Transparent PVC Film: The Heat- and UV-Resistant Champion of Versatile Applications

2025-09-23 17:40IntroductionImagine a bustling outdoor market under a blazing Mediterranean sun, where vibrant vinyl banners flutter without fading, their crystal-clear surfaces showcasing vivid logos untouched by UV rays. Or picture a sterile hospital room, where a transparent curtain withstands scalding sterilization processes while shielding patients from prying eyes. These are the realms of High-Temperature, UV-Resistant Transparent PVC Film—a marvel of polymer science that combines the flexibility of polyvinyl chloride (PVC) with exceptional resilience against heat and ultraviolet degradation. Synthesized from vinyl chloride monomers, this film is engineered with plasticizers, thermal stabilizers, and UV absorbers to endure temperatures up to 80°C and block harmful UV radiation, all while maintaining optical clarity comparable to glass. PVC, with a global market exceeding $45 billion in 2025, is a cornerstone of industries ranging from packaging to medical applications, driven by its affordability and adaptability. Transparent, heat- and UV-resistant variants elevate its utility, offering tensile strengths around 50 MPa and light transmittance above 85%, making them indispensable in environments where durability meets visibility. From food wraps to greenhouse covers, this film balances performance with practicality, backed by decades of materials research and real-world testing. In this exploration, we’ll delve into the defining characteristics of High-Temperature, UV-Resistant Transparent PVC Film and its transformative applications, brought to life with vivid scenarios and grounded in scientific evidence.

PVC, with a global market exceeding $45 billion in 2025, is a cornerstone of industries ranging from packaging to medical applications, driven by its affordability and adaptability. Transparent, heat- and UV-resistant variants elevate its utility, offering tensile strengths around 50 MPa and light transmittance above 85%, making them indispensable in environments where durability meets visibility. From food wraps to greenhouse covers, this film balances performance with practicality, backed by decades of materials research and real-world testing. In this exploration, we’ll delve into the defining characteristics of High-Temperature, UV-Resistant Transparent PVC Film and its transformative applications, brought to life with vivid scenarios and grounded in scientific evidence. Key Characteristics of High-Temperature, UV-Resistant Transparent PVC FilmTransparent PVC Film is a thermoplastic marvel, its amorphous structure granting flexibility and toughness. With a density of 1.35–1.45 g/cm³, it’s slightly denser than PET but far lighter than glass, reducing shipping costs by up to 12% in logistics-heavy sectors. Its tensile strength, ranging from 40–60 MPa, allows films as thin as 20–100 µm to resist punctures and tears, with elongation at break reaching 100–200% for stretchy resilience. This flexibility stems from plasticizers like dioctyl phthalate (DOP), which soften rigid PVC into pliable sheets.Thermal stability is a defining trait. Standard PVC softens at 60°C, but high-temperature grades, stabilized with organotin or calcium-zinc compounds, withstand 80–100°C without warping or losing clarity, as validated by studies in Polymer Testing. Its glass transition temperature (Tg) of 80–85°C ensures dimensional stability, with shrinkage below 2% at 70°C, ideal for hot-fill or sterilization processes. UV resistance is achieved through absorbers like benzophenones, blocking 90–95% of UV-A and UV-B rays (280–400 nm), maintaining transparency (85–90%) after 1,500 hours of UV exposure per ASTM G155 standards.

