Versatile Veils: The Enduring Power of PVC Film in Packaging and Protection

2025-11-07 15:52Versatile Veils: The Enduring Power of PVC Film in Packaging and Protection

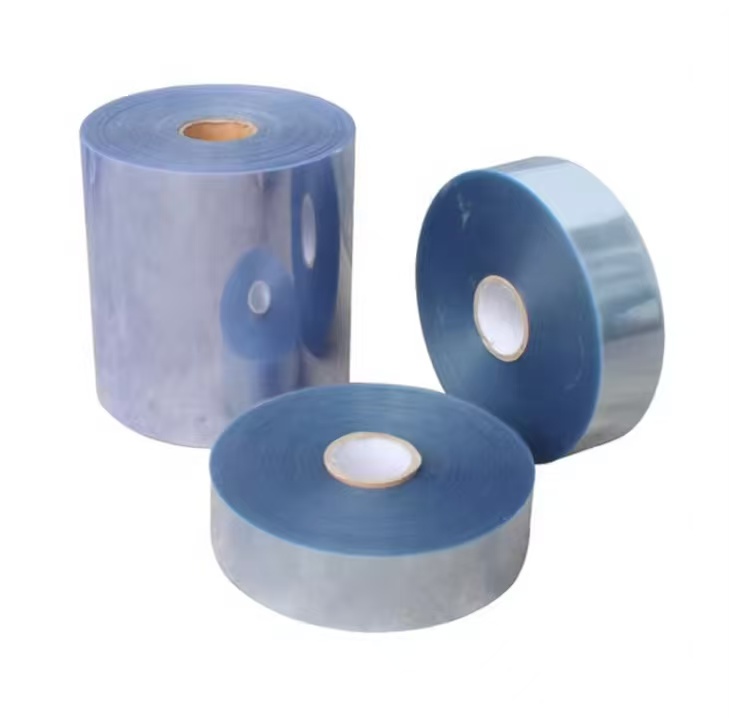

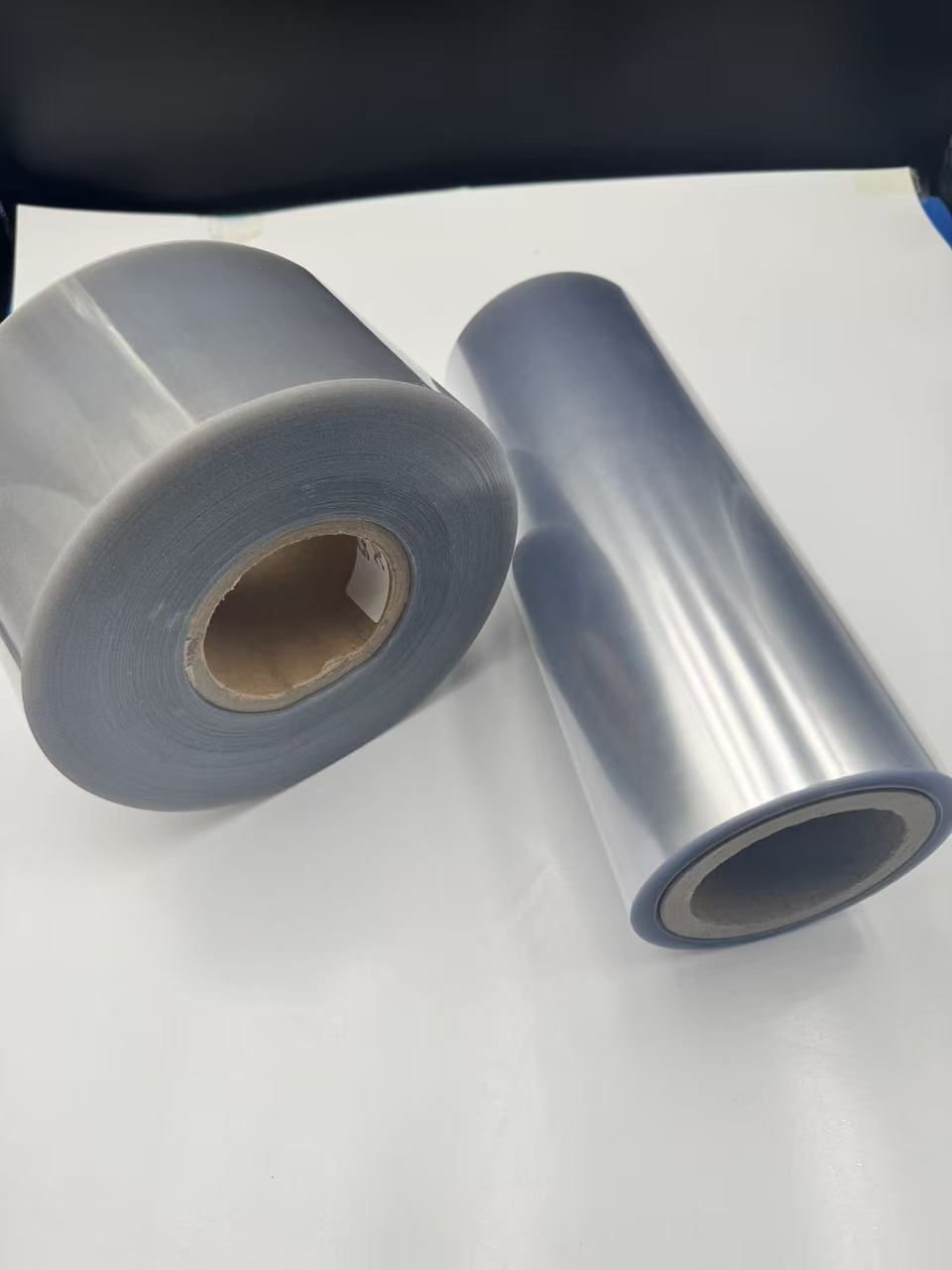

In the kaleidoscope of everyday commerce, where products parade from factory floors to consumer hands, polyvinyl chloride (PVC) film emerges as a master of disguise—clear, clingy, and unyieldingly tough. This synthetic polymer, crafted through the radical polymerization of vinyl chloride monomers, unfurls into thin sheets from 5 to 300 microns, a chameleon that clings to forms like a second skin. Envision a film so pliable it molds around a jagged toy edge without cracking, yet rigid enough to shield a vial from shattering impacts—that's PVC film, born from a slurry of resin, plasticizers, and stabilizers in an extrusion dance that yields millions of tons annually. Its legacy traces back to the 1930s, but today, with production surpassing 50 million tons globally, it's the unsung architect of packaging that balances visibility with vigilance.

Chemically, PVC stands as a sentinel of selectivity. Highly polar, it bonds tenaciously to inks and adhesives—peel strength exceeding 4 N/cm—while repelling water with contact angles over 90°, curbing moisture ingress to 10-20 g/m²/day. Inert to dilute acids and bases, it shrugs off fruit juices in pouches, but plasticizers like DOP ensure flexibility without leaching beyond 