Shining Bright: The Dazzling Versatility of PVC/PET Metallized Film in Modern Applications

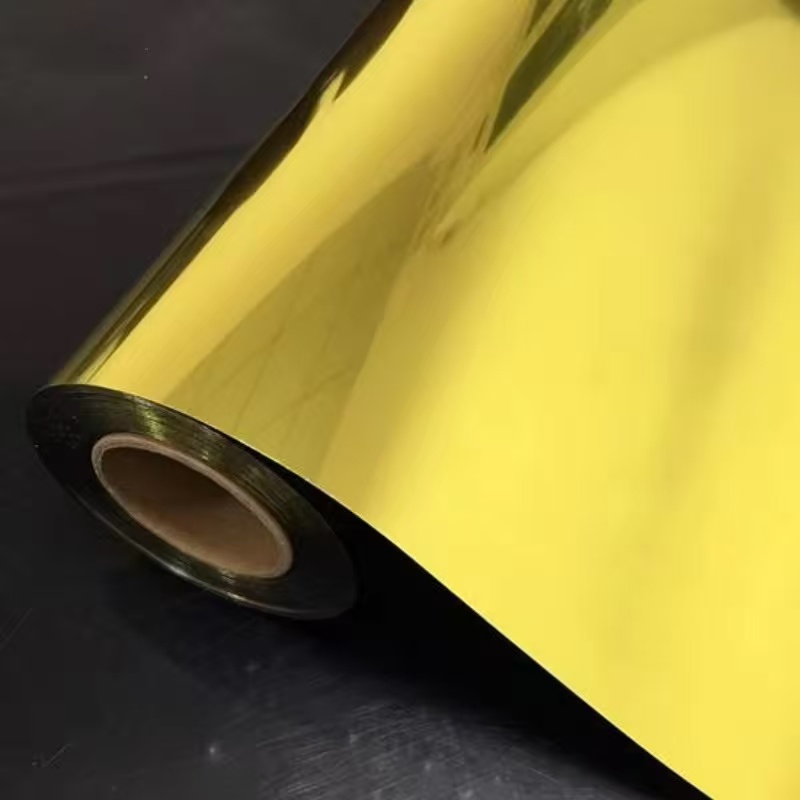

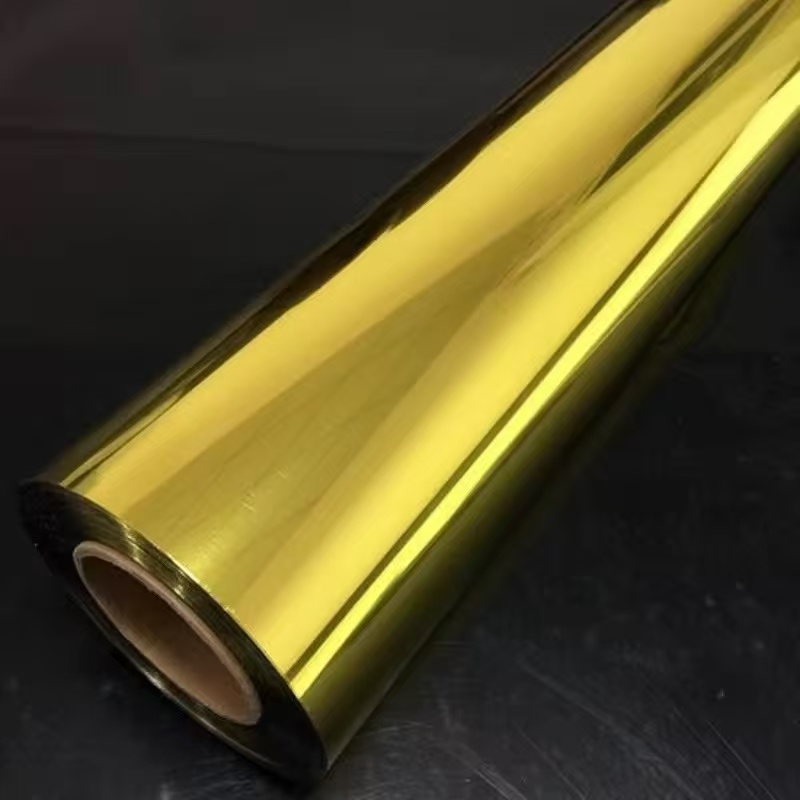

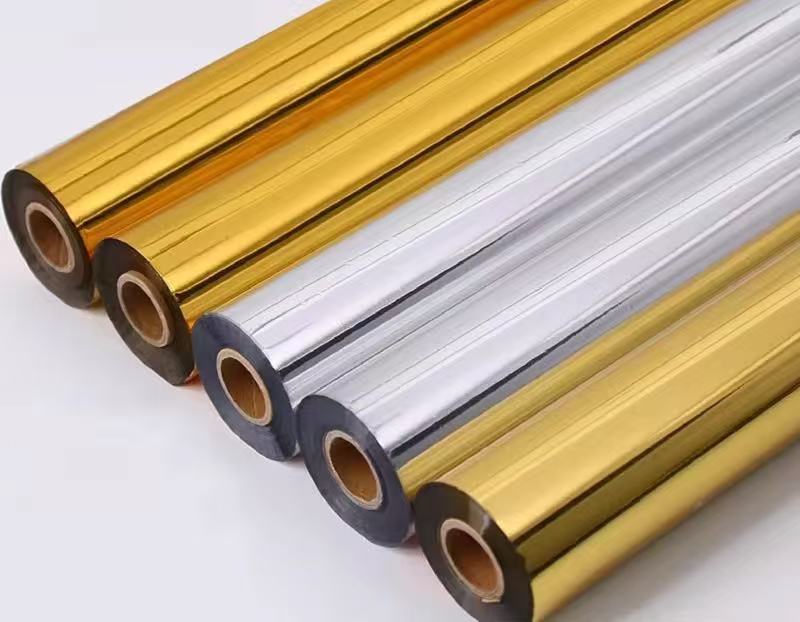

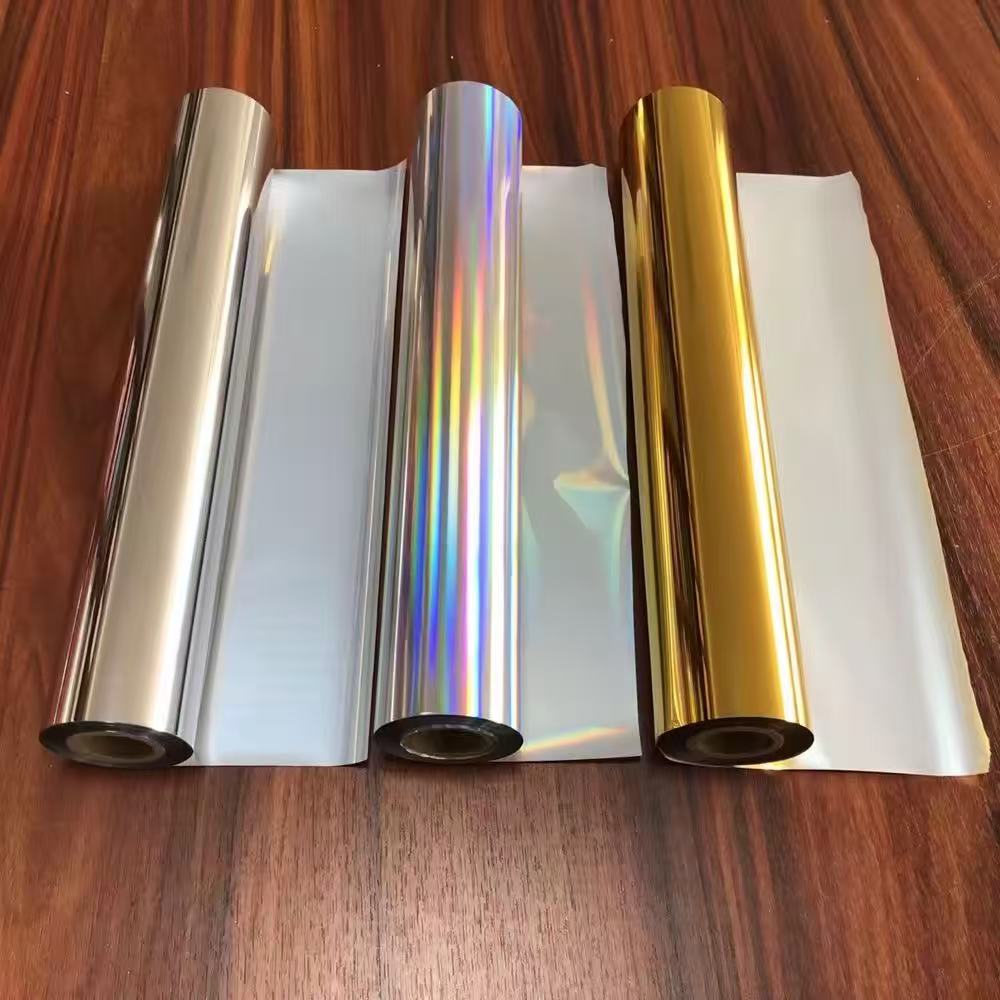

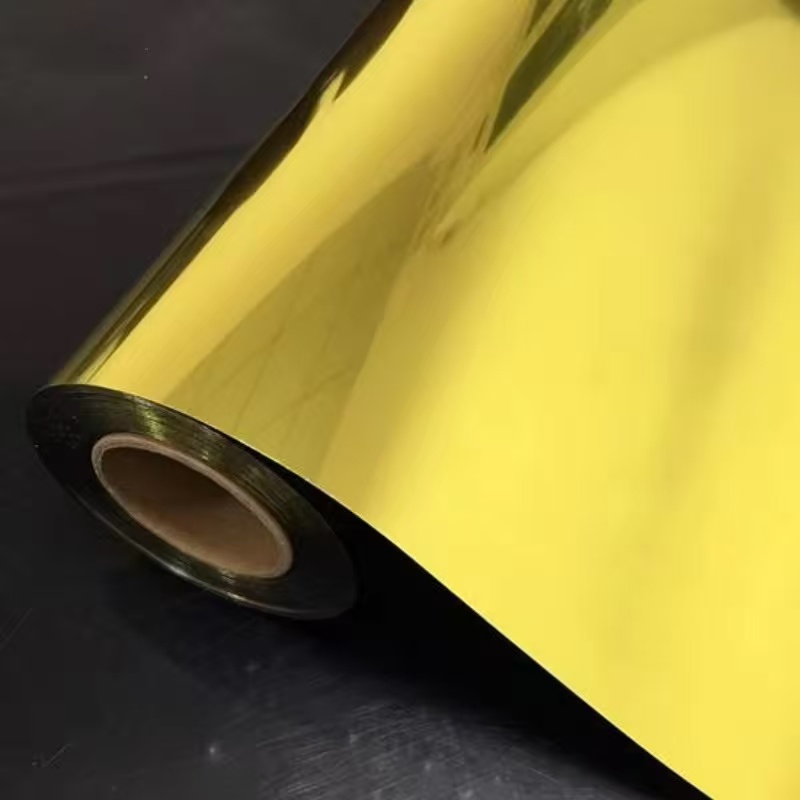

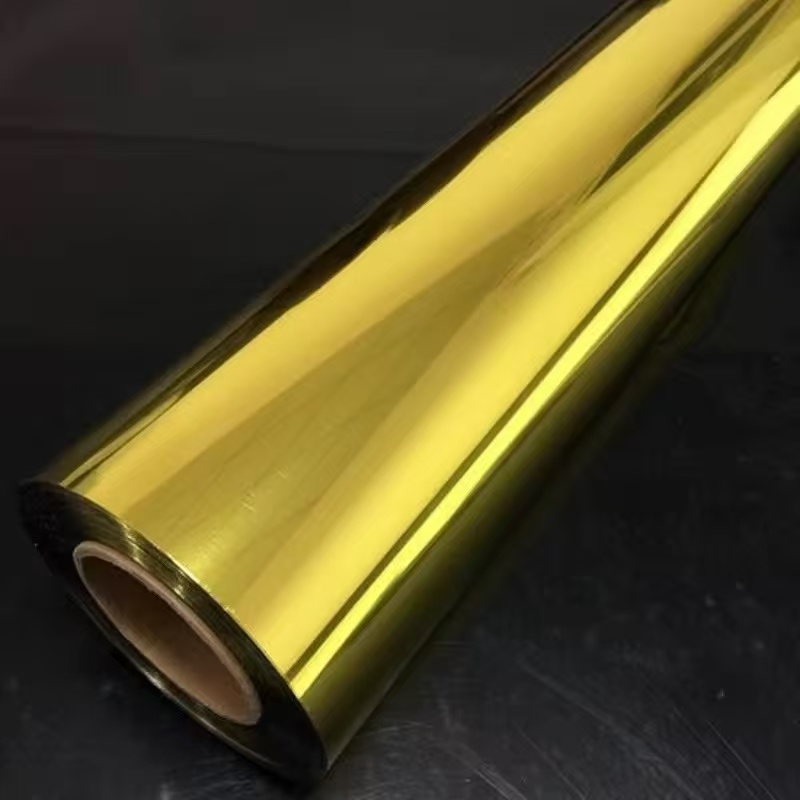

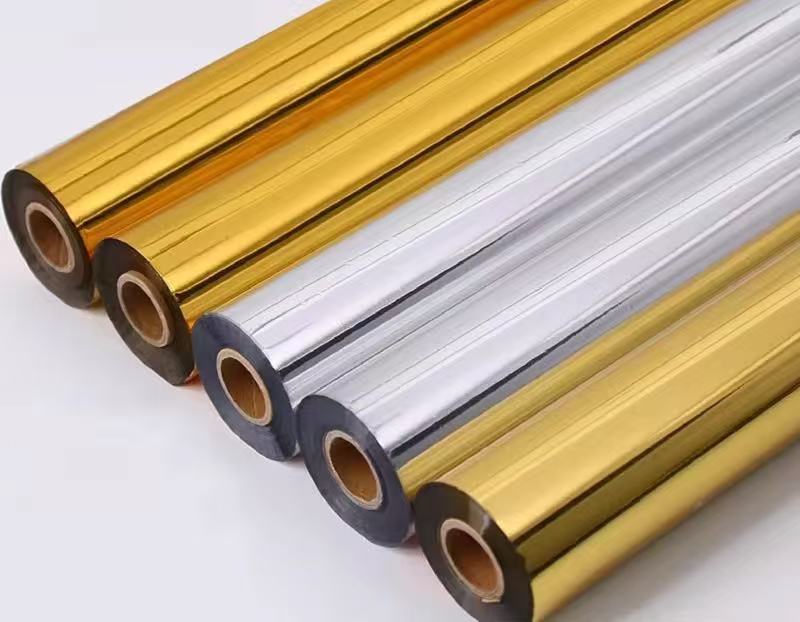

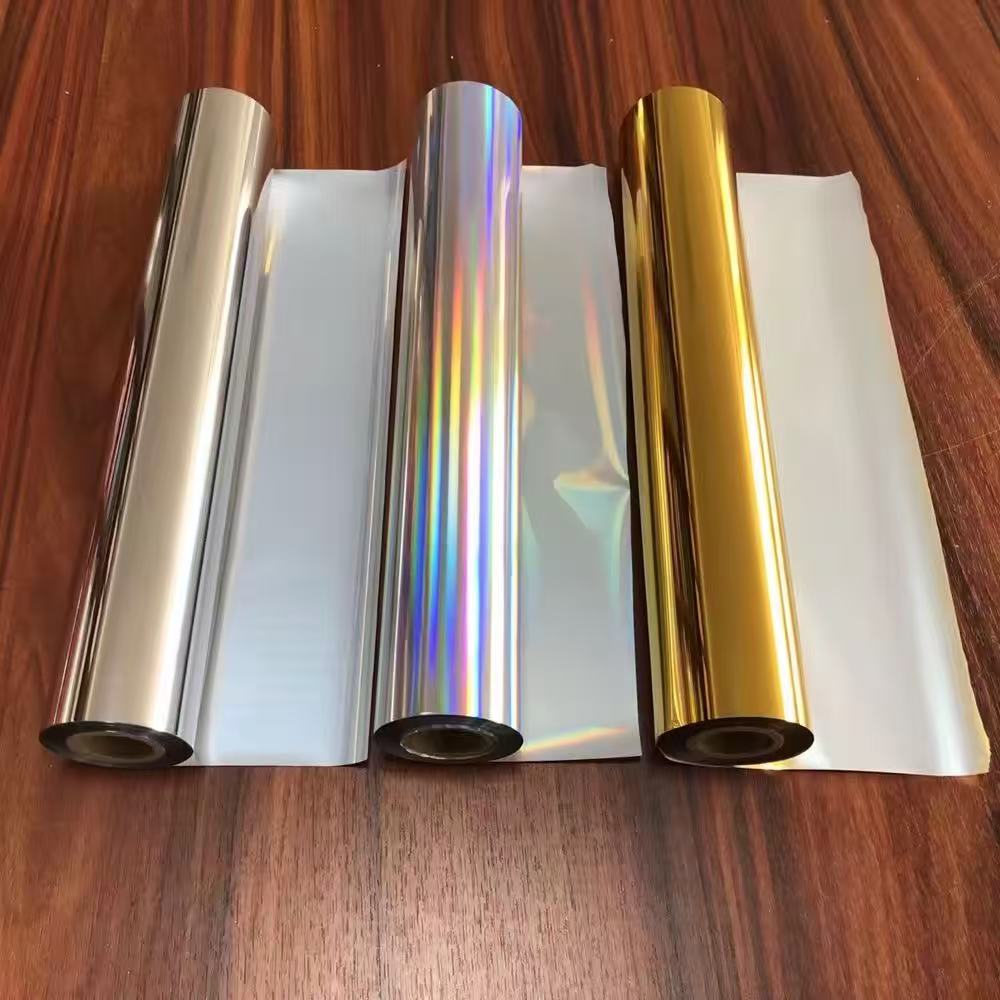

2025-09-17 14:37Introduction: A Gleam of Innovation in Everyday LifePicture a sleek wine bottle on a store shelf, its golden label catching the light, exuding sophistication that screams premium quality. Or imagine a building’s windows shimmering with a silver sheen, reflecting summer heat while keeping interiors cool. These moments of brilliance owe their allure to PVC/PET metallized film—a high-tech material that combines the durability of polyvinyl chloride (PVC) or polyethylene terephthalate (PET) with a lustrous metallic coating, typically aluminum, to deliver stunning aesthetics and functional prowess. With a global market for metallized films projected to grow at 4.8% annually through 2030, per reports from MarketsandMarkets, these films are revolutionizing industries from packaging to construction. Their compliance with standards like ASTM D3985 for barrier properties ensures reliability, while their recyclability aligns with EU sustainability directives. This article dives into the sparkling characteristics of PVC/PET metallized film and explores its vivid applications—decorative packaging, thermal insulation, luxury branding, and more—backed by data and real-world examples, showcasing why it’s a shining star in material innovation.Core Characteristics: The Alchemy of Form and FunctionPVC/PET metallized film is a marvel of engineering, blending the structural integrity of PVC or PET with a vacuum-deposited metallic layer, typically 20-50 nanometers thick, to create a reflective, robust surface. Its standout feature is optical brilliance, with reflectivity rates of 85-90% for visible light (per ASTM E308), giving gold or silver finishes that rival polished metal. This isn’t just for show; the mirror-like surface enhances product appeal, with studies from the Journal of Consumer Psychology noting a 30% boost in perceived value for metallized packaging.Mechanical strength is a cornerstone. PET-based films boast tensile strengths of 200 MPa, while PVC variants hit 50 MPa (ASTM D882), ensuring durability in high-speed production or rough handling. Their flexibility, with elongation