- Home

- >

- News

- >

- Plastics industry News

- >

News

1. Manufacturers: Companies like Coca-Cola, Nestlé, Toyota, and BMW. 2. Engineers and Architects: Construction professionals who believe in sustainability. 3. Researchers and Developers: Inventing better properties and uses for PET. Events: 1. The shift to PET bottles for beverage companies. 2. Additional applications of PET in automotive components. 3. Use of PET in construction for insulation and durable components.

1. Protective Enclosures: Anti-static flame-retardant PVC sheets for the enclosure of electronic devices, offering two-in-one protection. 2. Component Storage: Besides this, it provides storage and conveyance for electronic components without the risk of damage through electrostatic or by any possible fire hazards. 3. Workstations: Anti-static PVC sheets have an extended application at the manufacturing workstations in order to create an atmosphere controlled from the risks of electrostatic discharge. 4. Packaging: Flame-retardant PVC sheets find their usage in the packaging materials and hence add an extra layer of safety during transit and storage.

In-wall panels make an outstanding addition to interior decoration. Characters - Emily: Interior designer who has a reputation for being resourceful with materials. - John: Owner of a home looking to upgrade his living room. - Sarah: A contractor specializing in renovating homes. Spring 2023 John's Home: A modern mid-century home in suburbia. John had a living room with old-fashioned wallpaper and faded paint and wanted modernization. He contacted Emily with a view of achieving a modern look, which would further be functional and easily manageable. The main purpose for the renovation of the living room was to improve that part of the house's appeal to his family and guests. He also aimed at adding more value to his house. DECORATING Process 1. Consultation and Planning - John invited Emily into his home in early March 2023 to consult regarding the renovation job. He expressed interest during this consultation in a solution that would be modern, low-maintenance, and durable. She offered wall panels since they meet these specifications. 2. Material Choice -Then, Emily showed different kinds of wall panels: PVC, wooden and 3D texture. Looking through the samples, he chose to use PVC panels considering that the material is water-resistant, easy to clean, and inexpensive. 3. Design and Layout - Emily designed a layout that featured a feature wall with 3D textured PVC panels in a discreetly patterned design and, for the remaining walls, smooth PVC panels. She suggested a color scheme to blend with John's already owned furniture. 4. Preparation - By mid-March, the contractor, Sarah, and her crew began the preparation of the living room for this new look by removing old wallpaper and wall flaws so that panels can be put up nice and smooth. 5. Installation - Late March, Sarah's team began the installation. The panels had been cut to size according to the dimensions of the room and were securely mounted with adhesive and nails. Since PVC panels are very easy to install, all this took only two days. 6. Finishing Touches - With the mounting of the panels, Emily added finishing touches like moldings and trim to complete the room. She also proposed new lighting fixtures that would enhance the 3D effect of the feature wall. 7. Reveal -Early April, the renovation was complete. John and his family were so delighted with the transformation. There they had a living room that looked modern and trendy with the added comfort of easy cleaning and maintenance with PVC panels, hence, all requirements fulfilled by John. Outcome Such versatile material as wall panels found its successful application in the renovation of John's living room. Not only did John's home become more contemporary and inviting, but it also increased in value with the updated and now durable interior. The ingenuity of Emily's design and the expertise of Sarah's installation reflected both practical and aesthetic benefits from the wall panels, proving them to be an excellent choice for modern home renovation.

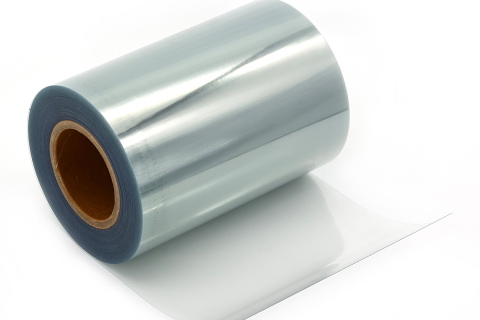

top leader plastic produced bopp film series. Today I will explain to you the common types, specific applications, market prospects, etc. of BOPP films.

commonly utilized transparent PET sheets for various toy packaging applications, PET (Polyethylene Terephthalate) Sheet (Thickness - 0.2mm & 0.4mm)

APET Plastic (Amorphous Polyethylene Terephthalate) is a thermoplastic, belonging to the polyester family. Widely known as APET, it is suitable for flat rigid sheet blister applications. It has two product forms: Apet Plastic Film, Apet Rigid Sheet, APET Plastic Sheet with 1 or 2-sided protective film. APET Plastic Film APET Rigid Sheet

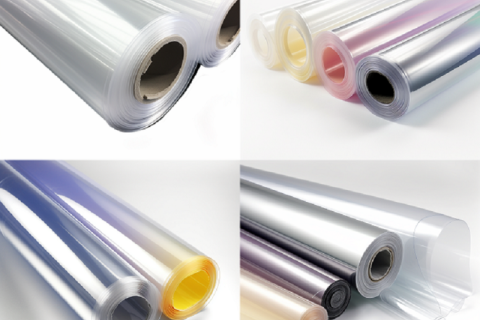

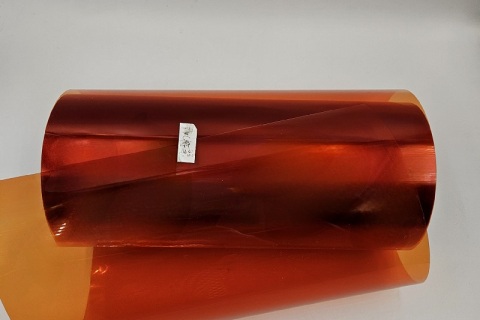

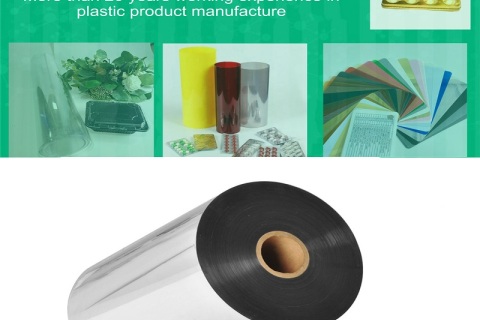

In the world of packaging materials, PVC rigid film has emerged as a versatile and durable option for various applications. Known for its strength and rigidity, PVC rigid film is commonly used in industries such as pharmaceuticals, food packaging, and more. This type of film offers excellent protection for products, ensuring they remain safe and secure during transportation and storage. Additionally, PVC rigid film is highly customizable, allowing for different thicknesses and sizes to suit specific packaging needs.

"PVC Packaging: The Controversial Material That's Taking the Industry by Storm" PVC or Polyvinyl Chloride is a common plastic material used in various applications, including food packaging, pharmaceutical packaging, and plastic products. It is known for its durability, flexibility, and resistance to abrasion, chemicals, and sunlight. However, concerns have been raised about the environmental impact of PVC, particularly in terms of disposal and recycling.

As a leading player in the plastic-products industry, Top Leader Group is committed to providing a comprehensive range of plastic-products plastic materials and manufacturing facilities to meet the growing demand for plastic products.

Research TOP LEADER's Medical Packaging Applications: Our PVC PVDC plastic sheet medical packaging solutions are designed for medical and pharmaceutical packaging. Our versatile portfolio of rigid and flexible polyethylene, polyvinyl chloride products enables innovative medical structural packaging that provides safety, flexibility, and regulatory compliance for the medical, pharmaceutical, and nutritional application industries.