Unveiling the Power of PVC Protective Film for Steel Plate Preservation

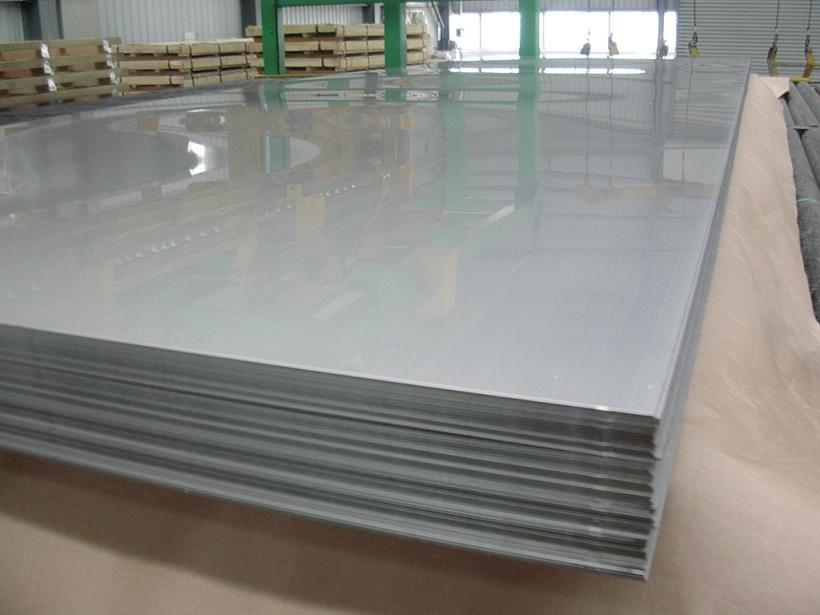

2025-03-13 13:48In the world of industrial manufacturing and material handling, protecting delicate surfaces like steel plates is a critical concern. Steel, while robust and versatile, is susceptible to scratches, abrasions, and environmental damage during processing, transportation, and storage. Enter the unsung hero of surface preservation: PVC protective film. This thin, flexible layer of polyvinyl chloride (PVC) has become a go-to solution for safeguarding steel plates, offering a blend of elasticity, adhesion, and resilience that ensures the material remains pristine from factory to final application. In this article, we’ll dive deep into the characteristics of PVC protective film and explore its indispensable role in steel plate protection, backed by practical insights and real-world applications.

The Core Characteristics of PVC Protective Film

1. Elasticity and Flexibility

One of the standout features of PVC protective film is its remarkable elasticity. Unlike rigid materials that might crack or fail under stress, PVC film stretches and conforms to the contours of steel plates, even during complex forming processes like bending or deep drawing. This elasticity stems from the molecular structure of polyvinyl chloride, a synthetic polymer known for its ability to deform without losing integrity. For instance, when a steel plate is subjected to mechanical shaping, the PVC protective film adapts seamlessly, maintaining a tight seal over the surface and preventing exposure to potential damage.

2. Slick Surface and Low Friction

The surface of PVC protective film is inherently smooth and slick, a trait that enhances its utility in steel plate protection. This low-friction quality minimizes the risk of scratches caused by rubbing or sliding during handling. Imagine a stack of steel plates being transported across a warehouse: without a protective layer, the metal surfaces could grind against each other, leaving unsightly marks. The slick nature of PVC film acts as a buffer, reducing friction and ensuring the steel remains unblemished.

3. Adhesive Strength and Residue-Free Removal

The adhesive properties of PVC protective film are carefully engineered to strike a balance between secure attachment and easy removal. Typically coated with a pressure-sensitive adhesive—often rubber-based or acrylic—the film adheres firmly to steel surfaces without requiring excessive force or heat. Peel strength, a key metric, can range from 10-80 g/cm depending on the specific formulation, ensuring it sticks well during use but peels off cleanly when the job is done. This residue-free removal is a game-changer: no sticky leftovers mean no additional cleaning or rework, saving time and labor costs.

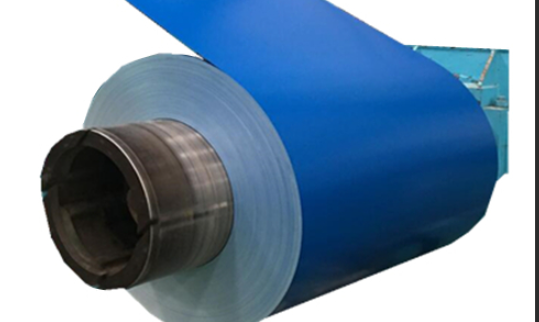

4. Durability and Weather Resistance

Steel plates often face harsh conditions—sunlight, moisture, and temperature fluctuations—especially during outdoor storage or long-haul shipping. PVC protective film is designed to withstand these challenges. With UV stabilizers incorporated into its composition, the film can endure several months of sunlight exposure without degrading. For example, a high-quality PVC film might offer up to six months of UV protection, making it ideal for steel plates destined for construction sites or overseas markets. Its resistance to moisture and temperature extremes (typically between 15°C and 40°C) further enhances its durability, ensuring consistent performance.