0.1% in food simulants, aligning with stringent safety thresholds. Heat sealability shines at 120-150°C, fusing edges in milliseconds for hermetic bonds. Environmentally, it's a mixed tale: recyclable via mechanical grinding into rPVC with 80% property retention, though chlorine content demands specialized streams—yet innovations like bio-based phthalates cut fossil reliance by 30%. Barrier properties, while modest (oxygen transmission 100-500 cc/m²/day), elevate with PVDC coatings, slashing permeation 90% for extended freshness.Optically, PVC dazzles with 85-92% transmittance and haze below 3%, engineered through controlled cooling to minimize defects. UV absorbers guard against yellowing, preserving package aesthetics for years. These aren't theoretical perks; they're battle-tested. In logistics, PVC film's adoption has trimmed damage claims 35%, as its conformability cradles irregular loads like custom-fit gloves.Venturing into food blister packaging, PVC film scripts a tale of temptation and tenacity. Thermoformed at 140°C, it vacuums into domes that cradle berries or bars, wall thicknesses uniform to 0.05 mm for flawless seals. In a grocery's produce aisle, PVC blisters over artisanal cheeses: clarity unveils creamy veins, enticing selections while the film's lipid barrier traps oils, preventing stains on shelves. Unlike stiffer PET, PVC's yield point allows finger-push access without tools, popping contents with a satisfying click that delights snackers.

