- Home

- >

News

Transparent Biaxially Oriented Polypropylene (BOPP) film has become an essential material in various industries due to its unique properties and versatility. This article will explore the extensive applications of transparent BOPP film in different fields, including food packaging, stationery, tobacco, and gift packaging. We will discuss its advantages, manufacturing process, and future prospects.

1. Advertising and Signage Printable transparent PVC film is widely used in the advertising and signage industry. Its transparency allows for creative designs that can be applied to windows, glass doors, and other transparent surfaces. Whether it's for promoting a brand, announcing an event, or providing directional signage, PVC film offers a sleek and eye-catching solution. The film can be printed with vibrant colors and high-resolution graphics, ensuring maximum visibility and impact. For example, in retail stores, printable PVC film is used to create window displays that attract customers and showcase products. The transparency of the film allows passersby to see inside the store while still being able to view the promotional messages printed on the film. In addition, PVC film can be used for outdoor signage, such as billboards and banners, as it is weather-resistant and can withstand exposure to sunlight, rain, and wind.

Antistatic and Thermoformable PET Film: Wonders of Versatility by In the bustling metropolis, one young, innovative entrepreneur named Lily Chang was going to change the world of materials. It was the year 2024, and Lily had just discovered the astonishing properties of antistatic and thermoformable PET film. Little did she know that this would be an exciting journey that would affect many industries and change lives. The finding of sustainable and practical solutions for day-to-day problems had always remained close to her heart. Progressing further in the world of materials, she found anti-static thermoformable PET film. Curious about its capabilities, she started to find ways where it can be used. It was on one such day while sitting in the small office and gazing out at the skyline of the city that she finally thought that with such film, she might print out A4 sheets that are singularly special. She was so thrilled by the very idea that soon she got down to work on it. Lily then called a local printing company and described her idea. To begin with, the printing company was somewhat skeptical, but once they had samples of the PET film, skepticism turned into interest. Together they began experimenting with different ways of printing the film and soon discovered that it could bear excellent bright prints. The news began to circulate about Lily's printable A4 PET film sheets. Their unique features increased the attraction of students and professionals alike towards these sheets. Because of the antistatic property, prints do not possess static electricity and hence are easily handleable and storable. The thermoformable nature of the film opens more ways of creative usage, such as making note cards or bookmarks in an arbitrary form. As the news spread, Lily was invited to present the product at a local trade show. She was happy to expose her innovation to more people, so she accepted the invitation. The booth was flooded with visitors during the trade show. Still, people were further surprised to see the versatility of PET film. One of them was Alex, a graphic designer who was pretty impressed and visualized using these sheets for his design projects. Alex walked up to Lily and started a conversation with her. Soon, both found that they shared an interest in innovation and design. Alex also mentioned to her about the PET film for customized packaging and how she could join on a project to work with it. The idea thrilled Lily, and they did not delay in starting their work. They started researching all types of packaging needs and came up with a few ideas. One of the ideas was to do some innovative packaging for a local cosmetics brand. The cosmetic company was looking for varnish and striking green packaging solutions. Lily and Alex presented their idea of using antistatic and thermoformable PET film. Interested, the company decided to give it a try. Thus, Lily and Alex were putting great effort into designing packaging and then actually making it. They used the thermoformable property of the film to create custom shapes that would fit the cosmetics products perfectly. The antistatic feature would protect them against electrostatic discharges during transport and storage. The result was amazing. The packaging was beautiful, but not only that-it was functional. It called the attention of the consumers and soon became a hit. The cosmetics company loved the result and ordered more of such packaging. Buoyed by the success, Lily and Alex continued to explore other applications of the PET film. They soon turned their attention to food and pharmaceutical industries. Safety and freshness are key factors in the food industry. Lily and Alex realized that the antistatic and thermoformable PET film would assist in maintaining the freshness of the food and containing no contaminants. They had a package designed with the local food manufacturer for his products. This proved ideal for properties such as packaging of food. Antistatic dispensers prohibited the adherence of dust and other particles onto the packagings, while the thermoformable property allowed customized shapes, which fit different food items. In this case, this turned out to be effective yet attractive packaging. The pharmaceutical industry demands sterile and safe packaging. Lily and Alex worked with a pharmaceutical company to develop packaging that would meet these demands. The PET film instantiated an antistatic property of the film which prevented the build-up of the charges capable of damaging some sensitive medications. The thermoformability was adjustable for those custom-designed packaging meant to secure the drugs during transportation and storage. Here, both Lily and Alex had a reason to look forward to further opportunities once their projects were successful in food and pharmaceuticals producing industries. As a matter of fact, they were invited as guest speakers in industry conferences where they shared their experiences with others. As they got more and more popular, one day, Lily and Alex were approached by a local interior designer. The interior designer wanted something very special for his next big decoration project. Lily and Alex recommended the PET film. They worked with designers for the creation of custom walls and decorative panels. The thermoformability of the film allowed for creative designs and figures, along with an antistatic feature of the decorations, which made them without static electric properties, thus giving an amazing look of space. In the field of glass decoration, Lily and Alex also carved their niche. They also developed a method of applying the PET film to glass surfaces to make privacy screens, decorative windows, and other unique glass features. Because of the properties of this film, installation and removal were pretty easy; thus, it found its place in residential and commercial usages. As the year drew to a close, Lily and Alex looked back with pride to see how it had been. They had taken an easily available material and molded it into a multiutility solution making a difference in various industries. From printable A4 sheets to creative packaging, decoration items, up to glass enhancement, the list of applications for thermoformable PET film is endless. Their story of Lily and Alex had emphasized the force of innovation and teamwork. They had proved that with just a little creativity and determination, even one simple material could go a long way into changing the world. They knew that their journey of thermoformable and antistatic PET film was far from over as they looked to the future. Actually, they were pretty excited about the new applications of the material and the new opportunities. Conclusion: This is quite a remarkable story involving discovery and use of antistatic and thermoformable PET film by Lily Chang and Alex. It's reached into printing and packaging, food, pharmaceuticals, decoration, and the decoration of glass. Their traits have proven-you just need to think differently, and you will definitely find something which is suitable and applicable in everyday industrial problems. With ever-growing sustainability concerns and the need for versatile materials, antistatic, and thermoformable PET film possibly holds a bright future for any who would dare to work and venture into it.