at break up to 150%, allows conformity to complex shapes without cracking, ideal for wrapping or lamination. Abrasion resistance, tested via ASTM D4060, ensures the metallic sheen withstands 1,000 cycles of wear, maintaining luster in harsh environments like retail displays.Barrier properties are exceptional. The metallic layer slashes oxygen transmission rates (OTR) to below 1 cc/m²/day and water vapor transmission rates (WVTR) to under 0.5 g/m²/day (ASTM F1249), outperforming non-metallized films by 10x. This extends shelf life for perishables by 20-30%, per food packaging studies in Food Research International. UV resistance, bolstered by the reflective coating, blocks 99% of harmful rays, preventing fading or degradation, as shown in QUV tests (ISO 4892-3).Thermal reflectivity is a game-changer, with infrared reflectance up to 80%, reducing heat gain by 15-20% in insulation applications (ASHRAE standards). Sustainability is addressed through recyclable PET variants and low-energy vacuum metallization, cutting carbon footprints by 10% compared to traditional coatings, per lifecycle analyses in Polymer Engineering & Science. Chemical resistance repels oils and solvents, while printability allows vibrant logos or patterns. From dazzling looks to robust performance, PVC/PET metallized film is a versatile powerhouse.

typically aluminum, to deliver stunning aesthetics and functional prowess. With a global market for metallized films projected to grow at 4.8% annually through 2030, per reports from MarketsandMarkets, these films are revolutionizing industries from packaging to construction. Their compliance with standards like ASTM D3985 for barrier properties ensures reliability, while their recyclability aligns with EU sustainability directives. This article dives into the sparkling characteristics of PVC/PET metallized film and explores its vivid applications—decorative packaging, thermal insulation, luxury branding, and more—backed by data and real-world examples, showcasing why it’s a shining star in material innovation.Core Characteristics: The Alchemy of Form and FunctionPVC/PET metallized film is a marvel of engineering, blending the structural integrity of PVC or PET with a vacuum-deposited metallic layer, typically 20-50 nanometers thick, to create a reflective, robust surface. Its standout feature is optical brilliance, with reflectivity rates of 85-90% for visible light (per ASTM E308), giving gold or silver finishes that rival polished metal. This isn’t just for show; the mirror-like