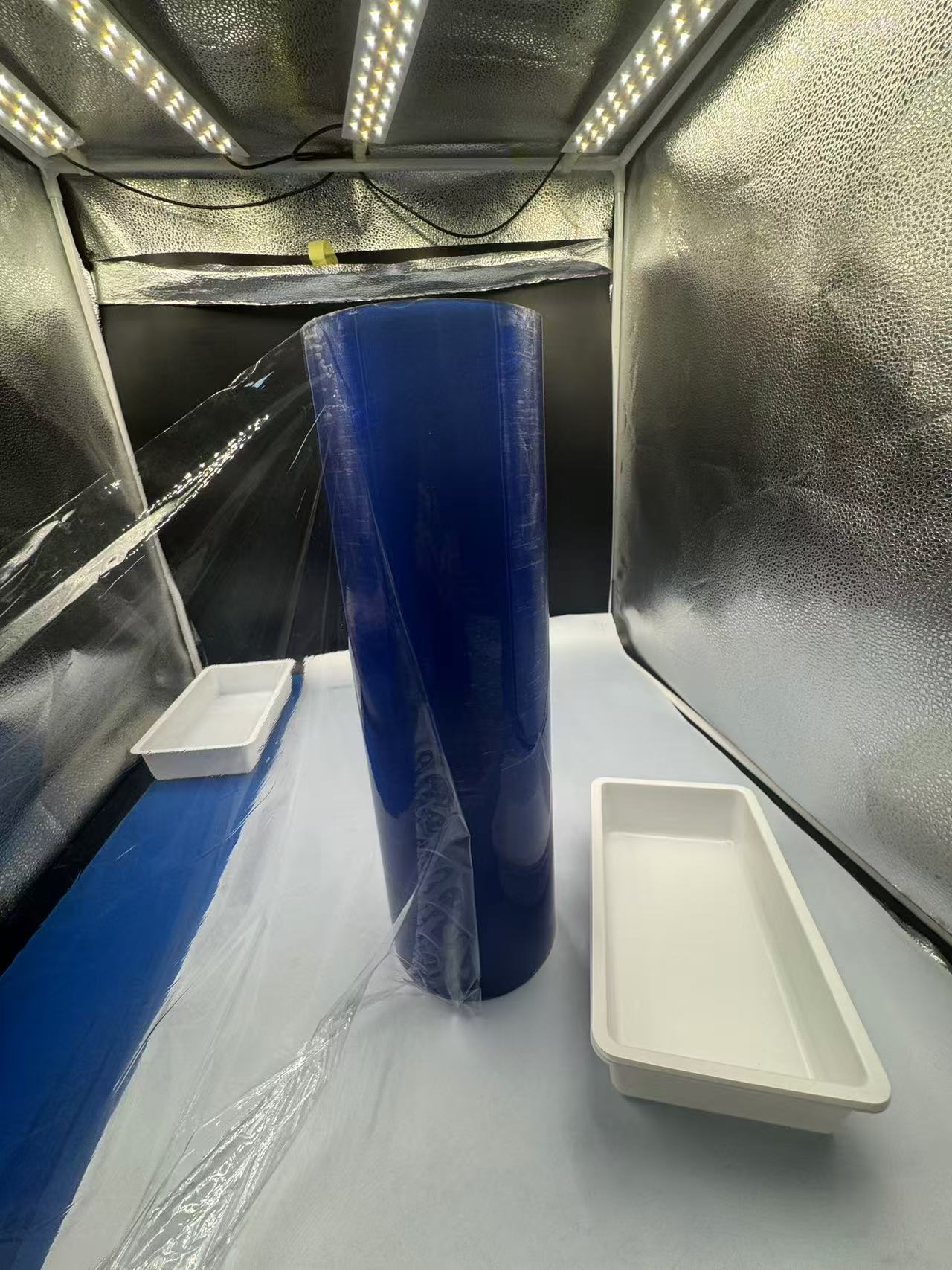

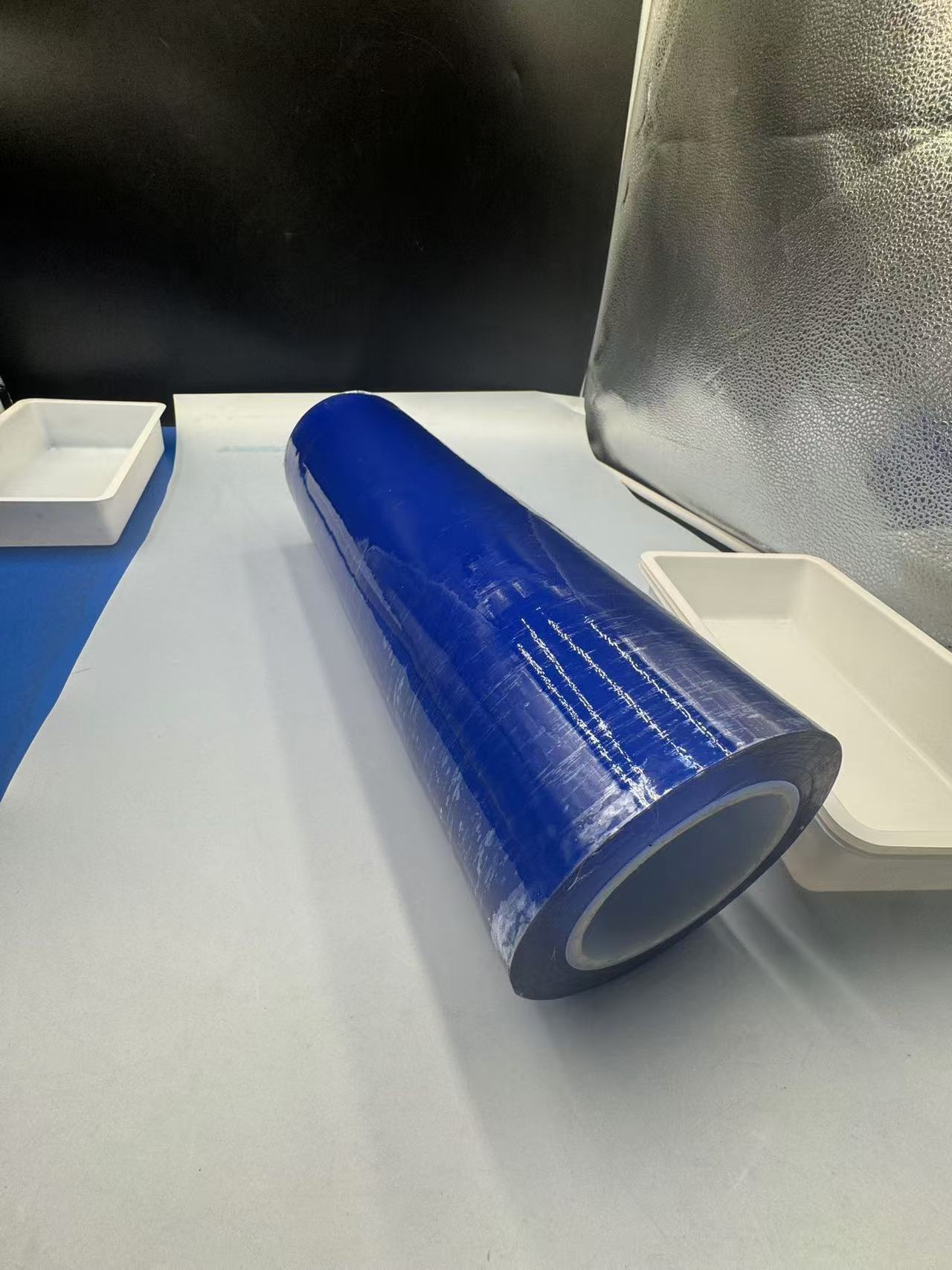

The Properties and Applications of Transparent PVC Stretch Film in Self-Adhesive Cold-Seal Packaging and Tableware Thermoforming

