Transparent POF Film in Modern Packaging A Transparent Revolution: How POF Film Seals Freshness, Shields Sensitivity, and Styles Protection

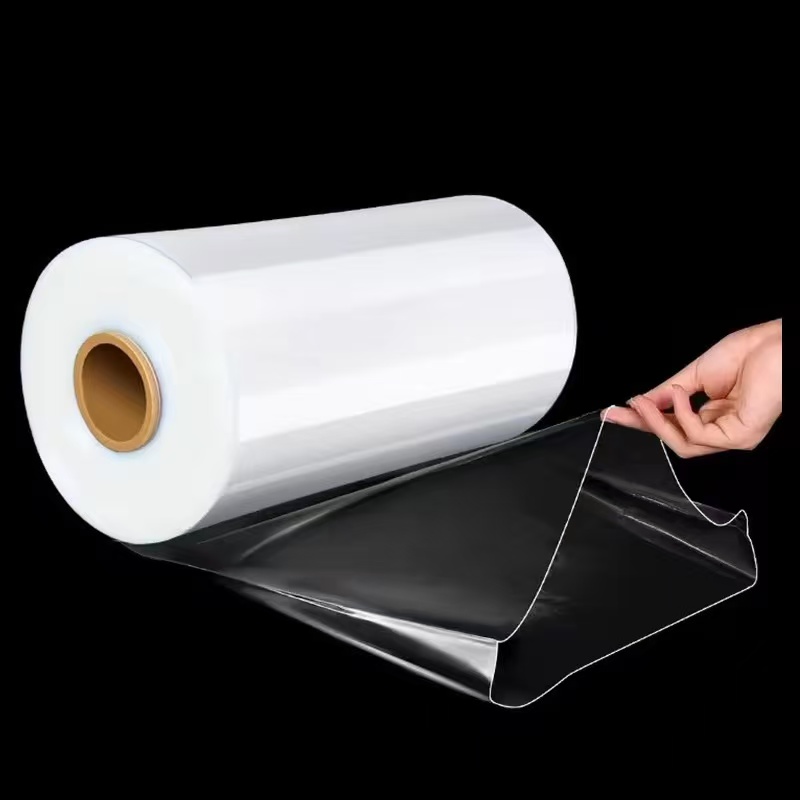

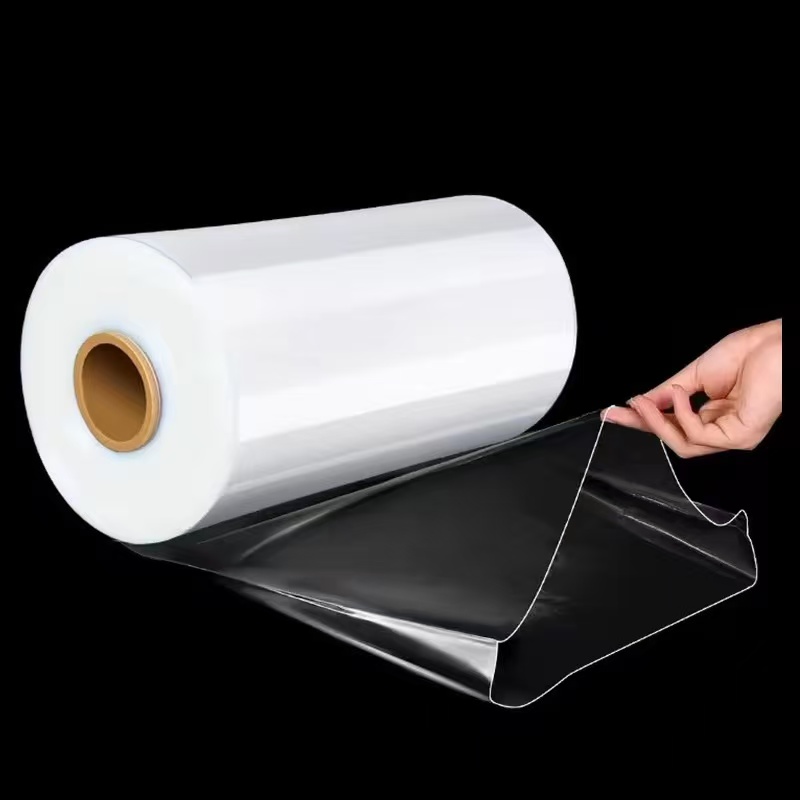

2025-11-06 17:13Unveiling the Crystal Clarity: Transparent POF Film in Modern Packaging  In the bustling world of packaging, where every layer counts toward preserving quality, allure, and safety, transparent POF film emerges as a silent hero. Polyolefin (POF) film, in its transparent form, is a marvel of modern materials science—a thin, flexible sheet of polymer that transforms under gentle heat into a snug, protective embrace around its contents. Imagine a delicate pastry, still warm from the oven, slipping into a crystal-clear cocoon that not only showcases its golden crust but also wards off the humid breath of time. Or picture a pair of sleek running shoes, fresh off the assembly line, wrapped in a seamless skin that highlights their contours while fending off dust and scratches. This is the essence of transparent POF film: versatile, resilient, and remarkably unobtrusive.

In the bustling world of packaging, where every layer counts toward preserving quality, allure, and safety, transparent POF film emerges as a silent hero. Polyolefin (POF) film, in its transparent form, is a marvel of modern materials science—a thin, flexible sheet of polymer that transforms under gentle heat into a snug, protective embrace around its contents. Imagine a delicate pastry, still warm from the oven, slipping into a crystal-clear cocoon that not only showcases its golden crust but also wards off the humid breath of time. Or picture a pair of sleek running shoes, fresh off the assembly line, wrapped in a seamless skin that highlights their contours while fending off dust and scratches. This is the essence of transparent POF film: versatile, resilient, and remarkably unobtrusive.  