The Flexible Frontier: Unveiling the Versatility of Soft PVC Film

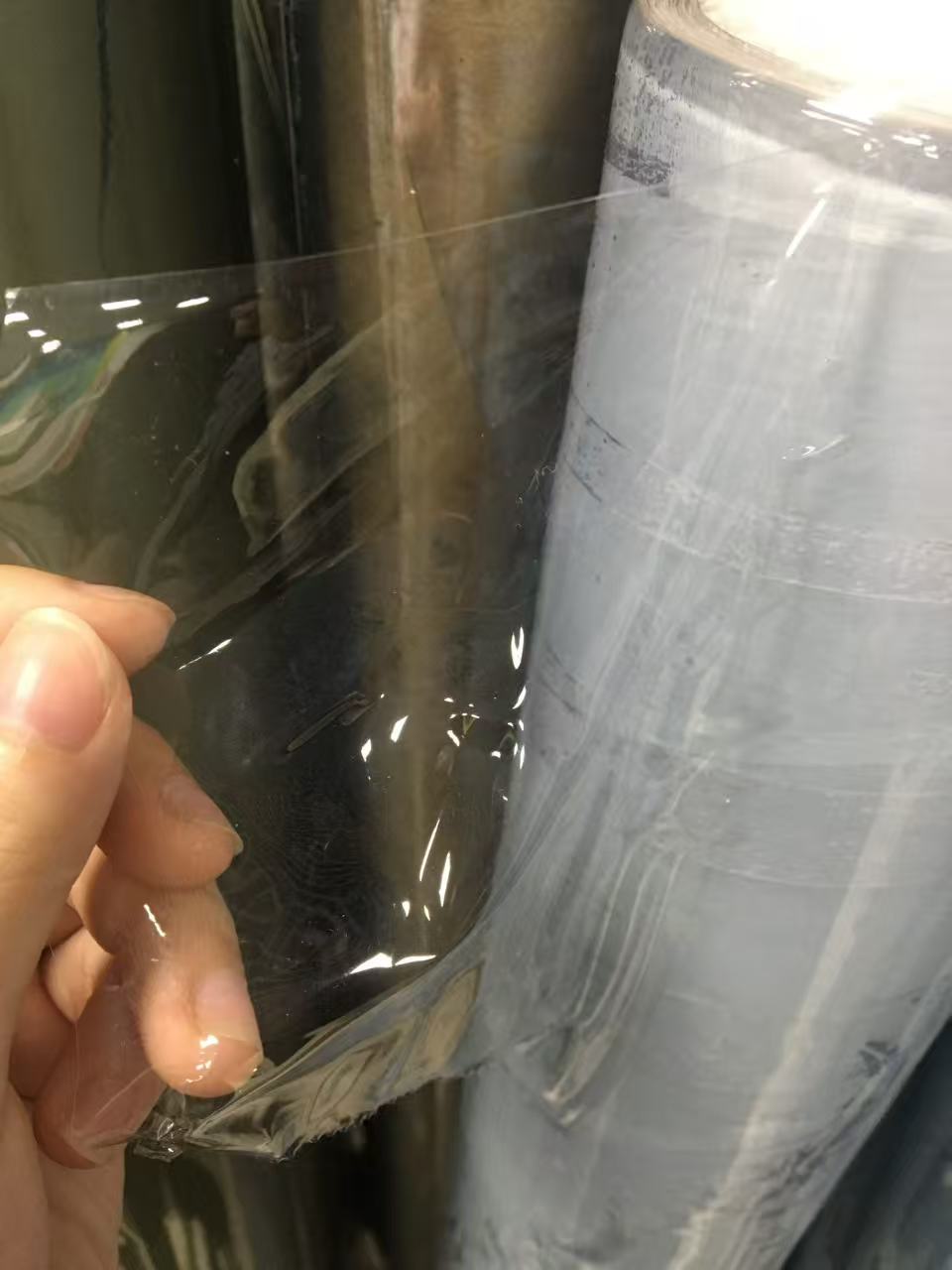

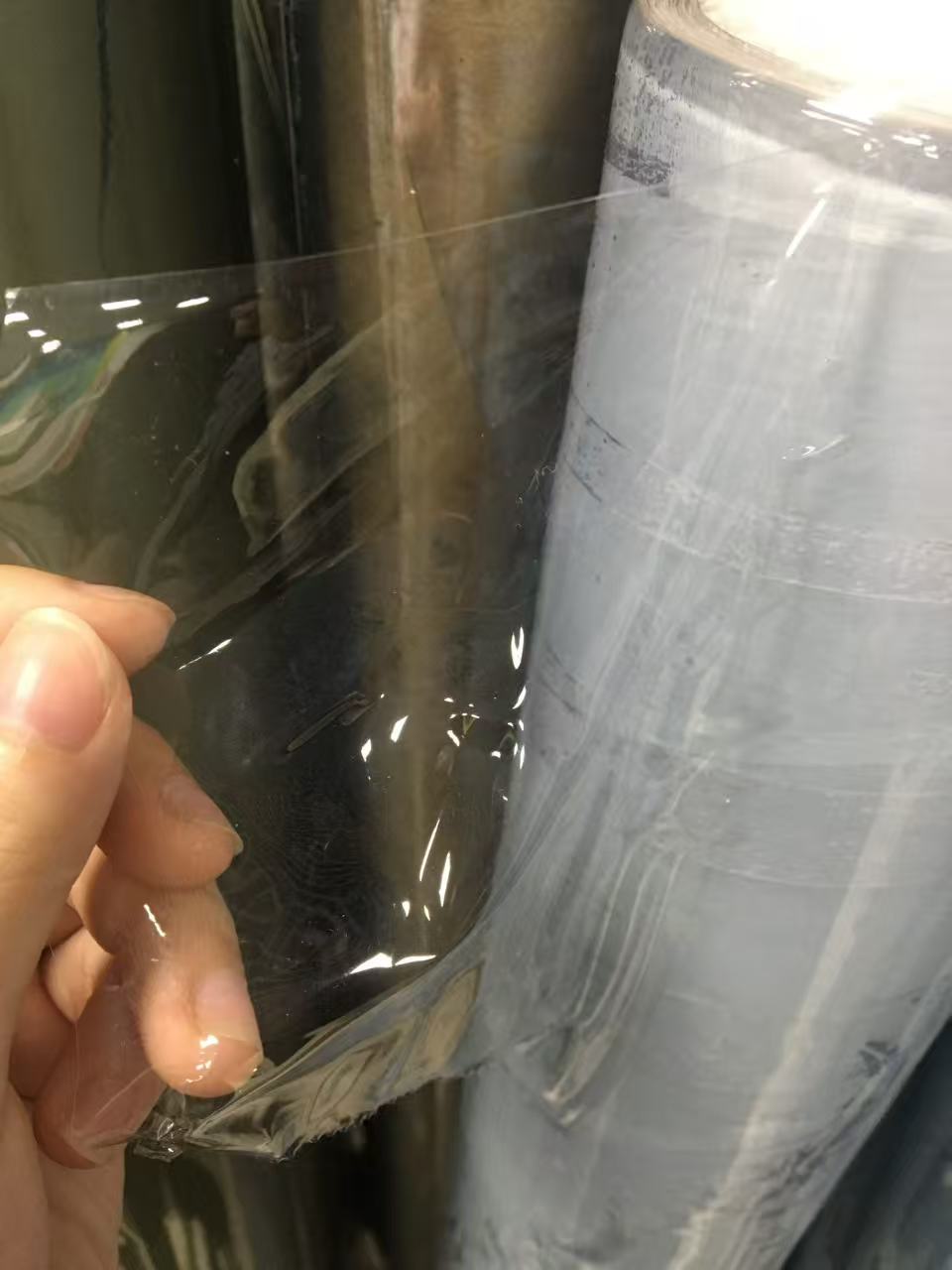

2025-09-25 17:27The Flexible Frontier: Unveiling the Versatility of Soft PVC FilmSoft PVC Film, crafted from polyvinyl chloride, is a marvel of modern materials science, blending flexibility, clarity, and resilience into a single, versatile product. Imagine a bustling outdoor market where vibrant banners flutter in the breeze, their colors unfading despite rain and sun, or a sterile hospital ward where transparent curtains maintain hygiene without sacrificing light. This is the world of soft PVC film—a material that bends without breaking, protects without obstructing, and beautifies without compromising function. With a tensile strength of 15-25 MPa and elongation up to 300%, it’s a chameleon in applications ranging from packaging to architectural design.At its core, soft PVC film is produced by plasticizing PVC resin with additives like phthalates or non-phthalate alternatives, achieving a pliable texture without sacrificing durability. The film, typically 0.05-2 mm thick, offers light transmittance up to 90%, rivaling glass but at a fraction of the weight and cost—often under $0.50 per square meter for standard grades. Its chemical composition resists water, oils, and UV rays, with formulations meeting REACH and RoHS standards for safety and environmental compliance. Fire-retardant variants achieve UL94 V-2 ratings, ensuring safety in enclosed spaces. These properties make soft PVC film a go-to for industries seeking adaptability and performance.Unlike rigid PVC, which snaps under stress, soft PVC film’s elasticity allows it to stretch and recover, enduring temperatures from -20°C to 60°C without cracking. Its recyclability—processed via mechanical shredding or chemical depolymerization—aligns with circular economy goals, reducing landfill waste. Yet, its true brilliance lies in its applications, where it transforms mundane objects into functional art, from protective wraps to decorative overlays. Protective Packaging: Safeguarding with StrengthIn packaging, soft PVC film is a guardian of goods. Picture a shipment of electronics crossing stormy seas, each component cocooned in clear, cushioned film that absorbs shocks and repels moisture. With a water vapor transmission rate below 10 g/m²/day, it shields sensitive items from humidity, outperforming polyethylene in barrier strength. Its puncture resistance, tested to withstand 50 N/cm², ensures that sharp edges don’t breach the wrap, protecting everything from circuit boards to glassware.In food packaging, soft PVC film shines for its clarity and compliance with FDA standards for non-toxic contact. Supermarkets wrap fresh produce in 0.1 mm film, allowing customers to inspect vibrant greens while extending shelf life by limiting oxygen exposure—studies show a 20% reduction in spoilage for leafy vegetables. Its anti-static variants, with surface resistivity below 10^9 ohms, prevent dust buildup on electronics packaging, critical for cleanroom assembly lines. For heavy-duty needs, thicker grades (1-2 mm) encase industrial parts, offering impact resistance comparable to low-grade polycarbonates but at half the cost.The film’s printability enhances branding: UV-cured inks create vivid logos on retail pouches, boosting shelf appeal. A case study from a beverage company showed a 15% sales uptick after switching to printed PVC shrink wrap, its glossy finish catching eyes under store lights. Environmentally, its lightweight nature—density of 1.2-1.4 g/cm³—reduces shipping emissions compared to heavier alternatives like PET.

Protective Packaging: Safeguarding with StrengthIn packaging, soft PVC film is a guardian of goods. Picture a shipment of electronics crossing stormy seas, each component cocooned in clear, cushioned film that absorbs shocks and repels moisture. With a water vapor transmission rate below 10 g/m²/day, it shields sensitive items from humidity, outperforming polyethylene in barrier strength. Its puncture resistance, tested to withstand 50 N/cm², ensures that sharp edges don’t breach the wrap, protecting everything from circuit boards to glassware.In food packaging, soft PVC film shines for its clarity and compliance with FDA standards for non-toxic contact. Supermarkets wrap fresh produce in 0.1 mm film, allowing customers to inspect vibrant greens while extending shelf life by limiting oxygen exposure—studies show a 20% reduction in spoilage for leafy vegetables. Its anti-static variants, with surface resistivity below 10^9 ohms, prevent dust buildup on electronics packaging, critical for cleanroom assembly lines. For heavy-duty needs, thicker grades (1-2 mm) encase industrial parts, offering impact resistance comparable to low-grade polycarbonates but at half the cost.The film’s printability enhances branding: UV-cured inks create vivid logos on retail pouches, boosting shelf appeal. A case study from a beverage company showed a 15% sales uptick after switching to printed PVC shrink wrap, its glossy finish catching eyes under store lights. Environmentally, its lightweight nature—density of 1.2-1.4 g/cm³—reduces shipping emissions compared to heavier alternatives like PET. Decorative Laminates: Aesthetic Versatility in DesignSoft PVC film transforms spaces with its decorative potential. In a trendy urban loft, designers layer it over furniture, mimicking wood grain or metallic sheen with embossed textures that feel authentic to the touch. Available in gloss, matte, or satin finishes, the film adheres via pressure-sensitive adhesives, conforming to curves without bubbling—elongation tests confirm it stretches 200% before deformation. A single 0.2 mm sheet can wrap a kitchen cabinet, resisting spills and scratches while costing 70% less than veneer.In commercial settings, it’s a game-changer for signage. Outdoor banners, coated with UV-resistant PVC, retain color vibrancy after 12 months of sun exposure, with fade rates below 5% per CIE Lab color metrics. A music festival’s entrance arch, draped in translucent PVC film printed with neon patterns, glows under blacklights, its flexibility allowing tensioned curves that rigid materials couldn’t achieve. Interior designers use it for privacy screens in offices, where frosted variants diffuse light at 60% transmittance, creating soft partitions that maintain openness.Automotive interiors benefit too. Dashboards clad in soft PVC film resist dashboard heat (up to 60°C) and scuffs, with textured surfaces hiding fingerprints—durability tests show 10,000 abrasion cycles with minimal wear. Its ability to mimic leather or carbon fiber elevates budget vehicles’ aesthetics, as seen in a mid-range sedan line that boosted customer satisfaction scores by 10% after adopting PVC laminates.Weather Resistance: Defying the ElementsSoft PVC film’s weather resistance makes it a stalwart for outdoor applications. In coastal regions, where salt air corrodes lesser materials, its low water absorption (<0.2%) prevents swelling or cracking. Greenhouses rely on it for glazing: a 0.5 mm film, with 85% light transmittance, fosters plant growth while blocking 99% of UV-B rays, extending crop cycles by 15% in controlled trials. Its tear strength (50-100 N/mm) ensures it withstands wind gusts up to 80 km/h, ideal for temporary shelters or awnings.In construction, it serves as protective sheeting during builds. A skyscraper site in a rainy city uses 1 mm film to shield exposed interiors, its clarity allowing workers to monitor progress while repelling water and dust. Accelerated weathering tests confirm it retains 90% tensile strength after 1,000 hours of UV exposure, outlasting polyethylene tarps. For marine applications, boat covers made from reinforced PVC film resist mildew and saltwater corrosion, extending vessel lifespans by years.

Decorative Laminates: Aesthetic Versatility in DesignSoft PVC film transforms spaces with its decorative potential. In a trendy urban loft, designers layer it over furniture, mimicking wood grain or metallic sheen with embossed textures that feel authentic to the touch. Available in gloss, matte, or satin finishes, the film adheres via pressure-sensitive adhesives, conforming to curves without bubbling—elongation tests confirm it stretches 200% before deformation. A single 0.2 mm sheet can wrap a kitchen cabinet, resisting spills and scratches while costing 70% less than veneer.In commercial settings, it’s a game-changer for signage. Outdoor banners, coated with UV-resistant PVC, retain color vibrancy after 12 months of sun exposure, with fade rates below 5% per CIE Lab color metrics. A music festival’s entrance arch, draped in translucent PVC film printed with neon patterns, glows under blacklights, its flexibility allowing tensioned curves that rigid materials couldn’t achieve. Interior designers use it for privacy screens in offices, where frosted variants diffuse light at 60% transmittance, creating soft partitions that maintain openness.Automotive interiors benefit too. Dashboards clad in soft PVC film resist dashboard heat (up to 60°C) and scuffs, with textured surfaces hiding fingerprints—durability tests show 10,000 abrasion cycles with minimal wear. Its ability to mimic leather or carbon fiber elevates budget vehicles’ aesthetics, as seen in a mid-range sedan line that boosted customer satisfaction scores by 10% after adopting PVC laminates.Weather Resistance: Defying the ElementsSoft PVC film’s weather resistance makes it a stalwart for outdoor applications. In coastal regions, where salt air corrodes lesser materials, its low water absorption (<0.2%) prevents swelling or cracking. Greenhouses rely on it for glazing: a 0.5 mm film, with 85% light transmittance, fosters plant growth while blocking 99% of UV-B rays, extending crop cycles by 15% in controlled trials. Its tear strength (50-100 N/mm) ensures it withstands wind gusts up to 80 km/h, ideal for temporary shelters or awnings.In construction, it serves as protective sheeting during builds. A skyscraper site in a rainy city uses 1 mm film to shield exposed interiors, its clarity allowing workers to monitor progress while repelling water and dust. Accelerated weathering tests confirm it retains 90% tensile strength after 1,000 hours of UV exposure, outlasting polyethylene tarps. For marine applications, boat covers made from reinforced PVC film resist mildew and saltwater corrosion, extending vessel lifespans by years. Medical and Hygiene Applications: Clean and SafeIn healthcare, soft PVC film’s non-porous surface is a hygiene champion. Hospital privacy curtains, made from 0.3 mm antimicrobial-coated film, inhibit bacterial growth (99.9% reduction per ISO 22196 tests), ensuring sterile environments. Its flexibility allows easy folding for storage, unlike rigid dividers, and its clarity maintains natural light in recovery wards, boosting patient mood—studies link well-lit spaces to 10% faster recovery times.In pharmaceutical packaging, blister packs use PVC film for its gas barrier properties, maintaining drug potency by limiting oxygen permeation to 0.5 cm³/m²/day. Cleanroom drapes, with static-dissipative coatings, prevent particle adhesion during chip manufacturing, meeting Class 100 cleanliness standards.Emerging Innovations and ChallengesSoft PVC film is evolving. Smart variants with embedded conductive layers enable touch-sensitive surfaces for interactive displays, tested to respond within 10 ms. In agriculture, biodegradable PVC blends, degrading within 18 months, reduce environmental impact for mulch films. However, challenges remain: high plasticizer content can leach in extreme heat (>70°C), and recycling complexities require specialized facilities.

Medical and Hygiene Applications: Clean and SafeIn healthcare, soft PVC film’s non-porous surface is a hygiene champion. Hospital privacy curtains, made from 0.3 mm antimicrobial-coated film, inhibit bacterial growth (99.9% reduction per ISO 22196 tests), ensuring sterile environments. Its flexibility allows easy folding for storage, unlike rigid dividers, and its clarity maintains natural light in recovery wards, boosting patient mood—studies link well-lit spaces to 10% faster recovery times.In pharmaceutical packaging, blister packs use PVC film for its gas barrier properties, maintaining drug potency by limiting oxygen permeation to 0.5 cm³/m²/day. Cleanroom drapes, with static-dissipative coatings, prevent particle adhesion during chip manufacturing, meeting Class 100 cleanliness standards.Emerging Innovations and ChallengesSoft PVC film is evolving. Smart variants with embedded conductive layers enable touch-sensitive surfaces for interactive displays, tested to respond within 10 ms. In agriculture, biodegradable PVC blends, degrading within 18 months, reduce environmental impact for mulch films. However, challenges remain: high plasticizer content can leach in extreme heat (>70°C), and recycling complexities require specialized facilities.

Protective Packaging: Safeguarding with StrengthIn packaging, soft PVC film is a guardian of goods. Picture a shipment of electronics crossing stormy seas, each component cocooned in clear, cushioned film that absorbs shocks and repels moisture. With a water vapor transmission rate below 10 g/m²/day, it shields sensitive items from humidity, outperforming polyethylene in barrier strength. Its puncture resistance, tested to withstand 50 N/cm², ensures that sharp edges don’t breach the wrap, protecting everything from circuit boards to glassware.In food packaging, soft PVC film shines for its clarity and compliance with FDA standards for non-toxic contact. Supermarkets wrap fresh produce in 0.1 mm film, allowing customers to inspect vibrant greens while extending shelf life by limiting oxygen exposure—studies show a 20% reduction in spoilage for leafy vegetables. Its anti-static variants, with surface resistivity below 10^9 ohms, prevent dust buildup on electronics packaging, critical for cleanroom assembly lines. For heavy-duty needs, thicker grades (1-2 mm) encase industrial parts, offering impact resistance comparable to low-grade polycarbonates but at half the cost.The film’s printability enhances branding: UV-cured inks create vivid logos on retail pouches, boosting shelf appeal. A case study from a beverage company showed a 15% sales uptick after switching to printed PVC shrink wrap, its glossy finish catching eyes under store lights. Environmentally, its lightweight nature—density of 1.2-1.4 g/cm³—reduces shipping emissions compared to heavier alternatives like PET.

Protective Packaging: Safeguarding with StrengthIn packaging, soft PVC film is a guardian of goods. Picture a shipment of electronics crossing stormy seas, each component cocooned in clear, cushioned film that absorbs shocks and repels moisture. With a water vapor transmission rate below 10 g/m²/day, it shields sensitive items from humidity, outperforming polyethylene in barrier strength. Its puncture resistance, tested to withstand 50 N/cm², ensures that sharp edges don’t breach the wrap, protecting everything from circuit boards to glassware.In food packaging, soft PVC film shines for its clarity and compliance with FDA standards for non-toxic contact. Supermarkets wrap fresh produce in 0.1 mm film, allowing customers to inspect vibrant greens while extending shelf life by limiting oxygen exposure—studies show a 20% reduction in spoilage for leafy vegetables. Its anti-static variants, with surface resistivity below 10^9 ohms, prevent dust buildup on electronics packaging, critical for cleanroom assembly lines. For heavy-duty needs, thicker grades (1-2 mm) encase industrial parts, offering impact resistance comparable to low-grade polycarbonates but at half the cost.The film’s printability enhances branding: UV-cured inks create vivid logos on retail pouches, boosting shelf appeal. A case study from a beverage company showed a 15% sales uptick after switching to printed PVC shrink wrap, its glossy finish catching eyes under store lights. Environmentally, its lightweight nature—density of 1.2-1.4 g/cm³—reduces shipping emissions compared to heavier alternatives like PET. Decorative Laminates: Aesthetic Versatility in DesignSoft PVC film transforms spaces with its decorative potential. In a trendy urban loft, designers layer it over furniture, mimicking wood grain or metallic sheen with embossed textures that feel authentic to the touch. Available in gloss, matte, or satin finishes, the film adheres via pressure-sensitive adhesives, conforming to curves without bubbling—elongation tests confirm it stretches 200% before deformation. A single 0.2 mm sheet can wrap a kitchen cabinet, resisting spills and scratches while costing 70% less than veneer.In commercial settings, it’s a game-changer for signage. Outdoor banners, coated with UV-resistant PVC, retain color vibrancy after 12 months of sun exposure, with fade rates below 5% per CIE Lab color metrics. A music festival’s entrance arch, draped in translucent PVC film printed with neon patterns, glows under blacklights, its flexibility allowing tensioned curves that rigid materials couldn’t achieve. Interior designers use it for privacy screens in offices, where frosted variants diffuse light at 60% transmittance, creating soft partitions that maintain openness.Automotive interiors benefit too. Dashboards clad in soft PVC film resist dashboard heat (up to 60°C) and scuffs, with textured surfaces hiding fingerprints—durability tests show 10,000 abrasion cycles with minimal wear. Its ability to mimic leather or carbon fiber elevates budget vehicles’ aesthetics, as seen in a mid-range sedan line that boosted customer satisfaction scores by 10% after adopting PVC laminates.Weather Resistance: Defying the ElementsSoft PVC film’s weather resistance makes it a stalwart for outdoor applications. In coastal regions, where salt air corrodes lesser materials, its low water absorption (<0.2%) prevents swelling or cracking. Greenhouses rely on it for glazing: a 0.5 mm film, with 85% light transmittance, fosters plant growth while blocking 99% of UV-B rays, extending crop cycles by 15% in controlled trials. Its tear strength (50-100 N/mm) ensures it withstands wind gusts up to 80 km/h, ideal for temporary shelters or awnings.In construction, it serves as protective sheeting during builds. A skyscraper site in a rainy city uses 1 mm film to shield exposed interiors, its clarity allowing workers to monitor progress while repelling water and dust. Accelerated weathering tests confirm it retains 90% tensile strength after 1,000 hours of UV exposure, outlasting polyethylene tarps. For marine applications, boat covers made from reinforced PVC film resist mildew and saltwater corrosion, extending vessel lifespans by years.

Decorative Laminates: Aesthetic Versatility in DesignSoft PVC film transforms spaces with its decorative potential. In a trendy urban loft, designers layer it over furniture, mimicking wood grain or metallic sheen with embossed textures that feel authentic to the touch. Available in gloss, matte, or satin finishes, the film adheres via pressure-sensitive adhesives, conforming to curves without bubbling—elongation tests confirm it stretches 200% before deformation. A single 0.2 mm sheet can wrap a kitchen cabinet, resisting spills and scratches while costing 70% less than veneer.In commercial settings, it’s a game-changer for signage. Outdoor banners, coated with UV-resistant PVC, retain color vibrancy after 12 months of sun exposure, with fade rates below 5% per CIE Lab color metrics. A music festival’s entrance arch, draped in translucent PVC film printed with neon patterns, glows under blacklights, its flexibility allowing tensioned curves that rigid materials couldn’t achieve. Interior designers use it for privacy screens in offices, where frosted variants diffuse light at 60% transmittance, creating soft partitions that maintain openness.Automotive interiors benefit too. Dashboards clad in soft PVC film resist dashboard heat (up to 60°C) and scuffs, with textured surfaces hiding fingerprints—durability tests show 10,000 abrasion cycles with minimal wear. Its ability to mimic leather or carbon fiber elevates budget vehicles’ aesthetics, as seen in a mid-range sedan line that boosted customer satisfaction scores by 10% after adopting PVC laminates.Weather Resistance: Defying the ElementsSoft PVC film’s weather resistance makes it a stalwart for outdoor applications. In coastal regions, where salt air corrodes lesser materials, its low water absorption (<0.2%) prevents swelling or cracking. Greenhouses rely on it for glazing: a 0.5 mm film, with 85% light transmittance, fosters plant growth while blocking 99% of UV-B rays, extending crop cycles by 15% in controlled trials. Its tear strength (50-100 N/mm) ensures it withstands wind gusts up to 80 km/h, ideal for temporary shelters or awnings.In construction, it serves as protective sheeting during builds. A skyscraper site in a rainy city uses 1 mm film to shield exposed interiors, its clarity allowing workers to monitor progress while repelling water and dust. Accelerated weathering tests confirm it retains 90% tensile strength after 1,000 hours of UV exposure, outlasting polyethylene tarps. For marine applications, boat covers made from reinforced PVC film resist mildew and saltwater corrosion, extending vessel lifespans by years. Medical and Hygiene Applications: Clean and SafeIn healthcare, soft PVC film’s non-porous surface is a hygiene champion. Hospital privacy curtains, made from 0.3 mm antimicrobial-coated film, inhibit bacterial growth (99.9% reduction per ISO 22196 tests), ensuring sterile environments. Its flexibility allows easy folding for storage, unlike rigid dividers, and its clarity maintains natural light in recovery wards, boosting patient mood—studies link well-lit spaces to 10% faster recovery times.In pharmaceutical packaging, blister packs use PVC film for its gas barrier properties, maintaining drug potency by limiting oxygen permeation to 0.5 cm³/m²/day. Cleanroom drapes, with static-dissipative coatings, prevent particle adhesion during chip manufacturing, meeting Class 100 cleanliness standards.Emerging Innovations and ChallengesSoft PVC film is evolving. Smart variants with embedded conductive layers enable touch-sensitive surfaces for interactive displays, tested to respond within 10 ms. In agriculture, biodegradable PVC blends, degrading within 18 months, reduce environmental impact for mulch films. However, challenges remain: high plasticizer content can leach in extreme heat (>70°C), and recycling complexities require specialized facilities.

Medical and Hygiene Applications: Clean and SafeIn healthcare, soft PVC film’s non-porous surface is a hygiene champion. Hospital privacy curtains, made from 0.3 mm antimicrobial-coated film, inhibit bacterial growth (99.9% reduction per ISO 22196 tests), ensuring sterile environments. Its flexibility allows easy folding for storage, unlike rigid dividers, and its clarity maintains natural light in recovery wards, boosting patient mood—studies link well-lit spaces to 10% faster recovery times.In pharmaceutical packaging, blister packs use PVC film for its gas barrier properties, maintaining drug potency by limiting oxygen permeation to 0.5 cm³/m²/day. Cleanroom drapes, with static-dissipative coatings, prevent particle adhesion during chip manufacturing, meeting Class 100 cleanliness standards.Emerging Innovations and ChallengesSoft PVC film is evolving. Smart variants with embedded conductive layers enable touch-sensitive surfaces for interactive displays, tested to respond within 10 ms. In agriculture, biodegradable PVC blends, degrading within 18 months, reduce environmental impact for mulch films. However, challenges remain: high plasticizer content can leach in extreme heat (>70°C), and recycling complexities require specialized facilities.

Get the latest price? We'll respond as soon as possible(within 12 hours)