The Unsung Hero of Blister Packaging Excellence

2025-02-24 13:50Introduction: The Quiet Power of BOPS Film

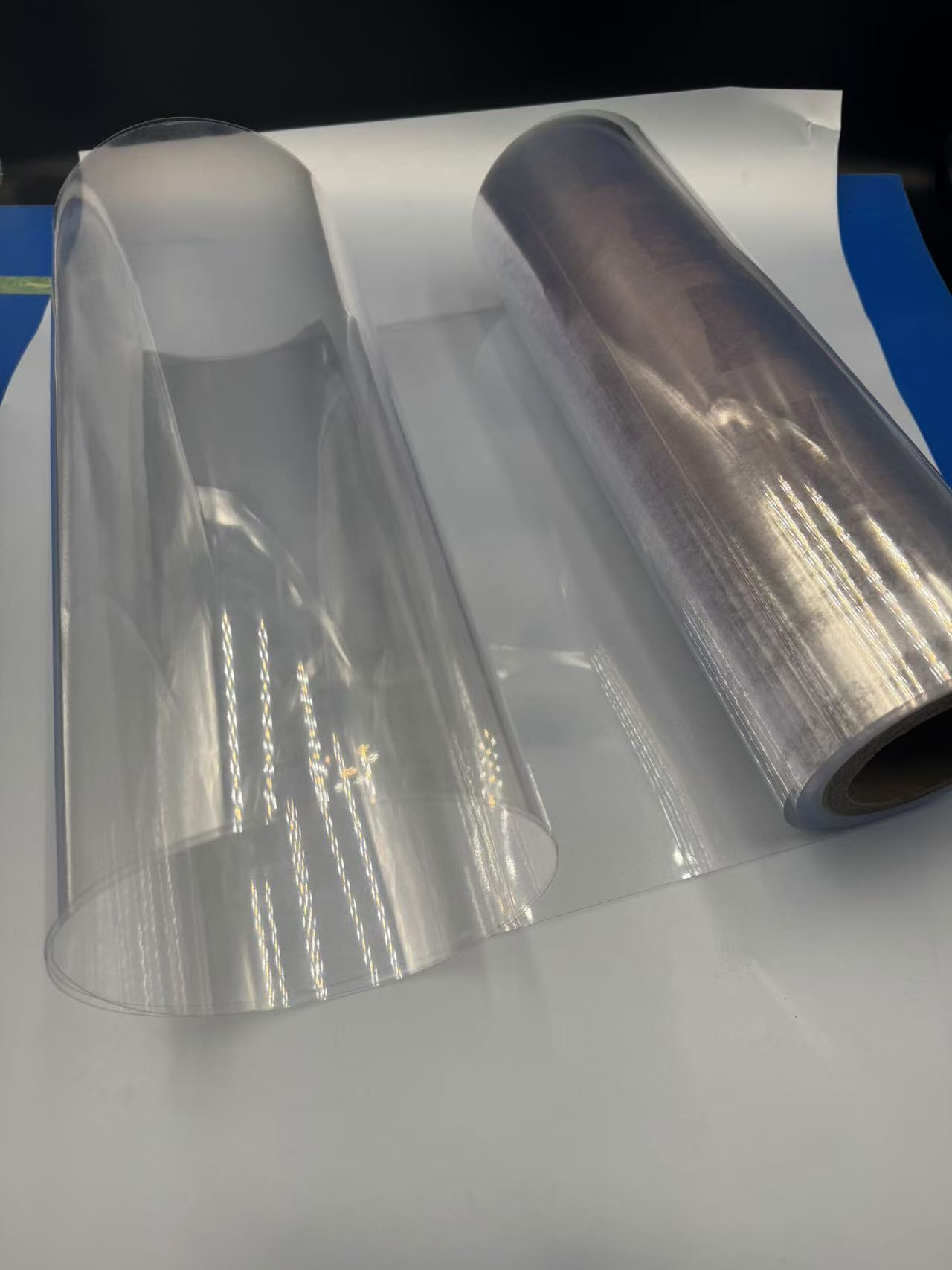

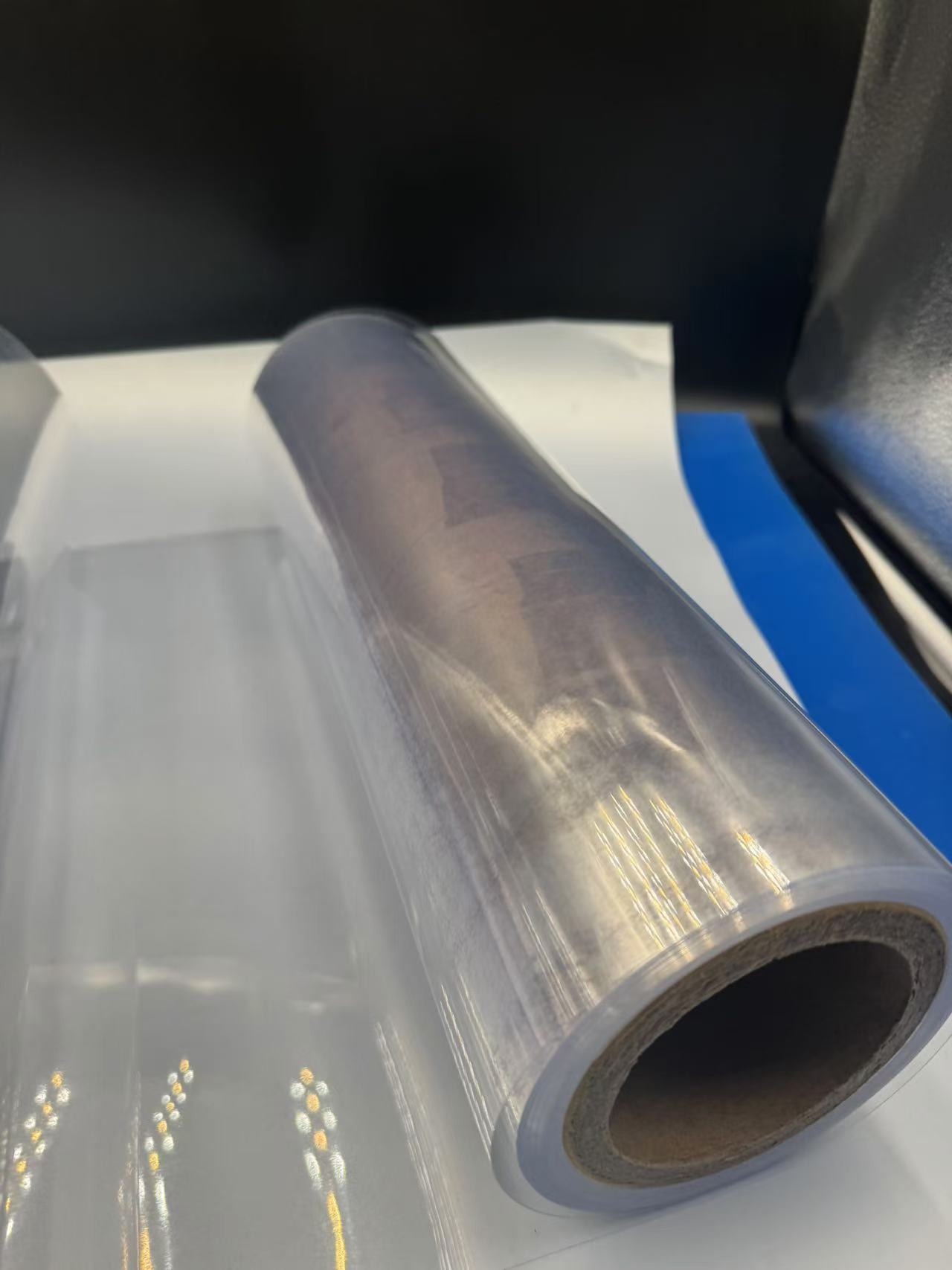

In the bustling world of packaging, where innovation meets necessity, Biaxially Oriented Polystyrene (BOPS) film stands out as a reliable yet often overlooked champion. This lightweight, Transparent, and robust material has carved a niche in blister packaging, offering a perfect blend of functionality and aesthetics.  Derived from polystyrene and enhanced through a biaxial stretching process—stretching it both lengthwise and widthwise—BOPS film delivers exceptional clarity, rigidity, and adaptability. From safeguarding delicate pastries to cradling luxurious cosmetics or presenting gifts with flair, BOPS film proves its worth across industries. This article dives into the unique properties of BOPS film and explores its vital role in food blister packaging, cosmetic packaging, and gift packaging, revealing why it’s a material worth celebrating.

Derived from polystyrene and enhanced through a biaxial stretching process—stretching it both lengthwise and widthwise—BOPS film delivers exceptional clarity, rigidity, and adaptability. From safeguarding delicate pastries to cradling luxurious cosmetics or presenting gifts with flair, BOPS film proves its worth across industries. This article dives into the unique properties of BOPS film and explores its vital role in food blister packaging, cosmetic packaging, and gift packaging, revealing why it’s a material worth celebrating.

The Defining Properties of BOPS Film

To appreciate BOPS film’s widespread use, we must first unpack its core characteristics. These qualities aren’t just technical specs—they’re the secret sauce behind its success in blister packaging.

