The Exceptional Properties and Applications of PP Film in Food Packaging for Blister Bowls and Cups

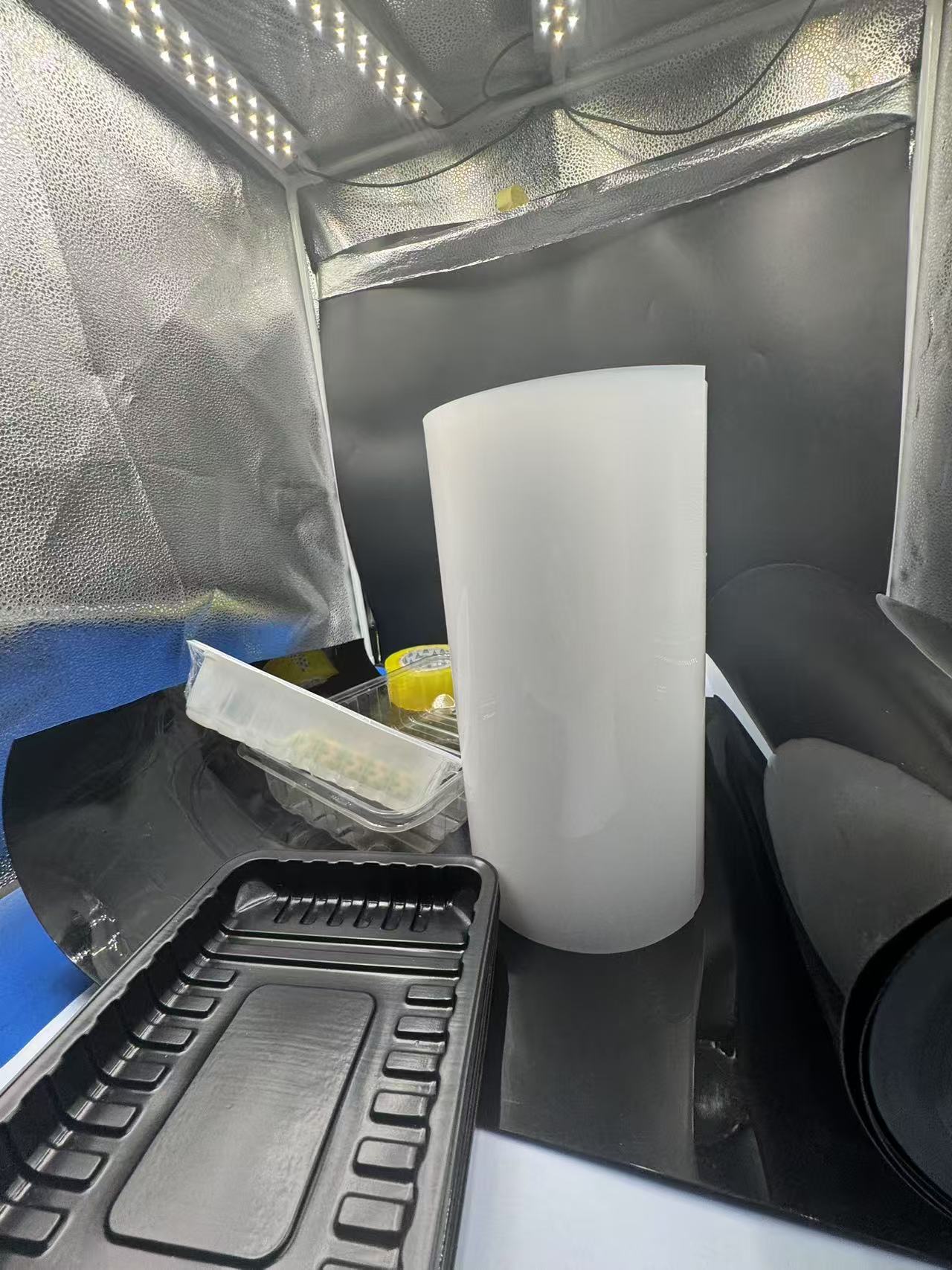

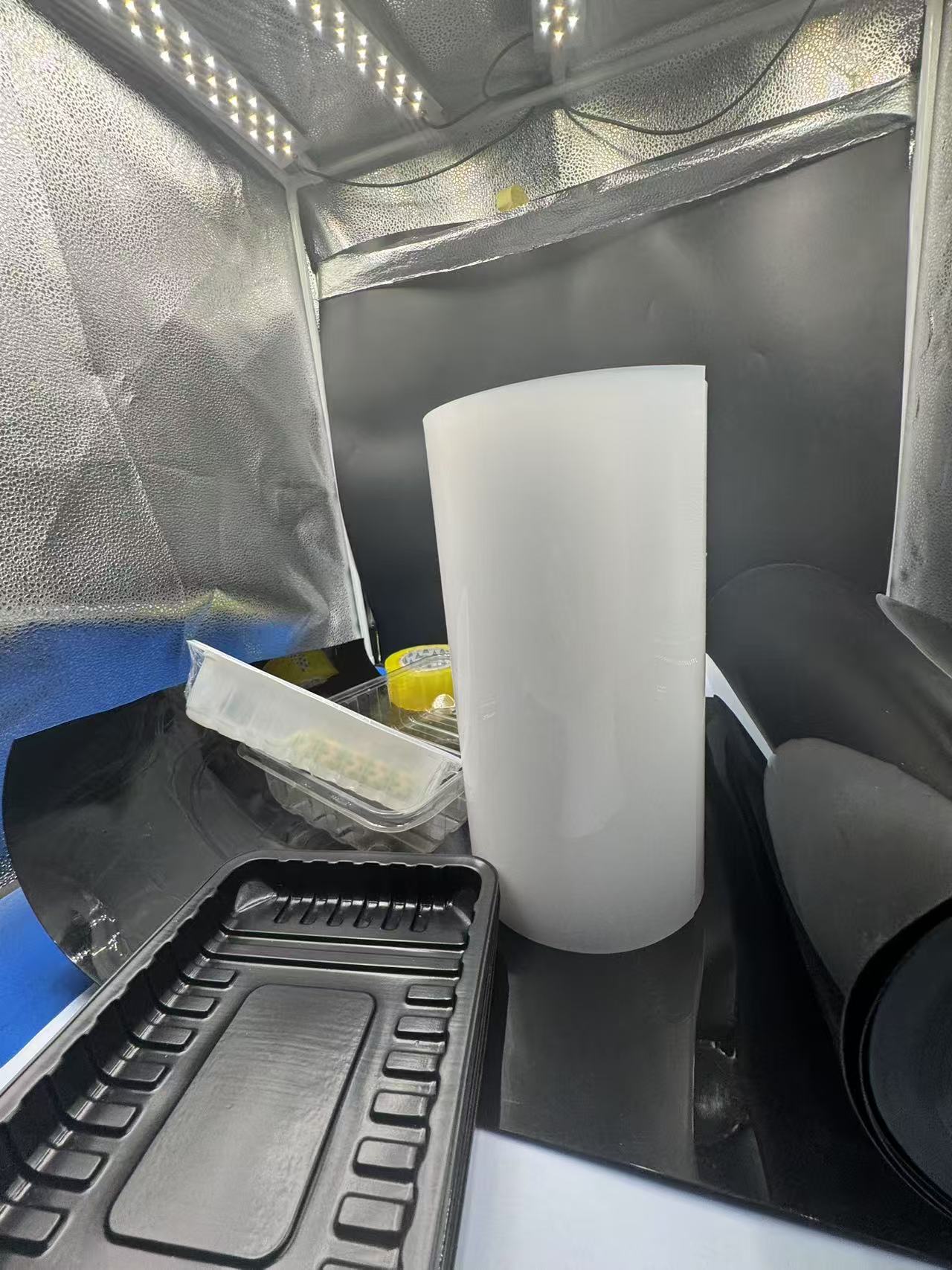

2025-04-18 16:06Transparent and semi-transparent PP (Polypropylene) film has become a cornerstone material in the food packaging industry, particularly for thermoformed tableware such as blister bowls, cups, and trays. Renowned for its versatility, safety, and cost-effectiveness, PP film meets the stringent requirements of food-grade packaging while offering manufacturers and consumers a balance of functionality and aesthetics. This article explores the defining characteristics of PP film and its transformative role in food packaging applications, with a focus on blister bowls and cups. Through technical insights, real-world examples, and vivid descriptions, we highlight why PP film is a preferred choice in this dynamic sector.