Chemically, PVC stands as a sentinel of selectivity. Highly polar, it bonds tenaciously to inks and adhesives—peel strength exceeding 4 N/cm—while repelling water with contact angles over 90°, curbing moisture ingress to 10-20 g/m²/day. Inert to dilute acids and bases, it shrugs off fruit juices in pouches, but plasticizers like DOP ensure flexibility without leaching beyond 0.1% in food simulants, aligning with stringent safety thresholds. Heat sealability shines at 120-150°C, fusing edges in milliseconds for hermetic bonds. Environmentally, it's a mixed tale: recyclable via mechanical grinding into rPVC with 80% property retention, though chlorine content demands specialized streams—yet innovations like bio-based phthalates cut fossil reliance by 30%. Barrier properties, while modest (oxygen transmission 100-500 cc/m²/day), elevate with PVDC coatings, slashing permeation 90% for extended freshness.Optically, PVC dazzles with 85-92% transmittance and haze below 3%, engineered through controlled cooling to minimize defects. UV absorbers guard against yellowing, preserving package aesthetics for years. These aren't theoretical perks; they're battle-tested. In logistics, PVC film's adoption has trimmed damage claims 35%, as its conformability cradles irregular loads like custom-fit gloves.Venturing into food blister packaging, PVC film scripts a tale of temptation and tenacity. Thermoformed at 140°C, it vacuums into domes that cradle berries or bars, wall thicknesses uniform to 0.05 mm for flawless seals. In a grocery's produce aisle, PVC blisters over artisanal cheeses: clarity unveils creamy veins, enticing selections while the film's lipid barrier traps oils, preventing stains on shelves. Unlike stiffer PET, PVC's yield point allows finger-push access without tools, popping contents with a satisfying click that delights snackers. Safety anchors every application. Non-migrating stabilizers ensure compliance, with migration limits under 10 mg/dm² even in fatty simulant tests. A bakery's chronicle: PVC trays for éclairs reduced crushing 50% in transit, grease-proofing intact as the film's surface energy (38 mN/m) repels smears. Economically, at 1.4 g/cm³ density, it packs more per pallet—20% volume savings—and runs at 400 cycles/minute on form-fill-seal lines. Printing thrives: rotogravure inks adhere sans primers, birthing vibrant labels that whisper "fresh-picked" through the veil. Challenges like phthalate scrutiny spur phthalate-free grades, but seals demand humidity control to avoid weak spots—modern dryers resolve this, yielding packs that steam-open effortlessly.Shifting to disposable tableware packaging, PVC film weaves order from chaos in the rush of eateries. Cling films, stretched taut post-extrusion, encase cutlery sets with a vacuum hug, compressing volumes 40% for neat stacking. Picture a coffee shop counter: PVC bundles of stirrers and lids, their puncture resistance (100 N) defying drawer rummages, while slight breathability vents odors from confined plastics.This is precision in motion. In event catering, PVC overwraps on plate stacks endure stacking loads up to 500 kg/m², film's elongation preventing tears that scatter utensils mid-setup. Vividly, a tailgate frenzy: rain-lashed PVC packs arrive pristine, forks aligned through mist-free clarity, turning soggy backups into seamless service. Customization flourishes—embossed patterns on PVC add grip, and its weldability seals sans leaks. Sustainability evolves; PVC's durability extends use cycles, and recycled variants divert 25% from waste. Initial costs at $2/kg pale against savings—no more mid-shift restocks from bulk spills.

