A Spectrum of Strength: The Vibrant World of Colored PP Film

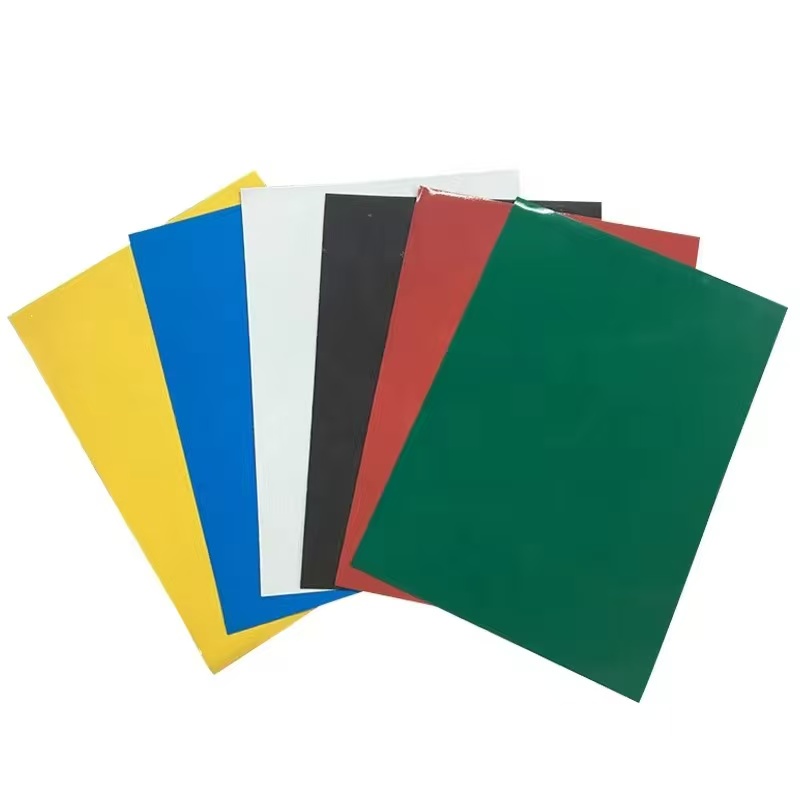

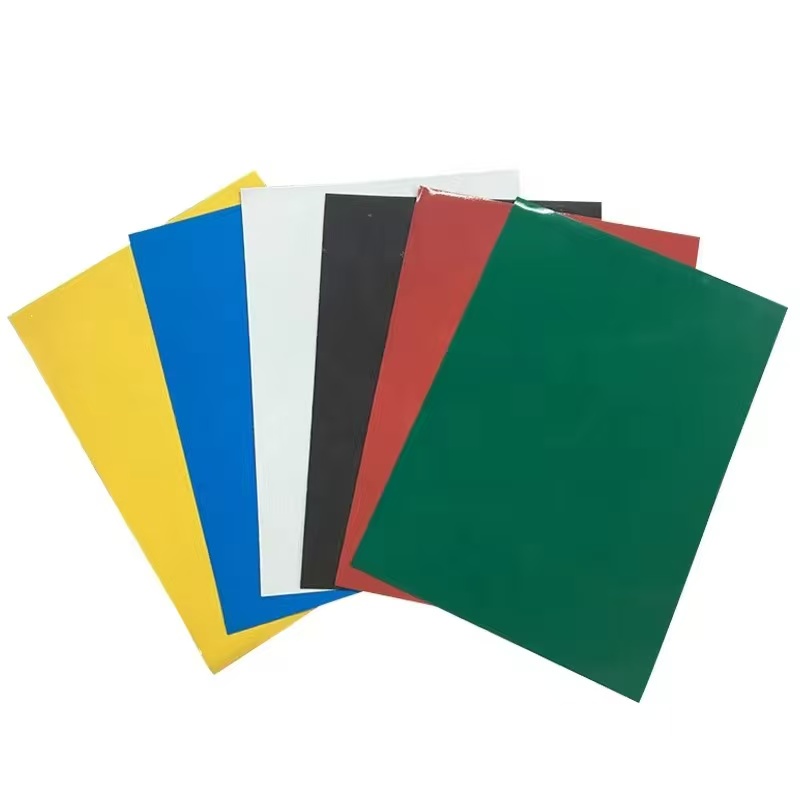

2025-09-24 16:57A Spectrum of Strength: The Vibrant World of Colored PP FilmIn a world where first impressions reign supreme, colored Polypropylene (PP) film emerges as a vibrant chameleon, blending eye-catching aesthetics with industrial-grade resilience. Imagine a sleek crimson folder cradling important documents, a sapphire-blue renovation membrane shielding a home’s interior, or a lime-green package making a snack pop off the shelf. Colored PP film, crafted from propylene monomers through extrusion and often biaxial orientation, transforms the mundane into the memorable. This thermoplastic titan marries vivid hues with unmatched durability, carving a niche across industries from office supplies to construction. With a palette as diverse as a painter’s canvas and properties that defy wear and tear, PP film proves that color can be more than skin-deep—it can be a powerhouse. At its core, PP film is a marvel of polymer engineering. Polypropylene’s semi-crystalline structure grants it a unique balance of stiffness and flexibility, with tensile strengths ranging from 30-150 MPa depending on processing. Available in cast (CPP) or biaxially oriented (BOPP) forms, colored PP film is infused with pigments or dyes during extrusion, achieving uniform hues without compromising clarity or strength. Its haze levels, as low as 2-4% in BOPP grades, ensure that even vibrant reds or deep blues retain a glossy, almost jewel-like sheen. The film’s thickness—typically 15-100 microns—offers versatility, from whisper-thin packaging to robust decorative layers. Add to that a melting point around 160-170°C, and PP film seals efficiently while resisting heat deformation, making it a darling of high-speed production lines.