2025-04-03 11:20Transparent PVC stretch film, crafted from polyvinyl chloride (PVC), has carved a niche in the food packaging and tableware industries due to its remarkable clarity, flexibility, and functional attributes. This material, widely recognized for its ability to adapt to diverse applications, serves as a reliable choice for self-adhesive cold-seal packaging and thermoformed tableware. In this article, we’ll explore the defining characteristics of transparent PVC stretch film and its practical uses in these domains, providing a detailed, evidence-based analysis enriched with vivid examples to illustrate its significance in modern food-related solutions.

flexibility, and functional attributes. This material, widely recognized for its ability to adapt to diverse applications, serves as a reliable choice for self-adhesive cold-seal packaging and thermoformed tableware. In this article, we’ll explore the defining characteristics of transparent PVC stretch film and its practical uses in these domains, providing a detailed, evidence-based analysis enriched with vivid examples to illustrate its significance in modern food-related solutions.

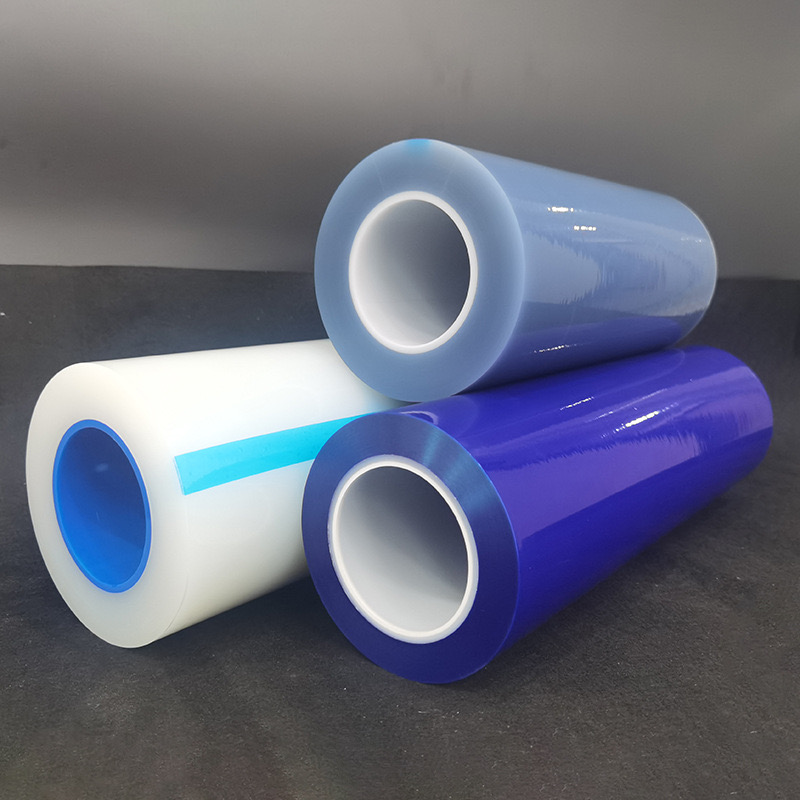

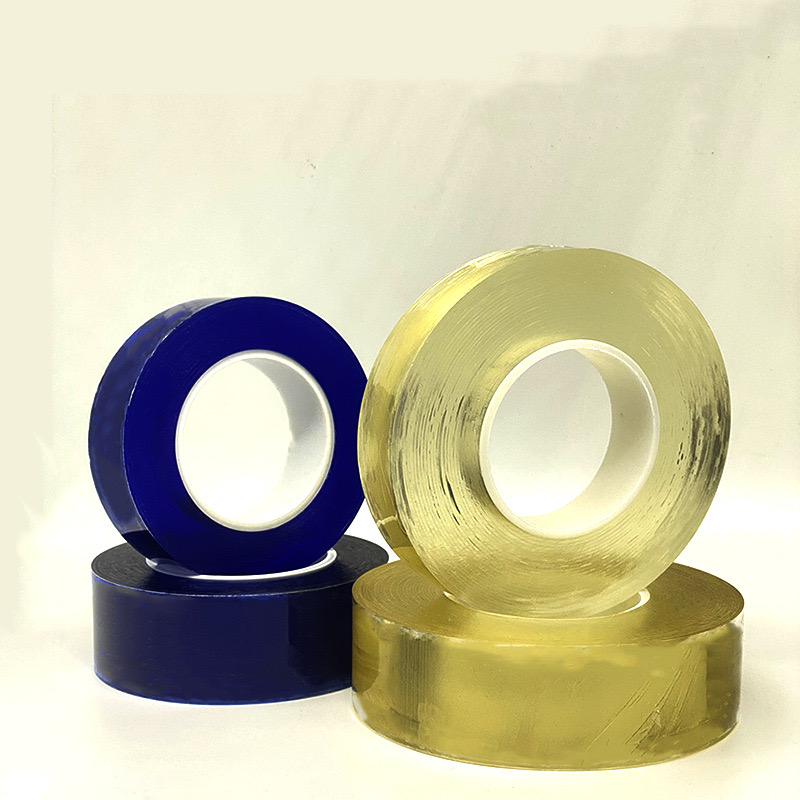

Characteristics of Transparent PVC Stretch Film

Transparent PVC stretch film is a thermoplastic material derived from vinyl chloride monomers, often enhanced with plasticizers to achieve its signature flexibility. Its properties make it a standout option for food applications. Here’s a closer look at its key traits:

Clarity and Transparency: The hallmark of transparent PVC stretch film is its exceptional optical clarity. With a light transmission rate often exceeding 90%, it allows consumers to see the packaged product in vivid detail. This transparency is achieved through precise manufacturing processes that minimize haze and impurities, making it ideal for showcasing food items where visual appeal is paramount.

Flexibility and Stretchability: Unlike rigid plastics, transparent PVC stretch film owes its elasticity to plasticizers like dioctyl phthalate (DOP) or citrate-based compounds. This flexibility enables the film to stretch up to 200-300% of its original length without tearing, conforming tightly to irregular shapes. This property is crucial for wrapping and sealing applications, ensuring a snug fit around food products.

