- Home

- >

- News

- >

- Food grade PET film

- >

Food grade PET film

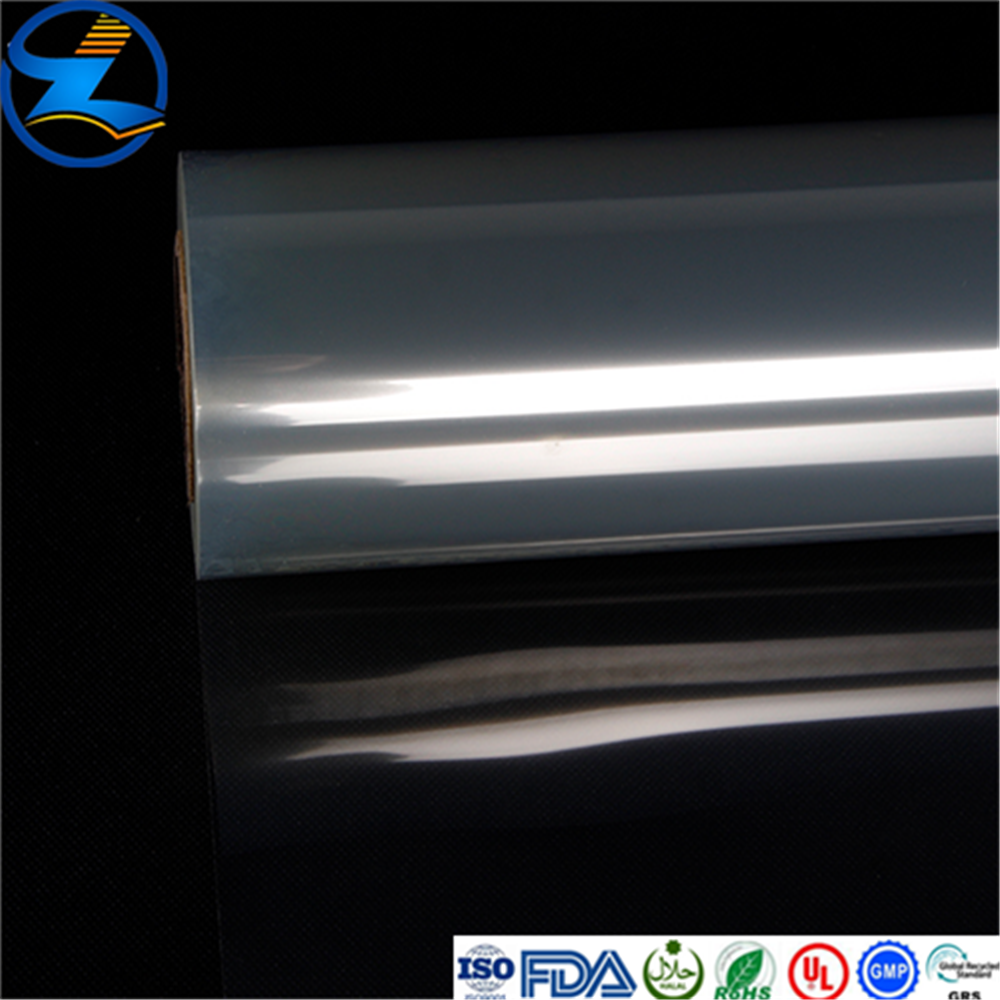

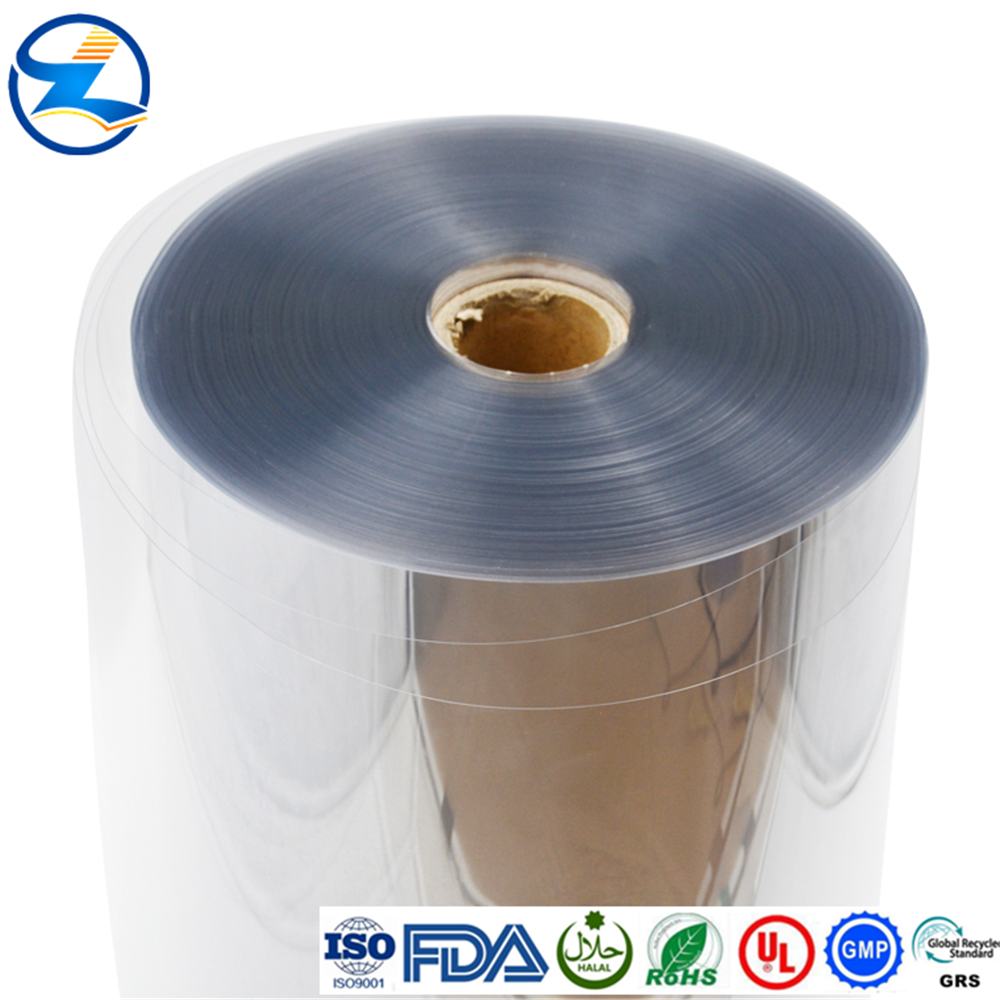

2024-12-18 16:47PET sheet series include APET, PETG, GAG. This is a new material sheet product developed rapidly in the recent years.

Excellent comprehensive performance, high transparency, good strength and easy to post-processing these are PET sheet's merits. As a result of good strength, the same thickness of the product, the protective effect is significantly better than PVC sheet. If same intensity will compare, can use thinner PET sheet. So although the price of PET sheet is a little bit higher. But actual cost increase not big. More basically is the glittering and translucent and transparent of PET sheet.

Advantages:

Compared with the widely used PVC film, A-PET has the following advantages:

1. The proportion of light: the proportion of PET than PVC 1.33,1.38,3.7% lower proportion

2. High strength: PET film strength than PVC film is more than 20% higher, low-temperature impact resistance performance is better, -40ºC capability brittle, so we usually use thinner than 10% film to replace PVC.

3. Good folding endurance. PET film does nor appear crease since crack like PVC, more suitable for the surface decoration of file etc.

4. APET film (PVC film with high transparency, especially shiny bluish) than the PVC film is good, more suitable for the exquisite packaging.

APET products without pollution, crystal, high transparency, good smoothness, strong impact resistance, can widely film according to customer requirements.