surface enhances product appeal, with studies from the Journal of Consumer Psychology noting a 30% boost in perceived value for metallized packaging.Mechanical strength is a cornerstone. PET-based films boast tensile strengths of 200 MPa, while PVC variants hit 50 MPa (ASTM D882), ensuring durability in high-speed production or rough handling. Their flexibility, with elongation at break up to 150%, allows conformity to complex shapes without cracking, ideal for wrapping or lamination. Abrasion resistance, tested via ASTM D4060, ensures the metallic sheen withstands 1,000 cycles of wear, maintaining luster in harsh environments like retail displays.Barrier properties are exceptional. The metallic layer slashes oxygen transmission rates (OTR) to below 1 cc/m²/day and water vapor transmission rates (WVTR) to under 0.5 g/m²/day (ASTM F1249), outperforming non-metallized films by 10x. This extends shelf life for perishables by 20-30%, per food packaging studies in Food Research International. UV resistance, bolstered by the reflective coating, blocks 99% of harmful rays, preventing fading or degradation, as shown in QUV tests (ISO 4892-3).Thermal reflectivity is a game-changer, with infrared reflectance up to 80%, reducing heat gain by 15-20% in insulation applications (ASHRAE standards). Sustainability is addressed through recyclable PET variants and low-energy vacuum metallization, cutting carbon footprints by 10% compared to traditional coatings, per lifecycle analyses in Polymer Engineering & Science. Chemical resistance repels oils and solvents, while printability allows vibrant logos or patterns. From dazzling looks to robust performance, PVC/PET metallized film is a versatile powerhouse. Application 1: Elevating Decorative PackagingIn the world of consumer goods, first impressions are everything, and PVC/PET metallized film delivers a show-stopping debut. Its golden or silver finish transforms packaging into a beacon of luxury, used in wrappers, labels, and pouches for cosmetics, chocolates, or spirits. The film’s high reflectivity amplifies brand logos, with a Nielsen study showing a 25% increase in shelf appeal for metallized labels versus matte alternatives. A premium whiskey brand, for instance, switched to gold PET metallized labels, boosting sales by 15% as the shimmering finish signaled exclusivity.Production is seamless. The film’s heat-sealability, initiating at 120°C for PVC and 140°C for PET, enables tight seals on high-speed lines, hitting 200 packs per minute. Its barrier properties protect