- Home

- >

- News

- >

- 0.18mm PVC Plastic Film

- >

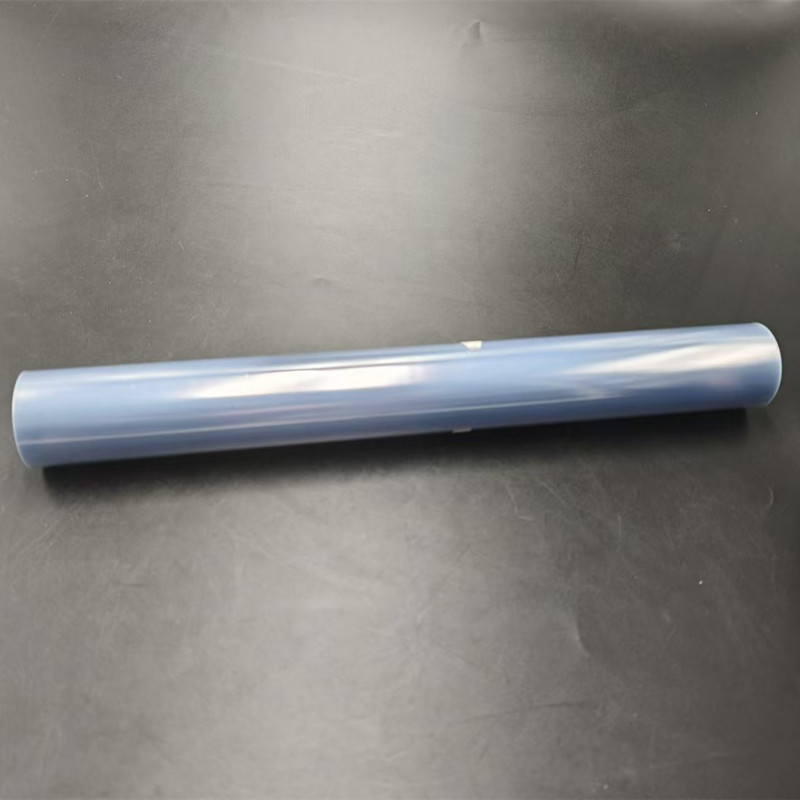

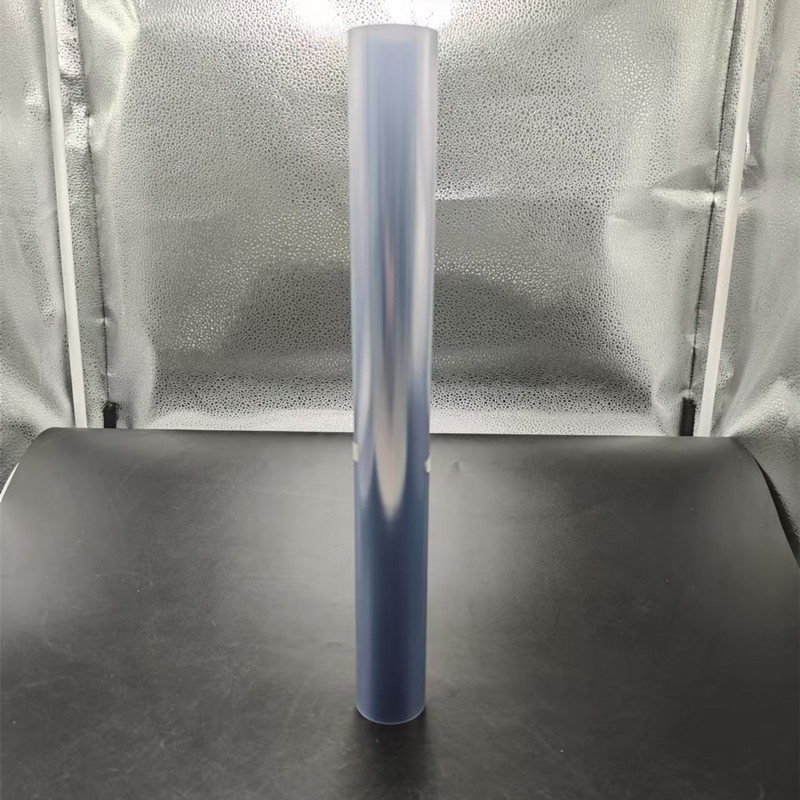

0.18mm PVC Plastic Film

2026-01-06 16:35Key Features & Advantages

Precision Thickness Control

Tightly calibrated to 0.18mm uniform gauge across the entire roll, ensuring no thickness deviation and stable performance in automated processing lines.

