The Power of Polyethylene: How PE Film Shapes Packaging Solutions

2025-03-14 15:55Polyethylene (PE) film, a thermoplastic marvel derived from ethylene polymerization, stands as one of the most ubiquitous materials in the packaging world. Known for its flexibility, resilience, and adaptability, PE film has carved a niche across industries, from food preservation to industrial wrapping. Its lightweight nature, combined with a remarkable ability to be tailored for specific needs, makes it a go-to choice for manufacturers and consumers alike. Whether it’s sealing a bag of frozen peas or protecting heavy machinery during transit, PE film delivers practicality with a touch of ingenuity. This article dives into the standout properties of PE Film and explores its diverse applications in packaging, bringing to life its role as a silent yet powerful player in our daily lives.

from food preservation to industrial wrapping. Its lightweight nature, combined with a remarkable ability to be tailored for specific needs, makes it a go-to choice for manufacturers and consumers alike. Whether it’s sealing a bag of frozen peas or protecting heavy machinery during transit, PE film delivers practicality with a touch of ingenuity. This article dives into the standout properties of PE Film and explores its diverse applications in packaging, bringing to life its role as a silent yet powerful player in our daily lives.

Section 1: Properties of PE Film

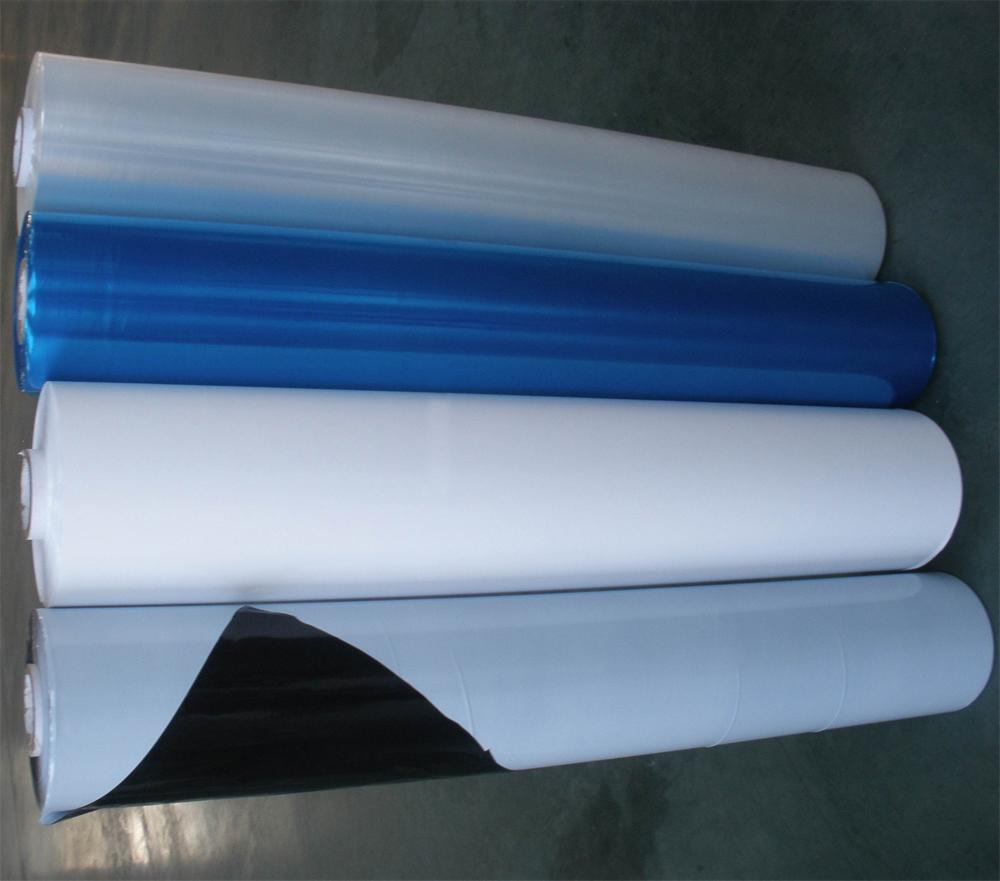

PE film comes in various forms—low-density (LDPE), high-density (HDPE), and linear low-density (LLDPE)—each offering unique traits that cater to different packaging demands. Produced through extrusion processes, this film can be as thin as 10 micrometers or as thick as several hundred, depending on its intended use. Let’s unpack the characteristics that make PE film a packaging powerhouse.

