Direct-to-Film (DTF) Printing: Characteristics and Applications in Pattern Transfer and Packaging

2025-06-17 17:08

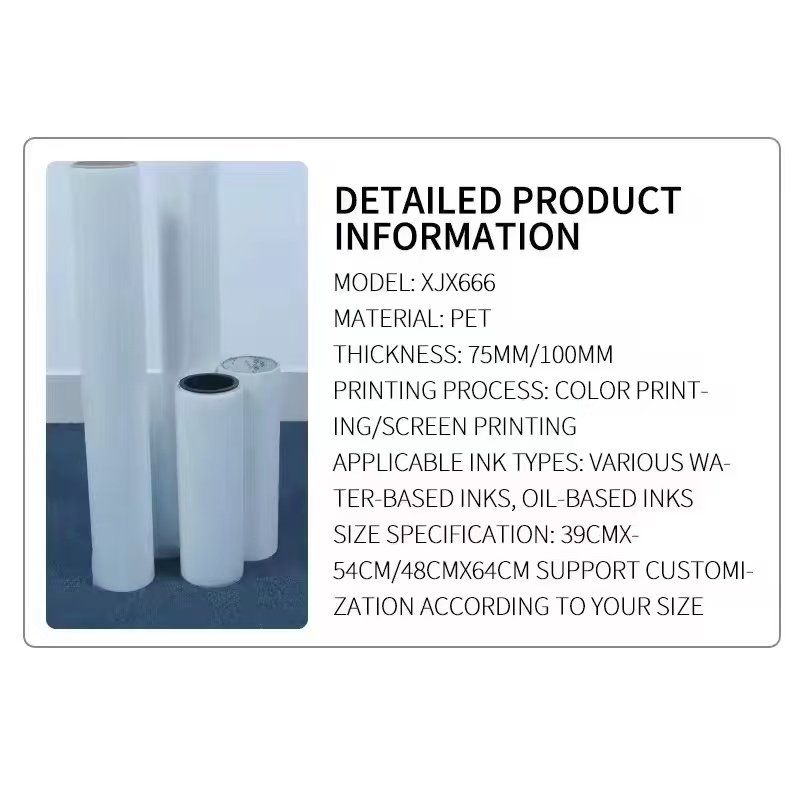

Direct-to-Film (DTF) printing has emerged as a transformative technology in the realms of textile printing and packaging design, offering unparalleled versatility, vibrant results, and cost-efficiency. Unlike traditional printing methods,  DTF employs a unique process that involves printing designs onto a specialized polyethylene terephthalate (PET) film, which is then transferred to various substrates using heat and pressure. This article explores the defining characteristics of DTF PET film, its applications in service pattern transfer for textiles, and its growing role in other pattern packaging, providing a comprehensive look at why this technology is reshaping industries.

DTF employs a unique process that involves printing designs onto a specialized polyethylene terephthalate (PET) film, which is then transferred to various substrates using heat and pressure. This article explores the defining characteristics of DTF PET film, its applications in service pattern transfer for textiles, and its growing role in other pattern packaging, providing a comprehensive look at why this technology is reshaping industries.

Characteristics of DTF PET Film

DTF PET film is the cornerstone of the DTF printing process, distinguished by its specialized properties that enable high-quality transfers. Below are the key characteristics that make DTF PET film a standout choice for printing applications:

High Ink Absorption and Coating Quality

DTF PET film is coated with a specialized ink-absorbing layer that ensures vibrant and precise prints. Unlike standard PET films, DTF films are designed with a matte or frosted finish, which enhances ink adhesion and prevents ink runoff during printing. This coating allows for high ink loading, enabling the film to handle complex, multi-colored designs without smudging or bleeding. For instance, a high-quality DTF PET film can produce fine lines and intricate patterns with clarity, making it ideal for detailed logos or artwork. Poor-quality films, on the other hand, may repel ink or result in uneven coating, leading to blotchy prints that compromise the final product’s appearance.

High-Temperature Resistance

The DTF printing process involves heat pressing at temperatures ranging from 150°C to 170°C, which demands a film that can withstand high temperatures without curling, melting, or deforming. DTF PET film is engineered with a heat-resistant base that maintains structural integrity during the transfer process. This characteristic ensures that the film remains stable, even when subjected to the intense heat of a curing oven or heat press, resulting in clean and consistent transfers. For example, low-quality films may curl or melt during heat transfer, ruining the design and potentially damaging equipment.

Versatile Peel Options

DTF PET film is available in both hot-peel and cold-peel variants, offering flexibility to suit different production workflows. Hot-peel films can be removed immediately after heat pressing, speeding up production for high-volume operations. Cold-peel films, conversely, require the substrate to cool before peeling, which may enhance durability for certain applications. This adaptability makes DTF PET film suitable for both small-scale custom shops and large-scale commercial setups. For instance, a small business owner producing personalized T-shirts might prefer hot-peel films for efficiency, while a manufacturer prioritizing durability might opt for cold-peel films.

