- Home

- >

News

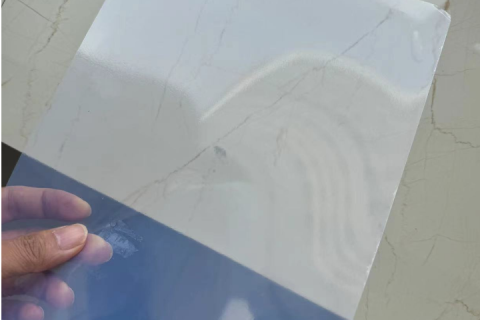

Title: Pharmaceutical Company Launches New Thermoformed PS Film Packaging to Enhance Product Safety Date: August 15, 2023 Location: Basel, Switzerland In a groundbreaking move for the pharmaceutical industry, Swiss-based pharmaceutical giant, MediPharm, has announced the launch of its latest packaging innovation—thermoformed polystyrene (PS) film packaging. The new packaging solution was unveiled at a press conference held at MediPharm's headquarters in Basel, where company executives highlighted the advantages and future implications of this development for the industry. Key People Involved: The announcement was led by MediPharm's CEO, Dr. Andreas Müller, and the Head of Packaging Development, Dr. Elena Weiss. Both have been instrumental in driving the project from concept to implementation. Also in attendance were representatives from the company’s manufacturing partners and key stakeholders in the pharmaceutical supply chain. Causes and Motivations: The initiative to develop thermoformed PS film packaging stemmed from MediPharm's commitment to enhancing the safety and integrity of its pharmaceutical products. In recent years, the company has faced challenges with existing packaging materials that, while effective, did not fully meet the evolving needs of the market, particularly regarding durability, product visibility, and cost efficiency. Additionally, the rising concern for product safety during transportation and storage pushed the company to seek out a more robust packaging solution. Development Process: The development of the new PS film packaging began two years ago, with MediPharm's R&D team conducting extensive research into various materials and packaging technologies. The team focused on identifying a material that could offer superior protection against environmental factors, maintain the integrity of sensitive medications, and be easily customizable for different pharmaceutical products. After rigorous testing and several iterations, the team settled on polystyrene (PS) films due to their clarity, rigidity, and excellent thermoforming capabilities. Collaborating with leading packaging manufacturers, MediPharm developed a production process that utilizes advanced thermoforming techniques to create custom-fit packaging for various pharmaceutical products, including blister packs, trays, and clamshells. Results of the Launch: The introduction of thermoformed PS film packaging has been met with positive responses from industry experts and partners. Dr. Elena Weiss highlighted that the new packaging not only enhances the protection of the products but also significantly improves the efficiency of the packaging process. “We’ve seen a 20% reduction in material costs and a 15% increase in production speed, thanks to the lightweight and easily moldable nature of PS films,” Dr. Weiss reported. Moreover, the clear visibility offered by PS films has been praised for its potential to reduce errors in product identification and enhance quality control. The launch also aligns with MediPharm’s sustainability goals, as the new packaging material is fully recyclable, addressing concerns about environmental impact. Effects and Future Implications: The successful rollout of thermoformed PS film packaging is expected to set a new standard in pharmaceutical packaging. MediPharm plans to extend the use of this packaging across its entire product line within the next year, with the potential for collaboration with other pharmaceutical companies seeking to adopt similar technologies. Dr. Andreas Müller expressed confidence that this innovation would not only improve the safety and efficiency of MediPharm's products but also drive positive change across the pharmaceutical industry. “We believe this new packaging will lead to greater confidence among consumers and healthcare providers in the safety and reliability of our products,” Dr. Müller stated. As the industry continues to prioritize product safety and sustainability, MediPharm’s introduction of thermoformed PS film packaging could mark a significant shift in how pharmaceutical products are packaged and delivered to the market.