1.1 Flexibility and Versatility

The hallmark of PEflexiblefilm is its pliability. LDPE, for instance, boasts an elongation at break of up to 500%, meaning it can stretch significantly without tearing. This flexibility allows it to conform to irregular shapes, making it ideal for wrapping everything from oddly shaped fruits to complex machinery parts. HDPE, while less stretchy, offers a stiffer, more rigid structure, perfect for applications requiring form stability, like rigid bags or liners. This adaptability ensures that PE film can be customized to suit virtually any packaging challenge.

1.2 Strength and Durability

Despite its lightweight nature, PEstrengthfilm punches above its weight in terms of durability. HDPE, with a tensile strength of 30–40 MPa, resists punctures and tears, making it a stalwart for heavy-duty packaging. LLDPE blends flexibility with toughness, offering excellent impact resistance—think of a sack of rice dropped from a shelf, still intact thanks to its PE film casing. This strength ensures products remain secure, whether stacked in a warehouse or jostled during shipping.

1.3 Moisture Resistance

One of PE film’s standout features is its ability to repel water. With a water vapor transmission rate (WVTR) as low as 5–10 g/m²/day for thicker variants, PEbarrierfilm excels at keeping moisture out. This property is critical for protecting hygroscopic goods—items that absorb water—like powdered milk or cement, ensuring they stay dry and usable. Unlike some plastics, PE film maintains this barrier even in humid conditions, offering reliable protection across climates.

1.4 Chemical Inertness

PE film is chemically stable, resisting degradation from acids, alkalis, and oils. This inertness means it won’t react with packaged contents, preserving the flavor of foods like olive oil or the efficacy of industrial chemicals. Its operating temperature range, from -50°C to 80°C for LDPE and up to 120°C for HDPE, further enhances its suitability for diverse environments, from frozen storage to warm climates.

1.5 Cost-Effectiveness and Sustainability

Affordability is a key driver of PE film ’s dominance. Its raw materials are abundant, and production is energy-efficient, keeping costs low. Moreover, PE sustainable film shines in the sustainability arena—PE is widely recyclable, with global recovery rates climbing in regions like Europe, where over 30% of PE packaging is reused. Advances in bio-based PE, derived from sugarcane, further bolster its eco-friendly credentials, aligning with the push for greener solutions.