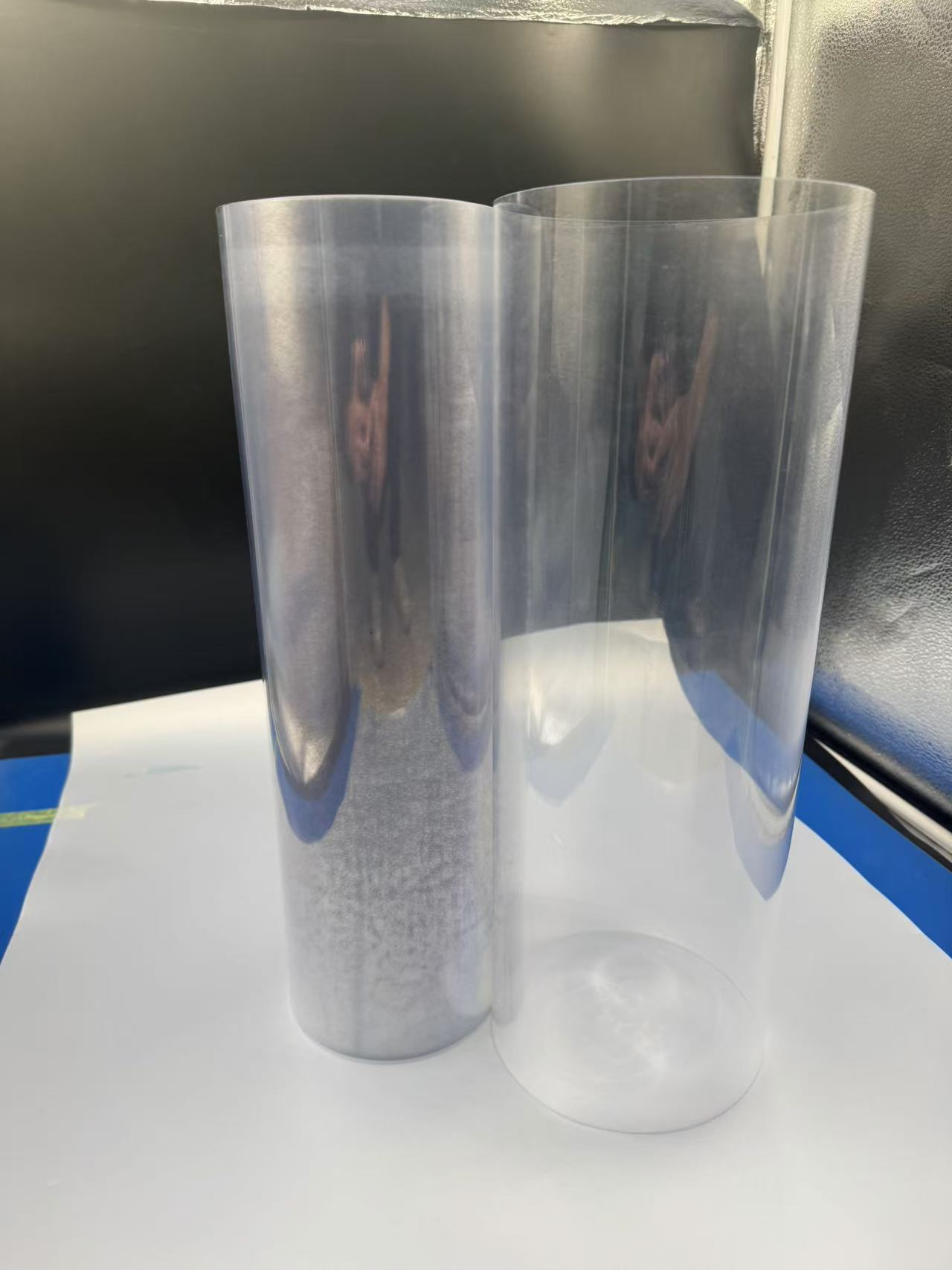

Crystal-Clear Transparency: BOPS film boasts unmatched optical clarity, often exceeding 90% light transmittance, making it a window to the product inside. This visibility is a marketer’s dream, turning packaging into a showcase.

High Rigidity and Strength: The biaxial orientation process aligns its molecular structure, granting BOPS film impressive tensile strength (25-30 MPa) and stiffness, ideal for forming sturdy blister trays.

Lightweight Design: With a density of around 1.05 g/cm³, BOPS film is lighter than many alternatives, reducing transportation costs while maintaining structural integrity.

Excellent Thermoformability: BOPS film molds effortlessly under heat and pressure, allowing precise shaping for blister packs of all sizes and complexities.

Food-Safe and Non-Toxic: Tasteless, odorless, and compliant with global health standards, BOPS film ensures safety for direct food contact—a must for edible goods.