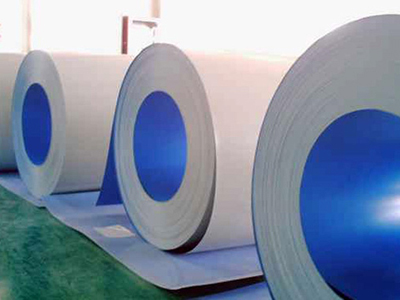

5. Customizability

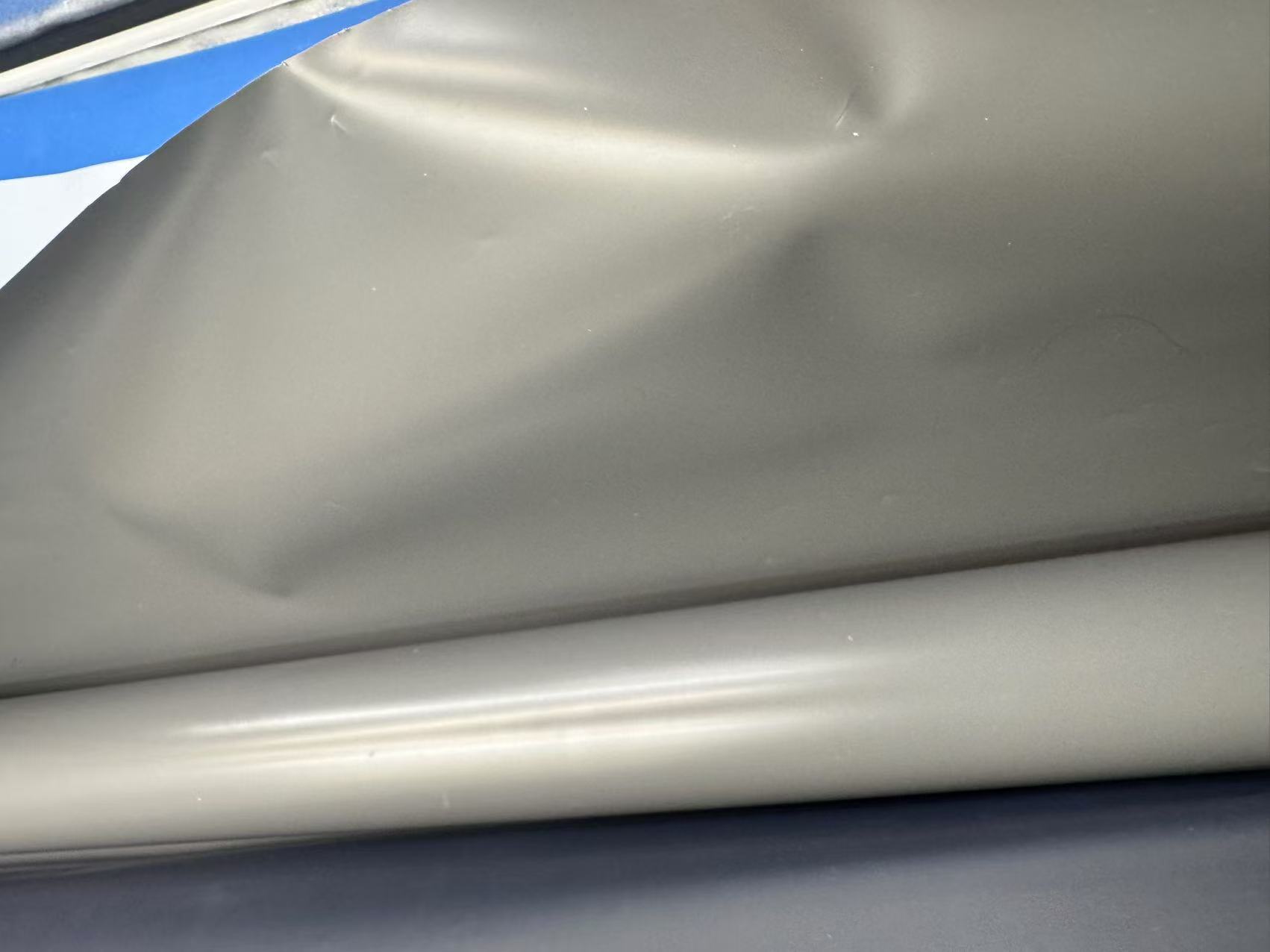

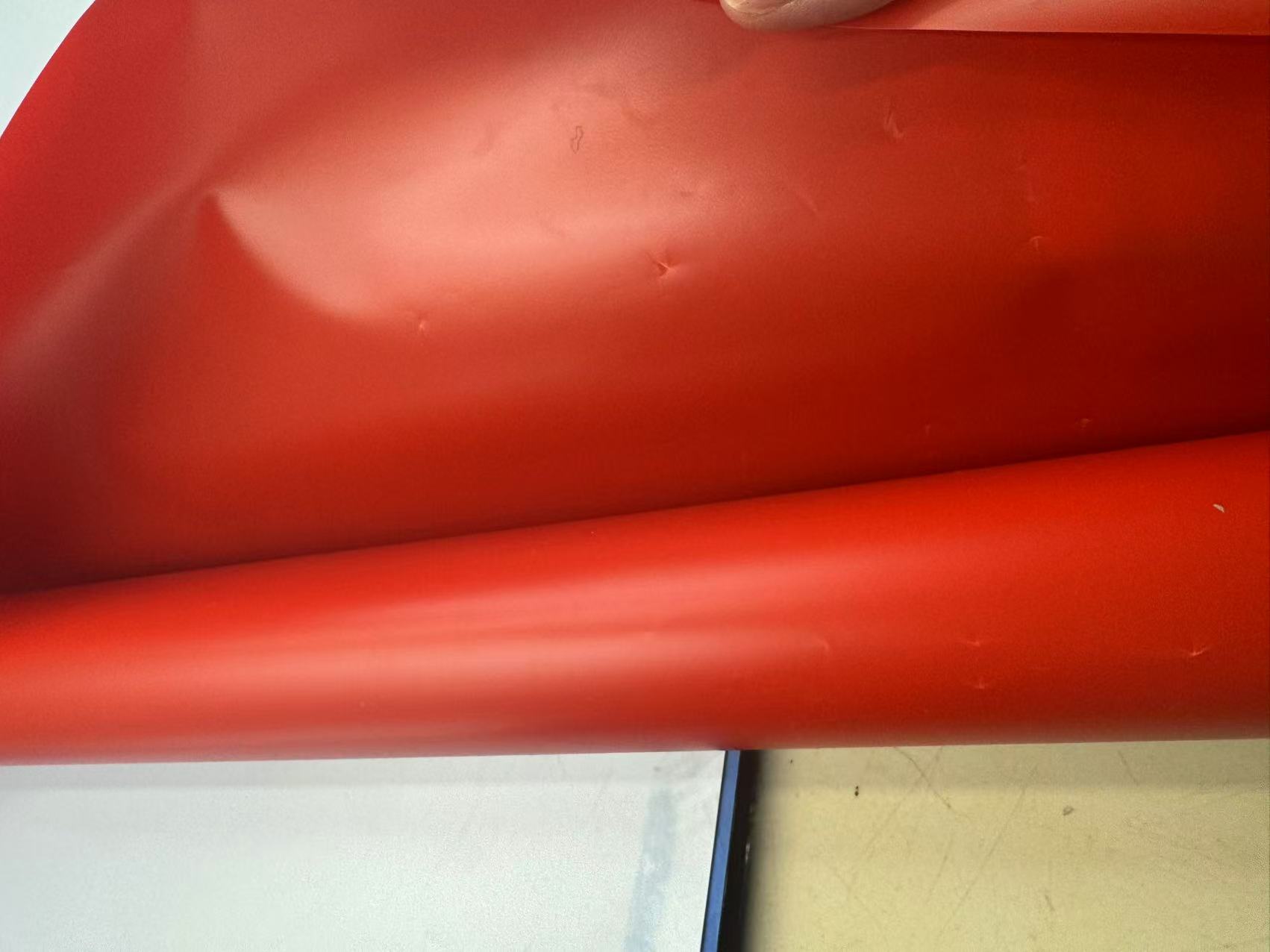

No two steel plates are identical in terms of surface finish or application, and PVC protective film rises to the occasion with its versatility. Manufacturers can tailor the film’s thickness (ranging from 0.05 mm to 0.1 mm or more), adhesive strength, and even color to suit specific needs. A polished stainless steel plate might require a transparent film with low adhesion, while a textured carbon steel plate could benefit from a thicker, high-bond variant. This customizability ensures that PVC protective film meets the diverse demands of steel plate protection.