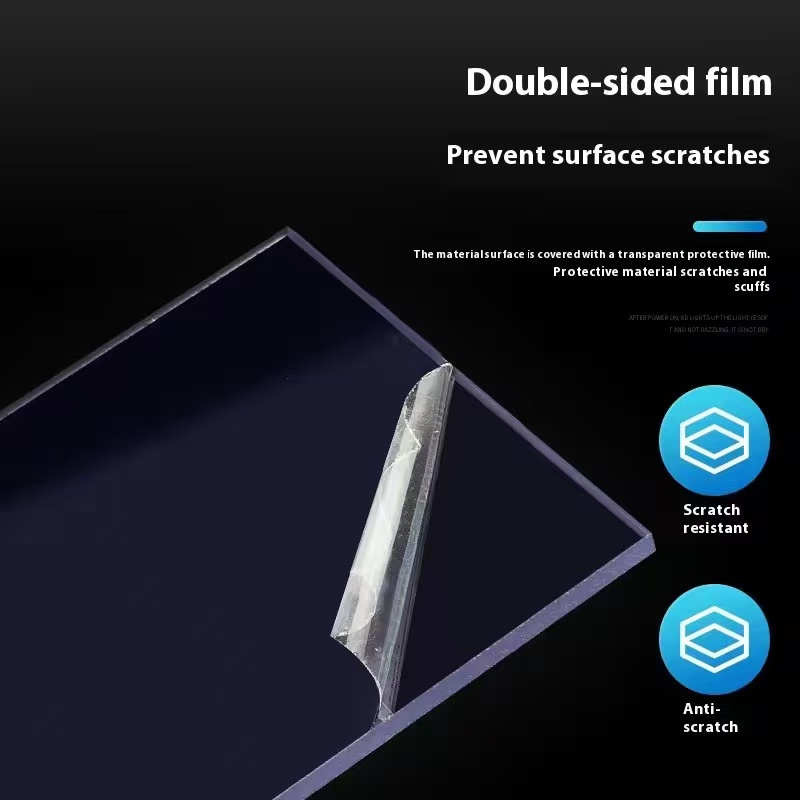

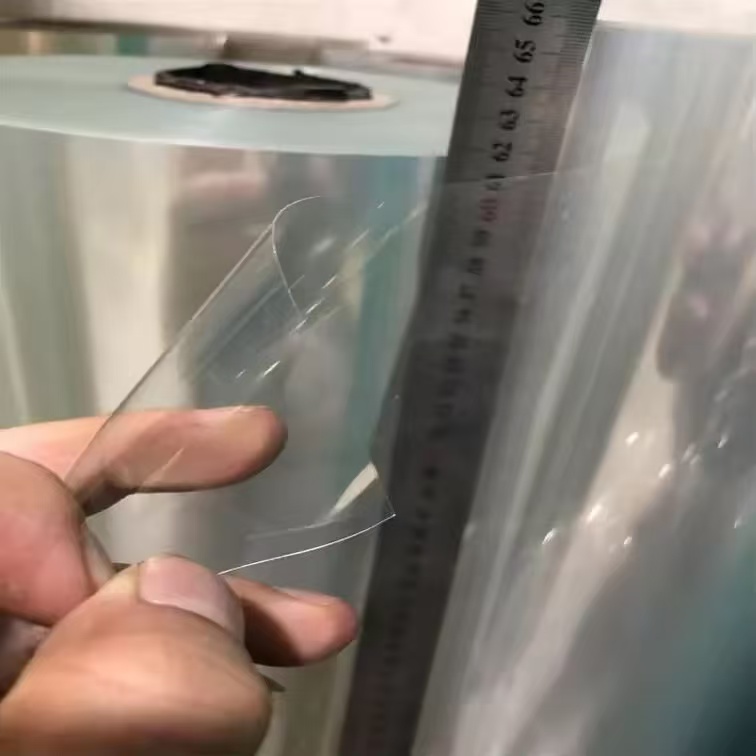

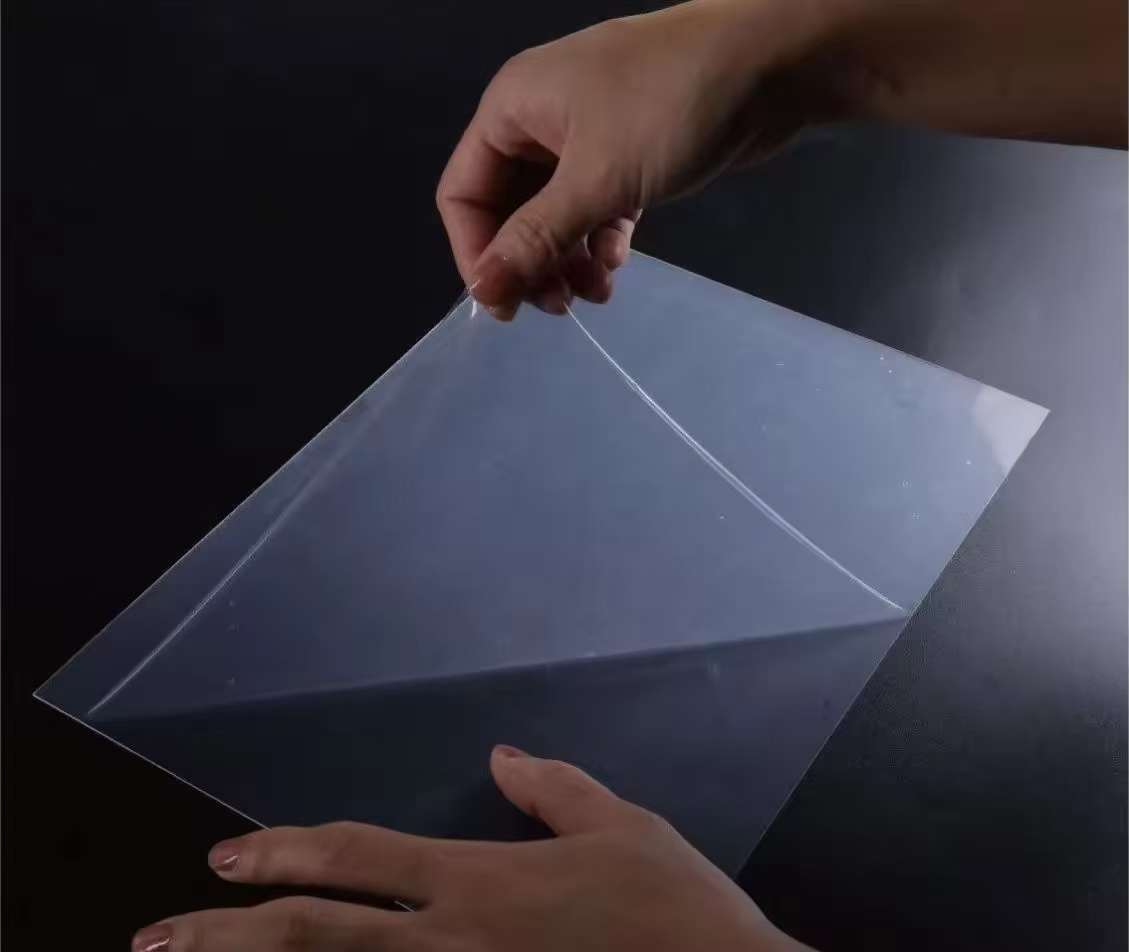

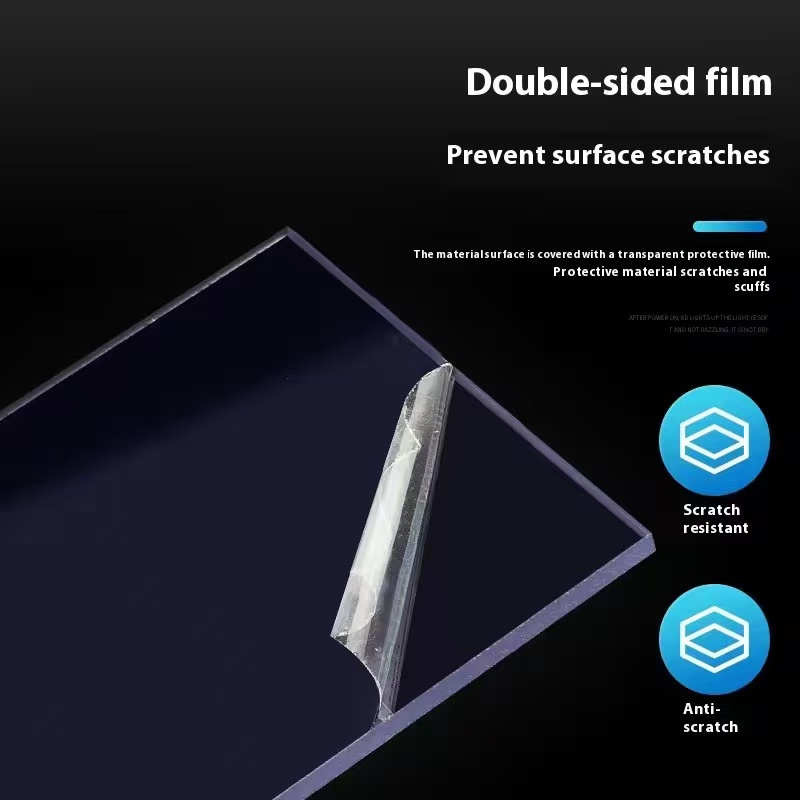

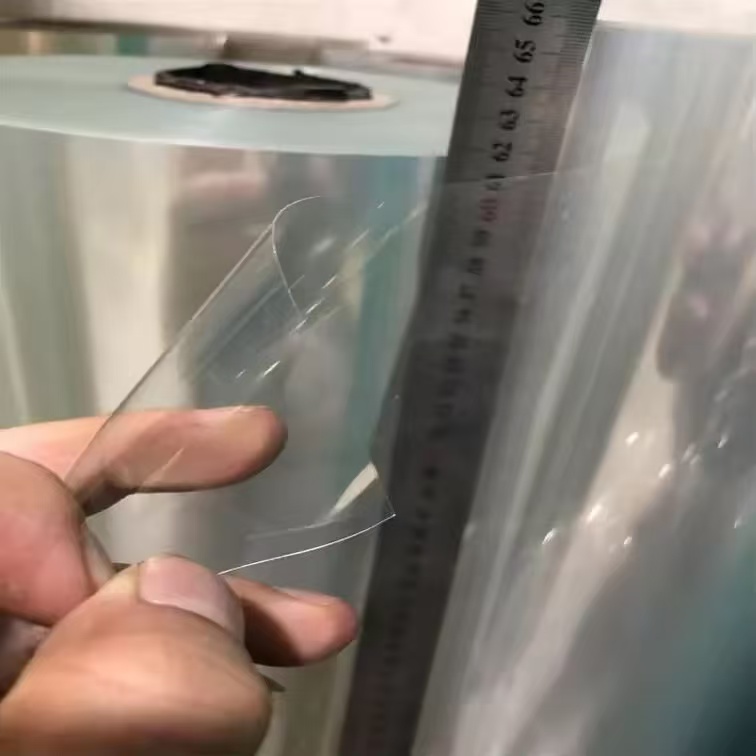

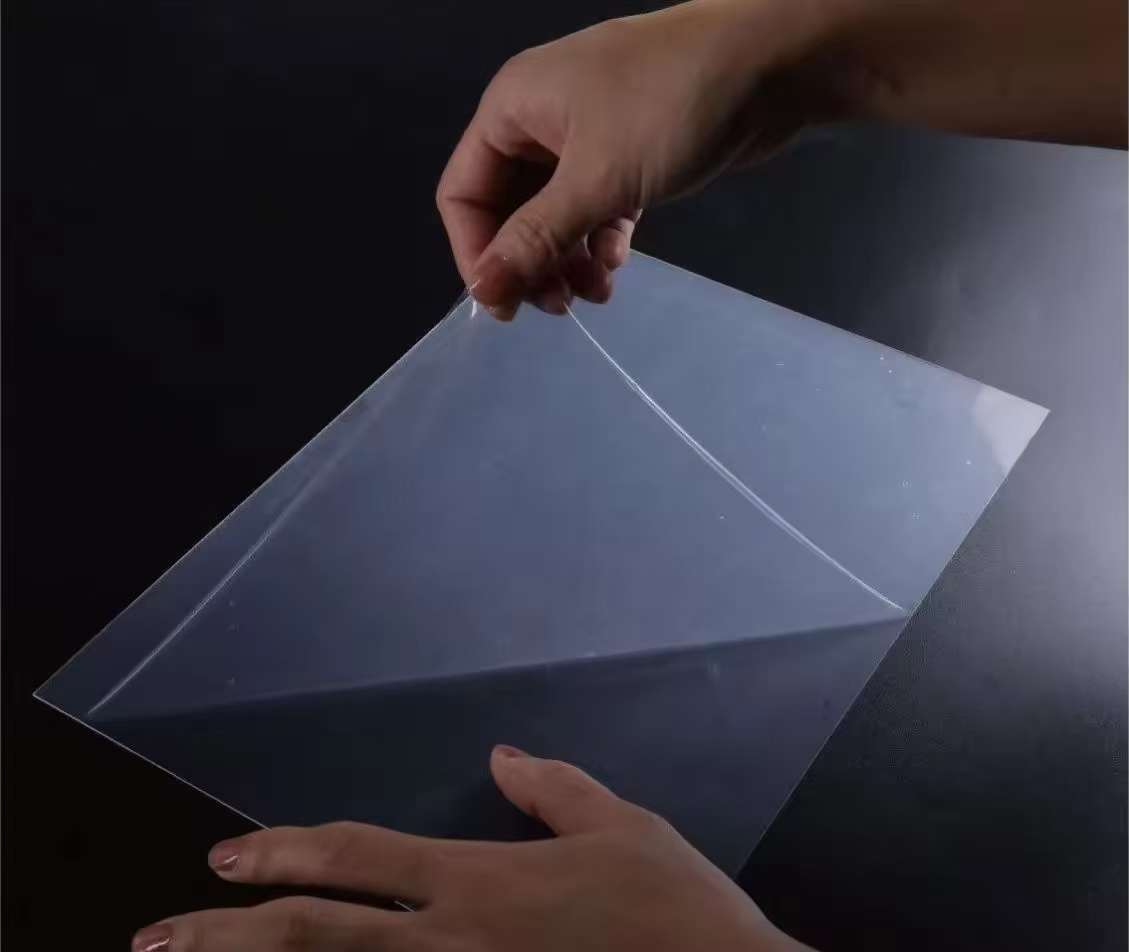

Key Characteristics of High-Temperature, UV-Resistant Transparent PVC FilmTransparent PVC Film is a thermoplastic marvel, its amorphous structure granting flexibility and toughness. With a density of 1.35–1.45 g/cm³, it’s slightly denser than PET but far lighter than glass, reducing shipping costs by up to 12% in logistics-heavy sectors. Its tensile strength, ranging from 40–60 MPa, allows films as thin as 20–100 µm to resist punctures and tears, with elongation at break reaching 100–200% for stretchy resilience. This flexibility stems from plasticizers like dioctyl phthalate (DOP), which soften rigid PVC into pliable sheets.Thermal stability is a defining trait. Standard PVC softens at 60°C, but high-temperature grades, stabilized with organotin or calcium-zinc compounds, withstand 80–100°C without warping or losing clarity, as validated by studies in Polymer Testing. Its glass transition temperature (Tg) of 80–85°C ensures dimensional stability, with shrinkage below 2% at 70°C, ideal for hot-fill or sterilization processes. UV resistance is achieved through absorbers like benzophenones, blocking 90–95% of UV-A and UV-B rays (280–400 nm), maintaining transparency (85–90%) after 1,500 hours of UV exposure per ASTM G155 standards. Optically, PVC Film shines with light transmittance of 85–90% and haze below 2%, rivaling