Self-Adhesive Properties: Transparent PVC stretch film exhibits a natural clinginess, often referred to as "tackiness," which allows it to adhere to itself without additional adhesives. This self-clinging ability stems from the film’s surface tension and molecular structure, making it perfect for cold-seal packaging where heat sealing isn’t required.

Moisture and Gas Barrier: PVC stretch film provides a moderate barrier to moisture and oxygen, with oxygen permeability typically ranging from 100-500 cm³/m²/day, depending on thickness and formulation. While not as impermeable as materials like EVOH, it offers sufficient protection for short-shelf-life foods, such as fresh produce or deli items, preventing spoilage from excess moisture or air exposure.

Durability and Puncture Resistance: Despite its thinness—often between 10-25 microns—transparent PVC stretch film is surprisingly tough. Its tensile strength, averaging 20-30 MPa, ensures it resists punctures and tears during handling, a vital trait for packaging sharp-edged items like cheese blocks or cutlery.

Cost-Effectiveness: PVC is relatively inexpensive to produce, thanks to its widespread availability and efficient manufacturing processes like calendaring or extrusion. This affordability makes transparent PVC stretch film a go-to for businesses seeking high-performance packaging at a low cost.

Thermal Stability: Transparent PVC stretch film remains stable at room temperature and can withstand mild heat (up to 60-70°C) without deforming. However, it softens at higher temperatures, limiting its use in hot-fill or microwaveable applications unless specially stabilized with additives.

While these attributes highlight its strengths, transparent PVC stretch film has limitations. Environmental concerns—due to chlorine content and challenges in recycling—along with potential plasticizer migration under scrutiny, temper its appeal. Nonetheless, its practical benefits keep it relevant in specific niches.