The Core Characteristics: A Blueprint of Brilliance and ResilienceAt its heart, transparent POF film is defined by a constellation of physical and chemical traits that make it a standout in the polymer family. Foremost is its exceptional clarity, often exceeding 90% light transmission, which rivals glass without the fragility. This optical purity stems from the film's amorphous structure, where polymer chains align in a way that minimizes light scattering. In practical terms, this means a consumer peering at a bundled bunch of asparagus can discern the vibrant green tips from afar, unmarred by haze or distortion. The film's gloss level, typically around 120-140 units on the standard gloss meter, adds a polished sheen that makes packaged goods pop under store lights, subtly influencing purchase decisions through visual appeal.Strength is another pillar, with tensile strength surpassing 100 MPa in both machine and transverse directions—a testament to its balanced molecular orientation during manufacturing. This isn't mere lab jargon; consider a scenario in a high-traffic supermarket where a tray of cheeses tumbles from a shelf. The POF wrap holds firm, resisting punctures from jagged edges or tears from rough handling, thanks to its high dart impact resistance, often over 200 grams. Elongation at break reaches up to 150%, allowing the film to stretch without snapping, which is crucial during the shrink process where it contracts by 50-70% upon exposure to 80-120°C heat. Revolutionizing Food Packaging: A Shield for Savor and SafetyIn the realm of food packaging, transparent POF film acts as a vigilant guardian, extending shelf life while inviting the senses to engage. Picture a family-owned bakery in a quaint European village, where artisan loaves emerge steaming from wood-fired ovens. Wrapped in POF shrink film, these breads retain their rustic aroma and crusty texture for days longer than unwrapped counterparts. The film's superior sealability, achieved through hot-wire or impulse sealing, creates an airtight bond that repels airborne contaminants, slashing microbial growth by inhibiting oxygen and humidity exposure.

