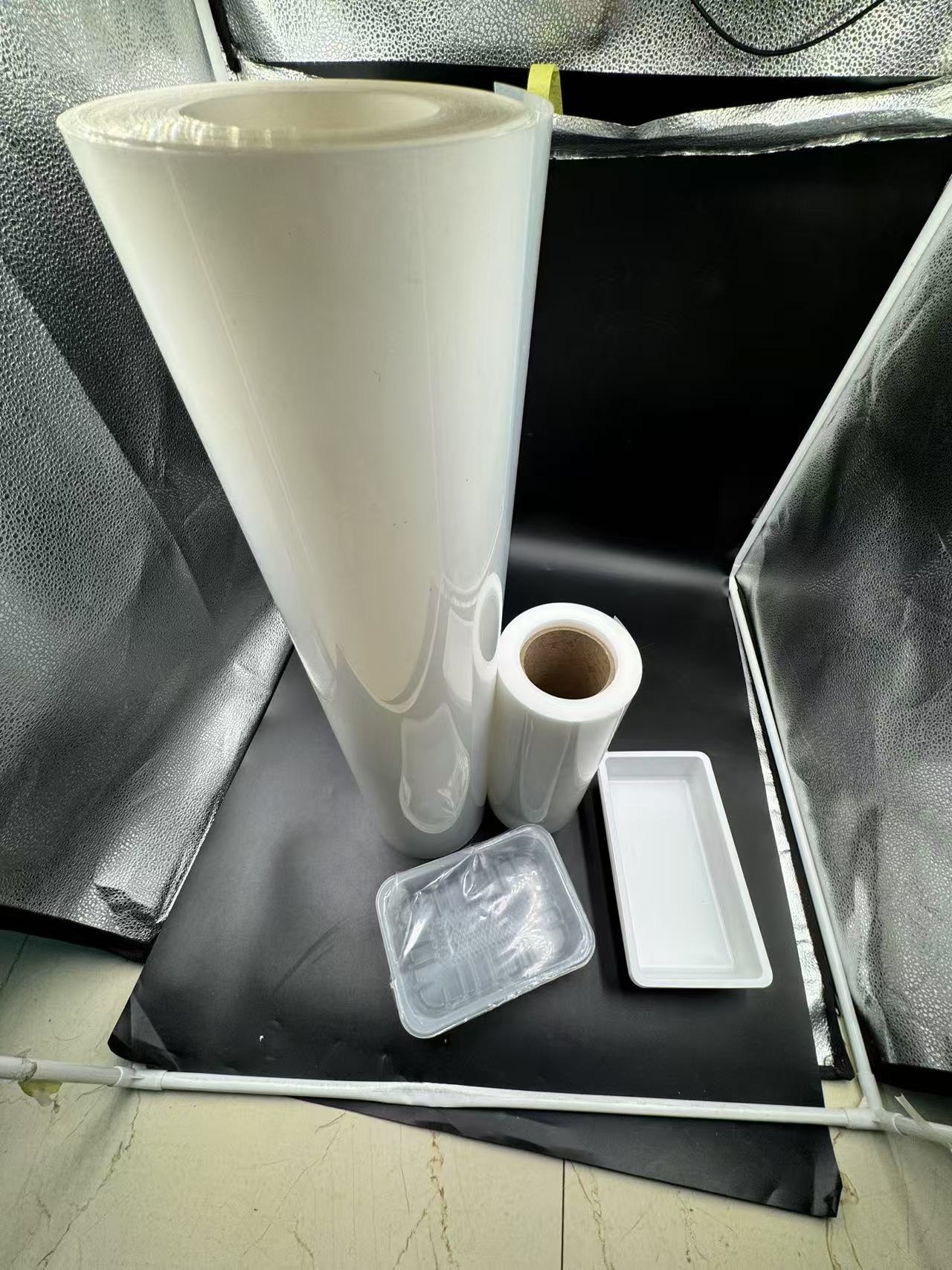

NamePP Plastic film roll

SizeTk:0.1-0.9mm, h100-1200mm

MaterialPET/PP/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageVegetable/Fruit/Meat

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Introduction

In the dynamic world of packaging, where functionality, safety, and aesthetics are paramount, natural PP (Polypropylene) film has emerged as a standout material. Renowned for its durability, heat resistance, and eco-friendly profile, natural PP film is revolutionizing applications in blister packaging for tableware, microwave-safe meal containers, and cold drink cups. Its subtle, translucent appearance and robust performance make it a favorite among manufacturers aiming to balance practicality with consumer appeal. This article explores the distinctive characteristics of natural PP film and its transformative role in these packaging sectors, weaving in vivid examples and industry insights to highlight its impact.

natural PP film is revolutionizing applications in blister packaging for tableware, microwave-safe meal containers, and cold drink cups. Its subtle, translucent appearance and robust performance make it a favorite among manufacturers aiming to balance practicality with consumer appeal. This article explores the distinctive characteristics of natural PP film and its transformative role in these packaging sectors, weaving in vivid examples and industry insights to highlight its impact.