《The Versatile Red PET Film: Transforming Industries》 Date: August 28, 2023 Location: Across the Globe Characters: Manufacturers, Designers, Consumers In the ever-evolving landscape of materials and packaging, red PET film has emerged as a star player, making its mark in various industries and transforming the way products are presented and protected. The story begins with the growing demand for unique and eye-catching packaging solutions. Manufacturers, constantly on the lookout for materials that can set their products apart on crowded store shelves, discovered the potential of red PET film. This vibrant and durable material offered a combination of aesthetic appeal and functionality that was hard to resist. In the packaging industry, red PET film quickly became a favorite. Its vivid color and glossy finish added a touch of elegance and sophistication to a wide range of products. From cosmetics to electronics, the film's ability to enhance the visual appeal of packaging was undeniable. Designers were inspired by its versatility, creating innovative packaging designs that caught the attention of consumers. One of the significant applications of red PET film was in food packaging. With its excellent barrier properties, it helped keep food fresh and protected from external elements. The bright red color also made food packages stand out, attracting customers in supermarkets and grocery stores. Food manufacturers soon realized the benefits of using red PET film not only for its aesthetic value but also for its practicality. In the realm of药品包装 (pharmaceutical packaging), red PET film played a crucial role as well. It provided a secure and tamper-evident packaging solution for medications. The color red often symbolizes urgency and importance, which was fitting for pharmaceutical products. The film's durability ensured that medications remained intact and safe during transportation and storage. Flower packaging was another area where red PET film made a significant impact. Florists around the world began using the film to wrap bouquets, adding a pop of color and elegance. The film not only protected the flowers but also enhanced their beauty, making them more appealing to customers. Whether it was a simple bouquet for a loved one or an elaborate floral arrangement for a special occasion, red PET film added that extra touch of charm. The decoration industry also embraced red PET film. Interior designers and decorators used it to create unique wall coverings, furniture accents, and decorative elements. The film's vivid color and reflective surface added a touch of glamour and modernity to any space. From trendy cafes to luxurious hotels, red PET film was used to create stunning interiors that left a lasting impression. Glass改色 (glass coloring) was yet another application of red PET film. Instead of traditional methods of coloring glass, which can be expensive and time-consuming, manufacturers and designers discovered that red PET film could be easily applied to glass surfaces to achieve a similar effect. This not only saved time and money but also offered a more flexible and customizable solution. As the use of red PET film spread across different industries, its effects became more and more apparent. Consumers were drawn to products packaged in red PET film, perceiving them as higher quality and more desirable. Manufacturers saw an increase in sales and brand recognition. The film's durability also led to reduced waste, as it could be recycled and reused. In conclusion, red PET film has truly revolutionized various industries with its versatility, aesthetic appeal, and functionality. From packaging to decoration and everything in between, this remarkable material has proven to be a game-changer. As we look to the future, it is likely that red PET film will continue to play an important role in shaping the way we package, present, and decorate products. Its vibrant color and durability will continue to inspire manufacturers and designers, while its practical benefits will satisfy the demands of consumers. The story of red PET film is one of innovation, transformation, and endless possibilities.