The Core Characteristics: A Blueprint of Brilliance and ResilienceAt its heart, transparent POF film is defined by a constellation of physical and chemical traits that make it a standout in the polymer family. Foremost is its exceptional clarity, often exceeding 90% light transmission, which rivals glass without the fragility. This optical purity stems from the film's amorphous structure, where polymer chains align in a way that minimizes light scattering. In practical terms, this means a consumer peering at a bundled bunch of asparagus can discern the vibrant green tips from afar, unmarred by haze or distortion. The film's gloss level, typically around 120-140 units on the standard gloss meter, adds a polished sheen that makes packaged goods pop under store lights, subtly influencing purchase decisions through visual appeal.Strength is another pillar, with tensile strength surpassing 100 MPa in both machine and transverse directions—a testament to its balanced molecular orientation during manufacturing. This isn't mere lab jargon; consider a scenario in a high-traffic supermarket where a tray of cheeses tumbles from a shelf. The POF wrap holds firm, resisting punctures from jagged edges or tears from rough handling, thanks to its high dart impact resistance, often over 200 grams. Elongation at break reaches up to 150%, allowing the film to stretch without snapping, which is crucial during the shrink process where it contracts by 50-70% upon exposure to 80-120°C heat. Revolutionizing Food Packaging: A Shield for Savor and SafetyIn the realm of food packaging, transparent POF film acts as a vigilant guardian, extending shelf life while inviting the senses to engage. Picture a family-owned bakery in a quaint European village, where artisan loaves emerge steaming from wood-fired ovens. Wrapped in POF shrink film, these breads retain their rustic aroma and crusty texture for days longer than unwrapped counterparts. The film's superior sealability, achieved through hot-wire or impulse sealing, creates an airtight bond that repels airborne contaminants, slashing microbial growth by inhibiting oxygen and humidity exposure.  Safeguarding Vegetables: Freshness Through a Green LensVegetables, with their fleeting vibrancy, demand packaging that breathes life into longevity, and transparent POF film excels here by striking a balance between barrier and permeability. Envision a sun-drenched California farmstand, where heirloom tomatoes—ruby-red orbs bursting with summer—nestle in POF bundles. The film's controlled OTR permits ethylene gas (the ripening hormone) to dissipate gradually, staving off over-maturation that turns firm produce mushy. This selective breathability extends harvest-to-table windows by 40%, as evidenced by post-harvest trials where POF-wrapped carrots retained crunch after two weeks in refrigerated transit, versus wilting in mere days for loose storage.Clarity plays a starring role, transforming mundane bundles into marketing masterpieces. Shoppers at a bustling Asian wet market can inspect the dew-kissed leaves of bok choy through the film's pristine surface, spotting blemishes or confirming dew-fresh quality without unwrapping. The shrink effect molds the film like a second skin, preventing bruising from jostling during truck hauls over rutted roads— a boon for delicate items like bell peppers, where impact tests show POF reducing damage by 25% over foam nets.

Safeguarding Vegetables: Freshness Through a Green LensVegetables, with their fleeting vibrancy, demand packaging that breathes life into longevity, and transparent POF film excels here by striking a balance between barrier and permeability. Envision a sun-drenched California farmstand, where heirloom tomatoes—ruby-red orbs bursting with summer—nestle in POF bundles. The film's controlled OTR permits ethylene gas (the ripening hormone) to dissipate gradually, staving off over-maturation that turns firm produce mushy. This selective breathability extends harvest-to-table windows by 40%, as evidenced by post-harvest trials where POF-wrapped carrots retained crunch after two weeks in refrigerated transit, versus wilting in mere days for loose storage.Clarity plays a starring role, transforming mundane bundles into marketing masterpieces. Shoppers at a bustling Asian wet market can inspect the dew-kissed leaves of bok choy through the film's pristine surface, spotting blemishes or confirming dew-fresh quality without unwrapping. The shrink effect molds the film like a second skin, preventing bruising from jostling during truck hauls over rutted roads— a boon for delicate items like bell peppers, where impact tests show POF reducing damage by 25% over foam nets.  Antistatic Mastery: Taming Invisible Sparks in Sensitive SpacesWhen static electricity lurks as an unseen saboteur, transparent POF film's antistatic variants step in as electrostatic tamers, particularly in electronics-adjacent packaging that intersects with food or general goods. Static, that pesky buildup from friction, can zap sensitive circuits or attract dust like a magnet, but POF's inherent low surface resistivity—enhanced to under 10^11 ohms/sq with conductive additives—dissipates charges in milliseconds. Imagine a semiconductor fab in Taiwan, where microchips destined for smart kitchen gadgets are cocooned in antistatic POF; the film grounds triboelectric forces, slashing ESD (electrostatic discharge) incidents by 90%, per industry benchmarks.Though primarily for tech, its food-safe formulations bridge to hybrid uses, like wrapping static-prone dried herbs or powdered spices that clump under charge. The transparency ensures operators spot contaminants mid-process, while the shrink conformance hugs irregular shapes without creases that harbor charges. Durability shines: even after repeated handling, the antistatic layer—often a slip-agent-infused outer ply—persists, unlike coatings that wear off.In a dynamic warehouse scenario, conveyor lines humming with boxed salads (containing embedded freshness sensors) rely on POF to prevent static-induced sensor failures. The film's balanced shrinkage avoids warping labels, and its low outgassing means no volatile emissions to contaminate nearby edibles. Quantitatively, tribo-testing reveals POF retaining antistatic efficacy post-1000 rubs, far outpacing PVC rivals. For global logistics, where humidity swings from arid deserts to humid ports, the film's stable conductivity—independent of RH levels above 20%—ensures reliability. Vividly, a tech-savvy grocer uses antistatic POF for RFID-tagged produce crates; no more zaps halting scans, just seamless inventory flow. Here, POF film neutralizes the invisible, fostering a charged-free sanctuary for precision packaging.