Eco-Friendly Potential: Fully recyclable with existing polystyrene streams, BOPS film supports sustainability efforts, appealing to environmentally conscious brands.

These traits make BOPS film a versatile player, ready to tackle the unique challenges of blister packaging across diverse sectors. Let’s explore how it shines in action.

BOPS Film in Food Blister Packaging: A Feast for the Eyes and Senses

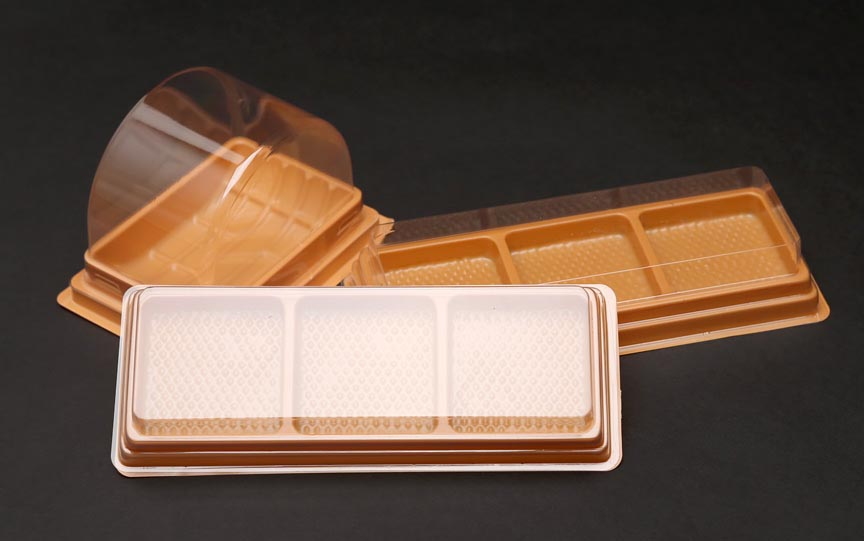

Blister packaging for food demands more than just containment—it must preserve freshness, ensure safety, and tempt the consumer. BOPS film rises to the occasion with finesse. Picture a bakery display: golden croissants nestled in rigid, transparent BOPS film trays, their flaky layers visible through the crystal-clear surface.  That’s the magic of BOPS film—its transparency turns packaging into a sales pitch.