The Role of PVC Protective Film in Steel Plate Protection

1. Safeguarding During Manufacturing

The journey of a steel plate begins in the mill, where it undergoes rolling, cutting, and finishing processes. Each step poses a risk: a stray tool could nick the surface, or dust could settle into micro-abrasions. PVC protective film steps in as a temporary shield, applied directly after production to preserve the plate’s pristine condition. For stainless steel, which is prized for its aesthetic appeal in gastronomy or architecture, this early protection is crucial. The film’s elasticity shines during processes like roll-forming or stamping, where it stretches without tearing, keeping the steel flawless.

2. Protection During Transportation

Transporting steel plates—whether by truck, ship, or rail—exposes them to vibrations, stacking pressure, and environmental hazards. Without proper care, a single scratch could render a plate unusable for high-end applications like appliance manufacturing. PVC protective film acts as a robust barrier, absorbing minor impacts and preventing metal-to-metal contact. Picture a shipment of steel plates crossing an ocean: the film’s weather resistance ensures that saltwater spray and UV rays don’t compromise the surface, delivering the cargo in showroom condition.

3. Storage and Handling Efficiency

Steel plates often sit in warehouses for weeks or months before use, gathering dust or facing accidental bumps from forklifts. Here, PVC protective film proves its worth by maintaining a clean, scratch-free surface. Its slick texture makes handling easier too—workers can slide plates without worrying about friction damage. In some cases, manufacturers print arrows or stripes on the film to indicate polishing direction, speeding up downstream processes and boosting productivity.

4. Specialized Applications in Deep Drawing and Fabrication

For steel plates destined for complex shapes—like automotive panels or kitchen sinks—deep drawing is a common technique. This process stretches the metal significantly, demanding a protective film that can keep up. PVC protective film, particularly variants with high elongation (over 400%), excels here. Its flexibility ensures it stays intact even as the steel is molded, preventing scratches from dies or tools. In fabrication shops, where steel is cut, welded, or polished, the film remains a steadfast guardian until the final product takes shape.

5. Environmental and Cost Benefits

Beyond its protective prowess, PVC protective film offers practical advantages. Compared to traditional methods like oil coatings, which require messy application and cleanup, PVC film is cleaner and more efficient. While polyethylene (PE) films are often touted as greener alternatives, PVC strikes a balance between performance and cost-effectiveness. Its durability reduces the need for frequent reapplication, and its residue-free removal eliminates secondary processing costs, making it a smart choice for budget-conscious industries.

Real-World Examples and Insights

Consider the construction industry, where stainless steel cladding graces modern skyscrapers. During installation, these plates are exposed to dust, mortar, and handling tools. A PVC protective film with medium adhesion and UV resistance keeps the steel spotless until the building is complete, at which point it’s peeled away to reveal a gleaming facade. In the appliance sector, manufacturers of refrigerators or ovens rely on PVC film to protect polished steel surfaces through assembly and shipping, ensuring customers receive a flawless product.

Data from industry practices supports these applications. A typical PVC protective film with a thickness of 0.05 mm and peel strength of 60-80 g/cm can withstand outdoor exposure for up to three months, ideal for short-term projects. For longer durations, a thicker film (0.1 mm) with enhanced UV stabilizers extends protection to six months or more, as seen in overseas steel exports. These specifications highlight the film’s adaptability to real-world challenges.

Challenges and Considerations

While PVC protective film is a powerhouse in steel plate protection, it’s not without limitations. Prolonged exposure to extreme heat (above 40°C) can weaken its adhesive, risking edge lift—where the film peels away prematurely. Similarly, overexposure to sunlight beyond its UV rating may cause the adhesive to break down, leaving faint residues. To mitigate these risks, users must select a film matched to their specific conditions, such as opting for a high-performance variant for outdoor use.

Another consideration is environmental impact. While PVC is recyclable, its production and disposal generate more emissions than PE alternatives. However, advancements in PVC formulations—such as incorporating recycled content—are narrowing this gap, making it a viable choice for sustainability-conscious firms.

Conclusion

PVC protective film is more than just a layer of plastic—it’s a meticulously designed solution that marries elasticity, adhesion, and durability to safeguard steel plates at every stage of their lifecycle. From the factory floor to the construction site, its ability to shield against scratches, weathering, and handling mishaps makes it indispensable in steel plate protection. With customizable options and proven performance, PVC film empowers industries to deliver flawless steel products efficiently and cost-effectively. As technology evolves, so too will this humble protector, ensuring that steel’s shine endures, unmarred by the rigors of the world.