PET for clarity. Its refractive index (1.52–1.54) minimizes distortion, perfect for display covers. Chemically, it resists water (absorption <0.2%), oils, and mild acids, with a water vapor transmission rate (WVTR) of 10–20 g/m²/day, offering moderate barrier properties. Electrically, its dielectric strength (20–40 kV/mm) supports insulation applications, while surface treatments like plasma coating enhance printability for vibrant graphics.Economically, PVC Film is a budget-friendly choice, costing $1.5–3/kg, cheaper than PET, with production scalability driving its dominance in a $10 billion flexible film market. While recyclability lags (global rate ~15%), advances in chemical recycling recover 80% of monomers, per the Journal of Cleaner Production. Safety-wise, migration of plasticizers is below 0.1 mg/kg, meeting FDA and EFSA standards for food contact. These properties make PVC Film a versatile warrior in high-stakes settings.

Optically, PVC Film shines with light transmittance of 85–90% and haze below 2%, rivaling PET for clarity. Its refractive index (1.52–1.54) minimizes distortion, perfect for display covers. Chemically, it resists water (absorption <0.2%), oils, and mild acids, with a water vapor transmission rate (WVTR) of 10–20 g/m²/day, offering moderate barrier properties. Electrically, its dielectric strength (20–40 kV/mm) supports insulation applications, while surface treatments like plasma coating enhance printability for vibrant graphics.Economically, PVC Film is a budget-friendly choice, costing $1.5–3/kg, cheaper than PET, with production scalability