Title: PP Film Revolutionizes Printable Materials Market Date: August 15, 2023 Location: New York City, NY Key Figures: John Carter, CEO of PrintTech Solutions, and Dr. Emily Roberts, Lead Researcher, Advanced Polymers Lab Event Overview: Although PP film has been a recent spotlight in printing, diverse applications make it an ideal material for various uses. On August 15, 2024, the company leading developments in printable materials, PrintTech Solutions, held a press conference in New York City to introduce their most current innovations in PP film technology. Background: This film is also in great demand in the printing area because of its unique features like flexibility, durability, and lower costs. Unlike other printing material, traditional printing PP film will provide a non-porous, smooth surface for high-quality printing of vivid colors and sharp details. With such properties, it finds greater application in labels, packages, banners, and several other printed material types. According to John Carter, chief executive of PrintTech Solutions, demand for sustainable, high-performance printing materials is growing fast. "As companies look at reducing their environmental footprint while maintaining the highest level of quality, PP film becomes the material of choice in a broadening range of applications," he added. Development Process: According to Dr. Emily Roberts, lead researcher of the Advanced Polymers Laboratory, several breakthroughs in science have made the development of advanced PP films possible. She further elaborates on the research orientation: "In our team, we had focused on the improvement of the printability of PP film by adjusting its surface properties and improving its compatibility with flexographic, digital, and screen printing technologies.". The team has also worked on enhancing its resistance to fading so that the film retains the brilliance of the printed matter, even when exposed to blinding sunlight for a longer period and harsh environmental conditions. Result and Impact: The result of these innovations is a new line of PP films that are more durable, flexible, and increasingly environment-friendly. PP films developed by PrintTech Solutions are fully recyclable and produced with a lower carbon footprint compared to traditional materials, in line with the growing consumer demand for sustainable products and the industry's move toward eco-friendly practices. These advanced PP films, therefore, within the very short time of their introduction, have brought tremendous change in the printing industry. Some big houses have started using the material for their packaging and promotional material and commented positively about the superior print quality, durability, and sustainability. Moreover, it is cost-effective and also turned out to be very impressive for a business venture by cutting down costs without affecting the quality. Conclusion: The importance of PP film in the future will only continue to rise with the further expansion of the market in printable materials. Companies at the forefront of such developments are those like PrintTech Solutions, and leading educational research institutions like Advanced Polymers Lab; PP film will soon become a benchmark within the industry for quality and sustainability in printing. Their success is just another indication of the growing requirement for materials that can answer both performance and environmental demands, setting a new benchmark for the future of printable materials.

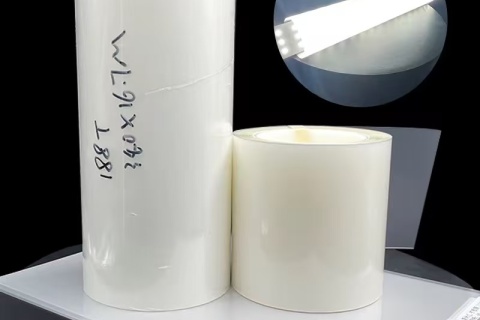

An application of the BPET conductive material boosts the electronics industry. August 2024, Shanghai, Global Electronics Manufacturing Exhibition; Zhang Qiang: technical director of a leading electronics materials R&D company. In August 2024, at the Global Electronics Manufacturing Exhibition held in Shanghai, a new type of conductive material took center stage. The Technical Director, Zhang Qiang, of one of the key Electronics Materials R&D enterprises, has brought along with him a team to introduce very latest BPET (Biaxially Oriented Polyethylene Terephthalate) conductive material. This launch marks the large step forward applying static protection and conductive materials within the electronics industry. Background: Help Needed to Meet Increased Demand for Static Protection With their ever-growing sophistication and complication, electronic products are also requiring more dependable static protection and conductive materials. Having noticed this emerging market demand, Zhang Qiang and his group embarked on a multi-year development program in search of creating a high-performance material to satisfy the demand. "We all noticed that all kinds of conductive materials available in the market had a number of problems, such as low transparency and unstable conductivity, which limited their usage in high-end electronic devices," Zhang Qiang explained during the launch. "It is this that moved us to develop a material that links high transparency, brightness, and stable conductive performance to serve the industry much better." Process: Overcoming Technical Challenges and Enhancing Performance The BPET material is produced with the help of imported production lines to ensure high transparency, brightness, and crystal-free surfaces with excellent flatness. Food grade slip agents were added by the team into the material to give it excellent surface smoothness, good processability, and well-preserved conductive properties. BPET sheets come in various specifications, thereby allowing for high production capacity at superior quality and cost-effectiveness. This is an environment-friendly and non-toxic material that meets QS food safety certification and passes the European Union's SGS environmental certification, hence suitable for industries with strict compliance criteria to safety and the environment. The following are several conductive grades for the materials: - Permanent Conductive Sheet: $10^10$ ohms - Permanent Antistatic Sheet: 10^10 ohms - Permanent Semi-Conductive Sheet: 10^6-10^9 ohms These variations show steady and smooth conductive performance, which ensures the stability and reliability of products for various applications. Besides, BPET can be processed into flat sheets, slit, and laminated; while PET-G and GAG grades are especially suitable for producing high-end electronic products. Result: Good Market Response and Wide Industrial Application In the exhibition, BPET conductive material was very fast.