Defining Characteristics of PP Film

PP film, derived from polypropylene resin, is produced through processes like cast or blown extrusion, resulting in a material with a unique combination of mechanical, thermal, and chemical properties. These attributes make PP film exceptionally suited for food packaging, particularly in thermoforming applications like blister bowls and cups.

- Thermal Stability: PP film exhibits excellent heat resistance, with a melting point around 160–170°C. This allows it to withstand high-temperature processes such as hot-fill packaging and microwave heating, making it ideal for ready-to-eat meals served in blister bowls. For instance, a PP film-based bowl can maintain its shape and integrity when filled with boiling soup at 100°C, ensuring consumer safety and convenience.

- Mechanical Strength and Flexibility: With tensile strengths typically ranging from 30–40 MPa for cast PP film, this material offers robustness without sacrificing flexibility. This balance ensures that PP film can be thermoformed into intricate shapes like deep-draw cups while resisting cracks or punctures during handling. Picture a PP film cup holding a chilled dessert, its sturdy walls protecting the contents even when squeezed during transport.

- Optical Clarity and Aesthetics: Transparent PP film provides good light transmission (around 85–90%), enabling clear visibility of packaged food, which is critical for consumer appeal. While not as glossy as PET, PP film’s clarity enhances the presentation of vibrant salads or colorful fruit cups in blister packaging. Its surface also accepts high-quality printing, allowing brands to showcase logos or nutritional information directly on the film.

- Barrier Properties: While PP film has moderate barrier properties compared to materials like EVOH or PVDC, its oxygen transmission rate (OTR) of approximately 2000–3000 cc/m²/day at 25 microns can be enhanced through co-extrusion with barrier layers. For dry or low-moisture foods like snacks or bakery items, PP film provides sufficient protection against external elements, preserving freshness.

- Chemical Inertness and Food Safety: PP film is FDA-approved for food contact and complies with regulations like EU 10/2011. Its resistance to acids, alkalis, and oils ensures it does not react with acidic foods like yogurt or oily sauces, maintaining product integrity. This inertness is crucial for blister cups used for dairy products, where any chemical migration could compromise taste or safety.

- Recyclability and Sustainability: PP film is recyclable in many regions, aligning with the growing demand for sustainable packaging. Advances in mono-material PP film structures are reducing the reliance on multi-layer composites, simplifying recycling streams. Additionally, PP film’s lightweight nature minimizes material usage, lowering the environmental footprint of packaging.

These properties collectively position PP film as a reliable, cost-effective, and consumer-friendly material for food packaging applications, particularly in thermoformed tableware.

Applications of PP Film in Food Packaging

PP film’s versatility shines in the production of blister bowls, cups, and trays, which are widely used for food packaging in retail, foodservice, and on-the-go consumption. Its ability to be thermoformed into precise shapes, coupled with its food-safe properties, makes it indispensable in the following applications:

- Blister Bowls for Ready-to-Eat Meals

Blister bowls made from PP film are a staple in the ready-meal sector, catering to the demand for convenient, microwaveable food options. A typical structure involves a 300–500 micron PP film thermoformed into a bowl shape, often sealed with a lidding film. These bowls are used for products like pasta dishes, curries, or steamed vegetables, where PP film’s heat resistance ensures the container remains intact during microwave reheating.

For example, imagine a supermarket shelf displaying a PP film blister bowl filled with a colorful stir-fry. The transparent PP film allows consumers to see the vibrant ingredients, while the bowl’s sturdy walls prevent deformation when heated. The film’s sealability also ensures an airtight closure, extending shelf life by preventing oxygen ingress. Data from packaging studies indicate that PP film bowls can maintain food freshness for up to 6 months under refrigerated conditions, making them ideal for pre-prepared meals.