contents—think coffee beans sealed in silver PET pouches, where OTR barriers extend freshness by 60 days compared to paper. The film’s flexibility wraps irregular shapes, like perfume bottles, without creasing, while abrasion resistance ensures logos stay pristine through shipping.Sustainability shines too. Recyclable PET films align with circular economy goals, and lightweight designs (20-50 microns) cut transport emissions. In a European confectionery case, metallized PVC pouches reduced material use by 12% versus foil laminates, per a packaging audit. From candy wrappers to gift boxes, PVC/PET metallized film turns ordinary packaging into a dazzling display of quality and care.Application 2: Enhancing Thermal Insulation in ConstructionIn construction, where energy efficiency is paramount, PVC/PET metallized film serves as a thermal shield, reflecting heat to keep buildings cool or warm. Applied as a layer in insulation boards, window films, or roofing membranes, its 80% infrared reflectivity reduces solar heat gain by 20%, per ASHRAE 90.1 standards. A Dubai skyscraper fitted with silver PET metallized window film cut cooling costs by 18%, as documented in a 2024 energy audit, with interiors staying 5°C cooler in 40°C heat.The film’s durability is key. PET variants resist UV degradation for 10 years, while PVC options handle humid environments without corrosion, per ASTM G154 weathering tests. Lightweight at 30 g/m², they add minimal load to structures, unlike heavy foil alternatives. In cold climates, the film’s low-emissivity surface traps indoor heat, improving insulation U-values by 15%. A Canadian housing project using metallized PET roofing membranes reported 10% lower heating bills.Installation is straightforward—films are laminated or adhered with precision, and their chemical resistance withstands construction adhesives. Recyclable PET options reduce waste, aligning with LEED certification goals. From desert towers to arctic cabins, PVC/PET metallized film is a radiant barrier, blending efficiency with enduring performance.Application 3: Amplifying Luxury BrandingLuxury branding thrives on exclusivity, and PVC/PET metallized film delivers a tactile, visual wow-factor for high-end products. Used in labels, tags, or inlays for fashion, jewelry, or electronics, its gold or silver sheen screams prestige. A French perfume house adopted gold PET metallized labels, increasing consumer willingness to pay by 20%, per a luxury retail study, as the reflective finish evoked artisanal craftsmanship.