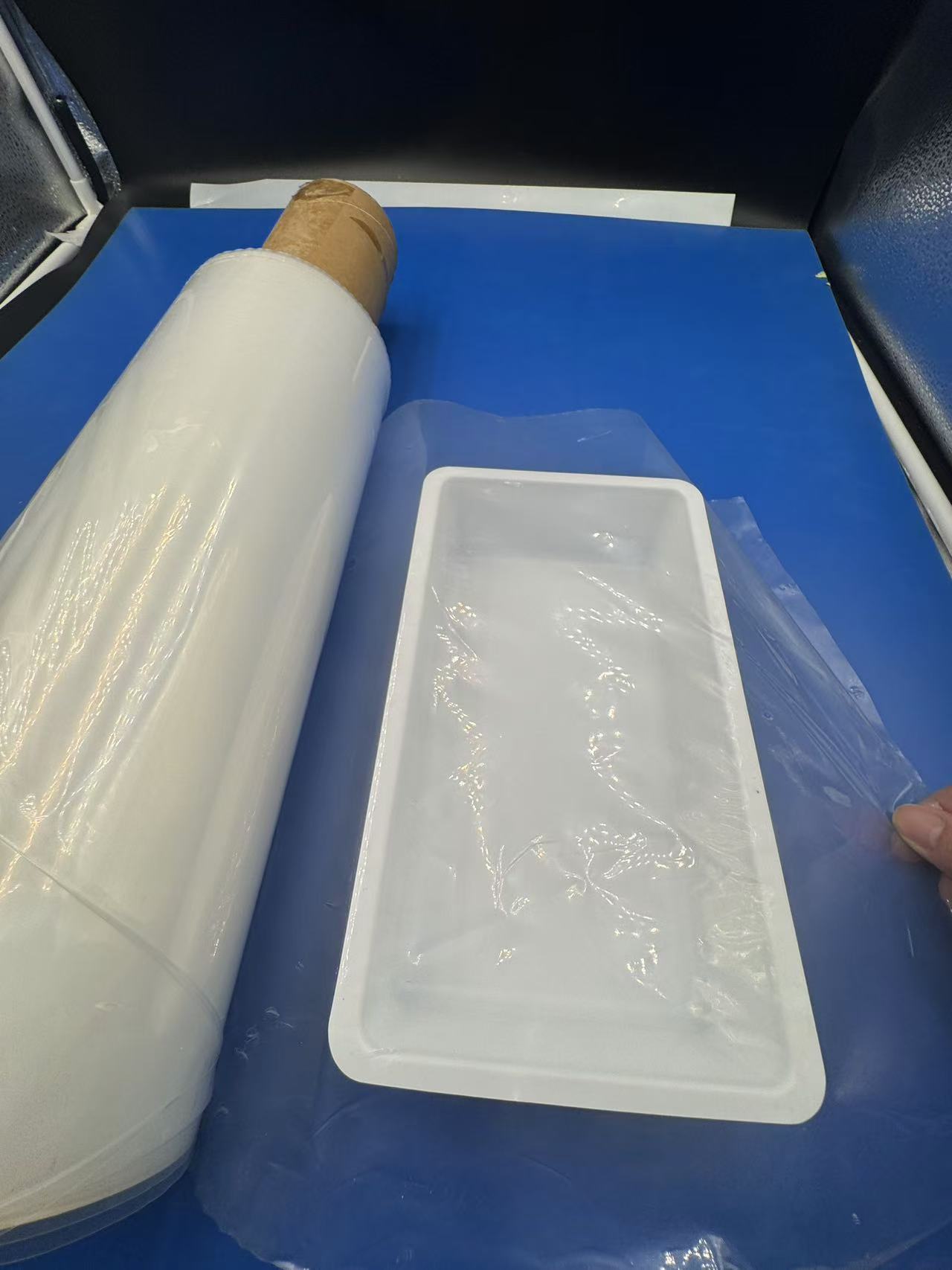

Section 2: Applications of PE Film in Packaging

The properties of PE film translate into a vast array of packaging applications, each leveraging its strengths to meet specific needs. Let’s explore how this material thrives across food, industrial, agricultural, and consumer goods packaging.

2.1 Food Packaging: Freshness Locked In

In the food industry, PE flexible film is a star performer, particularly for fresh and frozen goods. LDPE bags encase vegetables like carrots, their flexibility hugging each root while the film’s moisture resistance prevents sogginess. For frozen foods, HDPE’s toughness ensures that a bag of shrimp withstands icy conditions without splitting.

A vivid example: picture a loaf of sliced bread in a PE film bag. The film’s slight breathability (oxygen transmission rate of 3,000–6,000 cm³/m²/day for LDPE) prevents mold while retaining softness, and its clarity lets buyers see the golden crust. For snacks like chips, multilayer PE films with enhanced PE barrier film properties block air and oil, keeping them crisp and flavorful for months.