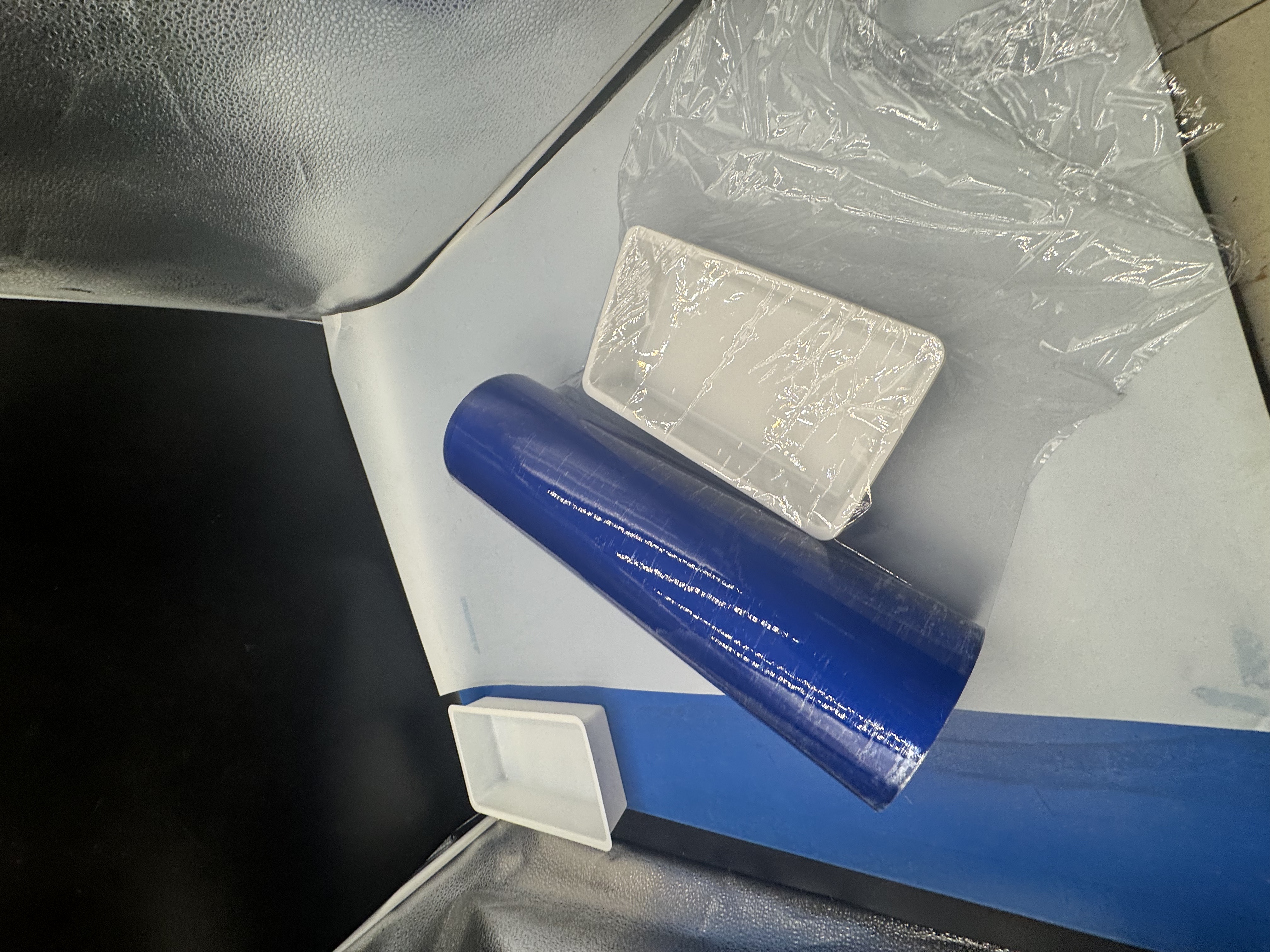

Applications in Self-Adhesive Cold-Seal Packaging

Self-adhesive cold-seal packaging relies on materials that can seal without heat, offering convenience and energy efficiency. Transparent PVC stretch film excels here, leveraging its cling and flexibility to protect and present food. Here’s how it’s applied:

Fresh Produce Wrapping: Transparent PVC stretch film is a staple for wrapping fruits and vegetables like apples, cucumbers, or bell peppers. Its stretchability allows it to envelop produce of varying shapes, while its clarity showcases vibrant colors—think of a supermarket display where glossy red tomatoes gleam through the film, enticing shoppers. The film’s self-adhesive nature ensures a tight seal, locking in freshness by reducing air exposure, with studies showing it can extend shelf life by up to 20% for items like lettuce compared to unwrapped storage.