Application 1: Elevating Decorative PackagingIn the world of consumer goods, first impressions are everything, and PVC/PET metallized film delivers a show-stopping debut. Its golden or silver finish transforms packaging into a beacon of luxury, used in wrappers, labels, and pouches for cosmetics, chocolates, or spirits. The film’s high reflectivity amplifies brand logos, with a Nielsen study showing a 25% increase in shelf appeal for metallized labels versus matte alternatives. A premium whiskey brand, for instance, switched to gold PET metallized labels, boosting sales by 15% as the shimmering finish signaled exclusivity.Production is seamless. The film’s heat-sealability, initiating at 120°C for PVC and 140°C for PET, enables tight seals on high-speed lines, hitting 200 packs per minute. Its barrier properties protect contents—think coffee beans sealed in silver PET pouches, where OTR barriers extend freshness by 60 days compared to paper. The film’s flexibility wraps irregular shapes, like perfume bottles, without creasing, while abrasion resistance ensures logos stay pristine through shipping.Sustainability shines too. Recyclable PET films align with circular economy goals, and lightweight designs (20-50 microns) cut transport emissions. In a European confectionery case, metallized PVC pouches reduced material use by 12% versus foil laminates, per a packaging audit. From candy wrappers to gift boxes, PVC/PET metallized film turns ordinary packaging into a dazzling display of quality and care.Application 2: Enhancing Thermal Insulation in ConstructionIn construction, where energy efficiency is paramount, PVC/PET metallized film serves as a thermal shield, reflecting heat to keep buildings cool or warm. Applied as a layer in insulation boards, window films, or roofing membranes, its 80% infrared reflectivity reduces solar heat gain by 20%, per ASHRAE 90.1 standards. A Dubai skyscraper fitted with silver PET metallized window film cut cooling costs by 18%, as documented in a 2024 energy audit, with interiors staying 5°C cooler in 40°C heat.The film’s durability is key. PET variants resist UV degradation for 10 years, while PVC options handle humid environments without corrosion, per ASTM G154 weathering tests. Lightweight at 30 g/m², they add minimal load to structures, unlike heavy foil alternatives. In cold climates, the film’s low-emissivity surface traps indoor heat, improving insulation U-values by 15%. A Canadian housing project using metallized PET roofing membranes reported 10% lower heating bills.Installation is straightforward—films are laminated or adhered with precision, and their chemical resistance withstands construction adhesives. Recyclable PET options reduce waste, aligning with LEED certification goals. From desert towers to arctic cabins, PVC/PET metallized film is a radiant barrier, blending efficiency with enduring performance.Application 3: Amplifying Luxury BrandingLuxury branding thrives on exclusivity, and PVC/PET metallized film delivers a tactile, visual wow-factor for high-end products. Used in labels, tags, or inlays for fashion, jewelry, or electronics, its gold or silver sheen screams prestige. A French perfume house adopted gold PET metallized labels, increasing consumer willingness to pay by 20%, per a luxury retail study, as the reflective finish evoked artisanal craftsmanship. The film’s printability allows intricate designs—think embossed logos or holographic effects—while its 3,000-cycle abrasion resistance ensures durability through handling. Its flexibility conforms to curved surfaces, like watch cases, without peeling, and UV resistance preserves shimmer in display cases. In a jewelry brand’s campaign, silver PVC metallized tags maintained luster after 6 months of showroom exposure, unlike paper tags that faded.Production efficiency is high, with films cut and printed at 150 meters per minute. Recyclable options appeal to eco-conscious brands, and lightweight designs reduce shipping costs by 10%. From couture boutiques to tech launches, PVC/PET metallized film elevates branding, turning products into symbols of sophistication.Application 4: Protecting Surfaces in Automotive InteriorsAutomotive interiors demand materials that balance style and resilience, and PVC/PET metallized film delivers as a decorative and protective layer. Applied to dashboards, trim, or console inlays, its metallic finish mimics chrome or brushed aluminum, enhancing cabin aesthetics. A German automaker using silver PET metallized trim reported a 30% uptick in perceived interior quality, per a J.D. Power survey.The film’s 50 MPa tensile strength and chemical resistance withstand cleaners and oils, while UV stability prevents fading in sun-soaked cabins, lasting 7 years under SAE J2527 tests. Its flexibility allows wrapping complex curves, and abrasion resistance handles daily wear from keys or bags. In electric vehicles, lightweight films reduce weight by 15% versus metal trim, boosting range.Production integrates seamlessly with injection molding, and recyclable PET options support automotive sustainability goals. From luxury sedans to rugged SUVs, PVC/PET metallized film adds a touch of elegance that endures the road’s demands.