At its core, PP film is a marvel of polymer engineering. Polypropylene’s semi-crystalline structure grants it a unique balance of stiffness and flexibility, with tensile strengths ranging from 30-150 MPa depending on processing. Available in cast (CPP) or biaxially oriented (BOPP) forms, colored PP film is infused with pigments or dyes during extrusion, achieving uniform hues without compromising clarity or strength. Its haze levels, as low as 2-4% in BOPP grades, ensure that even vibrant reds or deep blues retain a glossy, almost jewel-like sheen. The film’s thickness—typically 15-100 microns—offers versatility, from whisper-thin packaging to robust decorative layers. Add to that a melting point around 160-170°C, and PP film seals efficiently while resisting heat deformation, making it a darling of high-speed production lines. Stationery and Folders: Organizing with FlairIn the realm of stationery, colored PP film transforms folders into both practical tools and style statements. Picture a bustling office: a stack of emerald-green PP folders organizes client proposals, their translucent sheen revealing document titles while protecting against spills. With a tensile strength of 40-60 MPa in cast grades, these films resist tearing when overstuffed, unlike paper alternatives that fray under pressure. Their surface energy, boosted to 38-40 dynes/cm via corona treatment, ensures crisp printing for logos or labels, enhancing brand visibility. A 2024 study by a stationery supplier showed that PP film folders, at 200 microns thick, withstood 30% more bending cycles than PVC equivalents, extending lifespan in busy classrooms or boardrooms.The film’s chemical inertness shrugs off ink smudges or coffee stains, while UV-resistant pigments prevent fading under fluorescent lights. Flexible yet firm, PP film folders conform to overstuffed binders without cracking, their elongation at break (up to 300% in CPP) absorbing stress. A European school supplier reported a 15% sales boost after introducing rainbow-hued PP folders, as students gravitated toward their vibrant, durable appeal.