Antistatic Mastery: Taming Invisible Sparks in Sensitive SpacesWhen static electricity lurks as an unseen saboteur, transparent POF film's antistatic variants step in as electrostatic tamers, particularly in electronics-adjacent packaging that intersects with food or general goods. Static, that pesky buildup from friction, can zap sensitive circuits or attract dust like a magnet, but POF's inherent low surface resistivity—enhanced to under 10^11 ohms/sq with conductive additives—dissipates charges in milliseconds. Imagine a semiconductor fab in Taiwan, where microchips destined for smart kitchen gadgets are cocooned in antistatic POF; the film grounds triboelectric forces, slashing ESD (electrostatic discharge) incidents by 90%, per industry benchmarks.Though primarily for tech, its food-safe formulations bridge to hybrid uses, like wrapping static-prone dried herbs or powdered spices that clump under charge. The transparency ensures operators spot contaminants mid-process, while the shrink conformance hugs irregular shapes without creases that harbor charges. Durability shines: even after repeated handling, the antistatic layer—often a slip-agent-infused outer ply—persists, unlike coatings that wear off.In a dynamic warehouse scenario, conveyor lines humming with boxed salads (containing embedded freshness sensors) rely on POF to prevent static-induced sensor failures. The film's balanced shrinkage avoids warping labels, and its low outgassing means no volatile emissions to contaminate nearby edibles. Quantitatively, tribo-testing reveals POF retaining antistatic efficacy post-1000 rubs, far outpacing PVC rivals. For global logistics, where humidity swings from arid deserts to humid ports, the film's stable conductivity—independent of RH levels above 20%—ensures reliability. Vividly, a tech-savvy grocer uses antistatic POF for RFID-tagged produce crates; no more zaps halting scans, just seamless inventory flow. Here, POF film neutralizes the invisible, fostering a charged-free sanctuary for precision packaging. Footwear Fashion: Wrapping Style with Unseen StrengthIn the stylish domain of footwear, transparent POF film elevates protection to an art form, blending invisibility with indestructibility. Footwear, from ballet flats to hiking boots, demands packaging that showcases design while battling the elements. POF's high gloss and clarity turn a boxed sneaker into a display case, revealing laces, logos, and leather grains in high definition—boosting perceived value by 15% in retail studies, as visuals drive 70% of apparel buys.Shrink-wrapping prowess is paramount: heated, the film contracts uniformly, forming a tamper-evident seal that deters pilferage and withstands drops from waist height without rupture, thanks to its 200g dart impact. For a Milan fashion week prep, imagine Louboutin heels slipped into POF sleeves; the film hugs curves without creasing, preserving toe shapes during air freight turbulence. Dust and scuffs? The barrier properties repel them, with abrasion tests showing minimal wear after simulated shelf-stocking cycles.Breathability for boxed pairs prevents mildew in humid climates, while recyclability appeals to eco-fashion brands—POF scraps feed back into production loops, cutting virgin resin use by 20%. In athletic gear, like trail runners for Amazonian treks, the film's tear resistance (over 50N) handles rough loading, arriving unscathed. A poignant example: a streetwear drop in Tokyo, where limited-edition kicks in POF wraps arrive mirror-like, the transparency teasing exclusivity without obscuring details. For orthopedic lines, gentle flexibility avoids pressure marks on insoles. Thus, in footwear, POF film doesn't conceal—it celebrates, wrapping wanderlust in resilient elegance.