driving its dominance in a $10 billion flexible film market. While recyclability lags (global rate ~15%), advances in chemical recycling recover 80% of monomers, per the Journal of Cleaner Production. Safety-wise, migration of plasticizers is below 0.1 mg/kg, meeting FDA and EFSA standards for food contact. These properties make PVC Film a versatile warrior in high-stakes settings. Applications in Food PackagingIn food packaging, High-Temperature, UV-Resistant Transparent PVC Film is a go-to for clarity and protection. Picture a supermarket in Tokyo: PVC cling film wraps sushi trays, its clarity (88% transmittance) showcasing vibrant tuna slices while UV resistance prevents discoloration under store lights. Its oxygen transmission rate (OTR) of 100–200 cm³/m²/day allows controlled respiration for produce like strawberries, extending shelf life by 5–7 days, per Food Packaging and Shelf Life. The film’s flexibility (elongation ~150%) ensures a snug fit, preventing leaks during transport.For hot-fill applications, like sauces bottled at 70°C, PVC Film’s thermal stability prevents deformation, and its moderate WVTR keeps contents from drying out. In delis, thermoformed PVC trays hold cheeses, their puncture resistance (10–15 N) withstanding stacking in refrigerated displays. PVC holds a 25% share of the $50 billion food packaging market, driven by its low cost and printability, which supports vibrant labels via gravure printing. However, its gas barrier is weaker than PET, often requiring lamination with EVOH for high-barrier needs, as seen in vacuum-packed meats.

