TL-BOPP-325 THE BOPP MEMBRANE PACKAGING

2024-10-12 15:52《The Versatile Applications of Transparent BOPP Film in Different Fields》

Introduction

Transparent Biaxially Oriented Polypropylene (BOPP) film has become an essential material in various industries due to its unique properties and versatility. This article will explore the extensive applications of transparent BOPP film in different fields, including food packaging, stationery, tobacco, and gift packaging. We will discuss its advantages, manufacturing process, and future prospects.

I. Properties of Transparent BOPP Film

Transparent BOPP film offers several remarkable properties that make it suitable for a wide range of applications.

1. Transparency

One of the most notable features of BOPP film is its high transparency. It allows for clear visibility of the contents inside, making it an ideal choice for packaging products where aesthetics and visual appeal are important.

2. Strength and Durability

BOPP film is known for its strength and durability. It can withstand handling, transportation, and storage without tearing or breaking. This makes it suitable for packaging applications that require a reliable and sturdy material.

3. Moisture Barrier

The film provides a good moisture barrier, protecting the contents from moisture damage. This is particularly important for food products, as it helps to maintain their freshness and quality.

4. Chemical Resistance

BOPP film is resistant to a variety of chemicals, including oils, solvents, and acids. This property makes it suitable for packaging products that may come into contact with different substances.

5. Printability

The surface of BOPP film is smooth and receptive to printing, allowing for high-quality graphics and labels. This enables manufacturers to create attractive packaging designs that enhance the marketability of their products.

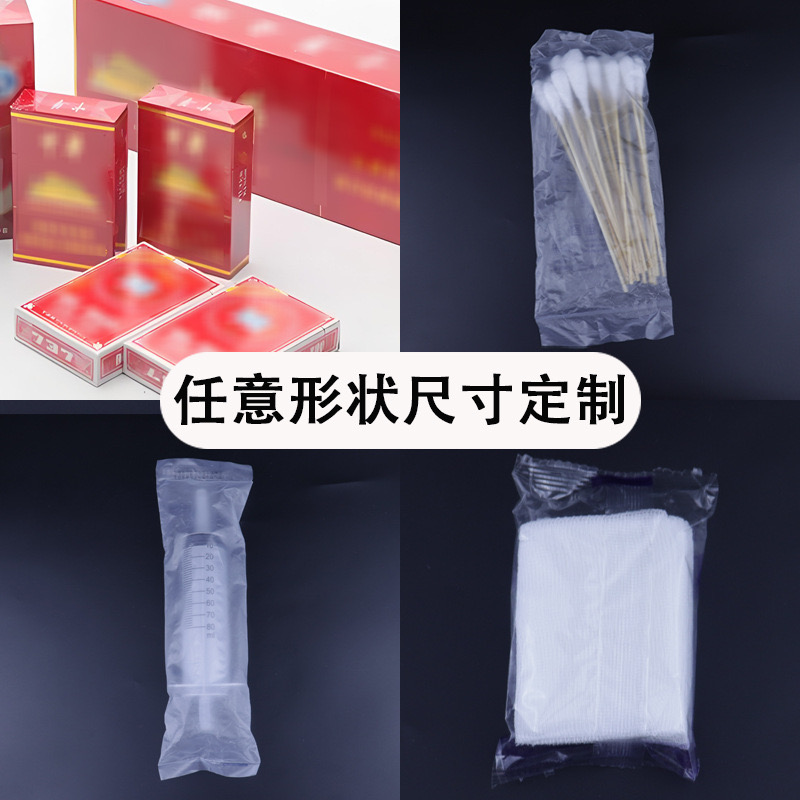

II. Applications in Food Packaging

1. Waterproof Fruit Boxes

Transparent BOPP film is widely used in the production of waterproof fruit boxes. The film's moisture barrier property helps to keep fruits fresh by preventing moisture from entering the box. The transparency of the film allows consumers to see the fruits inside, enhancing their appeal. Additionally, the film can be printed with product information and branding, making it an effective marketing tool.

2. Disposable Food Containers

BOPP film is also used in the manufacturing of disposable food containers. These containers are lightweight, convenient, and hygienic. The film's strength and durability ensure that the containers can hold food without collapsing or leaking. The transparency of the film allows consumers to see the contents, while the printability allows for branding and product information to be displayed.

3. Refrigerated Containers

For refrigerated containers, BOPP film provides a reliable moisture barrier and helps to maintain the freshness of the stored food. The film's transparency allows for easy identification of the contents, while its strength and durability make it suitable for use in cold environments.

4. Freshness Preservation Containers

BOPP film is used in the production of freshness preservation containers to extend the shelf life of food products. The film's moisture barrier and chemical resistance properties help to prevent spoilage and maintain the quality of the food. The transparency of the film allows consumers to monitor the condition of the food inside.