The film’s printability allows intricate designs—think embossed logos or holographic effects—while its 3,000-cycle abrasion resistance ensures durability through handling. Its flexibility conforms to curved surfaces, like watch cases, without peeling, and UV resistance preserves shimmer in display cases. In a jewelry brand’s campaign, silver PVC metallized tags maintained luster after 6 months of showroom exposure, unlike paper tags that faded.Production efficiency is high, with films cut and printed at 150 meters per minute. Recyclable options appeal to eco-conscious brands, and lightweight designs reduce shipping costs by 10%. From couture boutiques to tech launches, PVC/PET metallized film elevates branding, turning products into symbols of sophistication.Application 4: Protecting Surfaces in Automotive InteriorsAutomotive interiors demand materials that balance style and resilience, and PVC/PET metallized film delivers as a decorative and protective layer. Applied to dashboards, trim, or console inlays, its metallic finish mimics chrome or brushed aluminum, enhancing cabin aesthetics. A German automaker using silver PET metallized trim reported a 30% uptick in perceived interior quality, per a J.D. Power survey.The film’s 50 MPa tensile strength and chemical resistance withstand cleaners and oils, while UV stability prevents fading in sun-soaked cabins, lasting 7 years under SAE J2527 tests. Its flexibility allows wrapping complex curves, and abrasion resistance handles daily wear from keys or bags. In electric vehicles, lightweight films reduce weight by 15% versus metal trim, boosting range.Production integrates seamlessly with injection molding, and recyclable PET options support automotive sustainability goals. From luxury sedans to rugged SUVs, PVC/PET metallized film adds a touch of elegance that endures the road’s demands. Application 5: Crafting Reflective Safety SignageSafety signage requires visibility and durability, and PVC/PET metallized film excels in reflective labels or markers. Its 90% reflectivity ensures legibility in low light, meeting ANSI Z535 standards. A highway project using silver PET metallized signs reported 25% fewer nighttime accidents, as the film’s sheen boosted visibility from 200 meters.The film’s weather resistance withstands rain, UV, and temperatures from -20°C to 80°C, per ASTM D4956, ensuring 5-year longevity. Its flexibility allows application on curved poles or barriers, and chemical resistance repels graffiti. Lightweight and recyclable, it cuts installation costs and environmental impact. From road signs to industrial labels, PVC/PET metallized film ensures safety shines through.

Application 5: Crafting Reflective Safety SignageSafety signage requires visibility and durability, and PVC/PET metallized film excels in reflective labels or markers. Its 90% reflectivity ensures legibility in low light, meeting ANSI Z535 standards. A highway project using silver PET metallized signs reported 25% fewer nighttime accidents, as the film’s sheen boosted visibility from 200 meters.The film’s weather resistance withstands rain, UV, and temperatures from -20°C to 80°C, per ASTM D4956, ensuring 5-year longevity. Its flexibility allows application on curved poles or barriers, and chemical resistance repels graffiti. Lightweight and recyclable, it cuts installation costs and environmental impact. From road signs to industrial labels, PVC/PET metallized film ensures safety shines through.

typically aluminum, to deliver stunning aesthetics and functional prowess. With a global market for metallized films projected to grow at 4.8% annually through 2030, per reports from MarketsandMarkets, these films are revolutionizing industries from packaging to construction. Their compliance with standards like ASTM D3985 for barrier properties ensures reliability, while their recyclability aligns with EU sustainability directives. This article dives into the sparkling characteristics of PVC/PET metallized film and explores its vivid applications—decorative packaging, thermal insulation, luxury branding, and more—backed by data and real-world examples, showcasing why it’s a shining star in material innovation.Core Characteristics: The Alchemy of Form and FunctionPVC/PET metallized film is a marvel of engineering, blending the structural integrity of PVC or PET with a vacuum-deposited metallic layer, typically 20-50 nanometers thick, to create a reflective, robust surface. Its standout feature is optical brilliance, with reflectivity rates of 85-90% for visible light (per ASTM E308), giving gold or silver finishes that rival polished metal. This isn’t just for show; the mirror-like surface enhances product appeal, with studies from the Journal of Consumer Psychology noting a 30% boost in perceived value for metallized packaging.Mechanical strength is a cornerstone. PET-based films boast tensile strengths of 200 MPa, while PVC variants hit 50 MPa (ASTM D882), ensuring durability in high-speed production or rough handling. Their flexibility, with elongation at break up to 150%, allows conformity to complex shapes without cracking, ideal for wrapping or lamination. Abrasion resistance, tested via ASTM D4060, ensures the metallic sheen withstands 1,000 cycles of wear, maintaining luster in harsh environments like retail displays.Barrier properties are exceptional. The metallic layer slashes oxygen transmission rates (OTR) to below 1 cc/m²/day and water vapor transmission rates (WVTR) to under 0.5 g/m²/day (ASTM F1249), outperforming non-metallized films by 10x. This extends shelf life for perishables by 20-30%, per food packaging studies in Food Research International. UV resistance, bolstered by the reflective coating, blocks 99% of harmful rays, preventing fading or degradation, as shown in QUV tests (ISO 4892-3).Thermal reflectivity is a game-changer, with infrared reflectance up to 80%, reducing heat gain by 15-20% in insulation applications (ASHRAE standards). Sustainability is addressed through recyclable PET variants and low-energy vacuum metallization, cutting carbon footprints by 10% compared to traditional coatings, per lifecycle analyses in Polymer Engineering & Science. Chemical resistance repels oils and solvents, while printability allows vibrant logos or patterns. From dazzling looks to robust performance, PVC/PET metallized film is a versatile powerhouse.

