Our PLA (Polylactic Acid) Biodegradable Film is an innovative, sustainable alternative to traditional petroleum-based plastic films. Derived from 100% renewable plant resources (primarily corn starch, sugarcane bagasse, or cassava), this film combines excellent performance with full biodegradability, addressing the global challenge of plastic pollution while meeting diverse industrial and daily needs.

Unlike conventional plastics that persist in the environment for centuries, our PLA film naturally decomposes into harmless substances (carbon dioxide and water) under industrial composting conditions (temperature: 58±2℃, humidity: 50-60%) within 180-365 days. It is also non-toxic, odorless, and free from BPA, phthalates, and other harmful chemicals, making it safe for food contact, agricultural applications, and daily use.

100% Renewable & Carbon-Neutral

The raw material (PLA resin) is extracted from plants that absorb CO₂ during growth, creating a closed carbon cycle. Compared to petroleum-based plastics, our film reduces carbon emissions by up to 70% throughout its lifecycle.

Superior Biodegradability

Fully decomposes in industrial composting facilities without leaving microplastics. It also meets international standards such as ASTM D6400 (US), EN 13432 (EU), and GB/T 20197 (China) for biodegradable plastics.

Excellent Performance

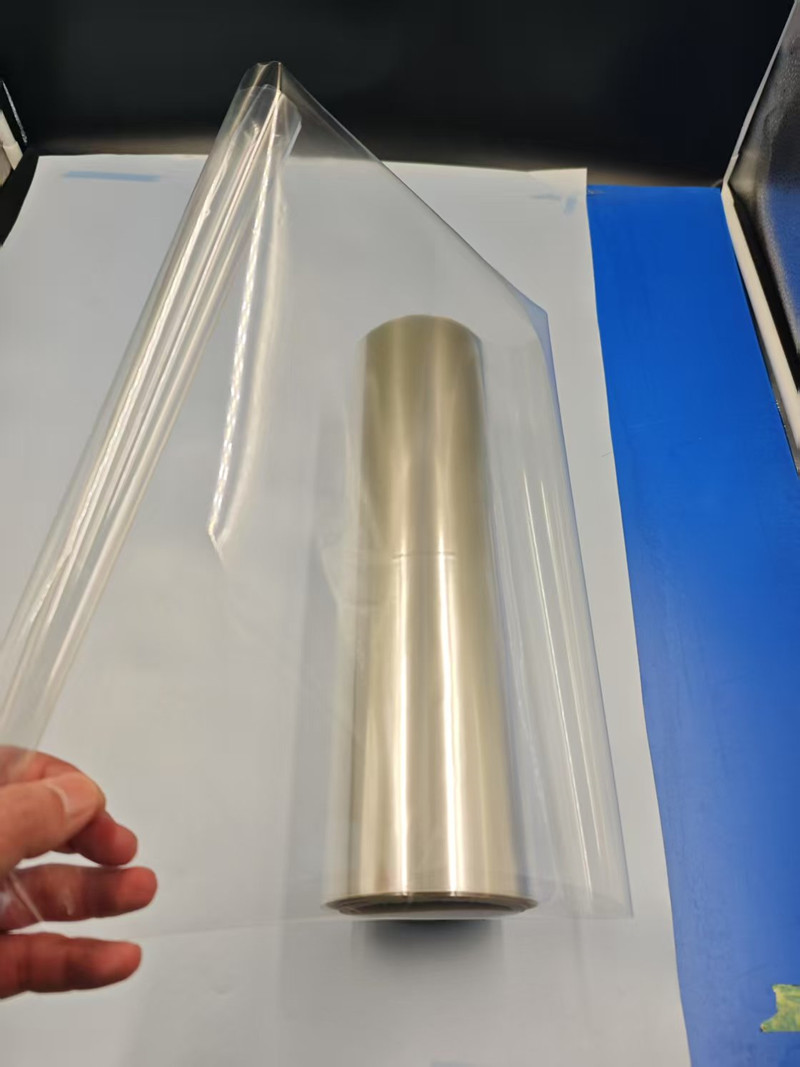

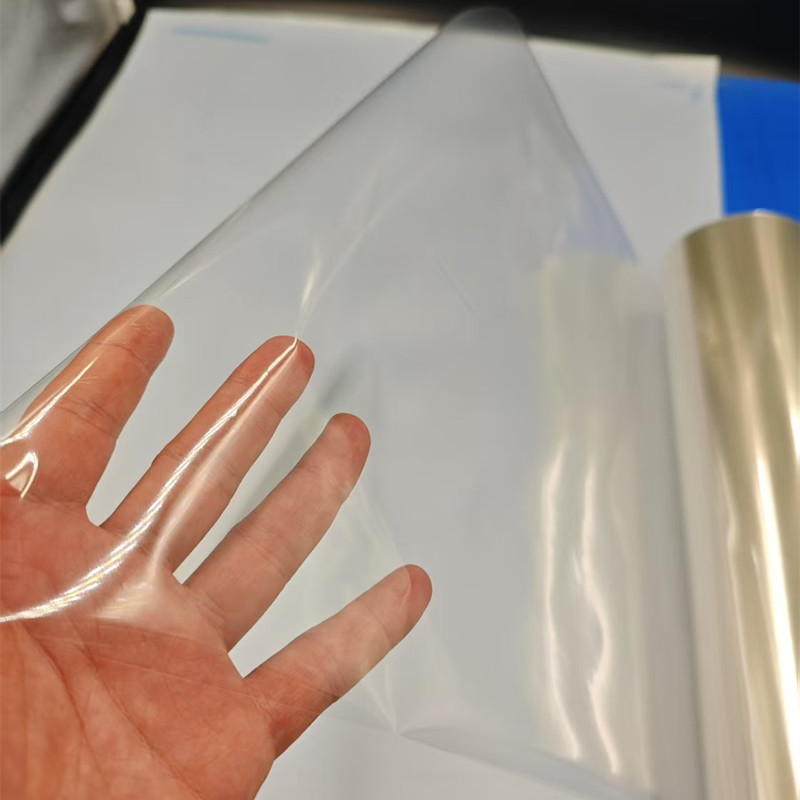

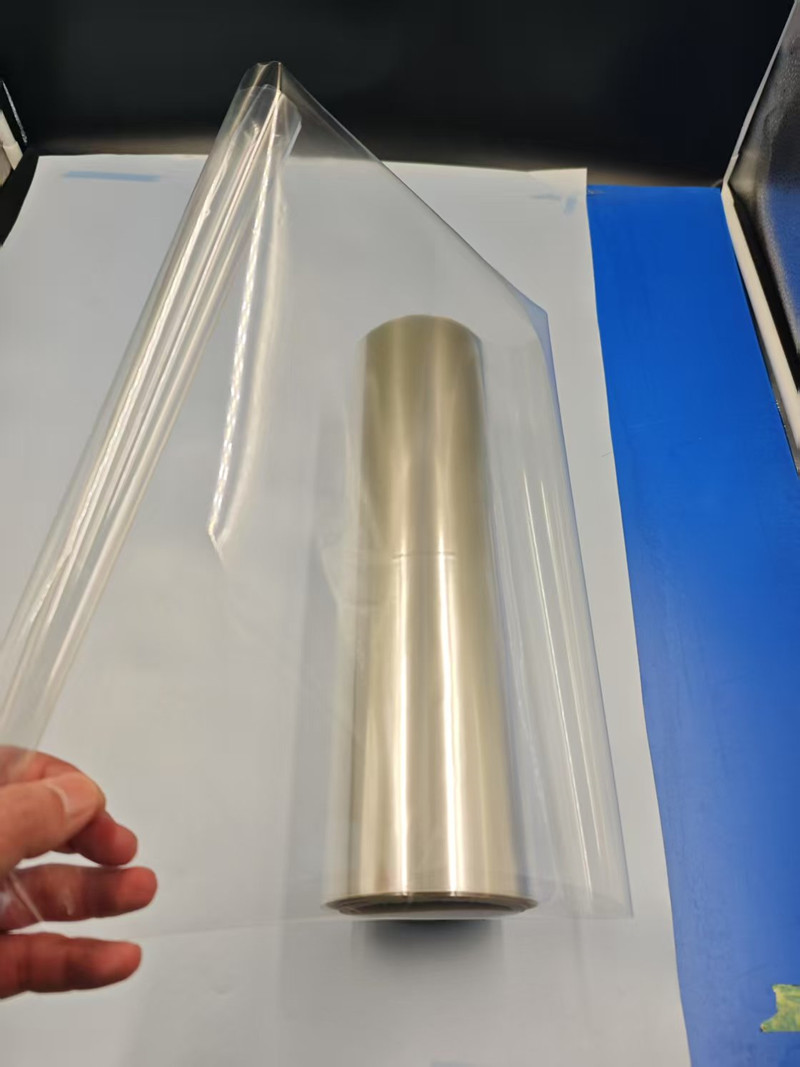