"The Versatile World of Colored PVC Film: Transforming Industries and Spaces" In today's fast-paced and ever-evolving world, innovative materials are constantly emerging to meet the diverse needs of various industries. One such material that has been making waves is colored PVC film. With its wide range of applications and remarkable properties, it has become a game-changer in the fields of packaging, pharmaceutical packaging, food packaging, decoration, and glass decoration. Time: Over the past few years. Location: Worldwide. Characters: Manufacturers, designers, consumers, and industry experts. I. Introduction Colored PVC film, with its vibrant hues and durability, has captured the attention of businesses and individuals alike. This versatile material offers a plethora of benefits, from enhancing product visibility to adding a touch of elegance to interiors. Let's explore how it has been making an impact in different sectors. II. Packaging Industry In the packaging industry, the quest for materials that are both functional and visually appealing is ongoing. Colored PVC film emerged as a promising solution due to its ability to protect products while also attracting consumers' attention. Manufacturers began incorporating colored PVC film into their packaging designs. For consumer goods packaging, the film was used to create eye-catching boxes, pouches, and wraps. In the food packaging sector, it was utilized to package snacks, candies, and other perishable items. The film's moisture-resistant and durable properties ensured that the food remained fresh and protected. In pharmaceutical packaging, colored PVC film was employed to distinguish different types of medications and provide a tamper-evident seal. The clear and colorful film allowed for easy identification of the product, while also ensuring its safety. The use of colored PVC film in packaging had several positive outcomes. Firstly, it increased product visibility on store shelves, leading to higher sales. Consumers were drawn to the attractive packaging, which made the products stand out from the competition. Secondly, the film's durability provided excellent protection to the packaged items, reducing the risk of damage during transportation and storage. Additionally, in pharmaceutical packaging, the tamper-evident feature gave consumers confidence in the safety and authenticity of the medications. III. Decoration As people's aesthetic preferences continue to evolve, there is a growing demand for unique and creative decoration solutions. Colored PVC film offered a new way to add color and texture to interiors and exteriors. Interior designers and architects started using colored PVC film to transform spaces. In homes, it was used to create feature walls, backsplashes, and furniture accents. The film's easy application and removal made it a popular choice for those looking to update their living spaces without a major renovation. In commercial spaces such as offices, restaurants, and retail stores, colored PVC film was used to create branded environments and enhance the overall atmosphere. The film could be printed with logos, patterns, and designs, adding a personalized touch to the space. The use of colored PVC film in decoration had a significant impact. It allowed for quick and cost-effective transformations, enabling businesses and homeowners to achieve their desired look. The film's variety of colors and finishes provided endless design possibilities, allowing for unique and personalized creations. Moreover, its durability ensured that the decorations would last for a long time, even in high-traffic areas. IV. Glass Decoration Glass is a popular material for both functional and decorative purposes. However, it can sometimes lack privacy or require an added touch of elegance. Colored PVC film offered a solution to these challenges. Colored PVC film was applied to glass windows, doors, and partitions to add privacy, reduce glare, and enhance the aesthetic appeal. The film could be frosted, tinted, or printed with designs, providing a variety of options to meet different needs. In residential settings, colored PVC film was used to create privacy in bathrooms, bedrooms, and home offices. In commercial spaces, it was used to divide office areas, create conference room partitions, and add branding to storefronts. The application of colored PVC film to glass had several benefits. It provided privacy without sacrificing natural light, creating a comfortable and inviting environment. The film also reduced glare, making it easier to view screens and work in bright areas. Additionally, the decorative options offered by the film added a touch of style and sophistication to the space. V. Conclusion Colored PVC film has truly revolutionized various industries with its versatility and functionality. From packaging to decoration and glass decoration, it has proven to be a valuable material that meets the diverse needs of today's consumers and businesses. As technology continues to advance, we can expect to see even more innovative applications of colored PVC film in the future. Whether it's enhancing product visibility, creating unique interiors, or adding privacy to glass, this remarkable material is sure to continue making an impact.