Safety anchors every application. Non-migrating stabilizers ensure compliance, with migration limits under 10 mg/dm² even in fatty simulant tests. A bakery's chronicle: PVC trays for éclairs reduced crushing 50% in transit, grease-proofing intact as the film's surface energy (38 mN/m) repels smears. Economically, at 1.4 g/cm³ density, it packs more per pallet—20% volume savings—and runs at 400 cycles/minute on form-fill-seal lines. Printing thrives: rotogravure inks adhere sans primers, birthing vibrant labels that whisper "fresh-picked" through the veil. Challenges like phthalate scrutiny spur phthalate-free grades, but seals demand humidity control to avoid weak spots—modern dryers resolve this, yielding packs that steam-open effortlessly.Shifting to disposable tableware packaging, PVC film weaves order from chaos in the rush of eateries. Cling films, stretched taut post-extrusion, encase cutlery sets with a vacuum hug, compressing volumes 40% for neat stacking. Picture a coffee shop counter: PVC bundles of stirrers and lids, their puncture resistance (100 N) defying drawer rummages, while slight breathability vents odors from confined plastics.This is precision in motion. In event catering, PVC overwraps on plate stacks endure stacking loads up to 500 kg/m², film's elongation preventing tears that scatter utensils mid-setup. Vividly, a tailgate frenzy: rain-lashed PVC packs arrive pristine, forks aligned through mist-free clarity, turning soggy backups into seamless service. Customization flourishes—embossed patterns on PVC add grip, and its weldability seals sans leaks. Sustainability evolves; PVC's durability extends use cycles, and recycled variants divert 25% from waste. Initial costs at $2/kg pale against savings—no more mid-shift restocks from bulk spills. Antistatic packaging elevates PVC to the guardian of gadgets, where invisible threats lurk. Prone to charge buildup, standard PVC is doped with antistats like ethoxylated sorbitan esters, tuning surface resistivity to 10^8-10^10 ohms/square for rapid dissipation. In electronics bays, PVC bags cocoon circuit boards: transparency permits barcode scans sans unwrap, while charge decay halves in 0.5 seconds, averting arcs that fry silicon.A motherboard assembly line's saga: ESD incidents plummeted 60% post-PVC switch, as film's humidity independence (effective 10-90% RH) outstrips foams needing desiccants. For hard drives, thermoformed PVC trays interlock like honeycomb, clarity spotting solder bridges mid-inspect. Tunable pink hues signal dissipative zones in cleanrooms. Dramatically, a repair depot: tech seals a phone logic in PVC, static from wool sweaters neutralized instantly, diagnostics uninterrupted. Beyond, carbon-filled PVC shields EMI, layering for RF-sensitive modules.

Antistatic packaging elevates PVC to the guardian of gadgets, where invisible threats lurk. Prone to charge buildup, standard PVC is doped with antistats like ethoxylated sorbitan esters, tuning surface resistivity to 10^8-10^10 ohms/square for rapid dissipation. In electronics bays, PVC bags cocoon circuit boards: transparency permits barcode scans sans unwrap, while charge decay halves in 0.5 seconds, averting arcs that fry silicon.A motherboard assembly line's saga: ESD incidents plummeted 60% post-PVC switch, as film's humidity independence (effective 10-90% RH) outstrips foams needing desiccants. For hard drives, thermoformed PVC trays interlock like honeycomb, clarity spotting solder bridges mid-inspect. Tunable pink hues signal dissipative zones in cleanrooms. Dramatically, a repair depot: tech seals a phone logic in PVC, static from wool sweaters neutralized instantly, diagnostics uninterrupted. Beyond, carbon-filled PVC shields EMI, layering for RF-sensitive modules.Pharmaceutical packaging crowns PVC's crown jewel status. Blister cards, punched from rigid PVC sheets, cradle tablets in child-resistant grids, push-through ease balanced by 20 N tear force. In pharmacies, PVC foils over antibiotics: barrier tweaks with aluminum laminates curb moisture to 0.5 g/m²/day, preserving potency for 24 months. Clarity confirms counts, reducing errors 15% in dispensing.