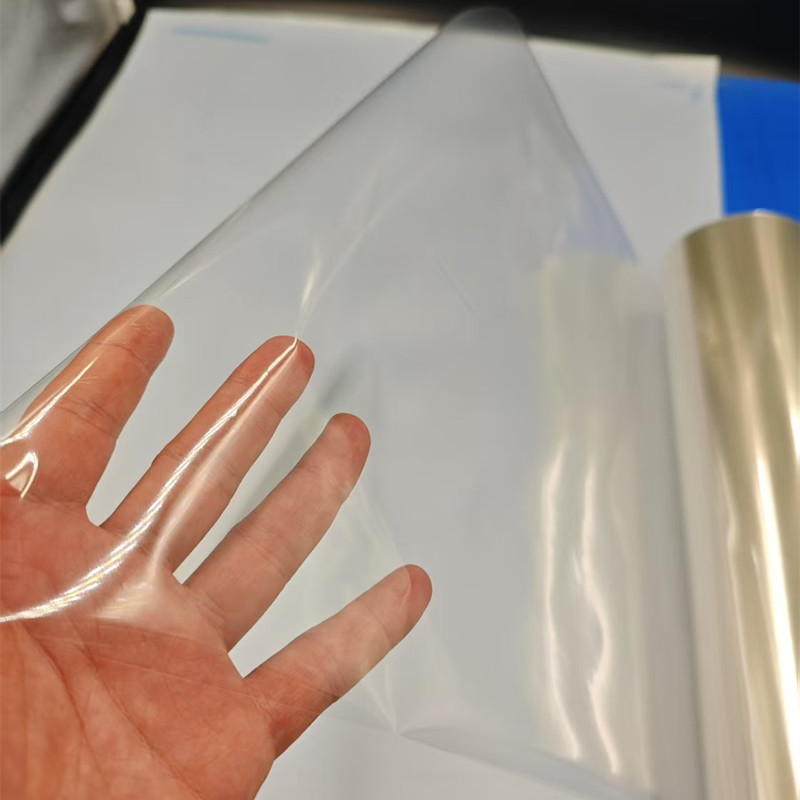

Boasts comparable mechanical properties to traditional PE (Polyethylene) films:

Tensile strength: 15-25 MPa (suitable for wrapping, covering, and packaging)

Transparency: ≥90% (ideal for food display and agricultural light transmission)

Moisture resistance: Water vapor transmission rate (WVTR) 5-15 g/(m²·24h) (varies by thickness)

Heat resistance: Can withstand temperatures from -10℃ to 60℃ (safe for cold storage and mild heat applications)

Versatile & Customizable

Available in various thicknesses (15μm-150μm), widths (50mm-2000mm), and colors (clear, white, green, etc.). Customizations for additives (e.g., anti-UV, anti-fog, or degradation-rate regulators) are also supported to meet specific industry needs.