Characteristics of Natural PP Film

Natural PP film possesses a unique combination of properties that make it an ideal choice for diverse packaging needs. Below are its key characteristics:

Subtle Transparency and Aesthetic Appeal

Unlike fully transparent films, natural PP film offers a soft, translucent finish that lends a sophisticated, understated look to packaged goods. This natural clarity enhances product visibility without overpowering the contents, making it perfect for showcasing tableware or beverages. For instance, a set of cutlery packaged in natural PP film appears clean and inviting on a retail shelf, with just enough transparency to highlight the product’s quality.

High Heat Resistance

PP film is renowned for its ability to withstand high temperatures, making it suitable for microwave-safe applications. Unlike other plastics that may warp or release harmful chemicals when heated, natural PP film remains stable, ensuring safety and reliability. This property is critical for microwave meal containers, where consumers expect both convenience and durability.

Excellent Durability and Flexibility

Natural PP film combines tensile strength with flexibility, allowing it to resist cracking or tearing during handling and transport. This durability is essential for blister packaging, where tableware like forks, spoons, or plates must remain secure. Picture a stack of disposable plates encased in PP film—its toughness ensures the packaging holds up under pressure, protecting the contents until they reach the consumer.

Eco-Friendly and Recyclable

Sustainability is a growing priority in packaging, and natural PP film aligns with this trend. It is recyclable and produces fewer emissions during manufacturing compared to alternatives like PVC. For environmentally conscious brands, PP film offers a way to reduce their ecological footprint while maintaining high performance. Cold drink cups made from PP film, for example, can be recycled in many regions, appealing to eco-aware consumers.

Chemical Resistance and Food Safety

PP film is inherently resistant to oils, grease, and most chemicals, making it a safe choice for food-contact applications. This property ensures that cold drink cups or microwave containers remain uncontaminated, preserving the flavor and quality of the contents. Regulatory compliance with food safety standards, such as FDA or EU guidelines, further enhances its suitability for these uses.

Cost-Effectiveness and Processability

Natural PP film is relatively inexpensive to produce and easy to process, supporting a range of manufacturing techniques like thermoforming and sealing. This versatility allows manufacturers to create intricate blister packs or lightweight cups efficiently, keeping production costs low without compromising quality.

Applications of Natural PP Film

Natural PP film’s unique properties translate into a wide range of applications in tableware blister packaging, microwave-safe containers, and cold drink cups. Below, we explore these uses with specific examples to illustrate their real-world impact.