That’s the magic of BOPS film—its transparency turns packaging into a sales pitch.

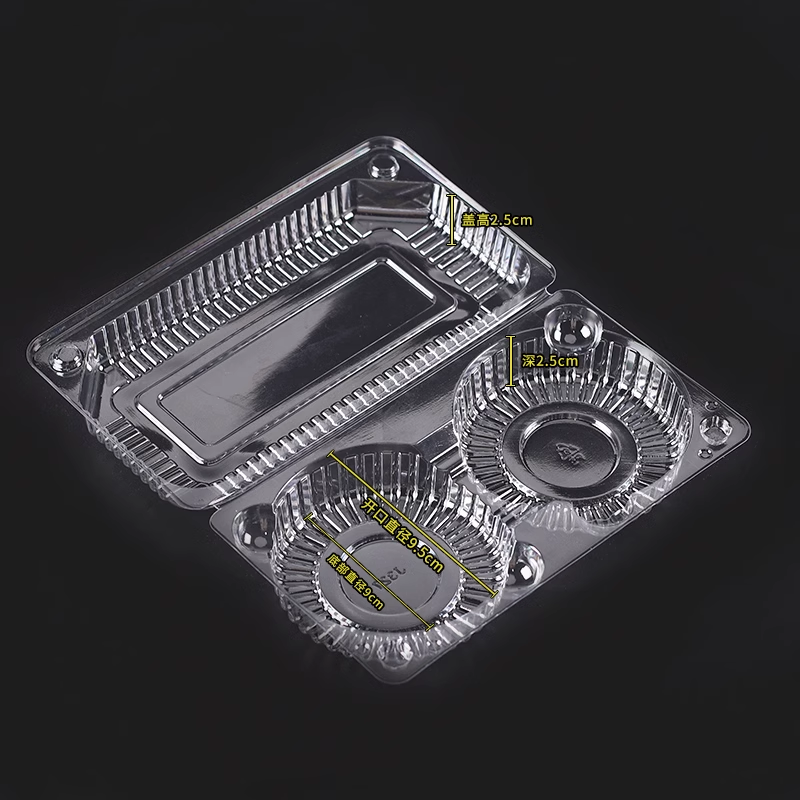

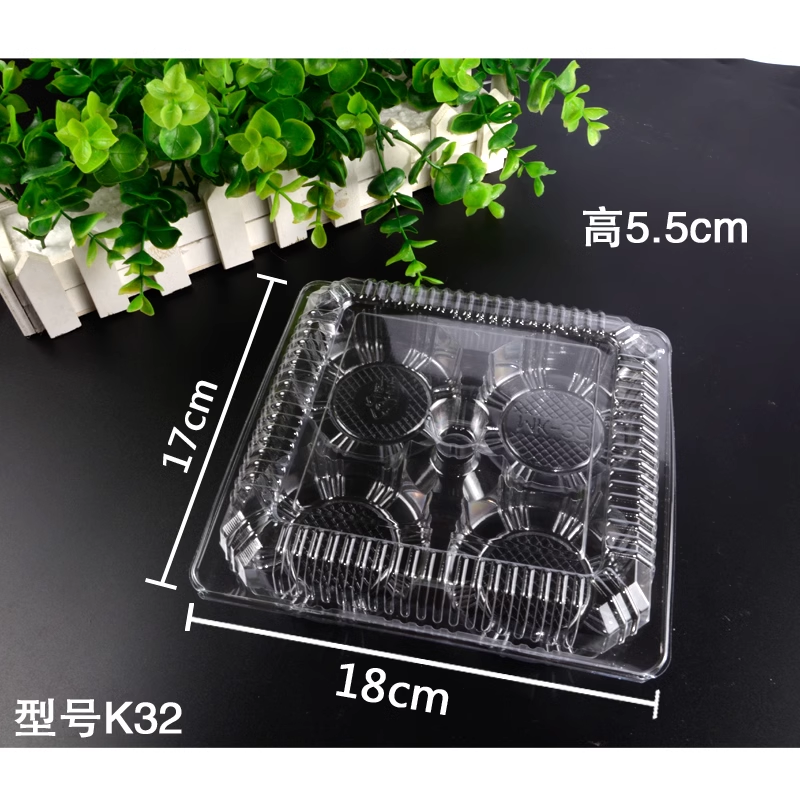

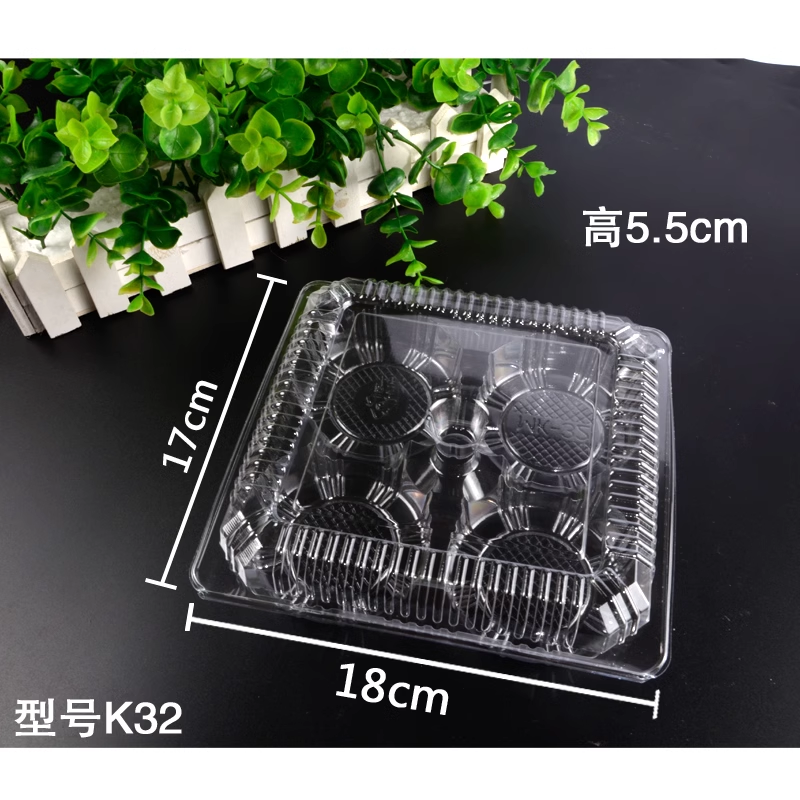

In food applications, BOPS film’s rigidity is a standout feature. Thermoformed into trays or clam shells, it holds items like sushi, pastries, or fresh fruits securely, resisting deformation even under stacking pressure. Its tensile strength ensures that delicate items—like a fragile macaron—arrive intact, while its lightweight nature keeps shipping costs low. For instance, a 150-micron BOPS film tray can support a dozen cupcakes without buckling, a testament to its structural prowess.

Safety is paramount in food packaging, and BOPS film delivers. Being inert to aqueous substances like acids, salts, and detergents, it won’t react with food contents. Its compliance with international food hygiene standards makes it a trusted choice for items ranging from cheese slices to ready-to-eat salads. Unlike some plastics with higher gas permeability, BOPS film offers moderate barrier properties, sufficient for short-shelf-life goods, though it’s often paired with lidding films (like aluminum foil) for extended preservation.

The thermoformability of BOPS film is a game-changer in food blister packaging. Using positive and negative pressure machines, manufacturers craft intricate cavities tailored to each product—think of a tray with individual slots for chocolate truffles. This precision not only enhances presentation but also minimizes waste, as the film adapts to the exact contours of the item. A real-world example: pre-packaged sushi trays in supermarkets often use BOPS film, offering a clear view of the vibrant fish while keeping it snugly in place.