III. Applications in Stationery

1. Book Covers

Transparent BOPP film is a popular choice for book covers due to its durability and transparency. The film protects books from damage, while allowing the cover design to be visible. It can be easily applied to books of different sizes and shapes, providing a sleek and professional look.

2. Notebooks and Diaries

BOPP film can be used to cover notebooks and diaries, adding a layer of protection and enhancing their aesthetic appeal. The transparency of the film allows the pages inside to be visible, while the printability allows for customization with designs and logos.

3. Stationery Packaging

In the stationery industry, BOPP film is used for packaging products such as pens, pencils, erasers, and rulers. The film's transparency allows consumers to see the contents inside, while the strength and durability ensure that the packaging remains intact during transportation and storage.

IV. Applications in Tobacco Packaging

1. Cigarette Packs

Transparent BOPP film is commonly used in cigarette packaging to provide a moisture barrier and protect the cigarettes from damage. The film's transparency allows consumers to see the brand and design of the cigarette pack, while the printability enables manufacturers to display important information such as health warnings and product details.

2. Cigarette Wrappers

BOPP film is also used as a wrapper for individual cigarettes. The film provides a smooth and shiny surface, enhancing the appearance of the cigarette. It also helps to keep the cigarette fresh and protect it from moisture and odors.

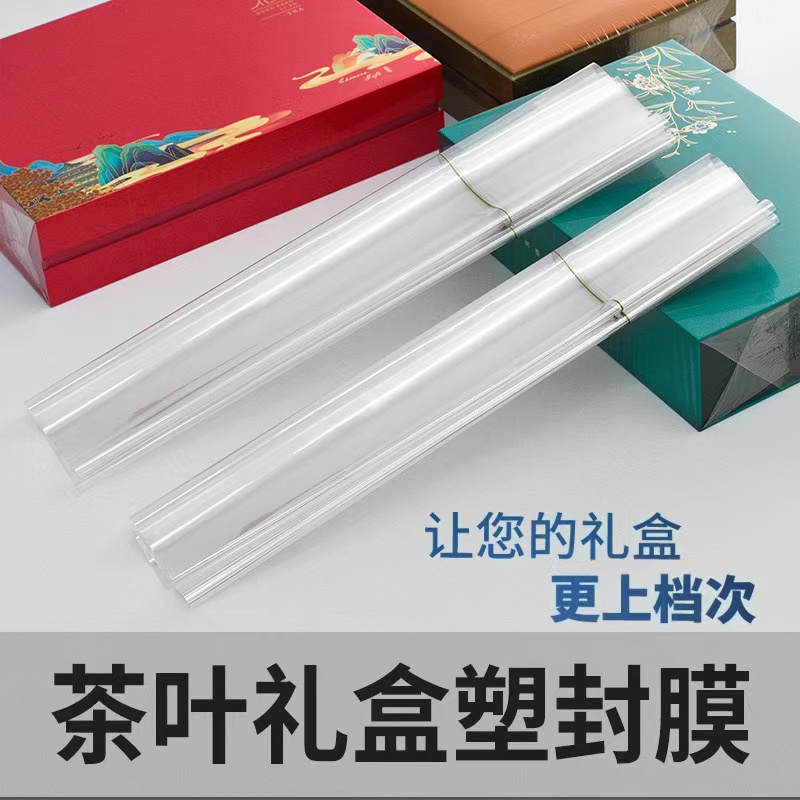

V. Applications in Gift Packaging

1. Gift Boxes

Transparent BOPP film is often used to wrap gift boxes, adding a touch of elegance and sophistication. The film's transparency allows the contents of the box to be visible, creating an enticing display. The strength and durability of the film ensure that the gift box remains protected during transportation and handling.

2. Gift Bags

BOPP film can be used to make gift bags, providing a lightweight and durable option for packaging gifts. The transparency of the film allows the contents to be seen, while the printability allows for customization with designs and messages.

3. Flower Wraps

In the floral industry, BOPP film is used to wrap flowers, creating a beautiful and protective packaging. The transparency of the film allows the colors and shapes of the flowers to be visible, while the moisture barrier property helps to keep the flowers fresh.