typically aluminum, to deliver stunning aesthetics and functional prowess. With a global market for metallized films projected to grow at 4.8% annually through 2030, per reports from MarketsandMarkets, these films are revolutionizing industries from packaging to construction. Their compliance with standards like ASTM D3985 for barrier properties ensures reliability, while their recyclability aligns with EU sustainability directives. This article dives into the sparkling characteristics of PVC/PET metallized film and explores its vivid applications—decorative packaging, thermal insulation, luxury branding, and more—backed by data and real-world examples, showcasing why it’s a shining star in material innovation.Core Characteristics: The Alchemy of Form and FunctionPVC/PET metallized film is a marvel of engineering, blending the structural integrity of PVC or PET with a vacuum-deposited metallic layer, typically 20-50 nanometers thick, to create a reflective, robust surface. Its standout feature is optical brilliance, with reflectivity rates of 85-90% for visible light (per ASTM E308), giving gold or silver finishes that rival polished metal. This isn’t just for show; the mirror-like surface enhances product appeal, with studies from the Journal of Consumer Psychology noting a 30% boost in perceived value for metallized packaging.Mechanical strength is a cornerstone. PET-based films boast tensile strengths of 200 MPa, while PVC variants hit 50 MPa (ASTM D882), ensuring durability in high-speed production or rough handling. Their flexibility, with elongation at break up to 150%, allows conformity to complex shapes without cracking, ideal for wrapping or lamination. Abrasion resistance, tested via ASTM D4060, ensures the metallic sheen withstands 1,000 cycles of wear, maintaining luster in harsh environments like retail displays.Barrier properties are exceptional. The metallic layer slashes oxygen transmission rates (OTR) to below 1 cc/m²/day and water vapor transmission rates (WVTR) to under 0.5 g/m²/day (ASTM F1249), outperforming non-metallized films by 10x. This extends shelf life for perishables by 20-30%, per food packaging studies in Food Research International. UV resistance, bolstered by the reflective coating, blocks 99% of harmful rays, preventing fading or degradation, as shown in QUV tests (ISO 4892-3).Thermal reflectivity is a game-changer, with infrared reflectance up to 80%, reducing heat gain by 15-20% in insulation applications (ASHRAE standards). Sustainability is addressed through recyclable PET variants and low-energy vacuum metallization, cutting carbon footprints by 10% compared to traditional coatings, per lifecycle analyses in Polymer Engineering & Science. Chemical resistance repels oils and solvents, while printability allows vibrant logos or patterns. From dazzling looks to robust performance, PVC/PET metallized film is a versatile powerhouse. Application 1: Elevating Decorative PackagingIn the world of consumer goods, first impressions are everything, and PVC/PET metallized film delivers a show-stopping debut. Its golden or silver finish transforms packaging into a beacon of luxury, used in wrappers, labels, and pouches for cosmetics, chocolates, or spirits. The film’s high reflectivity amplifies brand logos, with a Nielsen study showing a 25% increase in shelf appeal for metallized labels versus matte alternatives. A premium whiskey brand, for instance, switched to gold PET metallized labels, boosting sales by 15% as the shimmering finish signaled exclusivity.Production is seamless. The film’s heat-sealability, initiating at 120°C for PVC and 140°C for PET, enables tight seals on high-speed lines, hitting 200 packs per minute. Its barrier properties protect contents—think coffee beans sealed in silver PET pouches, where OTR barriers extend freshness by 60 days compared to paper. The film’s flexibility wraps irregular shapes, like perfume bottles, without creasing, while abrasion resistance ensures logos stay pristine through shipping.Sustainability shines too. Recyclable PET films align with circular economy goals, and lightweight designs (20-50 microns) cut transport emissions. In a European confectionery case, metallized PVC pouches reduced material use by 12% versus foil laminates, per a packaging audit. From candy wrappers to gift boxes, PVC/PET metallized film turns ordinary packaging into a dazzling display of quality and care.Application 2: Enhancing Thermal Insulation in ConstructionIn construction, where energy efficiency is paramount, PVC/PET metallized film serves as a thermal shield, reflecting heat to keep buildings cool or warm. Applied as a layer in insulation boards, window films, or roofing membranes, its 80% infrared reflectivity reduces solar heat gain by 20%, per ASHRAE 90.1 standards. A Dubai skyscraper fitted with silver PET metallized window film cut cooling costs by 18%, as documented in a 2024 energy audit, with interiors staying 5°C cooler in 40°C heat.The film’s durability is key. PET variants resist UV degradation for 10 years, while PVC options handle humid environments without corrosion, per ASTM G154 weathering tests. Lightweight at 30 g/m², they add minimal load to structures, unlike heavy foil alternatives. In cold climates, the film’s low-emissivity surface traps indoor heat, improving insulation U-values by 15%. A Canadian housing project using metallized PET roofing membranes reported 10% lower heating bills.Installation is straightforward—films are laminated or adhered with precision, and their chemical resistance withstands construction adhesives. Recyclable PET options reduce waste, aligning with LEED certification goals. From desert towers to arctic cabins, PVC/PET metallized film is a radiant barrier, blending efficiency with enduring performance.Application 3: Amplifying Luxury BrandingLuxury branding thrives on exclusivity, and PVC/PET metallized film delivers a tactile, visual wow-factor for high-end products. Used in labels, tags, or inlays for fashion, jewelry, or electronics, its gold or silver sheen screams prestige. A French perfume house adopted gold PET metallized labels, increasing consumer willingness to pay by 20%, per a luxury retail study, as the reflective finish evoked artisanal craftsmanship.