Sustainability adds another layer of appeal. BOPS film’s recyclability aligns with the push for greener packaging, allowing brands to reduce their environmental footprint without sacrificing quality. In short, BOPS film in food blister packaging isn’t just about protection—it’s about delivering an experience that’s fresh, safe, and visually irresistible.

BOPS Film in Cosmetic Blister Packaging: Beauty Under Wraps

Cosmetics demand packaging that’s as alluring as the products themselves, and BOPS film steps up with elegance and practicality. Imagine a sleek blister pack cradling a set of makeup brushes—their soft bristles and glossy handles framed perfectly by the film’s transparency. This clarity doesn’t just protect; it seduces, inviting consumers to envision the product in their hands.

Rigidity is key in cosmetic blister packaging, where items like lipsticks, compacts, or fragile glass vials need safeguarding. BOPS film’s high strength ensures these products withstand the rigors of shipping and retail handling. A 200-micron BOPS film tray, for example, can securely hold a row of nail polish bottles, preventing cracks or spills—a common headache with flimsier materials.

Thermoformability shines here too. BOPS film molds into custom shapes, creating snug compartments for multi-piece sets—like a skincare kit with creams, serums, and tools. This tailored fit not only enhances protection but also elevates the unboxing experience, a crucial factor in the luxury cosmetics market. Picture a high-end face mask pack: the BOPS film tray contours to each sachet, paired with a peelable lidding, offering both convenience and a premium feel.

The film’s smooth surface also supports branding. While BOPS film itself isn’t typically printed on (due to its nonpolar surface requiring special treatment), it pairs beautifully with printed cardstock or foil lids, showcasing logos and designs through its transparency. Its chemical resistance is a bonus—cosmetics with oils or alcohols won’t degrade the film, ensuring longevity on the shelf.

For travel-sized or sample products, BOPS film’s lightweight nature slashes costs, while its recyclability appeals to eco-friendly beauty brands. Whether it’s a budget mascara or a luxury perfume tester, BOPS film wraps cosmetics in a protective, eye-catching embrace.

BOPS Film in Gift Blister Packaging: Presentation with a Purpose

Gift packaging is all about the wow factor—making the recipient feel special from the moment they see it. BOPS film delivers this in spades. Visualize a set of artisanal soaps in a BOPS film blister pack: each bar nestled in its own compartment, visible through the gleaming surface, with vibrant colors popping against a festive card backing. It’s not just packaging—it’s a prelude to the gift itself.

The film’s clarity is a star here, turning everyday items into treasures. A blister pack for a jewelry set—think earrings and a pendant—uses BOPS film to display the sparkle of each piece, enhancing perceived value. Its rigidity ensures these delicate items stay secure, resisting crushing or shifting during transit. A 300-micron BOPS film tray, for instance, can cradle a fragile glass ornament, protecting it from holiday shipping chaos.

Thermoformability allows endless creativity in gift packaging. Manufacturers craft BOPS film into unique shapes—star-shaped cavities for Christmas trinkets or heart-shaped trays for Valentine’s chocolates. This customization makes every gift feel bespoke, a detail that resonates with consumers. Pair it with a colorful lidding or insert, and the package becomes part of the present.

Lightweight yet strong, BOPS film keeps costs down for bulk gift items like party favors, while its recyclability aligns with growing demand for sustainable gifting options. From small tokens to lavish hampers, BOPS film transforms gift blister packaging into a celebration of form and function.

Conclusion: BOPS Film’s Bright Future in Blister Packaging

BOPS film may not grab headlines like flashier materials, but its impact is undeniable. In food blister packaging, it preserves and presents with finesse; in cosmetics, it protects and entices; in gifts, it elevates and delights. Its blend of clarity, strength, thermoformability, and eco-friendliness makes it a standout choice in a competitive field. As industries push for sustainability and innovation, BOPS film is poised to evolve—perhaps with enhanced barriers or bio-based variants—ensuring its place in the packaging pantheon. Next time you admire a perfectly packed product, consider the quiet brilliance of BOPS film behind it—a material that proves simplicity can be extraordinary.