Stationery and Folders: Organizing with FlairIn the realm of stationery, colored PP film transforms folders into both practical tools and style statements. Picture a bustling office: a stack of emerald-green PP folders organizes client proposals, their translucent sheen revealing document titles while protecting against spills. With a tensile strength of 40-60 MPa in cast grades, these films resist tearing when overstuffed, unlike paper alternatives that fray under pressure. Their surface energy, boosted to 38-40 dynes/cm via corona treatment, ensures crisp printing for logos or labels, enhancing brand visibility. A 2024 study by a stationery supplier showed that PP film folders, at 200 microns thick, withstood 30% more bending cycles than PVC equivalents, extending lifespan in busy classrooms or boardrooms.The film’s chemical inertness shrugs off ink smudges or coffee stains, while UV-resistant pigments prevent fading under fluorescent lights. Flexible yet firm, PP film folders conform to overstuffed binders without cracking, their elongation at break (up to 300% in CPP) absorbing stress. A European school supplier reported a 15% sales boost after introducing rainbow-hued PP folders, as students gravitated toward their vibrant, durable appeal. Renovation Membranes: Shielding with StyleIn construction and home renovation, colored PP film serves as a protective membrane with a decorative twist. Imagine a renovation site: a cobalt-blue PP film drapes over furniture, its 50-micron thickness blocking dust and paint splatters while adding a pop of color to the chaos. With a tear strength of 15-20 N/mm, it resists punctures from dropped tools, and its water vapor transmission rate (WVTR) below 10 g/m²/day keeps moisture at bay, protecting hardwood floors or drywall. A U.S. contractor, using opaque PP film for wall liners, cut cleanup costs by 20%, as the film’s antistatic additives repelled dust buildup, simplifying post-renovation sweeps.Colored PP films in renovation often come in matte or textured finishes, reducing glare while masking scratches. Their heat resistance ensures they don’t melt under hot construction lights, and flame-retardant additives meet safety codes for commercial sites. In temporary wall dividers, translucent PP films in soft yellows or greens diffuse light, creating inviting workspaces. Industry data from 2023 showed PP renovation films, recyclable in dedicated streams, reduced landfill waste by 25% compared to traditional PE tarps.

Renovation Membranes: Shielding with StyleIn construction and home renovation, colored PP film serves as a protective membrane with a decorative twist. Imagine a renovation site: a cobalt-blue PP film drapes over furniture, its 50-micron thickness blocking dust and paint splatters while adding a pop of color to the chaos. With a tear strength of 15-20 N/mm, it resists punctures from dropped tools, and its water vapor transmission rate (WVTR) below 10 g/m²/day keeps moisture at bay, protecting hardwood floors or drywall. A U.S. contractor, using opaque PP film for wall liners, cut cleanup costs by 20%, as the film’s antistatic additives repelled dust buildup, simplifying post-renovation sweeps.Colored PP films in renovation often come in matte or textured finishes, reducing glare while masking scratches. Their heat resistance ensures they don’t melt under hot construction lights, and flame-retardant additives meet safety codes for commercial sites. In temporary wall dividers, translucent PP films in soft yellows or greens diffuse light, creating inviting workspaces. Industry data from 2023 showed PP renovation films, recyclable in dedicated streams, reduced landfill waste by 25% compared to traditional PE tarps. Colored Packaging Films: Making Products PopIn the fiercely competitive world of consumer goods, colored PP film is a packaging superstar. BOPP grades, with their high gloss (up to 95%) and vibrant pigment retention, wrap snacks, cosmetics, or electronics in hues that demand attention. Picture a candy aisle: a glossy purple PP film encases chocolate bars, its clarity highlighting embossed logos while its oxygen transmission rate (OTR) of 1500-2000 cc/m²/day preserves freshness. The film’s stiffness ensures crisp stand-up pouches, and its heat-seal strength—forming bonds at 120-140°C—prevents leaks in high-speed filling lines. A snack brand reported a 12% sales spike after switching to metallic-finish PP film, as its shimmer outshone competitors.For frozen foods, PP film’s low-temperature impact resistance (down to -20°C) prevents brittleness, protecting pizza boxes or ice cream tubs during transport. Its printability supports intricate designs, with a Southeast Asian beverage company noting 10% fewer printing defects after adopting BOPP for bottle labels. Food-safe grades comply with FDA and EU Regulation 10/2011, ensuring no migration of pigments into contents. Recyclability is a bonus—mono-material PP films slot into PE recycling streams, with a 2024 European study showing 35% of PP packaging reprocessed into new films or pipes.