Deli and Meat Packaging: In delis, transparent PVC stretch film wraps sliced meats, cheeses, and prepared foods. A butcher might use it to package a stack of ham slices, stretching the film over a tray and pressing it down to seal without heat. The film’s puncture resistance protects against tears from sharp edges, while its moisture barrier prevents drying, maintaining texture and flavor for days.

Bakery Goods: Bread, pastries, and sandwiches benefit from transparent PVC stretch film’s ability to conform and cling. A bakery might wrap a fresh baguette, where the film’s elasticity hugs the crusty surface, and its transparency highlights golden-brown perfection. The cold-seal process is quick—simply overlap the film edges, and they stick—saving time in high-volume settings.

Retail Ready-to-Eat Meals: Pre-made salads or sushi trays often use transparent PVC stretch film as a top layer. Its self-adhesive quality eliminates the need for adhesive strips or heat sealers, streamlining production. For instance, a sushi chef might stretch the film over a tray of nigiri, ensuring each piece is visible and secure, with the film’s slight breathability preventing condensation buildup that could soggy the rice.

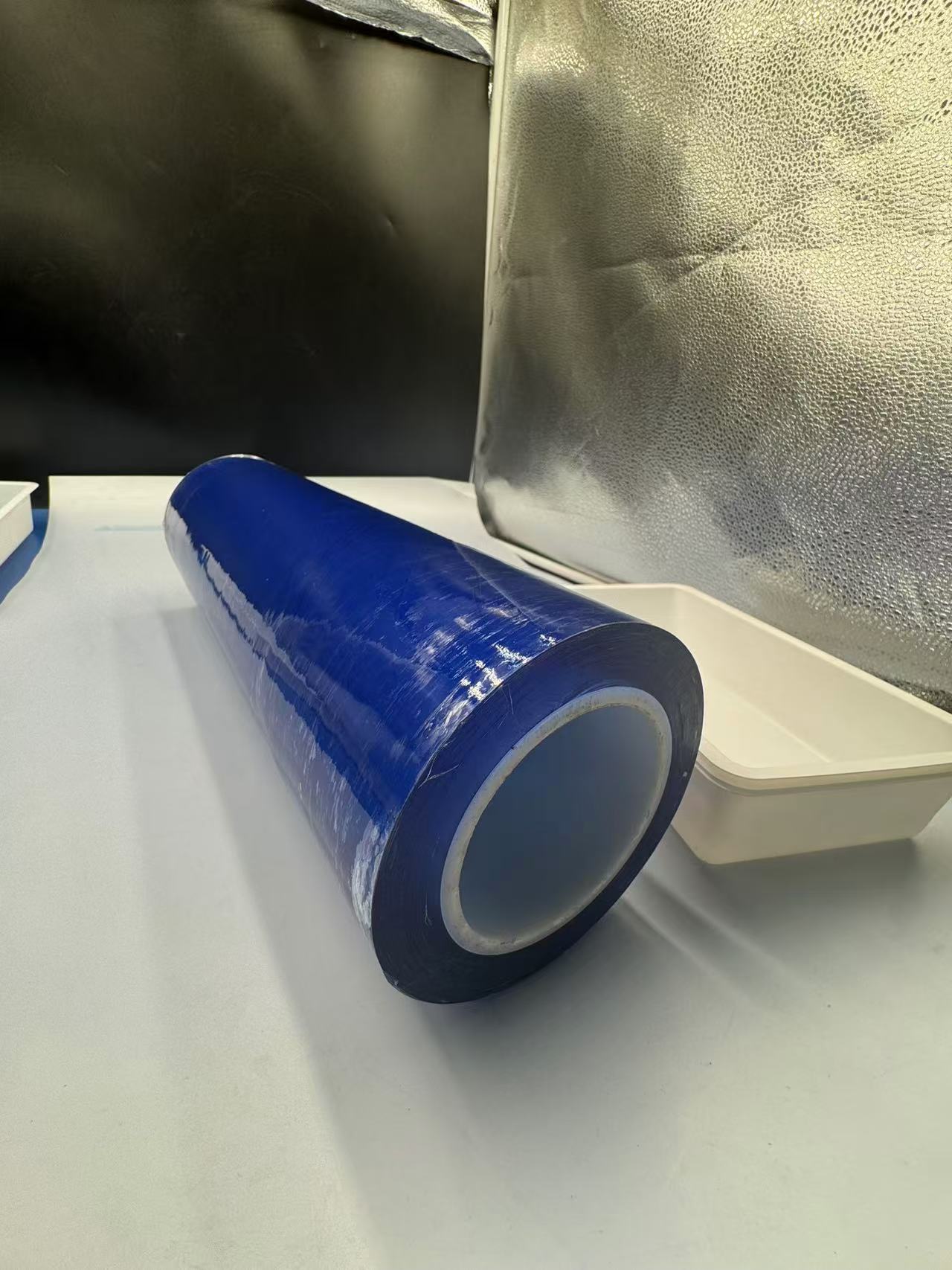

The application process is straightforward: the film is dispensed from rolls, stretched over the product or tray, and pressed to seal. Its cling ensures a tamper-evident closure, reassuring consumers of product integrity. This cold-seal method also reduces energy costs compared to heat-sealing alternatives like polyethylene, aligning with sustainable production goals.

Applications in Tableware Thermoforming

Thermoforming transforms flat plastic sheets into three-dimensional shapes, and transparent PVC stretch film adapts well to this process for disposable tableware. Its clarity and moldability shine in these applications:

applications:

Disposable Cups and Lids: Transparent PVC stretch film is thermoformed into clear cups and lids for cold beverages like iced coffee or smoothies. Imagine a café serving a vibrant fruit smoothie in a transparent PVC film cup—the drink’s layers of color pop through the crystal-clear walls, enhancing visual appeal. The film is heated to around 120°C, molded into shape, and cooled, retaining durability for single-use scenarios.

Food Trays and Containers: Thermoformed trays for salads, desserts, or snacks often use transparent PVC stretch film. Its flexibility allows it to take on intricate designs, like compartmentalized trays for a charcuterie assortment. A caterer might use such a tray to display cheeses and grapes, with the film’s clarity ensuring every item is visible, while its strength supports the weight without buckling.

