BOPET Terephthalate (BOPET) Film: Characteristics and Applications in Food Packaging

2025-06-11 16:52Introduction

Biaxially Oriented Polyethylene Terephthalate (BOPET) film, commonly referred to as PET film, is a versatile and high-performance polyester film created by stretching polyethylene terephthalate (PET) in both the machine direction (MD) and transverse direction (TD). This biaxial orientation process imparts exceptional mechanical, thermal, and barrier properties, making BOPET film a cornerstone material in various industries, particularly in food packaging. Its applications in food printing packaging, food label printing, and sealing packaging have revolutionized the way food products are preserved, presented, and protected. This article explores the unique characteristics of BOPET film and its critical role in these specific food packaging applications, supported by scientific insights and industry trends.

Characteristics of BOPET Film

BOPET film is renowned for its multifaceted properties, which make it an ideal choice for demanding applications in food packaging. Below are the key characteristics that define its utility:

Mechanical Strength and Durability:

BOPET film exhibits high tensile strength, typically ranging from 150–200 MPa, due to the alignment of polymer chains during the biaxial orientation process. This strength ensures that the film can withstand physical stresses during handling, transportation, and storage, reducing the risk of tears or punctures. For example, in food packaging, BOPET film maintains structural integrity even when subjected to stacking or palletizing pressures, ensuring that packaged goods remain intact.

Superior Barrier Properties:

BOPET film offers excellent resistance to gases (such as oxygen and carbon dioxide), moisture, and aromas. Its oxygen permeation can be reduced to less than 1 cm³/m²/day/bar when metallized, making it ideal for preserving the freshness and extending the shelf life of perishable food products. This is particularly crucial for sensitive products like dairy, snacks, and coffee, where exposure to oxygen or moisture can lead to spoilage or flavor degradation.

Thermal Stability:

With an operating temperature range of -60°C to 150°C (and up to 200°C for short durations), BOPET film is suitable for both high-temperature processes like hot-fill packaging and low-temperature applications such as frozen food packaging. Its low thermal shrinkage ensures dimensional stability, which is vital for maintaining the integrity of printed designs and seals during processing.

Optical Clarity and Printability:

BOPET film provides excellent transparency, low haze, and high gloss, making it an attractive choice for food packaging that requires visual appeal. Its smooth surface allows for high-quality printing, enabling vibrant and precise graphics for branding and product information. Additionally, surface treatments like corona or chemical coating enhance its adhesion to inks and adhesives, ensuring durable and visually appealing labels and packaging designs.

Chemical Resistance and Safety:

BOPET film is resistant to oils, greases, and many solvents, making it suitable for packaging foods with high fat or liquid content. It is also FDA-approved for food contact, ensuring safety for direct food packaging applications such as lidding for ready meals or pouches for snacks. Its low odor and chemical inertness further contribute to its suitability for food applications.

Recyclability and Sustainability:

BOPET film is fully recyclable, aligning with the growing demand for sustainable packaging solutions. Advances in recycling technologies have enabled BOPET to be repurposed into new packaging or other products, reducing environmental impact. Additionally, its lightweight nature reduces material usage and transportation costs, further enhancing its eco-friendly profile.

Applications in Food Printing Packaging

Food printing packaging, which involves the application of high-quality graphics and branding directly onto packaging materials, relies heavily on BOPET film due to its superior printability and durability. The following points highlight its role in this application:

High-Quality Graphics for Branding:

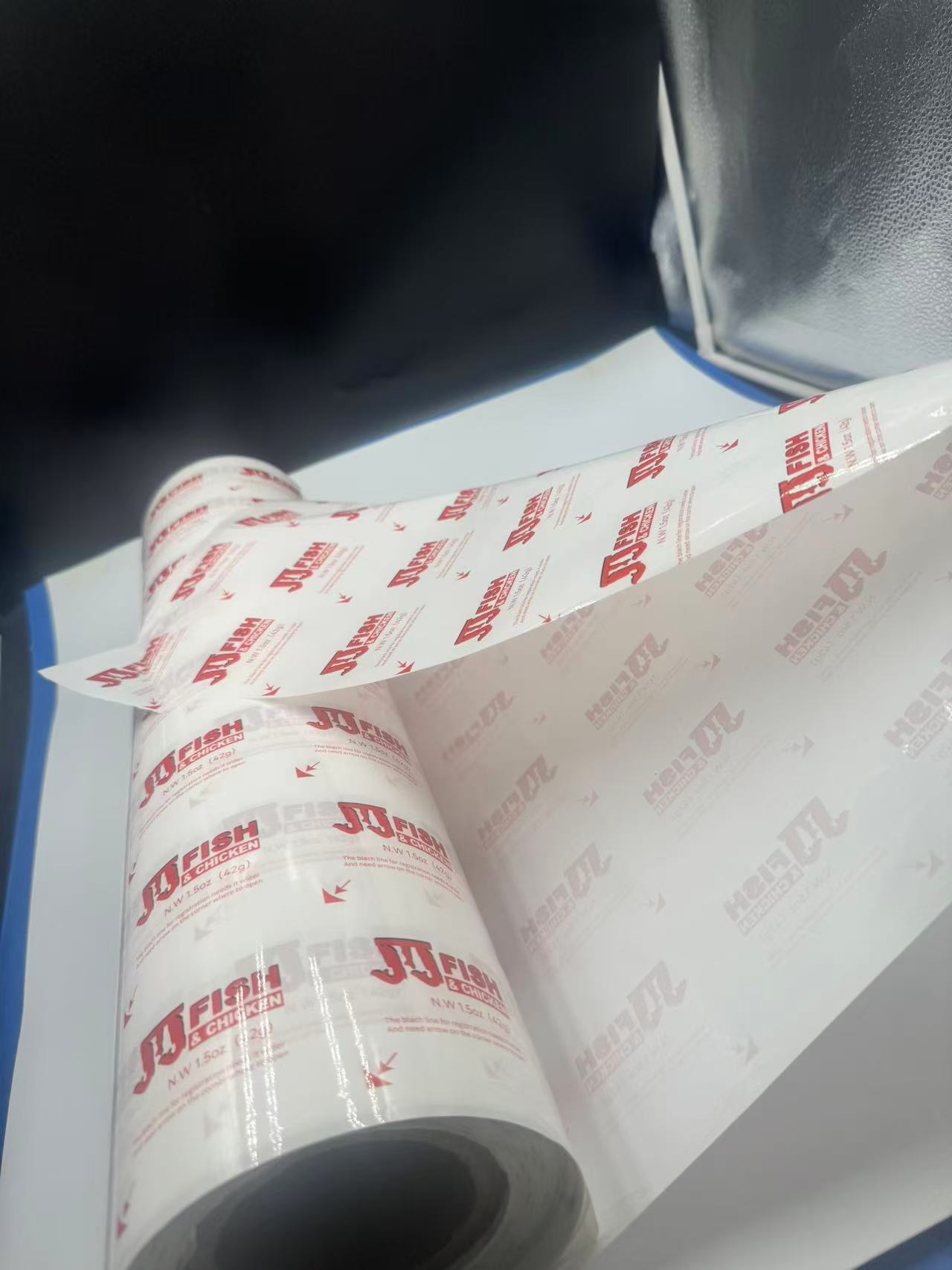

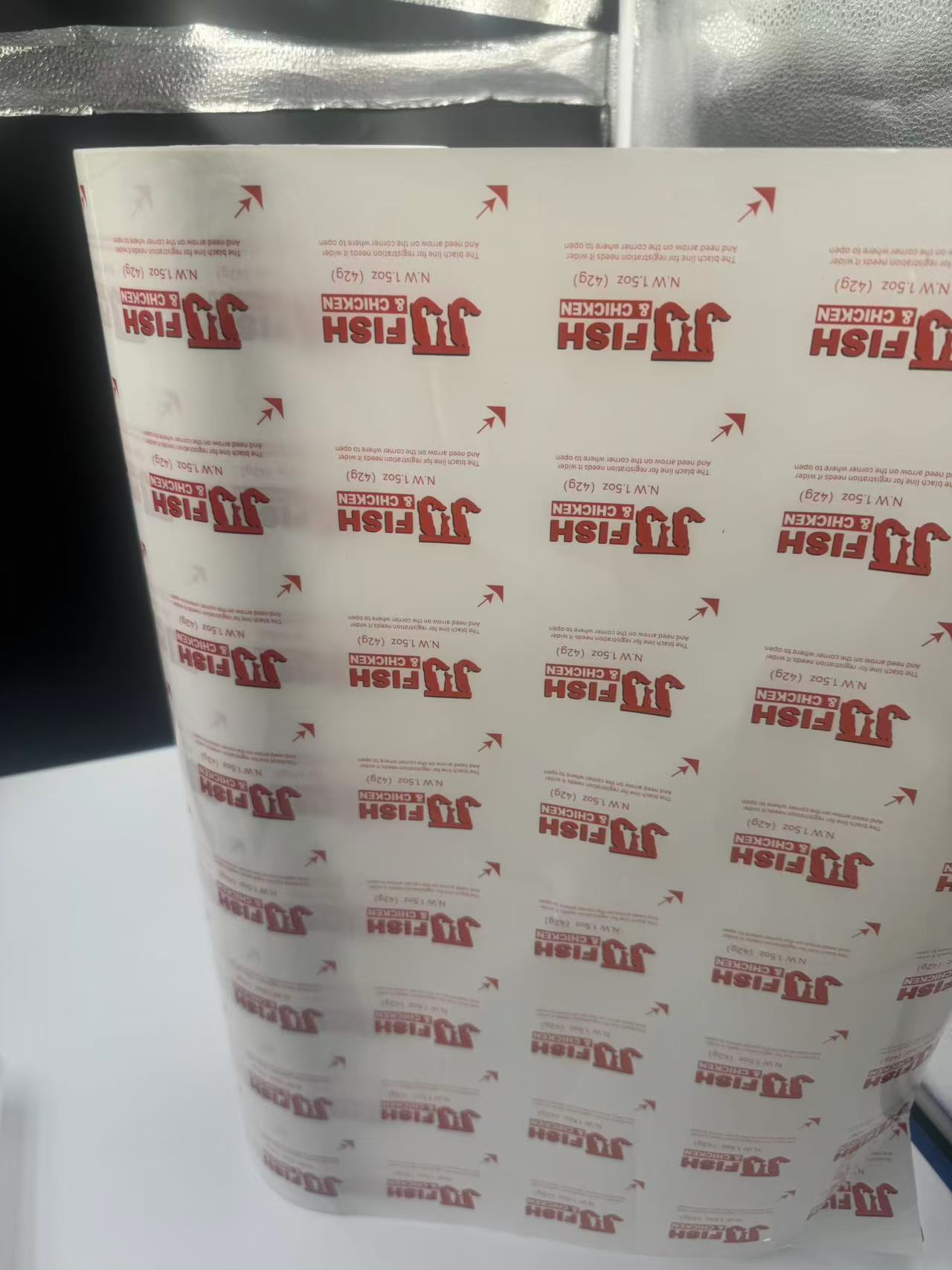

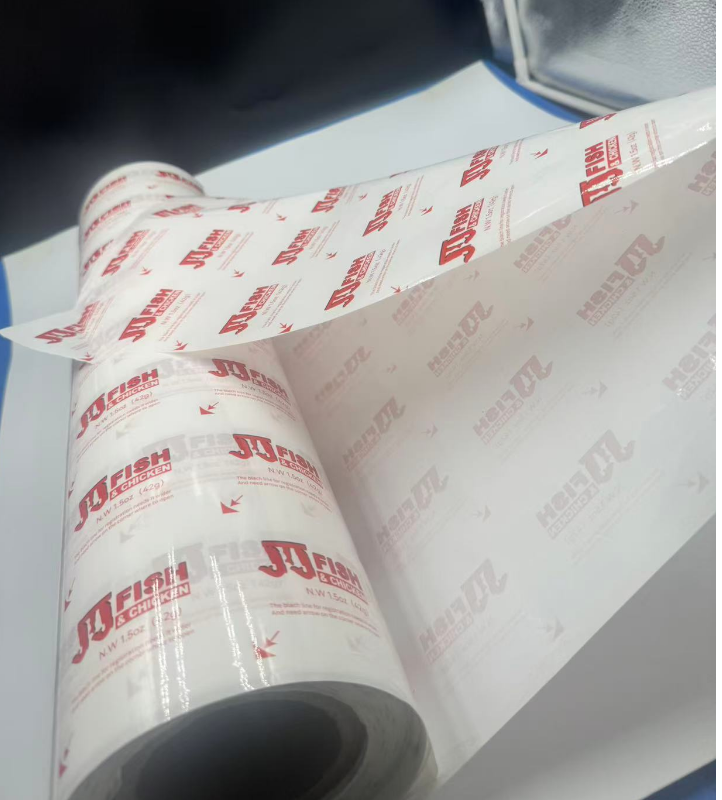

BOPET film’s smooth surface and optical clarity make it an ideal substrate for reverse-side printing, commonly used in multilayer plastic (MLP) structures for food packaging. For instance, coffee packaging often uses a laminate structure where BOPET film is printed and laminated with aluminum foil for barrier properties and polyethylene for sealing. This structure not only protects the product but also showcases vibrant logos and nutritional information, enhancing consumer appeal. A practical example is the shiny, colorful packaging of snack pouches, where BOPET film ensures that the printed designs remain intact even under harsh storage conditions.

Versatility in Printing Techniques:

BOPET film supports various printing methods, including gravure, flexographic, and UV offset printing, due to its ability to accept inks and coatings after surface treatments like corona or chemical coating. For example, a BOPET film variant like F-DSC-UA, designed for UV offset sheet printing, is used in box lamination for premium food products, ensuring sharp and durable prints. This versatility allows manufacturers to cater to diverse branding needs, from matte finishes for artisanal products to glossy finishes for mass-market snacks.