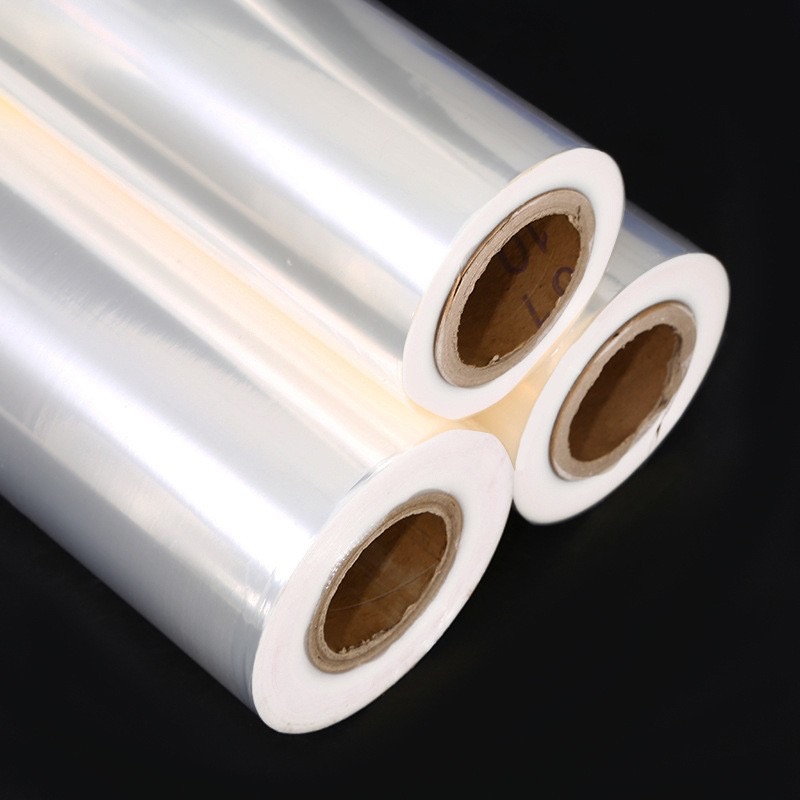

VI. Manufacturing Process of Transparent BOPP Film

The manufacturing process of transparent BOPP film involves several steps.

1. Extrusion

Polypropylene resin is melted and extruded through a flat die to form a thin sheet.

2. Biaxial Orientation

The sheet is then stretched in both the machine direction and the transverse direction to impart strength and improve its properties.

3. Annealing

The oriented film is annealed to relieve stress and stabilize its dimensions.

4. Coating and Printing

The film can be coated with various materials to enhance its properties, such as moisture barrier or anti-static coatings. It can also be printed with designs and labels using different printing methods.

VII. Advantages of Transparent BOPP Film in Different Applications

1. Visual Appeal

The transparency of BOPP film enhances the visual appeal of packaged products, making them more attractive to consumers. This is particularly important in food packaging, where consumers are more likely to purchase products that look fresh and appealing.

2. Protection

The film provides a protective layer for the contents, preventing damage from moisture, dust, and other environmental factors. This is crucial for food products, stationery, and gifts, as it helps to maintain their quality and integrity.

3. Convenience

BOPP film is lightweight and easy to handle, making it convenient for packaging and transportation. It can be easily cut, folded, and sealed, allowing for efficient packaging processes.

4. Cost-effectiveness

Compared to other packaging materials, BOPP film is relatively inexpensive. This makes it a cost-effective option for manufacturers, especially for large-scale production.

5. Sustainability

BOPP film is recyclable, which makes it an environmentally friendly choice. It can be recycled into new products, reducing waste and minimizing the environmental impact.

VIII. Challenges and Future Prospects

1. Environmental Concerns

Although BOPP film is recyclable, there is still a need to address environmental concerns associated with its production and disposal. Manufacturers need to explore more sustainable manufacturing processes and develop biodegradable alternatives to reduce the environmental impact.

2. Technological Advancements

As technology continues to advance, there is a potential for further improvements in the properties and performance of BOPP film. For example, research is being conducted on developing films with enhanced barrier properties, improved printability, and increased strength.

3. Market Demand

The demand for transparent BOPP film is expected to grow in the coming years, driven by the increasing demand for packaged food products, stationery, tobacco, and gift packaging. Manufacturers need to keep up with the market trends and invest in research and development to meet the evolving needs of their customers.

4. Competition

The market for packaging materials is highly competitive, with many alternative materials available. BOPP film manufacturers need to continuously innovate and improve their products to stay competitive in the market.

Conclusion

Transparent BOPP film has a wide range of applications in different fields due to its unique properties and versatility. From food packaging to stationery, tobacco, and gift packaging, the film offers several advantages, including transparency, strength, durability, moisture barrier, and printability. The manufacturing process of BOPP film involves several steps, ensuring a high-quality product. While there are challenges associated with environmental concerns and competition, the future prospects for BOPP film look promising, with technological advancements and growing market demand. As manufacturers continue to innovate and improve their products, transparent BOPP film is likely to remain an important material in various industries for years to come.