Footwear Fashion: Wrapping Style with Unseen StrengthIn the stylish domain of footwear, transparent POF film elevates protection to an art form, blending invisibility with indestructibility. Footwear, from ballet flats to hiking boots, demands packaging that showcases design while battling the elements. POF's high gloss and clarity turn a boxed sneaker into a display case, revealing laces, logos, and leather grains in high definition—boosting perceived value by 15% in retail studies, as visuals drive 70% of apparel buys.Shrink-wrapping prowess is paramount: heated, the film contracts uniformly, forming a tamper-evident seal that deters pilferage and withstands drops from waist height without rupture, thanks to its 200g dart impact. For a Milan fashion week prep, imagine Louboutin heels slipped into POF sleeves; the film hugs curves without creasing, preserving toe shapes during air freight turbulence. Dust and scuffs? The barrier properties repel them, with abrasion tests showing minimal wear after simulated shelf-stocking cycles.Breathability for boxed pairs prevents mildew in humid climates, while recyclability appeals to eco-fashion brands—POF scraps feed back into production loops, cutting virgin resin use by 20%. In athletic gear, like trail runners for Amazonian treks, the film's tear resistance (over 50N) handles rough loading, arriving unscathed. A poignant example: a streetwear drop in Tokyo, where limited-edition kicks in POF wraps arrive mirror-like, the transparency teasing exclusivity without obscuring details. For orthopedic lines, gentle flexibility avoids pressure marks on insoles. Thus, in footwear, POF film doesn't conceal—it celebrates, wrapping wanderlust in resilient elegance. Conclusion: The Enduring Wrap of InnovationTransparent POF film, with its crystalline clarity, unyielding strength, and adaptive genius, stands as a cornerstone of contemporary packaging. From cradling the ephemeral blush of a peach in vegetable trays to silencing static whispers around circuit boards, and from spotlighting a stiletto's arch to sealing a sandwich's savor, it weaves protection into every fold. Its properties—clarity that captivates, barriers that preserve, resilience that endures—aren't abstract; they manifest in longer shelf lives, safer transports, and delighted consumers. As industries evolve toward sustainability and efficiency, POF film's recyclability and versatility position it at the forefront, promising a future where packaging enhances rather than encumbers. In a world of fleeting freshness and fragile finery, this film endures, a transparent testament to thoughtful design.

Conclusion: The Enduring Wrap of InnovationTransparent POF film, with its crystalline clarity, unyielding strength, and adaptive genius, stands as a cornerstone of contemporary packaging. From cradling the ephemeral blush of a peach in vegetable trays to silencing static whispers around circuit boards, and from spotlighting a stiletto's arch to sealing a sandwich's savor, it weaves protection into every fold. Its properties—clarity that captivates, barriers that preserve, resilience that endures—aren't abstract; they manifest in longer shelf lives, safer transports, and delighted consumers. As industries evolve toward sustainability and efficiency, POF film's recyclability and versatility position it at the forefront, promising a future where packaging enhances rather than encumbers. In a world of fleeting freshness and fragile finery, this film endures, a transparent testament to thoughtful design.

In the bustling world of packaging, where every layer counts toward preserving quality, allure, and safety, transparent POF film emerges as a silent hero. Polyolefin (POF) film, in its transparent form, is a marvel of modern materials science—a thin, flexible sheet of polymer that transforms under gentle heat into a snug, protective embrace around its contents. Imagine a delicate pastry, still warm from the oven, slipping into a crystal-clear cocoon that not only showcases its golden crust but also wards off the humid breath of time. Or picture a pair of sleek running shoes, fresh off the assembly line, wrapped in a seamless skin that highlights their contours while fending off dust and scratches. This is the essence of transparent POF film: versatile, resilient, and remarkably unobtrusive.

In the bustling world of packaging, where every layer counts toward preserving quality, allure, and safety, transparent POF film emerges as a silent hero. Polyolefin (POF) film, in its transparent form, is a marvel of modern materials science—a thin, flexible sheet of polymer that transforms under gentle heat into a snug, protective embrace around its contents. Imagine a delicate pastry, still warm from the oven, slipping into a crystal-clear cocoon that not only showcases its golden crust but also wards off the humid breath of time. Or picture a pair of sleek running shoes, fresh off the assembly line, wrapped in a seamless skin that highlights their contours while fending off dust and scratches. This is the essence of transparent POF film: versatile, resilient, and remarkably unobtrusive.  The Core Characteristics: A Blueprint of Brilliance and ResilienceAt its heart, transparent POF film is defined by a constellation of physical and chemical traits that make it a standout in the polymer family. Foremost is its exceptional clarity, often exceeding 90% light transmission, which rivals glass without the fragility. This optical purity stems from the film's amorphous structure, where polymer chains align in a way that minimizes light scattering. In practical terms, this means a consumer peering at a bundled bunch of asparagus can discern the vibrant green tips from afar, unmarred by haze or distortion. The film's gloss level, typically around 120-140 units on the standard gloss meter, adds a polished sheen that makes packaged goods pop under store lights, subtly influencing purchase decisions through visual appeal.Strength is another pillar, with tensile strength surpassing 100 MPa in both machine and transverse directions—a testament to its balanced molecular orientation during manufacturing. This isn't mere lab jargon; consider a scenario in a high-traffic supermarket where a tray of cheeses tumbles from a shelf. The POF wrap holds firm, resisting punctures from jagged edges or tears from rough handling, thanks to its high dart impact resistance, often over 200 grams. Elongation at break reaches up to 150%, allowing the film to stretch without snapping, which is crucial during the shrink process where it contracts by 50-70% upon exposure to 80-120°C heat. Revolutionizing Food Packaging: A Shield for Savor and SafetyIn the realm of food packaging, transparent POF film acts as a vigilant guardian, extending shelf life while inviting the senses to engage. Picture a family-owned bakery in a quaint European village, where artisan loaves emerge steaming from wood-fired ovens. Wrapped in POF shrink film, these breads retain their rustic aroma and crusty texture for days longer than unwrapped counterparts. The film's superior sealability, achieved through hot-wire or impulse sealing, creates an airtight bond that repels airborne contaminants, slashing microbial growth by inhibiting oxygen and humidity exposure.

