The Clarity and Versatility of Transparent PET Film in Modern Packaging Solutions

2025-09-22 16:05IntroductionTransparent PET (Polyethylene Terephthalate) film is a highly versatile and widely used material in the packaging industry, valued for its clarity, durability, and adaptability. Known for its crystal-clear appearance, transparent PET film allows products to be showcased while providing robust protection, making it a go-to choice for applications such as food blister packaging, disposable tableware packaging, antistatic packaging, and biscuit and pastry packaging. This article explores the unique characteristics of transparent PET film and its critical role in these applications, supported by its mechanical, thermal, and chemical properties, which make it an indispensable material in modern packaging solutions.Characteristics of Transparent PET Film

Transparent PET film is a thermoplastic polymer renowned for its exceptional physical and chemical properties, which contribute to its widespread use across various industries. Below are the key characteristics that define its utility:Optical Clarity: Transparent PET film offers excellent transparency, allowing consumers to view the packaged product clearly. This property enhances the visual appeal of items like food or pastries, making it ideal for retail displays where product visibility drives sales.

Mechanical Strength and Durability: The film exhibits high tensile strength and flexibility, ensuring it can withstand mechanical stress during forming, handling, and transportation. Its toughness prevents tearing or deformation, making it suitable for demanding applications like blister packaging.

Thermal Stability: With a melting point of approximately 250°C, transparent PET film is resistant to heat, making it ideal for thermoforming processes and applications involving hot-fill packaging or microwaveable products. It maintains its shape and clarity under elevated temperatures.

Chemical and Moisture Resistance: Transparent PET film is highly resistant to chemicals, oils, and moisture, ensuring it remains intact in humid or chemically challenging environments. This property is crucial for food packaging, where exposure to acids, oils, or moisture is common.

Barrier Properties: The film provides excellent barriers against oxygen and moisture, extending the shelf life of perishable goods like biscuits and pastries. This makes it a preferred material for maintaining product freshness and quality.

Antistatic Properties: Certain formulations of transparent PET film are treated with antistatic coatings or additives, reducing static electricity buildup. This is essential for packaging sensitive electronic components, where static discharge could cause damage.

Recyclability: Transparent PET film is fully recyclable, aligning with global demands for sustainable packaging solutions. Recycled PET (rPET) can be used to produce new packaging, reducing environmental impact and supporting circular economy initiatives.

Customizability: The film can be easily cut, formed, or printed with branding or designs, allowing manufacturers to create tailored packaging solutions that meet specific product requirements.

