- Home

- >

News

Headline: Global Adoption of PP EVOH Film Revolutionizes Packaging Across Industries Date: August 22, 2024 Location: New York, NY Introduction: In a dramatic turn of events, PP EVOH film fast becomes the material of choice for thermoforming and blister packing in almost every industry—from food and pharmaceuticals to industrial uses—owing to the advanced and highly competent solution it offers through barrier performance and versatility. Key Characters: - John Harrison: GreenPack Industries' CEO and leading manufacturer of PP EVOH films. - Dr. Emily Roberts: The head of the Research and Development section at SafeSeal Pharmaceuticals. - Mark Davis: The senior operations manager at FreshFoods Packaging Solutions. - Global Packaging Consortium: A coalition of experts on packaging matters and industry leaders. Causes: Growing demand for sustainable, high-performance packaging has forced the move to PP EVOH film. Rising consumer awareness about food safety and pharmaceutical efficiency has forced manufacturers to look for materials that extend shelf life, durability, and environmental benefits. In view of emerging global supply chain challenges, the need for packaging with excellent barrier protection against oxygen, moisture, and other contaminants is increasingly important. Process: The application of PP EVOH film began in early 2023 when GreenPack Industries, under the business acumen of John Harrison, had invested in intensive research and development to improve the properties of this material. Their work paid off in introducing a new line of PP EVOH films specially designed for various industries. One of the first ones to have spotted the potential of this film in the pharmaceutical sector was Dr. Emily Roberts of SafeSeal Pharmaceuticals. Her team has done an exhaustive test on the potential of this film to protect medication from environmental factors, thereby opening it up for wide adoption in the blister packaging for drugs. About the same time, FreshFoods Packaging Solutions' Mark Davis had introduced a PP EVOH film for use with perishable food items that extended their shelf life by allowing its barrier properties to reduce food waste and enhance supply chain efficiency on their thermoforming lines. At the Global Packaging Consortium summit in New York, June 2024, experts and industry thought leaders debate the future of new packaging materials. PP EVOH film will be one of the key focuses; participants agree that this material can set new standards in packaging across a gamut of industries. Results: The introduction of PP EVOH film has massively advanced the field of packaging. In food processing, freshFoods Packaging Solutions recorded an added 20% shelf life to their products, hence less food wastage and customer satisfaction. SafeSeal Pharmaceuticals had product recalls reduced by 15% due to the improved protection qualities that the PP EVOH film offered over the products in its blister packs. On the industrial front, GreenPack Industries increased their market share by 30% due to surging demands for PP EVOH film across the globe. This success also fueled innovation in recycling technologies to come up with more sustainable packaging solutions. Effects: The extensive application of PP EVOH film has had a domino effect on various industries. From the angle of customers, they receive fresher food and are offered much safer pharmaceutical products. On the other hand, for manufacturers, while the cost goes down, efficiency rises. Actually, the success of PP EVOH film already made other companies look into developing similar high-performance materials that would surely further create innovations in the package sector. The environmental effect from packaging is lessened as more and more companies take up recyclable PP EVOH films, giving a realization to global sustainability. According to the Global Packaging Consortium, in 2025, PP EVOH film may prove to be the precedent for barrier packaging, seeing remarkable protection performance and environmental responsibility. Conclusion: With the packaging industry in continuous flow of evolution, PP EVOH film has emerged to be that one game-changing material best suited to both the modern consumer and manufacturer. Proving its benefits and gaining in popularity, this innovative film is sure to set a new trend in packaging standards worldwide.