The Core Characteristics: A Blueprint of Brilliance and ResilienceAt its heart, transparent POF film is defined by a constellation of physical and chemical traits that make it a standout in the polymer family. Foremost is its exceptional clarity, often exceeding 90% light transmission, which rivals glass without the fragility. This optical purity stems from the film's amorphous structure, where polymer chains align in a way that minimizes light scattering. In practical terms, this means a consumer peering at a bundled bunch of asparagus can discern the vibrant green tips from afar, unmarred by haze or distortion. The film's gloss level, typically around 120-140 units on the standard gloss meter, adds a polished sheen that makes packaged goods pop under store lights, subtly influencing purchase decisions through visual appeal.Strength is another pillar, with tensile strength surpassing 100 MPa in both machine and transverse directions—a testament to its balanced molecular orientation during manufacturing. This isn't mere lab jargon; consider a scenario in a high-traffic supermarket where a tray of cheeses tumbles from a shelf. The POF wrap holds firm, resisting punctures from jagged edges or tears from rough handling, thanks to its high dart impact resistance, often over 200 grams. Elongation at break reaches up to 150%, allowing the film to stretch without snapping, which is crucial during the shrink process where it contracts by 50-70% upon exposure to 80-120°C heat. Revolutionizing Food Packaging: A Shield for Savor and SafetyIn the realm of food packaging, transparent POF film acts as a vigilant guardian, extending shelf life while inviting the senses to engage. Picture a family-owned bakery in a quaint European village, where artisan loaves emerge steaming from wood-fired ovens. Wrapped in POF shrink film, these breads retain their rustic aroma and crusty texture for days longer than unwrapped counterparts. The film's superior sealability, achieved through hot-wire or impulse sealing, creates an airtight bond that repels airborne contaminants, slashing microbial growth by inhibiting oxygen and humidity exposure.  Safeguarding Vegetables: Freshness Through a Green LensVegetables, with their fleeting vibrancy, demand packaging that breathes life into longevity, and transparent POF film excels here by striking a balance between barrier and permeability. Envision a sun-drenched California farmstand, where heirloom tomatoes—ruby-red orbs bursting with summer—nestle in POF bundles. The film's controlled OTR permits ethylene gas (the ripening hormone) to dissipate gradually, staving off over-maturation that turns firm produce mushy. This selective breathability extends harvest-to-table windows by 40%, as evidenced by post-harvest trials where POF-wrapped carrots retained crunch after two weeks in refrigerated transit, versus wilting in mere days for loose storage.Clarity plays a starring role, transforming mundane bundles into marketing masterpieces. Shoppers at a bustling Asian wet market can inspect the dew-kissed leaves of bok choy through the film's pristine surface, spotting blemishes or confirming dew-fresh quality without unwrapping. The shrink effect molds the film like a second skin, preventing bruising from jostling during truck hauls over rutted roads— a boon for delicate items like bell peppers, where impact tests show POF reducing damage by 25% over foam nets.