Applications in Food PackagingIn food packaging, High-Temperature, UV-Resistant Transparent PVC Film is a go-to for clarity and protection. Picture a supermarket in Tokyo: PVC cling film wraps sushi trays, its clarity (88% transmittance) showcasing vibrant tuna slices while UV resistance prevents discoloration under store lights. Its oxygen transmission rate (OTR) of 100–200 cm³/m²/day allows controlled respiration for produce like strawberries, extending shelf life by 5–7 days, per Food Packaging and Shelf Life. The film’s flexibility (elongation ~150%) ensures a snug fit, preventing leaks during transport.For hot-fill applications, like sauces bottled at 70°C, PVC Film’s thermal stability prevents deformation, and its moderate WVTR keeps contents from drying out. In delis, thermoformed PVC trays hold cheeses, their puncture resistance (10–15 N) withstanding stacking in refrigerated displays. PVC holds a 25% share of the $50 billion food packaging market, driven by its low cost and printability, which supports vibrant labels via gravure printing. However, its gas barrier is weaker than PET, often requiring lamination with EVOH for high-barrier needs, as seen in vacuum-packed meats. Applications in Medical and Pharmaceutical PackagingIn medical settings, Transparent PVC Film’s sterilizability and clarity are critical. Imagine a hospital in Berlin: PVC Film forms blister packs for tablets, thermoformed at 80°C to create precise cavities that withstand ethylene oxide sterilization without clouding. Its UV resistance protects light-sensitive drugs like ibuprofen, retaining 90% clarity after 1,000 hours of UV exposure, per ISO 10993 testing. With leachables below 0.05 mg/kg, it meets USP Class VI standards for biocompatibility, ideal for IV bags or catheter packaging.PVC curtains in operating rooms leverage its heat resistance to endure steam cleaning at 70°C, while its flexibility allows easy folding. The global medical PVC market is projected to reach $3 billion by 2026, driven by its affordability and compliance with stringent regulations. Challenges include plasticizer migration concerns, but non-phthalate alternatives like DINCH ensure safety, as validated by Biomaterials studies.Applications in Outdoor and Industrial UsesIn outdoor settings, High-Temperature, UV-Resistant Transparent PVC Film thrives under harsh conditions. Envision a vineyard in Australia: PVC greenhouse films transmit 85% of photosynthetically active radiation (PAR) while blocking 95% of UV-B, boosting grape yields by 10% while resisting cracking in 40°C heat, per Horticulture Science. Its tensile strength (50 MPa) withstands wind gusts up to 100 km/h, and its UV stability prevents yellowing for 3–5 years.In advertising, PVC banners in Times Square resist UV fading, maintaining vibrant graphics under 1,200 W/m² sunlight. Their flexibility allows easy rolling for transport, and surface treatments ensure ink adhesion for 2-year outdoor durability. In construction, PVC Film serves as a vapor barrier in roofing, its heat resistance supporting hot asphalt application at 80°C, reducing energy loss by 8% in cold climates. The industrial PVC film market, valued at $2 billion, grows with demand for durable, transparent coatings.Applications in Electronics and Protective LayersIn electronics, Transparent PVC Film protects components and displays. Picture a factory in Taiwan: PVC Film, coated with antistatic agents, achieves surface resistivity of 10^8–10^10 ohms/sq, shielding touchscreens from static damage during assembly. Its heat resistance supports lamination at 75°C, and its clarity ensures no distortion in optical sensors. For outdoor electronics, like ATMs in Dubai, UV-resistant PVC covers maintain 85% transparency after 2 years, per accelerated weathering tests. Its dielectric strength makes it ideal for cable insulation, enduring 30 kV/mm without breakdown.

Applications in Medical and Pharmaceutical PackagingIn medical settings, Transparent PVC Film’s sterilizability and clarity are critical. Imagine a hospital in Berlin: PVC Film forms blister packs for tablets, thermoformed at 80°C to create precise cavities that withstand ethylene oxide sterilization without clouding. Its UV resistance protects light-sensitive drugs like ibuprofen, retaining 90% clarity after 1,000 hours of UV exposure, per ISO 10993 testing. With leachables below 0.05 mg/kg, it meets USP Class VI standards for biocompatibility, ideal for IV bags or catheter packaging.PVC curtains in operating rooms leverage its heat resistance to endure steam cleaning at 70°C, while its flexibility allows easy folding. The global medical PVC market is projected to reach $3 billion by 2026, driven by its affordability and compliance with stringent regulations. Challenges include plasticizer migration concerns, but non-phthalate alternatives like DINCH ensure safety, as validated by Biomaterials studies.Applications in Outdoor and Industrial UsesIn outdoor settings, High-Temperature, UV-Resistant Transparent PVC Film thrives under harsh conditions. Envision a vineyard in Australia: PVC greenhouse films transmit 85% of photosynthetically active radiation (PAR) while blocking 95% of UV-B, boosting grape yields by 10% while resisting cracking in 40°C heat, per Horticulture Science. Its tensile strength (50 MPa) withstands wind gusts up to 100 km/h, and its UV stability prevents yellowing for 3–5 years.In advertising, PVC banners in Times Square resist UV fading, maintaining vibrant graphics under 1,200 W/m² sunlight. Their flexibility allows easy rolling for transport, and surface treatments ensure ink adhesion for 2-year outdoor durability. In construction, PVC Film serves as a vapor barrier in roofing, its heat resistance supporting hot asphalt application at 80°C, reducing energy loss by 8% in cold climates. The industrial PVC film market, valued at $2 billion, grows with demand for durable, transparent coatings.Applications in Electronics and Protective LayersIn electronics, Transparent PVC Film protects components and displays. Picture a factory in Taiwan: PVC Film, coated with antistatic agents, achieves surface resistivity of 10^8–10^10 ohms/sq, shielding touchscreens from static damage during assembly. Its heat resistance supports lamination at 75°C, and its clarity ensures no distortion in optical sensors. For outdoor electronics, like ATMs in Dubai, UV-resistant PVC covers maintain 85% transparency after 2 years, per accelerated weathering tests. Its dielectric strength makes it ideal for cable insulation, enduring 30 kV/mm without breakdown. Sustainability and ChallengesSustainability is a critical concern for PVC Film. While recyclable, its global recycling rate is low (~15%), hindered by plasticizer complexity. Advances in chemical recycling, like depolymerization, recover 70% of vinyl chloride, reducing virgin material use by 30%. Environmental concerns over chlorine content spur bio-based plasticizers, aligning with EU regulations. Cost-wise, UV-resistant PVC is 10% pricier than standard grades but offsets this with longevity, lasting 2–3 times longer than non-treated films in outdoor use.