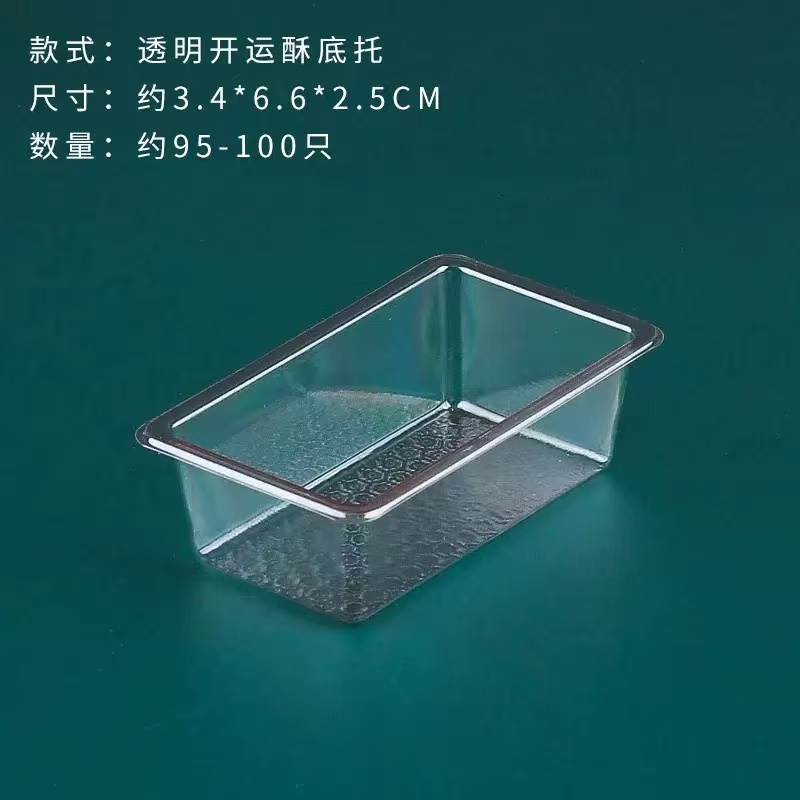

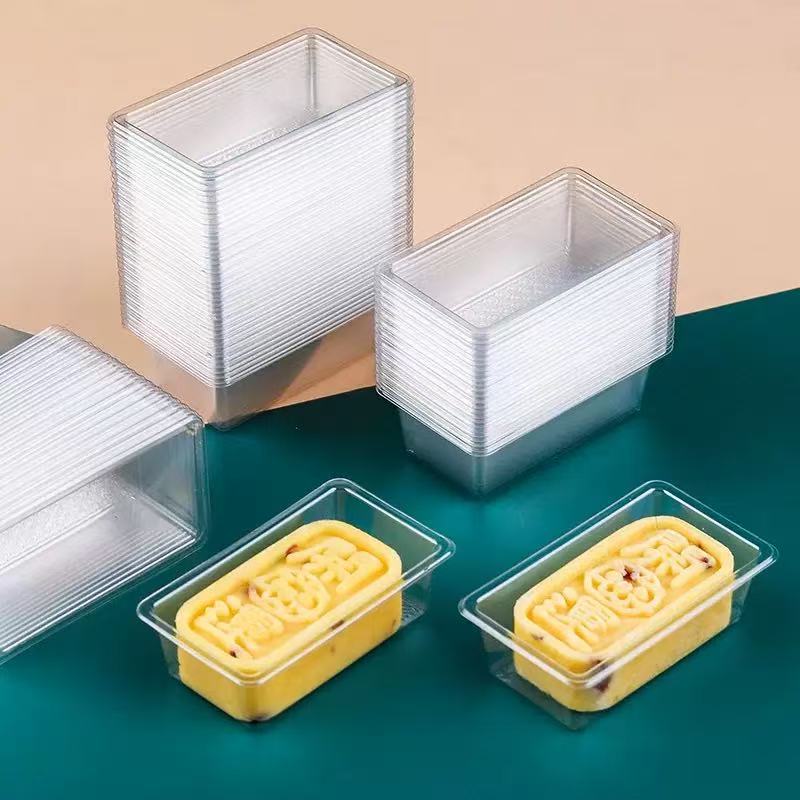

Applications of Transparent PET FilmThe combination of clarity, durability, and protective properties makes transparent PET film a versatile material for a wide range of applications. Below, we explore its use in four key areas: food blister packaging, disposable tableware packaging, antistatic packaging, and biscuit and pastry packaging.1. Food Blister PackagingTransparent PET film is extensively used in food blister packaging to create secure, visually appealing containers for perishable items like fruits, vegetables, meats, and ready-to-eat meals. Blister packaging involves forming a cavity from the film to hold the product, which is then sealed with a lidding material.Product Visibility: The film’s transparency allows consumers to inspect the food’s quality and freshness, which is critical for items like fresh produce or deli meats. This visibility builds trust and drives purchasing decisions.

Protective Barrier: Transparent PET film’s excellent oxygen and moisture barriers prevent spoilage, extending shelf life. For example, in meat packaging, the film minimizes oxygen exposure, reducing the risk of bacterial growth.

Thermoformability: The film’s ability to be thermoformed into precise shapes ensures a snug fit for the product, enhancing both protection and presentation. This is particularly important for retail displays where aesthetics matter.

Real-World Example: Picture a supermarket display of fresh blueberries in a transparent PET film blister pack. The clear film showcases the vibrant color of the berries, enticing customers while protecting them from bruising. The film’s barrier properties keep the berries fresh, ensuring they remain appealing from shelf to table.

2. Disposable Tableware PackagingTransparent PET film is widely used in the production and packaging of disposable tableware, such as plates, cups, and trays, particularly for catering, fast-food services, or events where convenience and aesthetics are priorities.Durability and Heat Resistance: The film’s mechanical strength ensures that tableware can hold food without bending or breaking. Its thermal stability allows it to handle hot foods or beverages, making it suitable for applications like microwaveable trays or hot drink cups.

Aesthetic Appeal: The transparency of the film gives disposable tableware a sleek, modern look, ideal for upscale events or restaurants. The clear surface can also be printed with logos or designs for branding purposes.

Sustainability: The recyclability of transparent PET film makes it an environmentally friendly option for disposable tableware, aligning with consumer demand for sustainable products.

Case Study: A catering company might use transparent PET film trays for a corporate event. The trays’ clarity allows guests to see the food presentation, while their durability ensures they can hold heavy dishes without collapsing. After the event, the trays can be recycled, supporting the company’s sustainability goals.

3. Antistatic PackagingIn the electronics industry, transparent PET film is valued for its antistatic properties, making it suitable for packaging sensitive components like circuit boards, microchips, or sensors, where static discharge could cause damage.Antistatic Performance: Specialized transparent PET films are coated with antistatic agents to dissipate static electricity, protecting delicate electronics from electrostatic discharge (ESD). This is critical in cleanroom environments or during transportation.

Visibility and Protection: The film’s clarity allows for easy inspection of components without opening the packaging, while its mechanical strength protects against physical damage during handling.

Custom Fit: The film can be formed into trays or clamshells tailored to the shape of electronic components, ensuring a secure fit and minimizing movement.

Industry Example: A manufacturer of smartphone components might use transparent PET film trays with antistatic properties to package microchips. The clear trays allow quality control teams to inspect the chips without handling them, while the antistatic coating ensures the chips remain functional, free from static damage.

4. Biscuit and Pastry PackagingTransparent PET film is a popular choice for biscuit and pastry packaging, where it provides both protection and an attractive presentation for baked goods like cookies, cakes, and pastries.Freshness Preservation: The film’s excellent barrier properties against moisture and oxygen prevent biscuits and pastries from becoming stale, extending their shelf life. This is particularly important for delicate items like macarons or buttery cookies.

ChallengesLight Sensitivity: While transparent PET film is ideal for showcasing products, it offers limited protection against UV light, which can affect light-sensitive foods like dairy or certain pastries. Additional coatings may be required.

Processing Costs: Achieving antistatic properties or precise thermoforming can increase production costs, particularly for specialized applications.

Recycling Infrastructure: While PET is recyclable, the availability and efficiency of recycling facilities can vary, posing challenges for achieving full sustainability.

Conclusion

Transparent PET film is a remarkable material that combines clarity, durability, and protective properties, making it indispensable in applications like food blister packaging, disposable tableware packaging, antistatic packaging, and biscuit and pastry packaging. Its optical clarity enhances product visibility, while its mechanical strength, thermal stability, and recyclability ensure functionality and sustainability. As industries continue to innovate and prioritize eco-friendly solutions, transparent PET film is poised to remain a cornerstone of modern packaging, delivering both aesthetic appeal and reliable performance.