PVC Film for Blister Packaging: A New Manufacturing Facility to Be Launched in 2023 August 20, 2023 — Houston, Texas: This was the day—the day the packaging industry awaited with bated breath. GlobalPack Industries, one of the largest manufacturers of packaging materials, opened a brand new state-of-the-art facility in Houston, Texas, for the manufacture of PVC film especially intended for use in blister packaging. Among those present at the launch were key figures from the industry, local government authorities, and company bosses. This marked a significant step in production capacity expansion for GlobalPack. Key People Present The event was spearheaded by GlobalPack CEO, Emily Carter, who was flanked by Texas Governor, Jake Martinez, and Houston Mayor, Maria Hernandez. The representatives were from the pharmaceutical, electronics, and consumer goods industries, signaling that this new facility would indeed affect a wide array of sectors. Reasons for Expanding This increase in production was based on a steep rise in demand for PVC film in blister packaging. The COVID-19 pandemic brought higher demands on safe and tamper-evident packaging, notably from the pharmaceutical industry. Substantially relying on the blister packs in medication protection and dispensing, their demands surged. Moreover, consumer electronics adds to pressures on existing capacities with protective packaging. According to Emily Carter, "Our customers need trustworthy, high-quality PVC film for their packaging solutions. This new facility is the direct response to those needs, ensuring that we can answer the growing demand without ever compromising our commitment to sustainability and innovation." The Manufacturing Process The facility in Houston represents a cutting-edge plant capable of producing PVC film of high quality to meet the stringent requirements for blister packaging. It starts polymerizing vinyl chloride monomers into PVC resin and then extrudes and biaxially orients the film. State-of-the-art machines equipped in this facility are able to produce film with well-controlled thickness and surface properties to meet all customer-specific needs. The facility is also designed with sustainability in mind. Energy-efficient processes and recycling of industrial waste are integrated in the facility in order to minimize its impact on the environment. "We invested in technology that would make a better product but would also lower our carbon footprint," said Carter during the launch. Results of the Expansion A new facility in Houston will increase GlobalPack's PVC film production capacity by 40%. This means significantly reduced lead times to any customer located anywhere in North America. This will also mean the creation of more than 200 new jobs within the Houston area, providing a boost to the local economy. This first batch of PVC film from the new facility is due to be shipped to major pharmaceutical and electronics manufacturers by the end of September 2023. Initial tests indicate that the film is well within industry standards in terms of clarity, durability, and resistance to chemicals, and can thus be used in a large variety of blister packaging applications. Industry Effects The opening of GlobalPack's new facility is likely to create a chain reaction within the packaging industry. With more volumes of high-quality PVC film made available, it raises the performance and reliability standards for blister packaging—thereby motivating further innovation in this direction for packaging design, particularly for where safety and tamper evidence come first. The facility will most likely set a new standard within the industry toward sustainability and push other manufacturers to be greener. "This is more than just an expansion; it's a commitment to the future of packaging," said Carter. Conclusion GlobalPack once again leads the way in the packaging industry with the launch of a new PVC film production facility in Houston. With increased capacity in production, attention to sustainability, and the creation of new jobs, it is sure to meet the growing demands of various industries for high-quality blister packaging solutions. As the first shipments come out over the coming weeks, the ripples of this growth will be felt throughout the supply chain, further entrenching GlobalPack's position as a leader in the packaging industry.

