- Home

- >

News

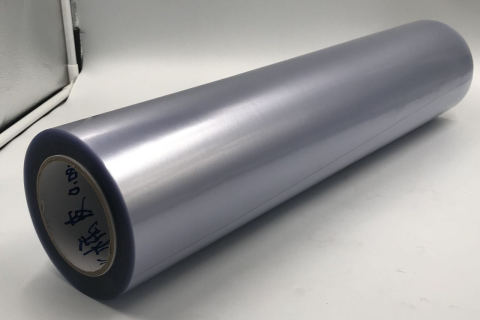

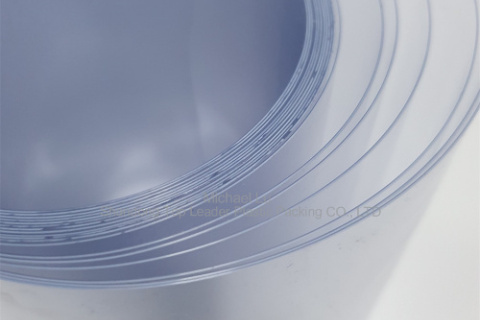

Polyvinyl chloride film is commonly known as (POLYVINYL CHLORIDE FILM). It is made of polyvinyl chloride resin and other modifiers through a calendering process or a blow molding process. The general thickness is 0.08~0.2mm, and anything greater than 0.25mm is called PVC sheet. Functional processing aids such as plasticizers, stabilizers, and lubricants are added to PVC resin and rolled into a film.

Plastic film (thickness of 0.06mm ~ 0.26mm) applications, the largest amount, the most varieties, the most widely used is the packaging industry

BOPP is the abbreviation of Biaxially Oriend Polypropylene. The film is biaxially oriented polypropylene film. The film is a very important flexible packaging material. The film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity and toughness. and good transparency.

At present, most blister films are made of PVC, which is a highly malleable plastic product that can be used on different furniture. It has high water resistance and corrosion resistance and can protect the furniture from environmental factors.

Recently, the European Parliament approved proposed amendments to the Packaging and Packaging Waste Regulation (PPWR), which will change the EU’s regulatory standards for packaging in the future. The specific points are summarized as follows: