Unlocking Efficiency: The Role of Printable PET Film in Food Packaging

2025-01-21 19:19Introduction

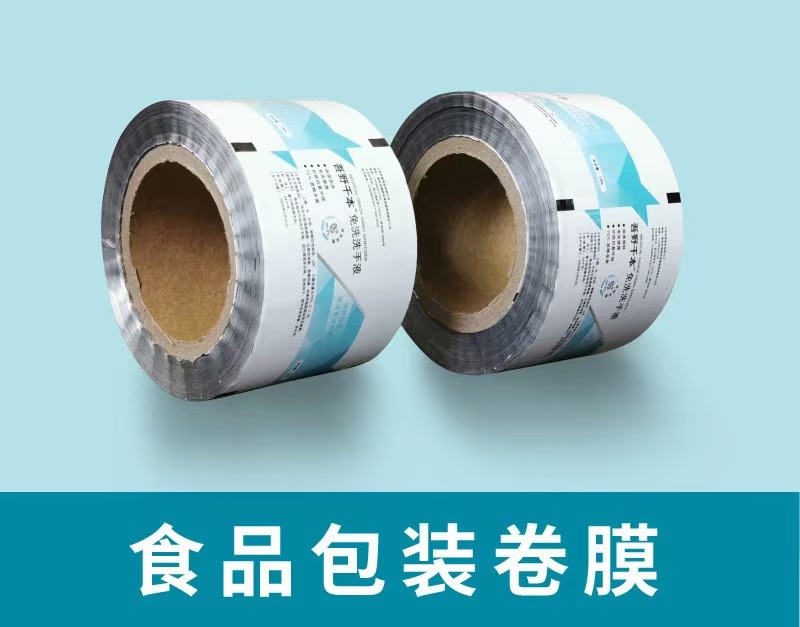

In this era of efficiency and consumer engagement, printable PET film has been a cornerstone of modern packaging solutions in food packaging. This article highlights how printable PET film is going to change the concept of automatic identification and sealing in food packaging, from cookie boxes and instant noodle packets to juice containers, sauces, and ready meals. We will review its applications, benefits, and technological advances that make it an ideal choice for today's market demands.

Understanding Printable PET Film

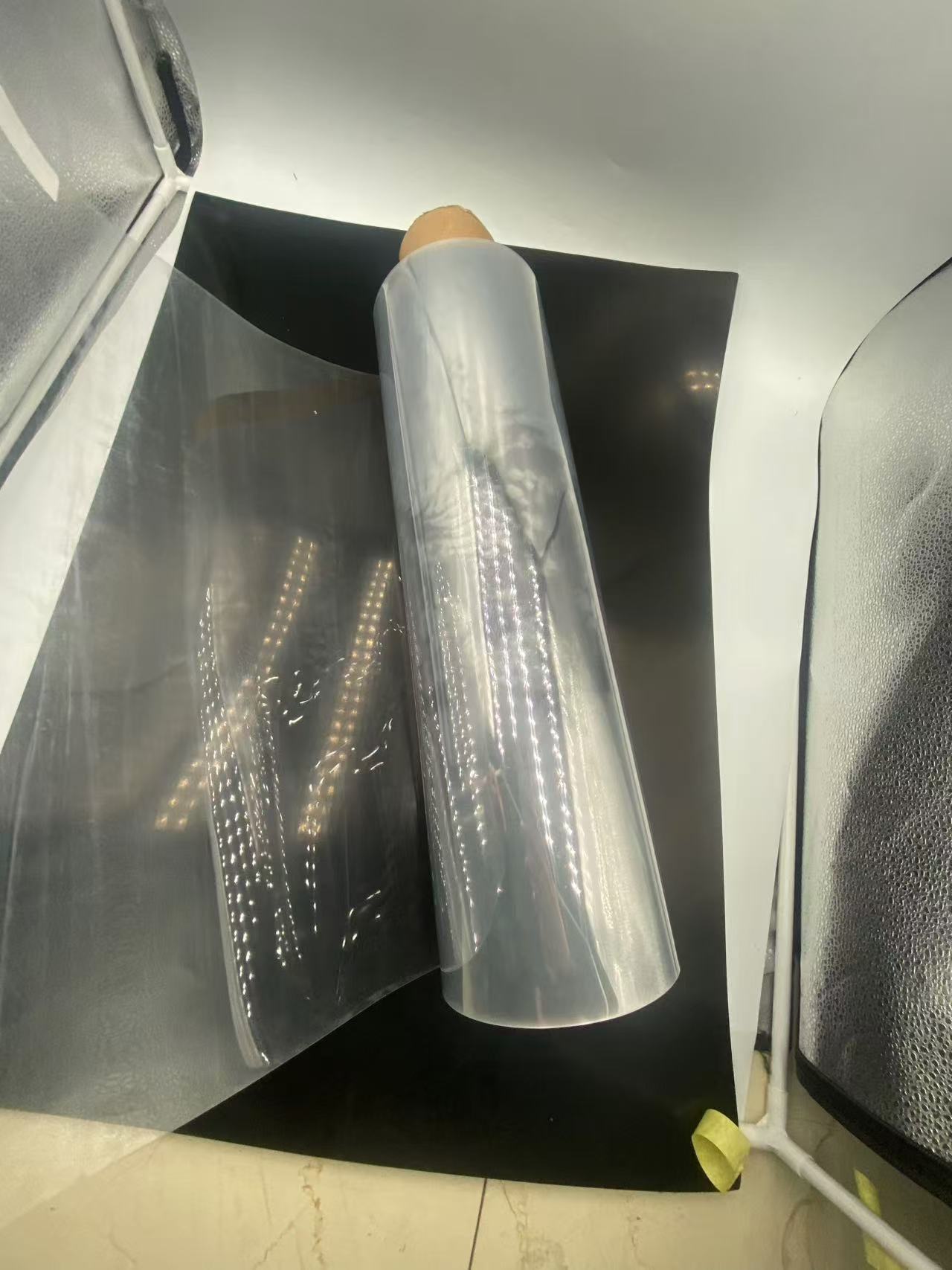

PET film is a variety of polyester film employed in packaging due to its strength, clarity, and resistance to chemicals and moisture. It has become so common in food packaging, especially in automated processes:

• Printability: PET film is printable through most printing technologies, such as flexographic, gravure, or digital printing to high-quality graphics, barcodes, and other identification markers for branding, information labeling, and traceability directly on the packaging.

• Barrier Properties: PET is a good oxygen, moisture, and UV barrier that is important in extending the shelf life of many foods.

• Durability and Flexibility: While this material is extremely strong, it can be blown into different shapes. That's why it's the perfect material both for rigid and flexible packaging.

Applications in Food Packaging

• Cookie Boxes: Printable PET film allows for a perfect view of the product for added appeal to the consumer. It can also allow printing of branding information and nutrition facts directly onto the package. The clarity of the film showcases the cookies and the barrier properties keep them fresh.

oExample: A high-end bakery uses PET film for packaging its artisan cookies. The packaging not only protects the cookies from humidity but also features bright prints of the bakery's logo and the cookies' ingredients, enhancing brand recognition and consumer trust.

• Instant Noodles: PET films are used in the packaging of instant noodles, whereby they provide a lightweight yet robust barrier to moisture, ensuring the noodles remain crisp until cooked. The printability aspect allows for complex labeling with cooking instructions, nutritional facts, and promotional offers directly onto the pack.

• Juice Packaging: Some single-serve juice packaging; the PET film can be used for lidding applications-that is, sealing the container while leaving space for printing essential consumer information that includes batch numbers, expiration dates, and barcodes for automatic checkout.

• Sauces: PET films are used in sauce sachets or pouches that provide a seal that maintains product integrity while allowing for vibrant, high-resolution printing of brand logos, product details, and usage instructions.

• Ready Meals: Be it microwaveable trays or vacuum-packed meals, PET film is ideal due to its high-temperature resistance and clarity for visual appeal. Heating instructions, nutrition facts, and even QR codes with recipe suggestions can be printed on labels using the PET film to help interact more with the consumer. Advantages of Printable PET Film in Automated Packaging

• Speed and Efficiency: Automatic printing and sealing with PET film make the packaging process faster, hence reducing labor costs and increasing production rates. Machines can print and seal at high speeds, ensuring that each package is consistent and error-free.

• Traceability: PET film has the ability to hold detailed prints, which can be used for comprehensive tracking systems. The fact that barcodes, QR codes, or RFID tags can be printed on PET and scanned at any point in the supply chain makes traceability easy for quality control and recalls.

• Branding Opportunities: The clarity and print quality on PET film allow companies to leverage packaging as a marketing tool, turning each package into a mini billboard.

• Sustainability: PET is recyclable, and development in printing inks and adhesives has meant that the printed PET film often can be recycled together with the rest of the package. This is particularly relevant in light of increased regulatory requirements for sustainable packaging.

Technology Developments

• Digital Printing: Digital printing technology, as it continues to evolve, enables variable data print on PET, which is critical either for personalized marketing or batch-specific information such as lot numbers.

• Inkjet and Laser Printing: Both these printing technologies have high-resolution graphics and text that are critical for small text such as ingredient lists or legal disclaimers on food packaging.

• Smart Packaging: Incorporation of sensors or indicators in or onto PET film may provide real-time information about product freshness or temperature exposure to enhance food safety protocols.

Challenges and Future Outlook

• Recycling Complexities: While PET is recyclable, inks and adhesives may make the process a bit complicated. Industry leaders are focusing on developing inks that can be easily removed during recycling or compatible with PET recycling streams.

• Cost: High-quality printing on PET may add to the cost, though this is often offset through the benefits in branding and consumer engagement.

• Innovation in Barrier Properties: Ongoing research aims to improve the barrier properties of PET by means of nanotechnology or new polymer blends, which could allow for even longer shelf life and less food waste.

Conclusion

Printable PET film has transformed food packaging, especially in environments where speed, clarity, and consumer interaction are paramount. From the humble cookie box to sophisticated ready meals, the versatility of PET film, combined with the latest printing technology, offers a route for manufacturers not only to protect but also to promote their products. As we move forward, the focus will be on enhancing sustainability, reducing costs, and further integrating technology into packaging solutions, ensuring that PET film remains at the forefront of packaging innovation.