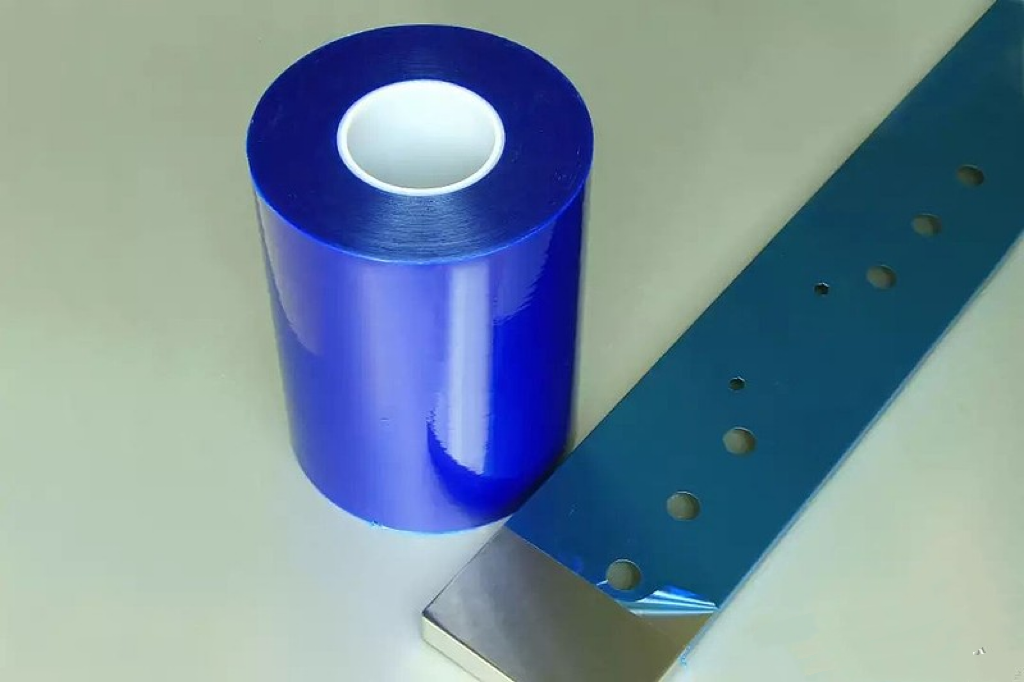

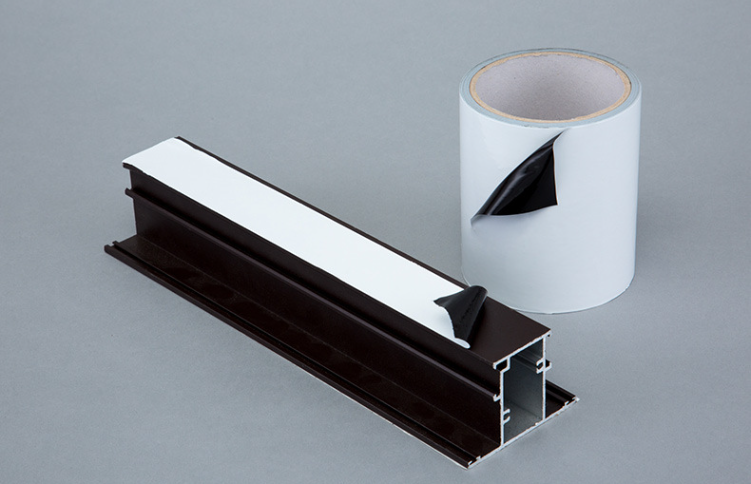

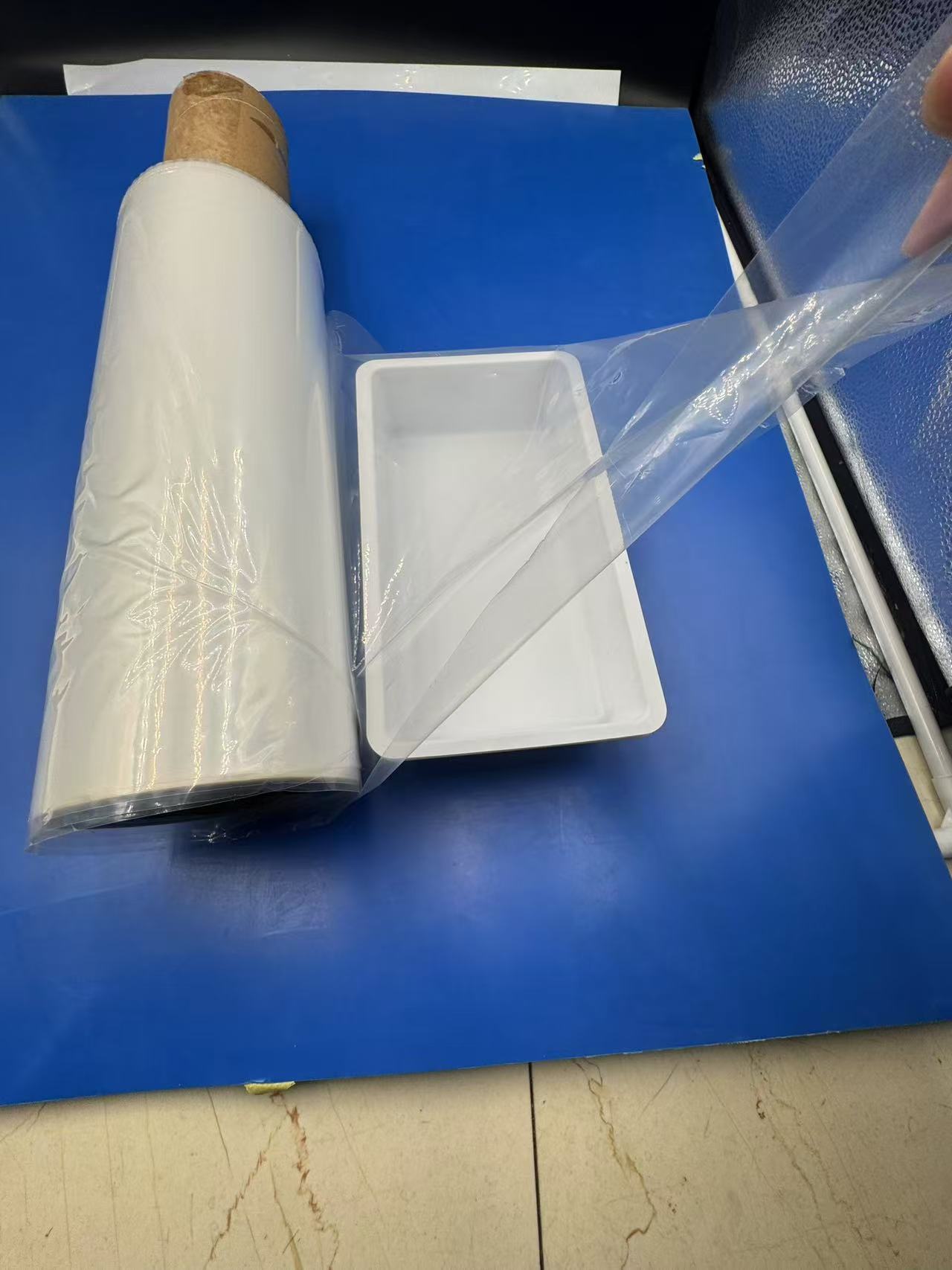

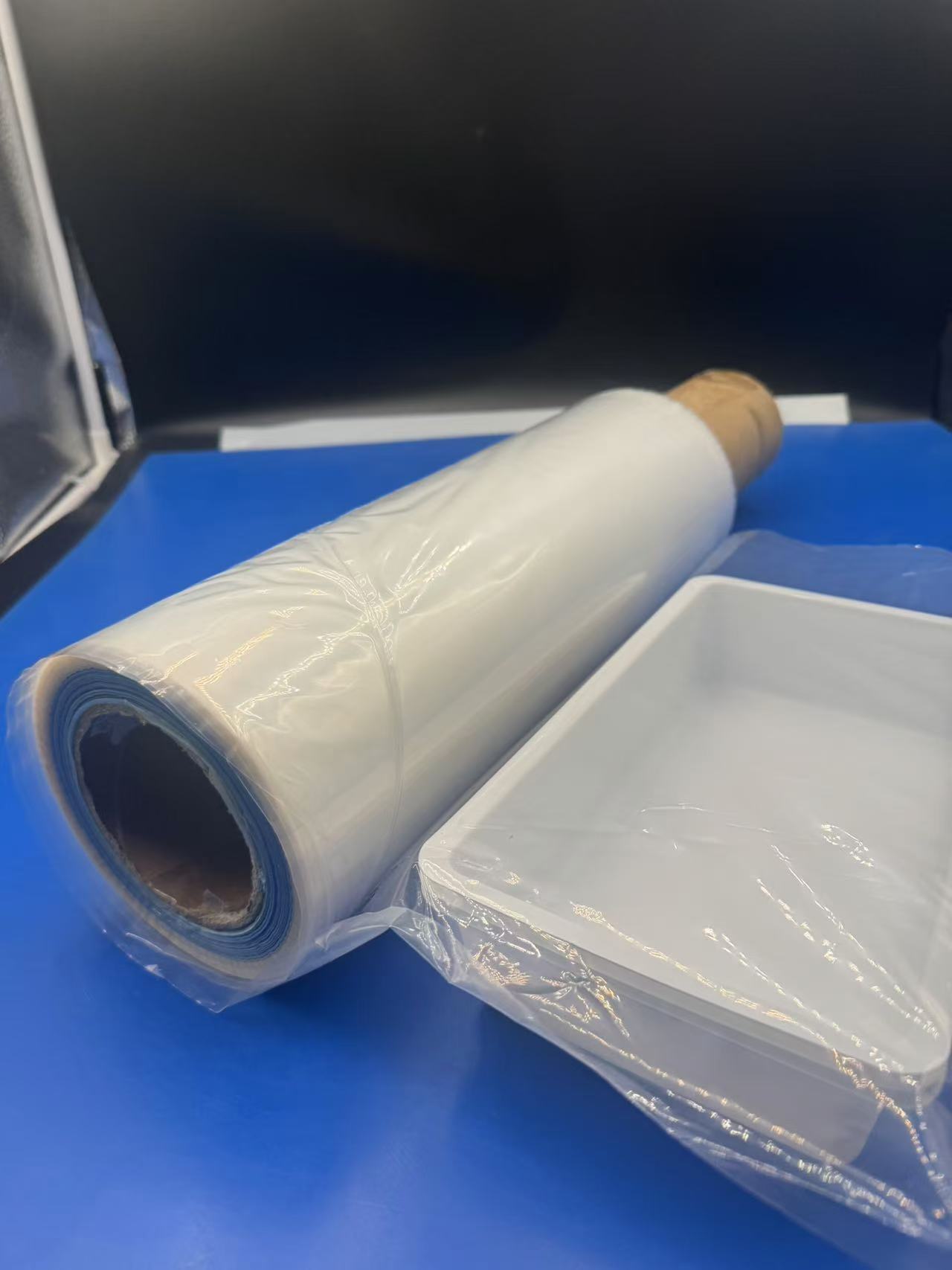

2.2 Industrial Packaging: Heavy Duty, Light Weight

When it comes to industrial goods, PE strength film takes center stage. HDPE shrink wrap secures pallets of bricks, its durability resisting tears from sharp edges during transit. LLDPE stretch film, with its clingy nature, wraps machinery parts, protecting them from dust and scratches without adding bulk.

Consider a shipment of steel pipes: wrapped in thick PE film, they arrive rust-free, thanks to the film’s water resistance. The lightweight nature of PE—often 30% lighter than alternatives like PVC—cuts shipping costs, making it a favorite for logistics managers worldwide.

2.3 Agricultural Packaging: From Field to Fork

In agriculture, PE film supports the journey of produce from harvest to market. Greenhouse films made of LDPE regulate light and heat, boosting crop yields, while mulch films suppress weeds and retain soil moisture. For packaging, PE bags protect bulk grains like wheat, their PE barrier film qualities shielding against dampness that could trigger spoilage.

A farmer packing apples might use perforated PE film bags, allowing just enough air circulation to prevent rot while showcasing the fruit’s rosy glow through the transparent material. This balance of protection and visibility is a testament to PE’s versatility