- Blister Cups for Dairy and Desserts

PP film is extensively used to create blister cups for yogurt, pudding, and other dairy products. These cups, typically formed from 200–400 micron PP film, offer a balance of rigidity and lightweight design. The film’s chemical inertness prevents interactions with acidic dairy products, ensuring flavor and safety are preserved.

Consider a PP film cup filled with creamy Greek yogurt topped with fruit compote. The cup’s clarity showcases the layered textures, enticing consumers, while its robust structure prevents cracking during stacking or transport. PP film cups are also compatible with high-speed filling and sealing lines, with manufacturers reporting production rates of up to 100,000 cups per hour. Additionally, PP film’s printability allows brands to incorporate vibrant designs or QR codes on the cup’s surface, enhancing marketing opportunities.

- Trays for Fresh Produce and Bakery Items

PP film is used to create thermoformed trays for fresh produce like salads or bakery items like pastries. These trays, often made from 150–300 micron PP film, provide a protective barrier while allowing consumers to inspect the product. The film’s flexibility enables the creation of shallow or deep trays, accommodating various product sizes.

For instance, a PP film tray holding a fresh salad mix highlights the greens’ crispness through its transparent surface. The tray’s design includes reinforced edges to prevent collapse, ensuring the product remains presentable from farm to table. Studies show that PP film trays reduce food waste by extending the shelf life of perishables by up to 10 days compared to non-packaged alternatives.

- Beverage and Smoothie Cups

PP film is increasingly used for single-serve beverage cups, such as those for smoothies or iced coffee. These cups, thermoformed from 250–350 micron PP film, are lightweight yet durable, with excellent sealability for leak-proof lids. The film’s thermal stability allows it to handle both cold and moderately hot liquids, making it versatile for on-the-go consumption.

Picture a PP film cup filled with a vibrant berry smoothie, its transparent walls revealing the drink’s rich color. The cup’s smooth surface, often printed with a brand’s logo, enhances its premium appeal. PP film’s recyclability also aligns with consumer preferences for eco-friendly packaging, with some brands reporting a 20% increase in sales after switching to recyclable PP film cups.

- Sustainable Packaging Innovations

As sustainability becomes a priority, PP film is evolving to meet environmental demands. Mono-material PP film structures are replacing multi-layer composites, improving recyclability. For example, a mono-PP blister bowl can be recycled in standard PP streams, reducing landfill waste. Additionally, bio-based PP films, derived from renewable sources, are gaining traction, offering similar performance to fossil-based PP film.

A practical example is a PP film blister bowl for a salad, designed with a recyclable mono-material structure. The bowl’s lightweight design reduces material usage by 15% compared to traditional multi-layer packaging, as reported in recent industry studies. Such innovations demonstrate PP film’s role in advancing sustainable food packaging.

Technical Advantages in Thermoforming and Processing

PP film’s thermoformability is a key advantage in producing blister bowls and cups. During thermoforming, PP film is heated to its softening point (around 130–150°C), stretched over molds, and cooled to form precise shapes. Its uniform thickness distribution ensures consistent wall strength, critical for deep-draw applications like bowls. Manufacturers report that PP film achieves draw ratios of up to 3:1, allowing for complex geometries without thinning or tearing.

The film’s compatibility with high-speed thermoforming lines enhances production efficiency. For instance, a PP film line can produce 50–100 bowls per minute, depending on mold complexity. PP film also supports various sealing methods, including heat sealing and ultrasonic sealing, ensuring secure closures for lidding films. Its surface can be treated to improve ink adhesion, enabling high-resolution printing via flexography or digital methods, with resolutions up to 150 lines per inch.

Moreover, PP film’s cost-effectiveness is a significant draw. Compared to alternatives like PET or PS (polystyrene), PP film is often 10–20% cheaper per ton, according to industry pricing data, making it an economical choice for large-scale production.

Get the latest price? We'll respond as soon as possible(within 12 hours)