PVC Film for Blister Packaging: A New Manufacturing Facility to Be Launched in 2023 August 20, 2023 — Houston, Texas: This was the day—the day the packaging industry awaited with bated breath. GlobalPack Industries, one of the largest manufacturers of packaging materials, opened a brand new state-of-the-art facility in Houston, Texas, for the manufacture of PVC film especially intended for use in blister packaging. Among those present at the launch were key figures from the industry, local government authorities, and company bosses. This marked a significant step in production capacity expansion for GlobalPack. Key People Present The event was spearheaded by GlobalPack CEO, Emily Carter, who was flanked by Texas Governor, Jake Martinez, and Houston Mayor, Maria Hernandez. The representatives were from the pharmaceutical, electronics, and consumer goods industries, signaling that this new facility would indeed affect a wide array of sectors. Reasons for Expanding This increase in production was based on a steep rise in demand for PVC film in blister packaging. The COVID-19 pandemic brought higher demands on safe and tamper-evident packaging, notably from the pharmaceutical industry. Substantially relying on the blister packs in medication protection and dispensing, their demands surged. Moreover, consumer electronics adds to pressures on existing capacities with protective packaging. According to Emily Carter, "Our customers need trustworthy, high-quality PVC film for their packaging solutions. This new facility is the direct response to those needs, ensuring that we can answer the growing demand without ever compromising our commitment to sustainability and innovation." The Manufacturing Process The facility in Houston represents a cutting-edge plant capable of producing PVC film of high quality to meet the stringent requirements for blister packaging. It starts polymerizing vinyl chloride monomers into PVC resin and then extrudes and biaxially orients the film. State-of-the-art machines equipped in this facility are able to produce film with well-controlled thickness and surface properties to meet all customer-specific needs. The facility is also designed with sustainability in mind. Energy-efficient processes and recycling of industrial waste are integrated in the facility in order to minimize its impact on the environment. "We invested in technology that would make a better product but would also lower our carbon footprint," said Carter during the launch. Results of the Expansion A new facility in Houston will increase GlobalPack's PVC film production capacity by 40%. This means significantly reduced lead times to any customer located anywhere in North America. This will also mean the creation of more than 200 new jobs within the Houston area, providing a boost to the local economy. This first batch of PVC film from the new facility is due to be shipped to major pharmaceutical and electronics manufacturers by the end of September 2023. Initial tests indicate that the film is well within industry standards in terms of clarity, durability, and resistance to chemicals, and can thus be used in a large variety of blister packaging applications. Industry Effects The opening of GlobalPack's new facility is likely to create a chain reaction within the packaging industry. With more volumes of high-quality PVC film made available, it raises the performance and reliability standards for blister packaging—thereby motivating further innovation in this direction for packaging design, particularly for where safety and tamper evidence come first. The facility will most likely set a new standard within the industry toward sustainability and push other manufacturers to be greener. "This is more than just an expansion; it's a commitment to the future of packaging," said Carter. Conclusion GlobalPack once again leads the way in the packaging industry with the launch of a new PVC film production facility in Houston. With increased capacity in production, attention to sustainability, and the creation of new jobs, it is sure to meet the growing demands of various industries for high-quality blister packaging solutions. As the first shipments come out over the coming weeks, the ripples of this growth will be felt throughout the supply chain, further entrenching GlobalPack's position as a leader in the packaging industry.

Title: PP Film Revolutionizes Printable Materials Market Date: August 15, 2023 Location: New York City, NY Key Figures: John Carter, CEO of PrintTech Solutions, and Dr. Emily Roberts, Lead Researcher, Advanced Polymers Lab Event Overview: Although PP film has been a recent spotlight in printing, diverse applications make it an ideal material for various uses. On August 15, 2024, the company leading developments in printable materials, PrintTech Solutions, held a press conference in New York City to introduce their most current innovations in PP film technology. Background: This film is also in great demand in the printing area because of its unique features like flexibility, durability, and lower costs. Unlike other printing material, traditional printing PP film will provide a non-porous, smooth surface for high-quality printing of vivid colors and sharp details. With such properties, it finds greater application in labels, packages, banners, and several other printed material types. According to John Carter, chief executive of PrintTech Solutions, demand for sustainable, high-performance printing materials is growing fast. "As companies look at reducing their environmental footprint while maintaining the highest level of quality, PP film becomes the material of choice in a broadening range of applications," he added. Development Process: According to Dr. Emily Roberts, lead researcher of the Advanced Polymers Laboratory, several breakthroughs in science have made the development of advanced PP films possible. She further elaborates on the research orientation: "In our team, we had focused on the improvement of the printability of PP film by adjusting its surface properties and improving its compatibility with flexographic, digital, and screen printing technologies.". The team has also worked on enhancing its resistance to fading so that the film retains the brilliance of the printed matter, even when exposed to blinding sunlight for a longer period and harsh environmental conditions. Result and Impact: The result of these innovations is a new line of PP films that are more durable, flexible, and increasingly environment-friendly. PP films developed by PrintTech Solutions are fully recyclable and produced with a lower carbon footprint compared to traditional materials, in line with the growing consumer demand for sustainable products and the industry's move toward eco-friendly practices. These advanced PP films, therefore, within the very short time of their introduction, have brought tremendous change in the printing industry. Some big houses have started using the material for their packaging and promotional material and commented positively about the superior print quality, durability, and sustainability. Moreover, it is cost-effective and also turned out to be very impressive for a business venture by cutting down costs without affecting the quality. Conclusion: The importance of PP film in the future will only continue to rise with the further expansion of the market in printable materials. Companies at the forefront of such developments are those like PrintTech Solutions, and leading educational research institutions like Advanced Polymers Lab; PP film will soon become a benchmark within the industry for quality and sustainability in printing. Their success is just another indication of the growing requirement for materials that can answer both performance and environmental demands, setting a new benchmark for the future of printable materials.