Safeguarding Vegetables: Freshness Through a Green LensVegetables, with their fleeting vibrancy, demand packaging that breathes life into longevity, and transparent POF film excels here by striking a balance between barrier and permeability. Envision a sun-drenched California farmstand, where heirloom tomatoes—ruby-red orbs bursting with summer—nestle in POF bundles. The film's controlled OTR permits ethylene gas (the ripening hormone) to dissipate gradually, staving off over-maturation that turns firm produce mushy. This selective breathability extends harvest-to-table windows by 40%, as evidenced by post-harvest trials where POF-wrapped carrots retained crunch after two weeks in refrigerated transit, versus wilting in mere days for loose storage.Clarity plays a starring role, transforming mundane bundles into marketing masterpieces. Shoppers at a bustling Asian wet market can inspect the dew-kissed leaves of bok choy through the film's pristine surface, spotting blemishes or confirming dew-fresh quality without unwrapping. The shrink effect molds the film like a second skin, preventing bruising from jostling during truck hauls over rutted roads— a boon for delicate items like bell peppers, where impact tests show POF reducing damage by 25% over foam nets.  Antistatic Mastery: Taming Invisible Sparks in Sensitive SpacesWhen static electricity lurks as an unseen saboteur, transparent POF film's antistatic variants step in as electrostatic tamers, particularly in electronics-adjacent packaging that intersects with food or general goods. Static, that pesky buildup from friction, can zap sensitive circuits or attract dust like a magnet, but POF's inherent low surface resistivity—enhanced to under 10^11 ohms/sq with conductive additives—dissipates charges in milliseconds. Imagine a semiconductor fab in Taiwan, where microchips destined for smart kitchen gadgets are cocooned in antistatic POF; the film grounds triboelectric forces, slashing ESD (electrostatic discharge) incidents by 90%, per industry benchmarks.Though primarily for tech, its food-safe formulations bridge to hybrid uses, like wrapping static-prone dried herbs or powdered spices that clump under charge. The transparency ensures operators spot contaminants mid-process, while the shrink conformance hugs irregular shapes without creases that harbor charges. Durability shines: even after repeated handling, the antistatic layer—often a slip-agent-infused outer ply—persists, unlike coatings that wear off.In a dynamic warehouse scenario, conveyor lines humming with boxed salads (containing embedded freshness sensors) rely on POF to prevent static-induced sensor failures. The film's balanced shrinkage avoids warping labels, and its low outgassing means no volatile emissions to contaminate nearby edibles. Quantitatively, tribo-testing reveals POF retaining antistatic efficacy post-1000 rubs, far outpacing PVC rivals. For global logistics, where humidity swings from arid deserts to humid ports, the film's stable conductivity—independent of RH levels above 20%—ensures reliability. Vividly, a tech-savvy grocer uses antistatic POF for RFID-tagged produce crates; no more zaps halting scans, just seamless inventory flow. Here, POF film neutralizes the invisible, fostering a charged-free sanctuary for precision packaging.

Antistatic Mastery: Taming Invisible Sparks in Sensitive SpacesWhen static electricity lurks as an unseen saboteur, transparent POF film's antistatic variants step in as electrostatic tamers, particularly in electronics-adjacent packaging that intersects with food or general goods. Static, that pesky buildup from friction, can zap sensitive circuits or attract dust like a magnet, but POF's inherent low surface resistivity—enhanced to under 10^11 ohms/sq with conductive additives—dissipates charges in milliseconds. Imagine a semiconductor fab in Taiwan, where microchips destined for smart kitchen gadgets are cocooned in antistatic POF; the film grounds triboelectric forces, slashing ESD (electrostatic discharge) incidents by 90%, per industry benchmarks.Though primarily for tech, its food-safe formulations bridge to hybrid uses, like wrapping static-prone dried herbs or powdered spices that clump under charge. The transparency ensures operators spot contaminants mid-process, while the shrink conformance hugs irregular shapes without creases that harbor charges. Durability shines: even after repeated handling, the antistatic layer—often a slip-agent-infused outer ply—persists, unlike coatings that wear off.In a dynamic warehouse scenario, conveyor lines humming with boxed salads (containing embedded freshness sensors) rely on POF to prevent static-induced sensor failures. The film's balanced shrinkage avoids warping labels, and its low outgassing means no volatile emissions to contaminate nearby edibles. Quantitatively, tribo-testing reveals POF retaining antistatic efficacy post-1000 rubs, far outpacing PVC rivals. For global logistics, where humidity swings from arid deserts to humid ports, the film's stable conductivity—independent of RH levels above 20%—ensures reliability. Vividly, a tech-savvy grocer uses antistatic POF for RFID-tagged produce crates; no more zaps halting scans, just seamless inventory flow. Here, POF film neutralizes the invisible, fostering a charged-free sanctuary for precision packaging. Footwear Fashion: Wrapping Style with Unseen StrengthIn the stylish domain of footwear, transparent POF film elevates protection to an art form, blending invisibility with indestructibility. Footwear, from ballet flats to hiking boots, demands packaging that showcases design while battling the elements. POF's high gloss and clarity turn a boxed sneaker into a display case, revealing laces, logos, and leather grains in high definition—boosting perceived value by 15% in retail studies, as visuals drive 70% of apparel buys.Shrink-wrapping prowess is paramount: heated, the film contracts uniformly, forming a tamper-evident seal that deters pilferage and withstands drops from waist height without rupture, thanks to its 200g dart impact. For a Milan fashion week prep, imagine Louboutin heels slipped into POF sleeves; the film hugs curves without creasing, preserving toe shapes during air freight turbulence. Dust and scuffs? The barrier properties repel them, with abrasion tests showing minimal wear after simulated shelf-stocking cycles.Breathability for boxed pairs prevents mildew in humid climates, while recyclability appeals to eco-fashion brands—POF scraps feed back into production loops, cutting virgin resin use by 20%. In athletic gear, like trail runners for Amazonian treks, the film's tear resistance (over 50N) handles rough loading, arriving unscathed. A poignant example: a streetwear drop in Tokyo, where limited-edition kicks in POF wraps arrive mirror-like, the transparency teasing exclusivity without obscuring details. For orthopedic lines, gentle flexibility avoids pressure marks on insoles. Thus, in footwear, POF film doesn't conceal—it celebrates, wrapping wanderlust in resilient elegance.