Sustainability and ChallengesSustainability is a critical concern for PVC Film. While recyclable, its global recycling rate is low (~15%), hindered by plasticizer complexity. Advances in chemical recycling, like depolymerization, recover 70% of vinyl chloride, reducing virgin material use by 30%. Environmental concerns over chlorine content spur bio-based plasticizers, aligning with EU regulations. Cost-wise, UV-resistant PVC is 10% pricier than standard grades but offsets this with longevity, lasting 2–3 times longer than non-treated films in outdoor use. ConclusionHigh-Temperature, UV-Resistant Transparent PVC Film is a dynamic force, blending clarity, flexibility, and resilience to conquer diverse challenges. From preserving sushi’s freshness to shielding crops from UV rays, it proves its worth in demanding environments, backed by rigorous science and practical triumphs. As sustainability innovations close the recycling gap, PVC Film remains a clear, cost-effective solution, illuminating the path to a durable, vibrant future.

ConclusionHigh-Temperature, UV-Resistant Transparent PVC Film is a dynamic force, blending clarity, flexibility, and resilience to conquer diverse challenges. From preserving sushi’s freshness to shielding crops from UV rays, it proves its worth in demanding environments, backed by rigorous science and practical triumphs. As sustainability innovations close the recycling gap, PVC Film remains a clear, cost-effective solution, illuminating the path to a durable, vibrant future.

PVC, with a global market exceeding $45 billion in 2025, is a cornerstone of industries ranging from packaging to medical applications, driven by its affordability and adaptability. Transparent, heat- and UV-resistant variants elevate its utility, offering tensile strengths around 50 MPa and light transmittance above 85%, making them indispensable in environments where durability meets visibility. From food wraps to greenhouse covers, this film balances performance with practicality, backed by decades of materials research and real-world testing. In this exploration, we’ll delve into the defining characteristics of High-Temperature, UV-Resistant Transparent PVC Film and its transformative applications, brought to life with vivid scenarios and grounded in scientific evidence.

PVC, with a global market exceeding $45 billion in 2025, is a cornerstone of industries ranging from packaging to medical applications, driven by its affordability and adaptability. Transparent, heat- and UV-resistant variants elevate its utility, offering tensile strengths around 50 MPa and light transmittance above 85%, making them indispensable in environments where durability meets visibility. From food wraps to greenhouse covers, this film balances performance with practicality, backed by decades of materials research and real-world testing. In this exploration, we’ll delve into the defining characteristics of High-Temperature, UV-Resistant Transparent PVC Film and its transformative applications, brought to life with vivid scenarios and grounded in scientific evidence. Key Characteristics of High-Temperature, UV-Resistant Transparent PVC FilmTransparent PVC Film is a thermoplastic marvel, its amorphous structure granting flexibility and toughness. With a density of 1.35–1.45 g/cm³, it’s slightly denser than PET but far lighter than glass, reducing shipping costs by up to 12% in logistics-heavy sectors. Its tensile strength, ranging from 40–60 MPa, allows films as thin as 20–100 µm to resist punctures and tears, with elongation at break reaching 100–200% for stretchy resilience. This flexibility stems from plasticizers like dioctyl phthalate (DOP), which soften rigid PVC into pliable sheets.Thermal stability is a defining trait. Standard PVC softens at 60°C, but high-temperature grades, stabilized with organotin or calcium-zinc compounds, withstand 80–100°C without warping or losing clarity, as validated by studies in Polymer Testing. Its glass transition temperature (Tg) of 80–85°C ensures dimensional stability, with shrinkage below 2% at 70°C, ideal for hot-fill or sterilization processes. UV resistance is achieved through absorbers like benzophenones, blocking 90–95% of UV-A and UV-B rays (280–400 nm), maintaining transparency (85–90%) after 1,500 hours of UV exposure per ASTM G155 standards.