.

2.4 Consumer Goods: Everyday Convenience

From trash bags to shopping bags, PE flexible film enhances daily life. HDPE’s strength makes it ideal for garbage bags that hold sharp cans without tearing, while LDPE’s softness suits reusable tote bags that fold into a pocket. In retail, PE film pouches package detergents or pet food, their chemical resistance ensuring no leaks or degradation.

Imagine a parent grabbing a pack of diapers wrapped in PE film: the film’s durability keeps the bundle intact, while printed designs on its surface catch the eye, blending practicality with marketing appeal.

2.5 Sustainable Packaging: A Green Frontier

As sustainability gains traction, PE sustainable film leads the charge. Recycled PE film is molded into bottles for household cleaners, reducing virgin plastic use. Bio-based PE, sourced from renewable feedstocks, wraps eco-friendly soaps, offering the same performance with a smaller carbon footprint.

A real-world case: a coffee brand switches to PE film bags made from 50% recycled content. The film’s strength and moisture resistance keep the beans fresh, while its recyclability earns eco-conscious customer loyalty—a win-win for business and the planet.

Section 3: Advantages and Challenges of PE Film

3.1 Key Advantages

Flexibility: PE flexible film molds to any shape, enhancing usability.

Durability: PE strength film withstands rough handling, ensuring product safety.

Moisture Protection: PE barrie rfilm keeps contents dry and intact.

Affordability: Low production costs benefit manufacturers and consumers.

Recyclability: PE sustainable film supports a circular economy.

3.2 Limitations and Solutions

PE film’s high oxygen permeability (up to 6,000 cm³/m²/day for LDPE) limits its use for oxygen-sensitive goods, often requiring laminates like EVOH to bolster barriers—adding cost. Its lower heat resistance compared to PET or PVC restricts hot-fill applications, though HDPE variants push the boundary. Environmentally, improper disposal can clog landfills, but robust recycling programs and biodegradable PE blends are shrinking this footprint.

Conclusion

PE film is more than just plastic—it’s a packaging pioneer that bends, protects, and sustains. Its flexibility, strength, and moisture resistance make it indispensable across food, industrial, agricultural, and consumer applications, while its affordability and recyclability keep it relevant in a sustainability-driven world. From a humble grocery bag to a high-tech mulch film, PE film quietly shapes how we store, ship, and enjoy goods. As innovations refine its properties and green credentials, PE film stands poised to remain a cornerstone of packaging for years to come—proof that simplicity, when engineered right, can be extraordinary.