Colored Packaging Films: Making Products PopIn the fiercely competitive world of consumer goods, colored PP film is a packaging superstar. BOPP grades, with their high gloss (up to 95%) and vibrant pigment retention, wrap snacks, cosmetics, or electronics in hues that demand attention. Picture a candy aisle: a glossy purple PP film encases chocolate bars, its clarity highlighting embossed logos while its oxygen transmission rate (OTR) of 1500-2000 cc/m²/day preserves freshness. The film’s stiffness ensures crisp stand-up pouches, and its heat-seal strength—forming bonds at 120-140°C—prevents leaks in high-speed filling lines. A snack brand reported a 12% sales spike after switching to metallic-finish PP film, as its shimmer outshone competitors.For frozen foods, PP film’s low-temperature impact resistance (down to -20°C) prevents brittleness, protecting pizza boxes or ice cream tubs during transport. Its printability supports intricate designs, with a Southeast Asian beverage company noting 10% fewer printing defects after adopting BOPP for bottle labels. Food-safe grades comply with FDA and EU Regulation 10/2011, ensuring no migration of pigments into contents. Recyclability is a bonus—mono-material PP films slot into PE recycling streams, with a 2024 European study showing 35% of PP packaging reprocessed into new films or pipes. Decorative Films: Aesthetic Meets UtilityColored PP film shines in decorative applications, from furniture laminates to vehicle wraps. In interior design, woodgrain-textured PP films in earthy browns or sleek grays clad cabinet surfaces, their abrasion resistance (Taber test scores of 500 cycles) outlasting vinyl coatings. A furniture maker in Italy, using 100-micron PP laminates, reported a 15% drop in warranty claims due to the film’s scratch resistance. Its chemical stability withstands cleaning agents, preserving luster in high-traffic kitchens.In automotive wraps, metallic or matte PP films in vibrant reds or matte blacks transform car exteriors. Their UV resistance (up to 2 years without fading) and elongation (150-200%) allow them to conform to curves without cracking, while adhesive-friendly surfaces ensure bubble-free application. A 2023 automotive survey found PP wraps cut reapplication costs by 18% compared to PVC, thanks to easier removal without residue. In retail displays, translucent PP films backlit with LEDs create glowing signage, their light diffusion enhancing color vibrancy.

Decorative Films: Aesthetic Meets UtilityColored PP film shines in decorative applications, from furniture laminates to vehicle wraps. In interior design, woodgrain-textured PP films in earthy browns or sleek grays clad cabinet surfaces, their abrasion resistance (Taber test scores of 500 cycles) outlasting vinyl coatings. A furniture maker in Italy, using 100-micron PP laminates, reported a 15% drop in warranty claims due to the film’s scratch resistance. Its chemical stability withstands cleaning agents, preserving luster in high-traffic kitchens.In automotive wraps, metallic or matte PP films in vibrant reds or matte blacks transform car exteriors. Their UV resistance (up to 2 years without fading) and elongation (150-200%) allow them to conform to curves without cracking, while adhesive-friendly surfaces ensure bubble-free application. A 2023 automotive survey found PP wraps cut reapplication costs by 18% compared to PVC, thanks to easier removal without residue. In retail displays, translucent PP films backlit with LEDs create glowing signage, their light diffusion enhancing color vibrancy. Other Applications: From Labels to AgricultureThe versatility of colored PP film extends to myriad niches. In labeling, self-adhesive PP films in bold hues grace wine bottles or shampoo containers, their water resistance preventing peel-off in humid bathrooms. A winery in California noted a 10% sales boost after adopting sapphire PP labels, their gloss amplifying shelf appeal. In agriculture, opaque PP films in green or black serve as mulch covers, suppressing weeds while retaining soil moisture, with trials showing 20% higher crop yields in arid regions.In electronics, antistatic PP films in muted grays protect circuit boards, their surface resistivity (10^10 ohms/sq) preventing static damage. A tech firm in South Korea cut defect rates by 15% using PP trays for chip transport, citing the film’s dimensional stability. In textiles, PP films laminate waterproof backpacks, their vibrant patterns enduring abrasion from hiking trails.Sustainability and ChallengesSustainability is a key draw. PP film’s mono-material nature makes it recyclable in established PE streams, with 2024 data showing 40% of European PP packaging reused in new products. Its lightweight nature—30% less resin than PVC for equivalent strength—cuts carbon footprints, with a lifecycle analysis estimating 25% lower emissions than PET alternatives. However, challenges linger: achieving uniform pigment dispersion in thin films demands precise extrusion, and vibrant dyes can raise costs by 10-15%. Recycling infrastructure for colored PP lags in some regions, though chemical recycling advancements are closing the gap.

Other Applications: From Labels to AgricultureThe versatility of colored PP film extends to myriad niches. In labeling, self-adhesive PP films in bold hues grace wine bottles or shampoo containers, their water resistance preventing peel-off in humid bathrooms. A winery in California noted a 10% sales boost after adopting sapphire PP labels, their gloss amplifying shelf appeal. In agriculture, opaque PP films in green or black serve as mulch covers, suppressing weeds while retaining soil moisture, with trials showing 20% higher crop yields in arid regions.In electronics, antistatic PP films in muted grays protect circuit boards, their surface resistivity (10^10 ohms/sq) preventing static damage. A tech firm in South Korea cut defect rates by 15% using PP trays for chip transport, citing the film’s dimensional stability. In textiles, PP films laminate waterproof backpacks, their vibrant patterns enduring abrasion from hiking trails.Sustainability and ChallengesSustainability is a key draw. PP film’s mono-material nature makes it recyclable in established PE streams, with 2024 data showing 40% of European PP packaging reused in new products. Its lightweight nature—30% less resin than PVC for equivalent strength—cuts carbon footprints, with a lifecycle analysis estimating 25% lower emissions than PET alternatives. However, challenges linger: achieving uniform pigment dispersion in thin films demands precise extrusion, and vibrant dyes can raise costs by 10-15%. Recycling infrastructure for colored PP lags in some regions, though chemical recycling advancements are closing the gap. The Future of Colored PP FilmThe horizon for colored PP film glows brightly. Nanocomposite additives could slash OTR to 500 cc/m²/day, rivaling multi-layer laminates for sensitive foods. Bio-based PP, derived from plant sugars, promises carbon-neutral options by 2030. Smart films with embedded sensors could signal product freshness through color shifts, with a 2025 pilot in Japan testing QR-coded PP wrappers for inventory tracking. In construction, self-healing PP films could mend micro-tears, extending renovation membrane lifespans.From folders that organize with flair to packages that dazzle, colored PP film is more than a material—it’s a canvas for innovation. It wraps the present in bold hues while paving a sustainable path for the future, proving that strength and beauty can coexist in every vibrant layer.

The Future of Colored PP FilmThe horizon for colored PP film glows brightly. Nanocomposite additives could slash OTR to 500 cc/m²/day, rivaling multi-layer laminates for sensitive foods. Bio-based PP, derived from plant sugars, promises carbon-neutral options by 2030. Smart films with embedded sensors could signal product freshness through color shifts, with a 2025 pilot in Japan testing QR-coded PP wrappers for inventory tracking. In construction, self-healing PP films could mend micro-tears, extending renovation membrane lifespans.From folders that organize with flair to packages that dazzle, colored PP film is more than a material—it’s a canvas for innovation. It wraps the present in bold hues while paving a sustainable path for the future, proving that strength and beauty can coexist in every vibrant layer.

At its core, PP film is a marvel of polymer engineering. Polypropylene’s semi-crystalline structure grants it a unique balance of stiffness and flexibility, with tensile strengths ranging from 30-150 MPa depending on processing. Available in cast (CPP) or biaxially oriented (BOPP) forms, colored PP film is infused with pigments or dyes during extrusion, achieving uniform hues without compromising clarity or strength. Its haze levels, as low as 2-4% in BOPP grades, ensure that even vibrant reds or deep blues retain a glossy, almost jewel-like sheen. The film’s thickness—typically 15-100 microns—offers versatility, from whisper-thin packaging to robust decorative layers. Add to that a melting point around 160-170°C, and PP film seals efficiently while resisting heat deformation, making it a darling of high-speed production lines.

At its core, PP film is a marvel of polymer engineering. Polypropylene’s semi-crystalline structure grants it a unique balance of stiffness and flexibility, with tensile strengths ranging from 30-150 MPa depending on processing. Available in cast (CPP) or biaxially oriented (BOPP) forms, colored PP film is infused with pigments or dyes during extrusion, achieving uniform hues without compromising clarity or strength. Its haze levels, as low as 2-4% in BOPP grades, ensure that even vibrant reds or deep blues retain a glossy, almost jewel-like sheen. The film’s thickness—typically 15-100 microns—offers versatility, from whisper-thin packaging to robust decorative layers. Add to that a melting point around 160-170°C, and PP film seals efficiently while resisting heat deformation, making it a darling of high-speed production lines. Stationery and Folders: Organizing with FlairIn the realm of stationery, colored PP film transforms folders into both practical tools and style statements. Picture a bustling office: a stack of emerald-green PP folders organizes client proposals, their translucent sheen revealing document titles while protecting against spills. With a tensile strength of 40-60 MPa in cast grades, these films resist tearing when overstuffed, unlike paper alternatives that fray under pressure. Their surface energy, boosted to 38-40 dynes/cm via corona treatment, ensures crisp printing for logos or labels, enhancing brand visibility. A 2024 study by a stationery supplier showed that PP film folders, at 200 microns thick, withstood 30% more bending cycles than PVC equivalents, extending lifespan in busy classrooms or boardrooms.The film’s chemical inertness shrugs off ink smudges or coffee stains, while UV-resistant pigments prevent fading under fluorescent lights. Flexible yet firm, PP film folders conform to overstuffed binders without cracking, their elongation at break (up to 300% in CPP) absorbing stress. A European school supplier reported a 15% sales boost after introducing rainbow-hued PP folders, as students gravitated toward their vibrant, durable appeal.

Stationery and Folders: Organizing with FlairIn the realm of stationery, colored PP film transforms folders into both practical tools and style statements. Picture a bustling office: a stack of emerald-green PP folders organizes client proposals, their translucent sheen revealing document titles while protecting against spills. With a tensile strength of 40-60 MPa in cast grades, these films resist tearing when overstuffed, unlike paper alternatives that fray under pressure. Their surface energy, boosted to 38-40 dynes/cm via corona treatment, ensures crisp printing for logos or labels, enhancing brand visibility. A 2024 study by a stationery supplier showed that PP film folders, at 200 microns thick, withstood 30% more bending cycles than PVC equivalents, extending lifespan in busy classrooms or boardrooms.The film’s chemical inertness shrugs off ink smudges or coffee stains, while UV-resistant pigments prevent fading under fluorescent lights. Flexible yet firm, PP film folders conform to overstuffed binders without cracking, their elongation at break (up to 300% in CPP) absorbing stress. A European school supplier reported a 15% sales boost after introducing rainbow-hued PP folders, as students gravitated toward their vibrant, durable appeal. Renovation Membranes: Shielding with StyleIn construction and home renovation, colored PP film serves as a protective membrane with a decorative twist. Imagine a renovation site: a cobalt-blue PP film drapes over furniture, its 50-micron thickness blocking dust and paint splatters while adding a pop of color to the chaos. With a tear strength of 15-20 N/mm, it resists punctures from dropped tools, and its water vapor transmission rate (WVTR) below 10 g/m²/day keeps moisture at bay, protecting hardwood floors or drywall. A U.S. contractor, using opaque PP film for wall liners, cut cleanup costs by 20%, as the film’s antistatic additives repelled dust buildup, simplifying post-renovation sweeps.Colored PP films in renovation often come in matte or textured finishes, reducing glare while masking scratches. Their heat resistance ensures they don’t melt under hot construction lights, and flame-retardant additives meet safety codes for commercial sites. In temporary wall dividers, translucent PP films in soft yellows or greens diffuse light, creating inviting workspaces. Industry data from 2023 showed PP renovation films, recyclable in dedicated streams, reduced landfill waste by 25% compared to traditional PE tarps.

Renovation Membranes: Shielding with StyleIn construction and home renovation, colored PP film serves as a protective membrane with a decorative twist. Imagine a renovation site: a cobalt-blue PP film drapes over furniture, its 50-micron thickness blocking dust and paint splatters while adding a pop of color to the chaos. With a tear strength of 15-20 N/mm, it resists punctures from dropped tools, and its water vapor transmission rate (WVTR) below 10 g/m²/day keeps moisture at bay, protecting hardwood floors or drywall. A U.S. contractor, using opaque PP film for wall liners, cut cleanup costs by 20%, as the film’s antistatic additives repelled dust buildup, simplifying post-renovation sweeps.Colored PP films in renovation often come in matte or textured finishes, reducing glare while masking scratches. Their heat resistance ensures they don’t melt under hot construction lights, and flame-retardant additives meet safety codes for commercial sites. In temporary wall dividers, translucent PP films in soft yellows or greens diffuse light, creating inviting workspaces. Industry data from 2023 showed PP renovation films, recyclable in dedicated streams, reduced landfill waste by 25% compared to traditional PE tarps. Colored Packaging Films: Making Products PopIn the fiercely competitive world of consumer goods, colored PP film is a packaging superstar. BOPP grades, with their high gloss (up to 95%) and vibrant pigment retention, wrap snacks, cosmetics, or electronics in hues that demand attention. Picture a candy aisle: a glossy purple PP film encases chocolate bars, its clarity highlighting embossed logos while its oxygen transmission rate (OTR) of 1500-2000 cc/m²/day preserves freshness. The film’s stiffness ensures crisp stand-up pouches, and its heat-seal strength—forming bonds at 120-140°C—prevents leaks in high-speed filling lines. A snack brand reported a 12% sales spike after switching to metallic-finish PP film, as its shimmer outshone competitors.For frozen foods, PP film’s low-temperature impact resistance (down to -20°C) prevents brittleness, protecting pizza boxes or ice cream tubs during transport. Its printability supports intricate designs, with a Southeast Asian beverage company noting 10% fewer printing defects after adopting BOPP for bottle labels. Food-safe grades comply with FDA and EU Regulation 10/2011, ensuring no migration of pigments into contents. Recyclability is a bonus—mono-material PP films slot into PE recycling streams, with a 2024 European study showing 35% of PP packaging reprocessed into new films or pipes.

