- Home

- >

News

Name: PVC Shrink film SizeTk:0.01-0.9mm, h100-12000mm MaterialPVC /Customized Color/printingTransparent/customized Packaging: Cartons/customized OEM/ODMAccepeted MOQ1000KG Usagefurniture ,PHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Material: PP Thermal formed sheet Thickness 0.25-0.9mm/customization Size: 300mm/Customization GRADE: Food grade film color: black/white/ customization location: china usage :for food tray ,mircronwave food container

Material: PP Thermal formed sheet Thickness 0.25-0.9mm/customization Size: 300mm/Customization GRADE: Food grade film color: black/white/ customization location: china usage :for food tray ,mircronwave food container

1.Cornstarch tray 2. Sustainable food packaging 3.Food service degradebale food packing 4.Biodegradability food packing 5.microwave food tray

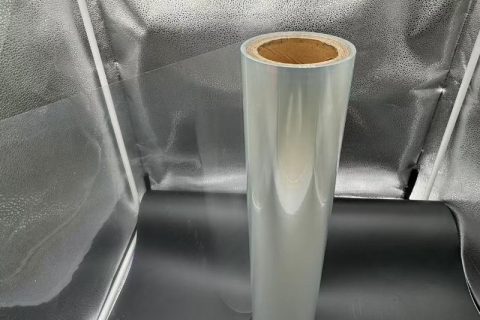

Material: petg shrink FILM ROLL Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food ,electronic ,fruit packing

Material: PET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Material: BOPET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Blister Pharmaceutical Packaging The pharmaceutical industry also relies heavily on transparent PET film for packaging. Similar to food packaging, the transparency of PET film allows for easy inspection of the contents, ensuring the integrity and quality of the medications. PET film provides a barrier against moisture, light, and oxygen, which can degrade the potency of drugs. This is especially important for sensitive medications such as tablets, capsules, and powders.

New APET Film Manufacturing Facility Opens in Dallas, Texas August 20, 2023 — Dallas, Texas The world of packaging witnessed a significant event today with the grand opening of a new production facility by EcoPack Industries, one of the top manufacturers of sustainable packaging materials in Dallas, Texas. In that respect, the facility also started producing APET film—a very famous material used in a myriad of different package applications. The presence of key house players in the industry, local government authorities, and company executives at the grand opening made this event very monumental to the company and the packaging industry at large. Key People Involved The event was led by EcoPack CEO Sarah Mitchell, who was flanked by Texas Governor Jake Martinez and Dallas Mayor Emily Harper. The representatives that showed up were from the food, pharmaceutical, and consumer goods industries, demonstrating just how broad the reach is that this new facility will have across multiple sectors. Causes Behind the Expansion The investment in this new facility responded to an increasing demand for high-performance, sustainable packaging solutions. APET film is known for its clarity, strength, and recyclability; it has been dominant in popularity as companies are shifting to more environmentally-friendly packaging materials. "The demand for APET film will only accelerate as businesses reduce their impact on the environment while maintaining product quality and appeal," according to Sarah Mitchell, vice president of Product Development and Commercialization at Munn Packaging, who spoke at the event. The Manufacturing Process The Dallas facility is equipped with state-of-the-art technology in the manufacture of high-quality APET film. The manufacturing process initiates with the extrusion of PET pellets, further stretched to create thin and flexible sheets of APET film. Later, these sheets are cut and processed to specific thickness and size requirements, thereby maintaining dimensions needed for many different packaging applications. The facility will also be designed with sustainability in mind, as it will feature energy-efficient machinery and a closed-loop recycling system that reuses production waste. "We are committed to not only providing top-tier packaging materials but also doing so in a way that minimizes our impact on the environment," Mitchell emphasized. Results of the Expansion With the new facility, the production capacity of EcoPack is expected to go up several-fold, thus helping the company meet growing demand for APET film in North America. The facility will have a projected output of over 20,000 tons a year of APET film, meant for the food, pharmaceutical, and consumer goods industries. Not only has the facility increased production, but more than 300 new jobs have been created in the Dallas area, contributing to an economic boom locally. Customers will be able to see the first batch of APET film shipped out at the end of September 2024. Effects on the Industry This facility is going to make a real difference in the packaging industry. The standards in packaging materials will be increased with the increased supply of high-quality, sustainable APET film, thus helping EcoPack in enhancing new standards for the same. Probably, this will further drive innovation in packaging design, particularly in sectors where sustainability and product presentation are key concerns. This facility's foray into sustainable production practices will set examples and influence other manufacturers to follow suit in an eco-friendly mode. "This facility isn't about raising our output; it's about leading the industry," Mitchell said. Conclusion The opening of EcoPack's new APET film manufacturing facility in Dallas marked another major step forward in the progress of the packaging industry. With increased capacity, green operations, and the creation of jobs, this facility is bound to meet the rising demand for quality and green packaging solutions. As the first products roll off in the coming weeks, the reverberations from this expansion will echo down the supply chain, cementing EcoPack's lead in the packaging industry.