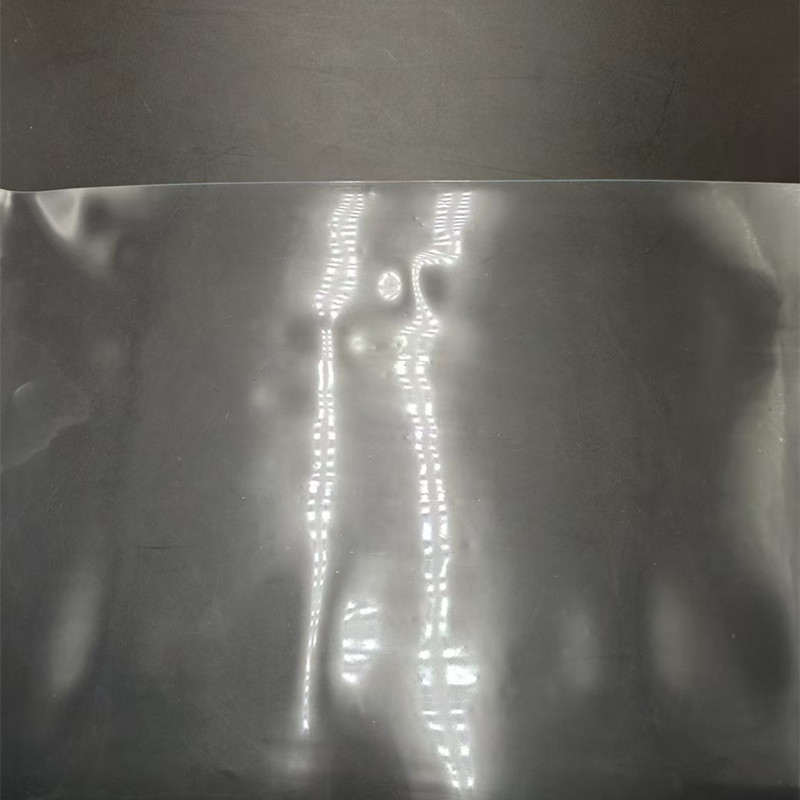

Superior Optical Clarity

Boasts high light transmittance (≥92%) with minimal haze, enabling crystal-clear visibility of packaged contents without distortion.

Excellent Physical Properties

High tensile strength (≥20 MPa) and tear resistance for enhanced durability during handling and application

Good cold resistance (-10℃) and heat stability (up to 60℃) for use in diverse temperature environments

Flexible and easy to cut, fold or laminate without cracking

Customizable Surface Treatments

Available with options including anti-static coating, matte finish or copysafe treatment to meet specialized requirements for security or processing needs.

Eco-friendly Compliance

RoHS and REACH compliant, free of heavy metals and harmful plasticizers, suitable for food-contact packaging applications (when ordered with food-grade certification).

Technical Specifications

| Parameter | Value |

|---|---|

| Thickness | 0.18mm ± 0.005mm |

| Width | Customizable (max 2,500mm) |

| Roll Length | 500m-1000m/roll (customizable) |

| Density | 1.38 g/cm³ |

| Light Transmittance | ≥92% |

| Tensile Strength (MD/TD) | ≥20 MPa / ≥18 MPa |

| Elongation at Break | ≥250% |

| Operating Temperature | -10℃ to 60℃ |

Typical Applications

Packaging Industry: Premium gift box wrapping, cosmetic packaging inserts, stationery lamination

Printing & Lamination: Label base material, thermal lamination film for brochures and certificates

Industrial Use: Thin-layer insulation, protective film for electronic components, die-cutting blanks

Security Applications: Base material for copysafe document lamination (with anti-copy coating option)