Colored Packaging Films: Making Products PopIn the fiercely competitive world of consumer goods, colored PP film is a packaging superstar. BOPP grades, with their high gloss (up to 95%) and vibrant pigment retention, wrap snacks, cosmetics, or electronics in hues that demand attention. Picture a candy aisle: a glossy purple PP film encases chocolate bars, its clarity highlighting embossed logos while its oxygen transmission rate (OTR) of 1500-2000 cc/m²/day preserves freshness. The film’s stiffness ensures crisp stand-up pouches, and its heat-seal strength—forming bonds at 120-140°C—prevents leaks in high-speed filling lines. A snack brand reported a 12% sales spike after switching to metallic-finish PP film, as its shimmer outshone competitors.For frozen foods, PP film’s low-temperature impact resistance (down to -20°C) prevents brittleness, protecting pizza boxes or ice cream tubs during transport. Its printability supports intricate designs, with a Southeast Asian beverage company noting 10% fewer printing defects after adopting BOPP for bottle labels. Food-safe grades comply with FDA and EU Regulation 10/2011, ensuring no migration of pigments into contents. Recyclability is a bonus—mono-material PP films slot into PE recycling streams, with a 2024 European study showing 35% of PP packaging reprocessed into new films or pipes. Decorative Films: Aesthetic Meets UtilityColored PP film shines in decorative applications, from furniture laminates to vehicle wraps. In interior design, woodgrain-textured PP films in earthy browns or sleek grays clad cabinet surfaces, their abrasion resistance (Taber test scores of 500 cycles) outlasting vinyl coatings. A furniture maker in Italy, using 100-micron PP laminates, reported a 15% drop in warranty claims due to the film’s scratch resistance. Its chemical stability withstands cleaning agents, preserving luster in high-traffic kitchens.In automotive wraps, metallic or matte PP films in vibrant reds or matte blacks transform car exteriors. Their UV resistance (up to 2 years without fading) and elongation (150-200%) allow them to conform to curves without cracking, while adhesive-friendly surfaces ensure bubble-free application. A 2023 automotive survey found PP wraps cut reapplication costs by 18% compared to PVC, thanks to easier removal without residue. In retail displays, translucent PP films backlit with LEDs create glowing signage, their light diffusion enhancing color vibrancy.