Revolutionizing Folded Box and Pharmaceutical Thermoforming Packaging—PVC Sheets Date: August 13, 2023 Location: Shanghai, China Key Players: Leading packing manufacturers, pharmaceutical companies, environmental advocates Event Summary: In what could emerge as the most radical paradigm shift in packaging, Shanghai's top manufacturers yesterday announced increased application of polyvinyl chloride sheets for folded box and pharmaceutical thermoforming packaging. This will change the world in terms of product protection, cost efficiency, and manufacturing versatility. Background: Durability, flexibility, and cost represent some of the most preferred characteristics of PVC, and it has thereby found a place in most industries. However, recent developments in manufacturing PVC sheets raise renewed interest in using the material for special applications in pharmaceutical packaging and other consumer products. Cause and Course of Events: The trend of using PVC sheets in folded box and pharmaceutical packaging started this year when a number of packaging specialists, associated with different pharmaceutical companies, launched an all-inclusive study regarding the effectiveness of the material. Their conclusions, published in June 2024, pointed to some main advantages of PVC sheets, first of all related to their better defense against moisture, oxygen, and light—parameters that play a very important role in the preservation of pharmaceutical products. After the research, some leading packaging companies in Shanghai started to apply PVC sheets in their production lines within a very short period of time. It is the possibility of easily cutting, folding, and thermoforming the material into desired shapes that allows these companies to fulfill the tough requirements from pharmaceutical industries while offering beautiful and functional packaging to consumer products. Result: Beginning with the adoption of PVC sheets, fruitful results have already started to show. Pharmaceutical firms are reportedly found to declare that most of the problems related to packaging, such as contamination and damage of the product during transportation, have reduced considerably. Consumers have also welcomed the enhanced protection and longer shelf life of products packaged with PVC. Moreover, this reduces the overall production cost of PVC sheets, thereby enabling the manufacturer to maintain a competitive price and upgrade the quality of packaging. Impact and Future Prospects: Interest in PVC sheets for folded box and pharmaceutical thermoforming packaging has been quite successful, and other markets, like food and electronics, where solid, protective, and cost-efficient packaging is a must, may get attracted to it. Environmentalists still are wary and remind that without recycling programs, harm to the environment from PVC will only continue to grow. As innovations further the development in the packaging industry, PVC sheets can only play an ever-increasing role as a solution providing a reliable performance-cost-consumer safety balance for manufacturers. With Shanghai at the helm of this change, its packaging sector is well on course to lead global efforts towards improving products' packaging through strategic material use, such as PVC.