Key Characteristics of High-Temperature, UV-Resistant Transparent PVC FilmTransparent PVC Film is a thermoplastic marvel, its amorphous structure granting flexibility and toughness. With a density of 1.35–1.45 g/cm³, it’s slightly denser than PET but far lighter than glass, reducing shipping costs by up to 12% in logistics-heavy sectors. Its tensile strength, ranging from 40–60 MPa, allows films as thin as 20–100 µm to resist punctures and tears, with elongation at break reaching 100–200% for stretchy resilience. This flexibility stems from plasticizers like dioctyl phthalate (DOP), which soften rigid PVC into pliable sheets.Thermal stability is a defining trait. Standard PVC softens at 60°C, but high-temperature grades, stabilized with organotin or calcium-zinc compounds, withstand 80–100°C without warping or losing clarity, as validated by studies in Polymer Testing. Its glass transition temperature (Tg) of 80–85°C ensures dimensional stability, with shrinkage below 2% at 70°C, ideal for hot-fill or sterilization processes. UV resistance is achieved through absorbers like benzophenones, blocking 90–95% of UV-A and UV-B rays (280–400 nm), maintaining transparency (85–90%) after 1,500 hours of UV exposure per ASTM G155 standards. Optically, PVC Film shines with light transmittance of 85–90% and haze below 2%, rivaling PET for clarity. Its refractive index (1.52–1.54) minimizes distortion, perfect for display covers. Chemically, it resists water (absorption <0.2%), oils, and mild acids, with a water vapor transmission rate (WVTR) of 10–20 g/m²/day, offering moderate barrier properties. Electrically, its dielectric strength (20–40 kV/mm) supports insulation applications, while surface treatments like plasma coating enhance printability for vibrant graphics.Economically, PVC Film is a budget-friendly choice, costing $1.5–3/kg, cheaper than PET, with production scalability driving its dominance in a $10 billion flexible film market. While recyclability lags (global rate ~15%), advances in chemical recycling recover 80% of monomers, per the Journal of Cleaner Production. Safety-wise, migration of plasticizers is below 0.1 mg/kg, meeting FDA and EFSA standards for food contact. These properties make PVC Film a versatile warrior in high-stakes settings.

Optically, PVC Film shines with light transmittance of 85–90% and haze below 2%, rivaling PET for clarity. Its refractive index (1.52–1.54) minimizes distortion, perfect for display covers. Chemically, it resists water (absorption <0.2%), oils, and mild acids, with a water vapor transmission rate (WVTR) of 10–20 g/m²/day, offering moderate barrier properties. Electrically, its dielectric strength (20–40 kV/mm) supports insulation applications, while surface treatments like plasma coating enhance printability for vibrant graphics.Economically, PVC Film is a budget-friendly choice, costing $1.5–3/kg, cheaper than PET, with production scalability driving its dominance in a $10 billion flexible film market. While recyclability lags (global rate ~15%), advances in chemical recycling recover 80% of monomers, per the Journal of Cleaner Production. Safety-wise, migration of plasticizers is below 0.1 mg/kg, meeting FDA and EFSA standards for food contact. These properties make PVC Film a versatile warrior in high-stakes settings. Applications in Food PackagingIn food packaging, High-Temperature, UV-Resistant Transparent PVC Film is a go-to for clarity and protection. Picture a supermarket in Tokyo: PVC cling film wraps sushi trays, its clarity (88% transmittance) showcasing vibrant tuna slices while UV resistance prevents discoloration under store lights. Its oxygen transmission rate (OTR) of 100–200 cm³/m²/day allows controlled respiration for produce like strawberries, extending shelf life by 5–7 days, per Food Packaging and Shelf Life. The film’s flexibility (elongation ~150%) ensures a snug fit, preventing leaks during transport.For hot-fill applications, like sauces bottled at 70°C, PVC Film’s thermal stability prevents deformation, and its moderate WVTR keeps contents from drying out. In delis, thermoformed PVC trays hold cheeses, their puncture resistance (10–15 N) withstanding stacking in refrigerated displays. PVC holds a 25% share of the $50 billion food packaging market, driven by its low cost and printability, which supports vibrant labels via gravure printing. However, its gas barrier is weaker than PET, often requiring lamination with EVOH for high-barrier needs, as seen in vacuum-packed meats.

Applications in Food PackagingIn food packaging, High-Temperature, UV-Resistant Transparent PVC Film is a go-to for clarity and protection. Picture a supermarket in Tokyo: PVC cling film wraps sushi trays, its clarity (88% transmittance) showcasing vibrant tuna slices while UV resistance prevents discoloration under store lights. Its oxygen transmission rate (OTR) of 100–200 cm³/m²/day allows controlled respiration for produce like strawberries, extending shelf life by 5–7 days, per Food Packaging and Shelf Life. The film’s flexibility (elongation ~150%) ensures a snug fit, preventing leaks during transport.For hot-fill applications, like sauces bottled at 70°C, PVC Film’s thermal stability prevents deformation, and its moderate WVTR keeps contents from drying out. In delis, thermoformed PVC trays hold cheeses, their puncture resistance (10–15 N) withstanding stacking in refrigerated displays. PVC holds a 25% share of the $50 billion food packaging market, driven by its low cost and printability, which supports vibrant labels via gravure printing. However, its gas barrier is weaker than PET, often requiring lamination with EVOH for high-barrier needs, as seen in vacuum-packed meats. Applications in Medical and Pharmaceutical PackagingIn medical settings, Transparent PVC Film’s sterilizability and clarity are critical. Imagine a hospital in Berlin: PVC Film forms blister packs for tablets, thermoformed at 80°C to create precise cavities that withstand ethylene oxide sterilization without clouding. Its UV resistance protects light-sensitive drugs like ibuprofen, retaining 90% clarity after 1,000 hours of UV exposure, per ISO 10993 testing. With leachables below 0.05 mg/kg, it meets USP Class VI standards for biocompatibility, ideal for IV bags or catheter packaging.PVC curtains in operating rooms leverage its heat resistance to endure steam cleaning at 70°C, while its flexibility allows easy folding. The global medical PVC market is projected to reach $3 billion by 2026, driven by its affordability and compliance with stringent regulations. Challenges include plasticizer migration concerns, but non-phthalate alternatives like DINCH ensure safety, as validated by Biomaterials studies.Applications in Outdoor and Industrial UsesIn outdoor settings, High-Temperature, UV-Resistant Transparent PVC Film thrives under harsh conditions. Envision a vineyard in Australia: PVC greenhouse films transmit 85% of photosynthetically active radiation (PAR) while blocking 95% of UV-B, boosting grape yields by 10% while resisting cracking in 40°C heat, per Horticulture Science. Its tensile strength (50 MPa) withstands wind gusts up to 100 km/h, and its UV stability prevents yellowing for 3–5 years.In advertising, PVC banners in Times Square resist UV fading, maintaining vibrant graphics under 1,200 W/m² sunlight. Their flexibility allows easy rolling for transport, and surface treatments ensure ink adhesion for 2-year outdoor durability. In construction, PVC Film serves as a vapor barrier in roofing, its heat resistance supporting hot asphalt application at 80°C, reducing energy loss by 8% in cold climates. The industrial PVC film market, valued at $2 billion, grows with demand for durable, transparent coatings.Applications in Electronics and Protective LayersIn electronics, Transparent PVC Film protects components and displays. Picture a factory in Taiwan: PVC Film, coated with antistatic agents, achieves surface resistivity of 10^8–10^10 ohms/sq, shielding touchscreens from static damage during assembly. Its heat resistance supports lamination at 75°C, and its clarity ensures no distortion in optical sensors. For outdoor electronics, like ATMs in Dubai, UV-resistant PVC covers maintain 85% transparency after 2 years, per accelerated weathering tests. Its dielectric strength makes it ideal for cable insulation, enduring 30 kV/mm without breakdown.