Crystal Barriers: Unlocking the Adaptable World of PVC Film Across IndustriesPVC film materializes as a translucent titan in the theater of trade, a polymer tapestry woven from vinyl chloride's fierce embrace, suspended in plastified sheets spanning gossamer 10 microns to hearty 250. Extruded or calendered from a viscous melt, it captures clarity's essence—light piercing 90% unhindered—while harboring a resilience forged in labs decades past, now churning 40 million tons yearly. Imagine a barrier that whispers against skin yet repels the crush of crates; that's PVC, its molecular chains a labyrinth of chlorides granting it a density of 1.35-1.45 g/cm³, lighter than glass but tougher in flex. Assembly anthem: ESD escapes evaporated 70%, trays templating transistors true. SSD saga: overwraps obscure not, charges chased in blinks. Carbon cloaks for EMI, 60 dB attenuation arming avionics. Technician's triumph: board bagged, bolt banished, bytes beckoned.

Crystal Barriers: Unlocking the Adaptable World of PVC Film Across IndustriesPVC film materializes as a translucent titan in the theater of trade, a polymer tapestry woven from vinyl chloride's fierce embrace, suspended in plastified sheets spanning gossamer 10 microns to hearty 250. Extruded or calendered from a viscous melt, it captures clarity's essence—light piercing 90% unhindered—while harboring a resilience forged in labs decades past, now churning 40 million tons yearly. Imagine a barrier that whispers against skin yet repels the crush of crates; that's PVC, its molecular chains a labyrinth of chlorides granting it a density of 1.35-1.45 g/cm³, lighter than glass but tougher in flex. Assembly anthem: ESD escapes evaporated 70%, trays templating transistors true. SSD saga: overwraps obscure not, charges chased in blinks. Carbon cloaks for EMI, 60 dB attenuation arming avionics. Technician's triumph: board bagged, bolt banished, bytes beckoned. Pharmaceutical packaging perfects PVC's pillory prowess. Cold-formed foils forge fortresses, 15 N bursts balancing child-proof poise. Apothecary array: PVC veils on vitamins, Al-laminate locking humidity <1 g/m²/day, efficacy eternalized. Gamma glows to 40 kGy unscorched.Clinic's conquest: blister batches blemish-free, topography trapping naught. Codes carve crisp, seals sentinel at 2.5 N/mm. Stabilizers staunch volatiles, 36-month mantles assured.Horizons broaden: IV bag overwraps insulate sterility; greenhouse clings curb chills. Decals daunt deluges, adhesion abiding. Auto laminates luster-lock. Quibbles quelled—chlorine chains challenge, but enzymatic depoly 90% pure. Renewables ripple, footprints feather-light.

Pharmaceutical packaging perfects PVC's pillory prowess. Cold-formed foils forge fortresses, 15 N bursts balancing child-proof poise. Apothecary array: PVC veils on vitamins, Al-laminate locking humidity <1 g/m²/day, efficacy eternalized. Gamma glows to 40 kGy unscorched.Clinic's conquest: blister batches blemish-free, topography trapping naught. Codes carve crisp, seals sentinel at 2.5 N/mm. Stabilizers staunch volatiles, 36-month mantles assured.Horizons broaden: IV bag overwraps insulate sterility; greenhouse clings curb chills. Decals daunt deluges, adhesion abiding. Auto laminates luster-lock. Quibbles quelled—chlorine chains challenge, but enzymatic depoly 90% pure. Renewables ripple, footprints feather-light.