Revolutionizing Folded Box and Pharmaceutical Thermoforming Packaging—PVC Sheets Date: August 13, 2023 Location: Shanghai, China Key Players: Leading packing manufacturers, pharmaceutical companies, environmental advocates Event Summary: In what could emerge as the most radical paradigm shift in packaging, Shanghai's top manufacturers yesterday announced increased application of polyvinyl chloride sheets for folded box and pharmaceutical thermoforming packaging. This will change the world in terms of product protection, cost efficiency, and manufacturing versatility. Background: Durability, flexibility, and cost represent some of the most preferred characteristics of PVC, and it has thereby found a place in most industries. However, recent developments in manufacturing PVC sheets raise renewed interest in using the material for special applications in pharmaceutical packaging and other consumer products. Cause and Course of Events: The trend of using PVC sheets in folded box and pharmaceutical packaging started this year when a number of packaging specialists, associated with different pharmaceutical companies, launched an all-inclusive study regarding the effectiveness of the material. Their conclusions, published in June 2024, pointed to some main advantages of PVC sheets, first of all related to their better defense against moisture, oxygen, and light—parameters that play a very important role in the preservation of pharmaceutical products. After the research, some leading packaging companies in Shanghai started to apply PVC sheets in their production lines within a very short period of time. It is the possibility of easily cutting, folding, and thermoforming the material into desired shapes that allows these companies to fulfill the tough requirements from pharmaceutical industries while offering beautiful and functional packaging to consumer products. Result: Beginning with the adoption of PVC sheets, fruitful results have already started to show. Pharmaceutical firms are reportedly found to declare that most of the problems related to packaging, such as contamination and damage of the product during transportation, have reduced considerably. Consumers have also welcomed the enhanced protection and longer shelf life of products packaged with PVC. Moreover, this reduces the overall production cost of PVC sheets, thereby enabling the manufacturer to maintain a competitive price and upgrade the quality of packaging. Impact and Future Prospects: Interest in PVC sheets for folded box and pharmaceutical thermoforming packaging has been quite successful, and other markets, like food and electronics, where solid, protective, and cost-efficient packaging is a must, may get attracted to it. Environmentalists still are wary and remind that without recycling programs, harm to the environment from PVC will only continue to grow. As innovations further the development in the packaging industry, PVC sheets can only play an ever-increasing role as a solution providing a reliable performance-cost-consumer safety balance for manufacturers. With Shanghai at the helm of this change, its packaging sector is well on course to lead global efforts towards improving products' packaging through strategic material use, such as PVC.

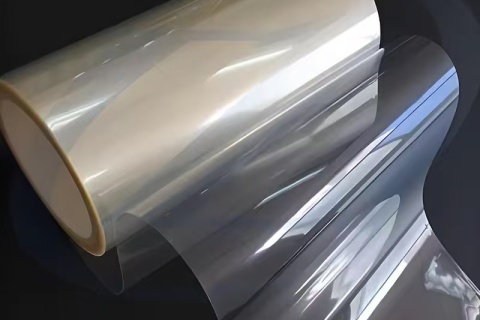

NamePP Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name:PP Plastic food packing Size: DIA 140 *DIA90*H80MM MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

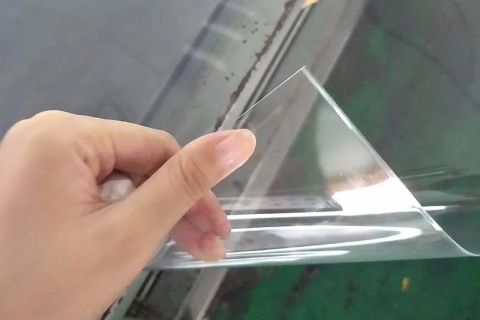

NameCPP Plastic film roll SizeTk:0.010-0.023mm, h100-800mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePrinting packing Vegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Black PP/EVOH/PP film, food vacuum packaging, disposable cutlery packaging, antistatic packaging, leak-proof packaging

Name: PET/ PE Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/ PE/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

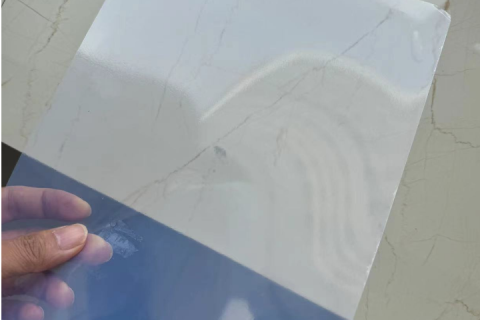

NamePP Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

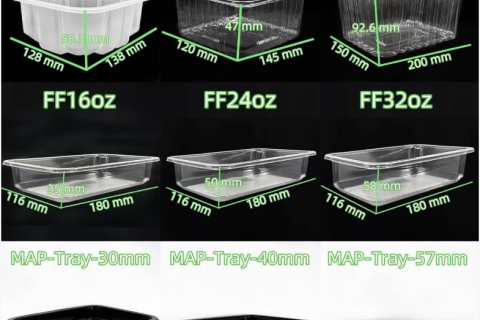

Name:PP FOOD tray Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm Material: pp film blister /Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG Usagefood tray , PHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name: PP Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm Material: PP /Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service