Applications in Medical and Pharmaceutical PackagingIn medical settings, Transparent PVC Film’s sterilizability and clarity are critical. Imagine a hospital in Berlin: PVC Film forms blister packs for tablets, thermoformed at 80°C to create precise cavities that withstand ethylene oxide sterilization without clouding. Its UV resistance protects light-sensitive drugs like ibuprofen, retaining 90% clarity after 1,000 hours of UV exposure, per ISO 10993 testing. With leachables below 0.05 mg/kg, it meets USP Class VI standards for biocompatibility, ideal for IV bags or catheter packaging.PVC curtains in operating rooms leverage its heat resistance to endure steam cleaning at 70°C, while its flexibility allows easy folding. The global medical PVC market is projected to reach $3 billion by 2026, driven by its affordability and compliance with stringent regulations. Challenges include plasticizer migration concerns, but non-phthalate alternatives like DINCH ensure safety, as validated by Biomaterials studies.Applications in Outdoor and Industrial UsesIn outdoor settings, High-Temperature, UV-Resistant Transparent PVC Film thrives under harsh conditions. Envision a vineyard in Australia: PVC greenhouse films transmit 85% of photosynthetically active radiation (PAR) while blocking 95% of UV-B, boosting grape yields by 10% while resisting cracking in 40°C heat, per Horticulture Science. Its tensile strength (50 MPa) withstands wind gusts up to 100 km/h, and its UV stability prevents yellowing for 3–5 years.In advertising, PVC banners in Times Square resist UV fading, maintaining vibrant graphics under 1,200 W/m² sunlight. Their flexibility allows easy rolling for transport, and surface treatments ensure ink adhesion for 2-year outdoor durability. In construction, PVC Film serves as a vapor barrier in roofing, its heat resistance supporting hot asphalt application at 80°C, reducing energy loss by 8% in cold climates. The industrial PVC film market, valued at $2 billion, grows with demand for durable, transparent coatings.Applications in Electronics and Protective LayersIn electronics, Transparent PVC Film protects components and displays. Picture a factory in Taiwan: PVC Film, coated with antistatic agents, achieves surface resistivity of 10^8–10^10 ohms/sq, shielding touchscreens from static damage during assembly. Its heat resistance supports lamination at 75°C, and its clarity ensures no distortion in optical sensors. For outdoor electronics, like ATMs in Dubai, UV-resistant PVC covers maintain 85% transparency after 2 years, per accelerated weathering tests. Its dielectric strength makes it ideal for cable insulation, enduring 30 kV/mm without breakdown. Sustainability and ChallengesSustainability is a critical concern for PVC Film. While recyclable, its global recycling rate is low (~15%), hindered by plasticizer complexity. Advances in chemical recycling, like depolymerization, recover 70% of vinyl chloride, reducing virgin material use by 30%. Environmental concerns over chlorine content spur bio-based plasticizers, aligning with EU regulations. Cost-wise, UV-resistant PVC is 10% pricier than standard grades but offsets this with longevity, lasting 2–3 times longer than non-treated films in outdoor use.

Sustainability and ChallengesSustainability is a critical concern for PVC Film. While recyclable, its global recycling rate is low (~15%), hindered by plasticizer complexity. Advances in chemical recycling, like depolymerization, recover 70% of vinyl chloride, reducing virgin material use by 30%. Environmental concerns over chlorine content spur bio-based plasticizers, aligning with EU regulations. Cost-wise, UV-resistant PVC is 10% pricier than standard grades but offsets this with longevity, lasting 2–3 times longer than non-treated films in outdoor use. ConclusionHigh-Temperature, UV-Resistant Transparent PVC Film is a dynamic force, blending clarity, flexibility, and resilience to conquer diverse challenges. From preserving sushi’s freshness to shielding crops from UV rays, it proves its worth in demanding environments, backed by rigorous science and practical triumphs. As sustainability innovations close the recycling gap, PVC Film remains a clear, cost-effective solution, illuminating the path to a durable, vibrant future.

ConclusionHigh-Temperature, UV-Resistant Transparent PVC Film is a dynamic force, blending clarity, flexibility, and resilience to conquer diverse challenges. From preserving sushi’s freshness to shielding crops from UV rays, it proves its worth in demanding environments, backed by rigorous science and practical triumphs. As sustainability innovations close the recycling gap, PVC Film remains a clear, cost-effective solution, illuminating the path to a durable, vibrant future.

Get the latest price? We'll respond as soon as possible(within 12 hours)