Decorative Films: Aesthetic Meets UtilityColored PP film shines in decorative applications, from furniture laminates to vehicle wraps. In interior design, woodgrain-textured PP films in earthy browns or sleek grays clad cabinet surfaces, their abrasion resistance (Taber test scores of 500 cycles) outlasting vinyl coatings. A furniture maker in Italy, using 100-micron PP laminates, reported a 15% drop in warranty claims due to the film’s scratch resistance. Its chemical stability withstands cleaning agents, preserving luster in high-traffic kitchens.In automotive wraps, metallic or matte PP films in vibrant reds or matte blacks transform car exteriors. Their UV resistance (up to 2 years without fading) and elongation (150-200%) allow them to conform to curves without cracking, while adhesive-friendly surfaces ensure bubble-free application. A 2023 automotive survey found PP wraps cut reapplication costs by 18% compared to PVC, thanks to easier removal without residue. In retail displays, translucent PP films backlit with LEDs create glowing signage, their light diffusion enhancing color vibrancy. Other Applications: From Labels to AgricultureThe versatility of colored PP film extends to myriad niches. In labeling, self-adhesive PP films in bold hues grace wine bottles or shampoo containers, their water resistance preventing peel-off in humid bathrooms. A winery in California noted a 10% sales boost after adopting sapphire PP labels, their gloss amplifying shelf appeal. In agriculture, opaque PP films in green or black serve as mulch covers, suppressing weeds while retaining soil moisture, with trials showing 20% higher crop yields in arid regions.In electronics, antistatic PP films in muted grays protect circuit boards, their surface resistivity (10^10 ohms/sq) preventing static damage. A tech firm in South Korea cut defect rates by 15% using PP trays for chip transport, citing the film’s dimensional stability. In textiles, PP films laminate waterproof backpacks, their vibrant patterns enduring abrasion from hiking trails.Sustainability and ChallengesSustainability is a key draw. PP film’s mono-material nature makes it recyclable in established PE streams, with 2024 data showing 40% of European PP packaging reused in new products. Its lightweight nature—30% less resin than PVC for equivalent strength—cuts carbon footprints, with a lifecycle analysis estimating 25% lower emissions than PET alternatives. However, challenges linger: achieving uniform pigment dispersion in thin films demands precise extrusion, and vibrant dyes can raise costs by 10-15%. Recycling infrastructure for colored PP lags in some regions, though chemical recycling advancements are closing the gap.

Other Applications: From Labels to AgricultureThe versatility of colored PP film extends to myriad niches. In labeling, self-adhesive PP films in bold hues grace wine bottles or shampoo containers, their water resistance preventing peel-off in humid bathrooms. A winery in California noted a 10% sales boost after adopting sapphire PP labels, their gloss amplifying shelf appeal. In agriculture, opaque PP films in green or black serve as mulch covers, suppressing weeds while retaining soil moisture, with trials showing 20% higher crop yields in arid regions.In electronics, antistatic PP films in muted grays protect circuit boards, their surface resistivity (10^10 ohms/sq) preventing static damage. A tech firm in South Korea cut defect rates by 15% using PP trays for chip transport, citing the film’s dimensional stability. In textiles, PP films laminate waterproof backpacks, their vibrant patterns enduring abrasion from hiking trails.Sustainability and ChallengesSustainability is a key draw. PP film’s mono-material nature makes it recyclable in established PE streams, with 2024 data showing 40% of European PP packaging reused in new products. Its lightweight nature—30% less resin than PVC for equivalent strength—cuts carbon footprints, with a lifecycle analysis estimating 25% lower emissions than PET alternatives. However, challenges linger: achieving uniform pigment dispersion in thin films demands precise extrusion, and vibrant dyes can raise costs by 10-15%. Recycling infrastructure for colored PP lags in some regions, though chemical recycling advancements are closing the gap. The Future of Colored PP FilmThe horizon for colored PP film glows brightly. Nanocomposite additives could slash OTR to 500 cc/m²/day, rivaling multi-layer laminates for sensitive foods. Bio-based PP, derived from plant sugars, promises carbon-neutral options by 2030. Smart films with embedded sensors could signal product freshness through color shifts, with a 2025 pilot in Japan testing QR-coded PP wrappers for inventory tracking. In construction, self-healing PP films could mend micro-tears, extending renovation membrane lifespans.From folders that organize with flair to packages that dazzle, colored PP film is more than a material—it’s a canvas for innovation. It wraps the present in bold hues while paving a sustainable path for the future, proving that strength and beauty can coexist in every vibrant layer.

The Future of Colored PP FilmThe horizon for colored PP film glows brightly. Nanocomposite additives could slash OTR to 500 cc/m²/day, rivaling multi-layer laminates for sensitive foods. Bio-based PP, derived from plant sugars, promises carbon-neutral options by 2030. Smart films with embedded sensors could signal product freshness through color shifts, with a 2025 pilot in Japan testing QR-coded PP wrappers for inventory tracking. In construction, self-healing PP films could mend micro-tears, extending renovation membrane lifespans.From folders that organize with flair to packages that dazzle, colored PP film is more than a material—it’s a canvas for innovation. It wraps the present in bold hues while paving a sustainable path for the future, proving that strength and beauty can coexist in every vibrant layer.

Get the latest price? We'll respond as soon as possible(within 12 hours)