GAG plastic sheet

GAG is a three layers supply sheet

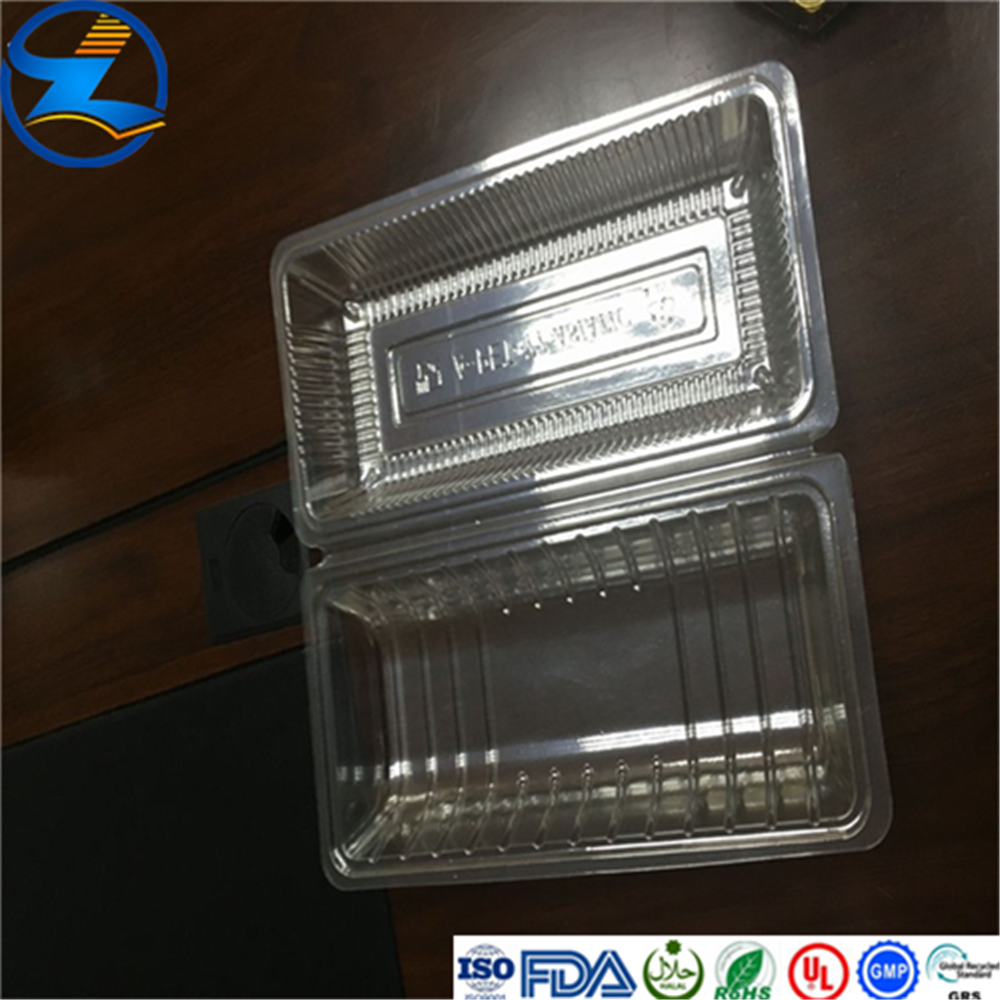

It is produced by CO-extrusion in proportion which a middle layer of APET and two layer up and down of PETG. Especially suitable for packaging boxes which need to be bonded by high frequency heat sealing and glue.

The advantages are as follow:

Super transparent, Transparency can be more than 90%, High quality, suitable for products requiring high transparency.

Excellent impact strength and rigidity, hard and durable material, suitable for high impact strength applications.

Can use sawing, die cutting, drilling and laser cutting processing methods, but also cold bending and hot bending adhesion, welding and polishing,printing and printing and cold bending does not whiten, bright appearance.

Thermoforming nicely, no need preheating, high precision, shrinkage rate of about 0.5%, good deep formablitity, not broken and uniform thickness.

Environmental protection, recyclable use does not pollute the environment

With national food hygiene standards.