The Rise of PET Sheets in Food Packaging and Labeling: A Sustainable Choice *Date: August 9, 2023 Location: Global Market Key Stakeholders: PET Manufacturers, Food Industry, Environmental Organizations* Introduction Polyethylene Terephthalate (PET) sheets have rapidly gained traction in recent years as an innovative material in the packaging industry. Renowned for their excellent toughness, high strength, and superior transparency, PET sheets have become a favored choice for food packaging and labeling applications. The material’s ability to be printed on, recycled, and its environmentally friendly properties, particularly its non-toxic combustion process, have further solidified its position as a leading packaging solution. This article explores how PET sheets are transforming the food packaging and labeling landscape, highlighting key developments and their impact on the market. Background PET sheets were developed to address the growing demand for materials that not only provide strong protective packaging but also align with global environmental sustainability goals. With the increasing awareness and concern over environmental degradation, particularly from non-recyclable plastics, the food industry began searching for alternatives that could offer both functionality and eco-friendliness. PET sheets, with their remarkable features, emerged as an ideal solution, gradually gaining popularity among consumers, producers, and environmental advocates alike. Features and Advantages 1. Transparency and Gloss: PET sheets offer exceptional transparency and surface gloss, making them highly effective in showcasing food products. This feature is especially valuable in retail environments, where product visibility is a critical factor in consumer decision-making. 2. Surface Decoration: The surface of PET sheets is highly receptive to decoration without the need for additional surface treatments. They are easy to print on, emboss, and even metalize using vacuum metal coating, making them ideal for creating attractive and informative labels. 3. Mechanical Strength: The robust mechanical strength of PET sheets ensures that food products are well-protected during transportation and handling, reducing the risk of damage and spoilage. 4. Barrier Properties: PET’s excellent barrier properties against oxygen and water vapor help preserve the freshness and quality of food products, extending their shelf life. 5. Chemical Resistance: PET sheets are resistant to various chemicals, which is crucial for packaging foods that may come into contact with reactive substances. 6. Safety and Hygiene: Non-toxic and compliant with stringent hygiene standards (such as GB13113-91), PET sheets are suitable for packaging food, pharmaceuticals, and medical devices. They can also be sterilized using radiation, ensuring the safety and integrity of the packaged goods. 7. Environmental Compatibility: PET is not only recyclable but also burns without releasing harmful substances, making it a key material in the global push for sustainable packaging solutions. Its excellent thermoforming capabilities allow it to be easily molded into various shapes, further enhancing its versatility in packaging applications. Event and Impact In recent years, several leading food manufacturers have transitioned to using PET sheets for their packaging and labeling needs. This shift was primarily driven by the material’s superior performance and environmental benefits. For instance, in a significant move in 2023, a global food giant replaced its traditional PVC packaging with PET for its entire line of snack products. This decision was lauded by environmental groups and resulted in a notable increase in sales, as consumers responded positively to the company’s commitment to sustainability. Moreover, the adoption of PET sheets in labeling has revolutionized the way food products are presented and marketed. The ability to easily print high-quality graphics and text directly onto the packaging has enabled brands to create more engaging and informative labels, enhancing their appeal on store shelves. Outcome and Future Prospects The widespread adoption of PET sheets in food packaging and labeling has led to a significant reduction in the environmental footprint of the packaging industry. The material’s recyclability and safe combustion have addressed many of the environmental concerns associated with traditional packaging materials. As a result, PET sheets have not only met the immediate needs of the food industry but also contributed to the long-term goal of reducing plastic waste and promoting sustainability. Looking ahead, the market for PET sheets is expected to continue growing, with more industries recognizing their value. Ongoing advancements in PET technology, such as improved barrier properties and enhanced printability, will likely further solidify PET’s position as the material of choice for food packaging and labeling. In an era where environmental sustainability is no longer an option but a necessity, PET sheets are set to play a pivotal role in shaping the future of packaging.

Name:PP Plastic food packing Size: DIA 140 *DIA90*H80MM MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Anti-Static Protection Static electricity can cause damage to electronic components and interfere with the functioning of sensitive equipment. Transparent PET rigid film with anti-static properties is designed to dissipate static charge and prevent electrostatic discharge.