The Rise of PET Sheets in Food Packaging and Labeling: A Sustainable Choice *Date: August 9, 2023 Location: Global Market Key Stakeholders: PET Manufacturers, Food Industry, Environmental Organizations* Introduction Polyethylene Terephthalate (PET) sheets have rapidly gained traction in recent years as an innovative material in the packaging industry. Renowned for their excellent toughness, high strength, and superior transparency, PET sheets have become a favored choice for food packaging and labeling applications. The material’s ability to be printed on, recycled, and its environmentally friendly properties, particularly its non-toxic combustion process, have further solidified its position as a leading packaging solution. This article explores how PET sheets are transforming the food packaging and labeling landscape, highlighting key developments and their impact on the market. Background PET sheets were developed to address the growing demand for materials that not only provide strong protective packaging but also align with global environmental sustainability goals. With the increasing awareness and concern over environmental degradation, particularly from non-recyclable plastics, the food industry began searching for alternatives that could offer both functionality and eco-friendliness. PET sheets, with their remarkable features, emerged as an ideal solution, gradually gaining popularity among consumers, producers, and environmental advocates alike. Features and Advantages 1. Transparency and Gloss: PET sheets offer exceptional transparency and surface gloss, making them highly effective in showcasing food products. This feature is especially valuable in retail environments, where product visibility is a critical factor in consumer decision-making. 2. Surface Decoration: The surface of PET sheets is highly receptive to decoration without the need for additional surface treatments. They are easy to print on, emboss, and even metalize using vacuum metal coating, making them ideal for creating attractive and informative labels. 3. Mechanical Strength: The robust mechanical strength of PET sheets ensures that food products are well-protected during transportation and handling, reducing the risk of damage and spoilage. 4. Barrier Properties: PET’s excellent barrier properties against oxygen and water vapor help preserve the freshness and quality of food products, extending their shelf life. 5. Chemical Resistance: PET sheets are resistant to various chemicals, which is crucial for packaging foods that may come into contact with reactive substances. 6. Safety and Hygiene: Non-toxic and compliant with stringent hygiene standards (such as GB13113-91), PET sheets are suitable for packaging food, pharmaceuticals, and medical devices. They can also be sterilized using radiation, ensuring the safety and integrity of the packaged goods. 7. Environmental Compatibility: PET is not only recyclable but also burns without releasing harmful substances, making it a key material in the global push for sustainable packaging solutions. Its excellent thermoforming capabilities allow it to be easily molded into various shapes, further enhancing its versatility in packaging applications. Event and Impact In recent years, several leading food manufacturers have transitioned to using PET sheets for their packaging and labeling needs. This shift was primarily driven by the material’s superior performance and environmental benefits. For instance, in a significant move in 2023, a global food giant replaced its traditional PVC packaging with PET for its entire line of snack products. This decision was lauded by environmental groups and resulted in a notable increase in sales, as consumers responded positively to the company’s commitment to sustainability. Moreover, the adoption of PET sheets in labeling has revolutionized the way food products are presented and marketed. The ability to easily print high-quality graphics and text directly onto the packaging has enabled brands to create more engaging and informative labels, enhancing their appeal on store shelves. Outcome and Future Prospects The widespread adoption of PET sheets in food packaging and labeling has led to a significant reduction in the environmental footprint of the packaging industry. The material’s recyclability and safe combustion have addressed many of the environmental concerns associated with traditional packaging materials. As a result, PET sheets have not only met the immediate needs of the food industry but also contributed to the long-term goal of reducing plastic waste and promoting sustainability. Looking ahead, the market for PET sheets is expected to continue growing, with more industries recognizing their value. Ongoing advancements in PET technology, such as improved barrier properties and enhanced printability, will likely further solidify PET’s position as the material of choice for food packaging and labeling. In an era where environmental sustainability is no longer an option but a necessity, PET sheets are set to play a pivotal role in shaping the future of packaging.

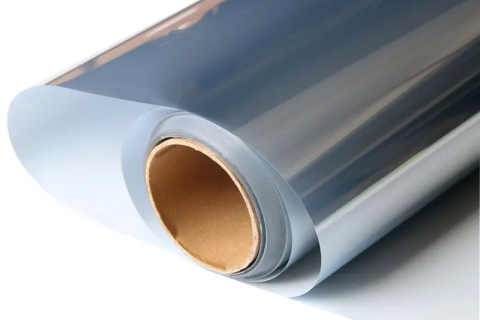

NamePET Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

NamePP Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

NamePVC/PE Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name:PP Plastic food packing Size: DIA 140 *DIA90*H80MM MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

NameLLDPE shrink/stretch film roll SizeTk:0.012-0.023mm, h100-1200mm MaterialPETG/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

NameCPP Plastic film roll SizeTk:0.010-0.023mm, h100-800mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePrinting packing Vegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

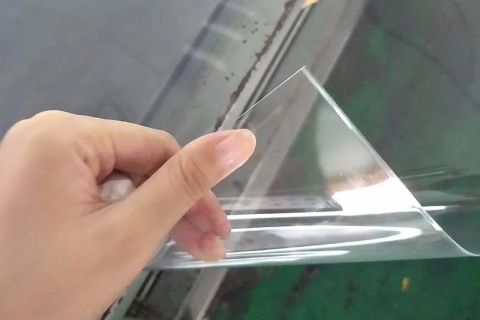

NamePVC flexible film Size0.05-2mm Materialpvc Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageBeddings packing, garment packing FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service