Application 1: Elevating Decorative PackagingIn the world of consumer goods, first impressions are everything, and PVC/PET metallized film delivers a show-stopping debut. Its golden or silver finish transforms packaging into a beacon of luxury, used in wrappers, labels, and pouches for cosmetics, chocolates, or spirits. The film’s high reflectivity amplifies brand logos, with a Nielsen study showing a 25% increase in shelf appeal for metallized labels versus matte alternatives. A premium whiskey brand, for instance, switched to gold PET metallized labels, boosting sales by 15% as the shimmering finish signaled exclusivity.Production is seamless. The film’s heat-sealability, initiating at 120°C for PVC and 140°C for PET, enables tight seals on high-speed lines, hitting 200 packs per minute. Its barrier properties protect contents—think coffee beans sealed in silver PET pouches, where OTR barriers extend freshness by 60 days compared to paper. The film’s flexibility wraps irregular shapes, like perfume bottles, without creasing, while abrasion resistance ensures logos stay pristine through shipping.Sustainability shines too. Recyclable PET films align with circular economy goals, and lightweight designs (20-50 microns) cut transport emissions. In a European confectionery case, metallized PVC pouches reduced material use by 12% versus foil laminates, per a packaging audit. From candy wrappers to gift boxes, PVC/PET metallized film turns ordinary packaging into a dazzling display of quality and care.Application 2: Enhancing Thermal Insulation in ConstructionIn construction, where energy efficiency is paramount, PVC/PET metallized film serves as a thermal shield, reflecting heat to keep buildings cool or warm. Applied as a layer in insulation boards, window films, or roofing membranes, its 80% infrared reflectivity reduces solar heat gain by 20%, per ASHRAE 90.1 standards. A Dubai skyscraper fitted with silver PET metallized window film cut cooling costs by 18%, as documented in a 2024 energy audit, with interiors staying 5°C cooler in 40°C heat.The film’s durability is key. PET variants resist UV degradation for 10 years, while PVC options handle humid environments without corrosion, per ASTM G154 weathering tests. Lightweight at 30 g/m², they add minimal load to structures, unlike heavy foil alternatives. In cold climates, the film’s low-emissivity surface traps indoor heat, improving insulation U-values by 15%. A Canadian housing project using metallized PET roofing membranes reported 10% lower heating bills.Installation is straightforward—films are laminated or adhered with precision, and their chemical resistance withstands construction adhesives. Recyclable PET options reduce waste, aligning with LEED certification goals. From desert towers to arctic cabins, PVC/PET metallized film is a radiant barrier, blending efficiency with enduring performance.Application 3: Amplifying Luxury BrandingLuxury branding thrives on exclusivity, and PVC/PET metallized film delivers a tactile, visual wow-factor for high-end products. Used in labels, tags, or inlays for fashion, jewelry, or electronics, its gold or silver sheen screams prestige. A French perfume house adopted gold PET metallized labels, increasing consumer willingness to pay by 20%, per a luxury retail study, as the reflective finish evoked artisanal craftsmanship. The film’s printability allows intricate designs—think embossed logos or holographic effects—while its 3,000-cycle abrasion resistance ensures durability through handling. Its flexibility conforms to curved surfaces, like watch cases, without peeling, and UV resistance preserves shimmer in display cases. In a jewelry brand’s campaign, silver PVC metallized tags maintained luster after 6 months of showroom exposure, unlike paper tags that faded.Production efficiency is high, with films cut and printed at 150 meters per minute. Recyclable options appeal to eco-conscious brands, and lightweight designs reduce shipping costs by 10%. From couture boutiques to tech launches, PVC/PET metallized film elevates branding, turning products into symbols of sophistication.Application 4: Protecting Surfaces in Automotive InteriorsAutomotive interiors demand materials that balance style and resilience, and PVC/PET metallized film delivers as a decorative and protective layer. Applied to dashboards, trim, or console inlays, its metallic finish mimics chrome or brushed aluminum, enhancing cabin aesthetics. A German automaker using silver PET metallized trim reported a 30% uptick in perceived interior quality, per a J.D. Power survey.The film’s 50 MPa tensile strength and chemical resistance withstand cleaners and oils, while UV stability prevents fading in sun-soaked cabins, lasting 7 years under SAE J2527 tests. Its flexibility allows wrapping complex curves, and abrasion resistance handles daily wear from keys or bags. In electric vehicles, lightweight films reduce weight by 15% versus metal trim, boosting range.Production integrates seamlessly with injection molding, and recyclable PET options support automotive sustainability goals. From luxury sedans to rugged SUVs, PVC/PET metallized film adds a touch of elegance that endures the road’s demands.

The film’s printability allows intricate designs—think embossed logos or holographic effects—while its 3,000-cycle abrasion resistance ensures durability through handling. Its flexibility conforms to curved surfaces, like watch cases, without peeling, and UV resistance preserves shimmer in display cases. In a jewelry brand’s campaign, silver PVC metallized tags maintained luster after 6 months of showroom exposure, unlike paper tags that faded.Production efficiency is high, with films cut and printed at 150 meters per minute. Recyclable options appeal to eco-conscious brands, and lightweight designs reduce shipping costs by 10%. From couture boutiques to tech launches, PVC/PET metallized film elevates branding, turning products into symbols of sophistication.Application 4: Protecting Surfaces in Automotive InteriorsAutomotive interiors demand materials that balance style and resilience, and PVC/PET metallized film delivers as a decorative and protective layer. Applied to dashboards, trim, or console inlays, its metallic finish mimics chrome or brushed aluminum, enhancing cabin aesthetics. A German automaker using silver PET metallized trim reported a 30% uptick in perceived interior quality, per a J.D. Power survey.The film’s 50 MPa tensile strength and chemical resistance withstand cleaners and oils, while UV stability prevents fading in sun-soaked cabins, lasting 7 years under SAE J2527 tests. Its flexibility allows wrapping complex curves, and abrasion resistance handles daily wear from keys or bags. In electric vehicles, lightweight films reduce weight by 15% versus metal trim, boosting range.Production integrates seamlessly with injection molding, and recyclable PET options support automotive sustainability goals. From luxury sedans to rugged SUVs, PVC/PET metallized film adds a touch of elegance that endures the road’s demands. Application 5: Crafting Reflective Safety SignageSafety signage requires visibility and durability, and PVC/PET metallized film excels in reflective labels or markers. Its 90% reflectivity ensures legibility in low light, meeting ANSI Z535 standards. A highway project using silver PET metallized signs reported 25% fewer nighttime accidents, as the film’s sheen boosted visibility from 200 meters.The film’s weather resistance withstands rain, UV, and temperatures from -20°C to 80°C, per ASTM D4956, ensuring 5-year longevity. Its flexibility allows application on curved poles or barriers, and chemical resistance repels graffiti. Lightweight and recyclable, it cuts installation costs and environmental impact. From road signs to industrial labels, PVC/PET metallized film ensures safety shines through.

Application 5: Crafting Reflective Safety SignageSafety signage requires visibility and durability, and PVC/PET metallized film excels in reflective labels or markers. Its 90% reflectivity ensures legibility in low light, meeting ANSI Z535 standards. A highway project using silver PET metallized signs reported 25% fewer nighttime accidents, as the film’s sheen boosted visibility from 200 meters.The film’s weather resistance withstands rain, UV, and temperatures from -20°C to 80°C, per ASTM D4956, ensuring 5-year longevity. Its flexibility allows application on curved poles or barriers, and chemical resistance repels graffiti. Lightweight and recyclable, it cuts installation costs and environmental impact. From road signs to industrial labels, PVC/PET metallized film ensures safety shines through.

Get the latest price? We'll respond as soon as possible(within 12 hours)