Cutlery Packaging: Transparent PVC stretch film can be thermoformed into blister packs for disposable cutlery sets. A picnic pack with a fork, spoon, and knife might be encased in a clear PVC shell, molded to fit each utensil snugly. The transparency lets consumers verify contents, and the film’s toughness protects against damage during transport.

Serving Bowls: Small, transparent PVC film bowls are popular for single-serve portions at events. Picture a wedding buffet with individual fruit salads in clear bowls—the film’s glossy finish and clarity elevate the presentation, while its lightweight nature (density around 1.35 g/cm³) keeps costs and handling effort low. Thermoforming ensures smooth edges and consistent thickness, enhancing user comfort.

The thermoforming process involves heating the PVC film until pliable, then using vacuum or pressure to shape it against a mold. The result is a precise, durable product that retains the film’s transparency, making it ideal for applications where aesthetics matter as much as function.

Challenges and Considerations

Transparent PVC stretch film isn’t without flaws. Environmentalists critique its chlorine content, which releases dioxins if incinerated improperly, and its recycling is hampered by plasticizer contamination—only about 1% of PVC is recycled globally, per industry estimates. Health concerns also arise: while the FDA approves PVC for food contact, with plasticizer migration below 0.1 mg/kg deemed safe, public wariness persists, especially for fatty foods where migration risks increase.

Its thermal limitations—softening above 70°C—restrict it to cold or ambient uses, and alternatives like PLA or PET are gaining traction for their eco-friendliness. Still, transparent PVC stretch film’s cost and performance keep it competitive.

Future Prospects

Innovations like bio-based plasticizers or improved recycling systems could address PVC’s drawbacks, extending its lifespan in food applications. For now, its clarity, cling, and moldability ensure it remains a vital tool in cold-seal packaging and tableware.

In summary, transparent PVC stretch film blends practicality with visual appeal, wrapping produce with ease and shaping tableware with precision. From a deli counter to a picnic table, its presence enhances convenience and presentation, proving that a clear film can deliver big results.