Footwear Fashion: Wrapping Style with Unseen StrengthIn the stylish domain of footwear, transparent POF film elevates protection to an art form, blending invisibility with indestructibility. Footwear, from ballet flats to hiking boots, demands packaging that showcases design while battling the elements. POF's high gloss and clarity turn a boxed sneaker into a display case, revealing laces, logos, and leather grains in high definition—boosting perceived value by 15% in retail studies, as visuals drive 70% of apparel buys.Shrink-wrapping prowess is paramount: heated, the film contracts uniformly, forming a tamper-evident seal that deters pilferage and withstands drops from waist height without rupture, thanks to its 200g dart impact. For a Milan fashion week prep, imagine Louboutin heels slipped into POF sleeves; the film hugs curves without creasing, preserving toe shapes during air freight turbulence. Dust and scuffs? The barrier properties repel them, with abrasion tests showing minimal wear after simulated shelf-stocking cycles.Breathability for boxed pairs prevents mildew in humid climates, while recyclability appeals to eco-fashion brands—POF scraps feed back into production loops, cutting virgin resin use by 20%. In athletic gear, like trail runners for Amazonian treks, the film's tear resistance (over 50N) handles rough loading, arriving unscathed. A poignant example: a streetwear drop in Tokyo, where limited-edition kicks in POF wraps arrive mirror-like, the transparency teasing exclusivity without obscuring details. For orthopedic lines, gentle flexibility avoids pressure marks on insoles. Thus, in footwear, POF film doesn't conceal—it celebrates, wrapping wanderlust in resilient elegance. Conclusion: The Enduring Wrap of InnovationTransparent POF film, with its crystalline clarity, unyielding strength, and adaptive genius, stands as a cornerstone of contemporary packaging. From cradling the ephemeral blush of a peach in vegetable trays to silencing static whispers around circuit boards, and from spotlighting a stiletto's arch to sealing a sandwich's savor, it weaves protection into every fold. Its properties—clarity that captivates, barriers that preserve, resilience that endures—aren't abstract; they manifest in longer shelf lives, safer transports, and delighted consumers. As industries evolve toward sustainability and efficiency, POF film's recyclability and versatility position it at the forefront, promising a future where packaging enhances rather than encumbers. In a world of fleeting freshness and fragile finery, this film endures, a transparent testament to thoughtful design.

Conclusion: The Enduring Wrap of InnovationTransparent POF film, with its crystalline clarity, unyielding strength, and adaptive genius, stands as a cornerstone of contemporary packaging. From cradling the ephemeral blush of a peach in vegetable trays to silencing static whispers around circuit boards, and from spotlighting a stiletto's arch to sealing a sandwich's savor, it weaves protection into every fold. Its properties—clarity that captivates, barriers that preserve, resilience that endures—aren't abstract; they manifest in longer shelf lives, safer transports, and delighted consumers. As industries evolve toward sustainability and efficiency, POF film's recyclability and versatility position it at the forefront, promising a future where packaging enhances rather than encumbers. In a world of fleeting freshness and fragile finery, this film endures, a transparent testament to thoughtful design.

Get the latest price? We'll respond as soon as possible(within 12 hours)