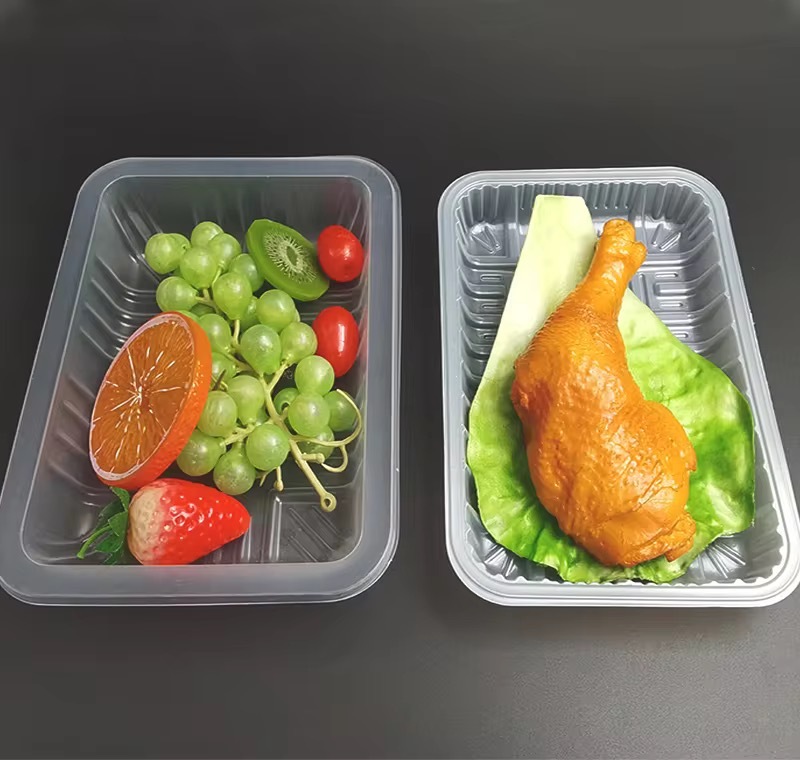

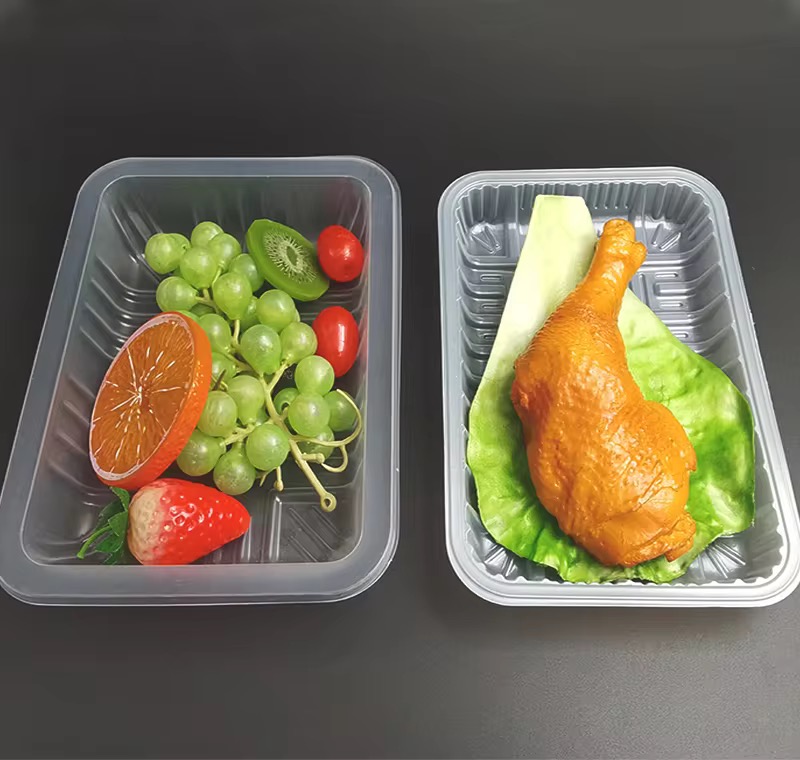

Blister Packaging for Tableware

Blister packaging is a staple for disposable and reusable tableware, and natural PP film excels in this role. Its flexibility allows it to form tight, protective shells around items like plastic forks, knives, or ceramic plates, while its transparency showcases the product’s design. For instance, a set of biodegradable bamboo spoons packaged in a PP film blister pack stands out in a supermarket, with the film’s natural sheen highlighting the eco-friendly material. The film’s strength also ensures the packaging remains intact during shipping, preventing damage to delicate items.

Microwave-Safe Meal Containers

The demand for convenient, microwave-safe meal solutions has surged, and natural PP film is at the forefront of this trend. Used as a lidding film or structural component in containers, PP film withstands the heat of microwave cooking without deforming or leaching chemicals. Imagine a busy professional reheating a pre-packaged lasagna in a PP film-sealed container—the film maintains a secure seal, prevents splattering, and ensures the meal is safe to eat. Its clarity also allows consumers to check the food’s condition before heating, adding a layer of confidence.

Cold Drink Cups

Cold drink cups, whether for iced coffee, smoothies, or soft drinks, benefit immensely from natural PP film. Often used to create the cup itself or as a sealing film for lids, PP film offers durability and clarity that enhance the drinking experience. A vibrant bubble tea in a PP film cup, for example, showcases the colorful layers of tapioca pearls and fruit syrups through the translucent material, enticing customers. The film’s resistance to condensation ensures the cup remains sturdy even when sweating in warm weather, preventing leaks or collapses.

Tamper-Evident Seals for Safety

Safety is critical in food and beverage packaging, and PP film is often used to create tamper-evident seals for both tableware and cold drink cups. For microwave containers, a PP film seal ensures the meal remains untouched until opened, while in cold drink cups, it prevents spills and contamination during delivery. A consumer ordering an iced latte from a café can trust that the PP film seal on the lid hasn’t been breached, guaranteeing freshness and hygiene.

Promotional and Multi-Pack Packaging

Natural PP film is also used to bundle tableware or cold drink cups for promotional or bulk sales. Its strength and flexibility make it ideal for wrapping multiple items, such as a set of reusable straws or a six-pack of iced tea cups. The film’s subtle transparency allows branding and barcodes to remain visible, enhancing marketability. For example, a picnic-themed tableware set wrapped in PP film conveys a sense of practicality and style, appealing to families planning outdoor gatherings.

Within 15-20 days after received payment...more