Polystyrene in Seedling Trays and Food Containers: An Overview of its Role Date: 8th August 2023 Location: Global Key Figures: Environmentalists, Industry Experts, Policymakers Introduction 8th August 2024 is the day that saw a heated, highly perceived argument of the use of Polystyrene commonly abbreviated as PS in the making of growing seedling trays and food containers. The debate borders on the balance between the practical usefulness of PS and its effect on the surrounding environment. Background Sand used to be the raw material for the production of polystyrene, which is a very wide applied plastic because of its cost-effectiveness and versatility in application. In horticulture, PS is used for seedling trays so that they can give their supporting plant effective drainage and serve a longer time due to their strength. In the food service sector, PS is used for containers like clamshells and cups due to its insulative and affordable properties. Events Horticulture Sector: Environmentalists in the previous decades have already raised concern on the future environmental impacts of PS seedling trays. Although the trays are durable and even to some extent, are reusable, these trays still add to plastic pollution because they are non-biodegradable. Other areas have already explored alternative materials to reduce plastic waste on gardening refuse. Food Service Sector In the same vein, the food service sector has been pressured by the public to discontinue its heavy use of PS containers. While the reasons behind this popularity are insulation and cost reduction, they have been faulted for contributing to the volume of landfill sites and being potential health risks. Recent reports have shown the need to shift to biodegradable packaging systems. Findings Plan Response from Industry: Going Green. In response to these perceptions, the horticulture and food service industries have began to react to the environmental impact of PS. These key steps include, 1. Alternatives: Research over biodegradable and compostable alternatives has been expedited. Industries now look into materials like plant based plastics and recycled fibers that can substitute common PS. 2. Developed Recycling Programs: Advanced recycling infrastructure is developed to manage a better waste load from PS. Developed recycling technologies and programs are being introduced to recover and reutilize materials made from PS. 3. Policy Change: Many countries' governments have framed regulations to control and limit the use of PS in single-use products. The policies have been framed to promote and encourage the use of sustainable alternatives and improve the management of waste. Impact And, the following are some of the positive impacts that the global response to the PS issues resulted in: Increased Awareness: Increased awareness among consumers and industry-related people about the environmental effects of PS and their role has facilitated informed choices and practices. Developing New Materials: The search and, to a contrary, immediate need for alternative sustainable gear had resulted in developing new eco-friendly types of materials in place of the traditional PS used in the nursery trays and food containers. - Advancements in Policies and Regulations: New policies and regulations enable changes toward sustainable operations directed to horticulture and foodservice sectors. Conclusion The ongoing discussion of the role of Polystyrene in seedling trays and food containers really brings the point of balancing practical advantages with environmental responsibility. The work on these challenges has been attended to, in developing partnership with industry and government, while the focus is on sustainability and being innovative with the future of eco-friendliness in both gardening and food service.

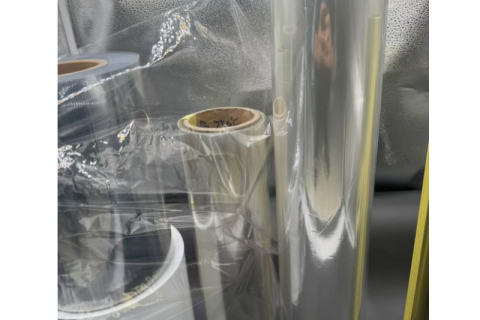

NamePP Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

NamePVC/PE Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name:PP Plastic food packing Size: DIA 140 *DIA90*H80MM MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

NameLLDPE shrink/stretch film roll SizeTk:0.012-0.023mm, h100-1200mm MaterialPETG/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

NameCPP Plastic film roll SizeTk:0.010-0.023mm, h100-800mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePrinting packing Vegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service