Durability and Wash Resistance

One of the standout features of DTF PET film is its ability to produce durable, wash-resistant prints. The adhesive powder applied during the DTF process bonds the ink securely to the substrate, ensuring that designs resist cracking, peeling, or fading even after hundreds of washes. This durability is particularly valuable in apparel, where longevity is a key consumer expectation. For example, a DTF-printed T-shirt can maintain its vibrant colors and sharp details through repeated laundry cycles, unlike some traditional methods that may fade over time.

Specialized Finishes for Visual Appeal

DTF PET film comes in various finishes, such as matte, glossy, glitter, and gold, allowing for creative customization. Matte finishes offer a subtle, professional look, while glossy finishes enhance color vibrancy for eye-catching designs. Specialty films like glitter or gold DTF PET film add a luxurious or reflective effect, making them ideal for premium products or promotional items. For instance, a fashion brand might use gold DTF PET film to create shimmering logos on high-end apparel, elevating the perceived value of their products.

Applications in Service Pattern Transfer

DTF PET film’s versatility makes it a game-changer in service pattern transfer, particularly in the textile industry. Its ability to print on a wide range of fabrics—cotton, polyester, nylon, denim, leather, and blends—sets it apart from methods like Direct-to-Garment (DTG) printing, which is limited to cotton-based materials. The following sections highlight how DTF PET film excels in this domain:

Apparel Customization

DTF printing is widely used for creating personalized apparel, such as T-shirts, hoodies, and sportswear. The process begins with printing a design onto DTF PET film using water-based inks and a DTF printer. A layer of white ink is applied over the colored design to ensure opacity on dark fabrics, followed by adhesive powder that binds the ink to the film. The film is then cured and heat-pressed onto the garment, transferring the design seamlessly. This method allows for vibrant, full-color designs on both light and dark fabrics without the need for pretreatment, unlike DTG. For example, a sports team could use DTF PET film to print detailed logos and player numbers on jerseys, achieving a professional finish that withstands rigorous use.

Versatility Across Substrates

The ability to transfer designs onto diverse materials makes DTF PET film a favorite among textile printers. Whether it’s a cotton T-shirt, a polyester jacket, or a leather bag, DTF PET film delivers consistent results. This versatility reduces inventory costs, as businesses can store pre-printed DTF transfers and apply them to various products on demand. For instance, a print shop could create a batch of DTF transfers featuring a seasonal design and apply them to T-shirts, tote bags, and caps as needed, streamlining production and minimizing waste.

Cost-Effective Small-Batch Production

DTF printing is particularly advantageous for small businesses or print-on-demand services due to its low setup costs and flexibility. Unlike screen printing, which requires expensive setup for each design, DTF PET film allows for quick design changes without additional costs. A single DTF printer can produce transfers for multiple projects, making it ideal for custom orders or limited-edition runs. For example, an Etsy seller offering personalized pet-themed T-shirts could use DTF PET film to produce small batches of unique designs, catering to niche markets without investing in large-scale equipment.

Durability for Functional Apparel

The durability of DTF transfers makes them suitable for functional apparel, such as workwear or sportswear, where prints must withstand wear and tear. The adhesive powder used in the DTF process ensures a strong bond between the design and the fabric, resulting in prints that are stretchable and resistant to abrasion. For instance, a construction company could use DTF PET film to print logos on high-visibility vests, ensuring that the designs remain intact despite exposure to harsh conditions.

Applications in Other Pattern Packaging

Beyond textiles, DTF PET film is gaining traction in the packaging industry, where it is used to create visually appealing and durable designs for various products. Its adaptability and high-quality output make it a compelling choice for packaging applications, as outlined below:

Customized Product Packaging

DTF PET film can be used to print vibrant, high-resolution designs on packaging materials such as bags, boxes, and labels. For example, a boutique coffee brand could use DTF PET film to transfer intricate logos or artwork onto canvas bags, creating a premium, reusable packaging solution that enhances brand visibility. The film’s ability to adhere to materials like canvas and leather ensures that the packaging is both functional and aesthetically pleasing.

Specialty Packaging with Visual Effects

Specialty DTF PET films, such as glitter or reflective films, are particularly suited for creating eye-catching packaging. For instance, a cosmetics company might use glitter DTF PET film to print sparkling designs on product pouches, making the packaging stand out on retail shelves. Similarly, reflective DTF PET film can be used for safety-related packaging, such as labels on outdoor gear, where visibility in low-light conditions is essential. These specialty films add a unique flair that differentiates products in competitive markets.

Eco-Friendly Considerations

Learning Curve: Achieving optimal results requires mastering the DTF process, including ink management and heat press settings.

Conclusion

DTF PET film has revolutionized the way businesses approach service pattern transfer and packaging design. Its high ink absorption, heat resistance, versatile peel options, and durability make it an ideal choice for creating vibrant, long-lasting designs on textiles and packaging materials. From personalized T-shirts to premium product packaging, DTF PET film offers unmatched flexibility and quality, enabling businesses to cater to diverse markets with cost-effective solutions. As the technology continues to evolve, with advancements in eco-friendly materials and streamlined processes, DTF PET film is poised to remain a cornerstone of modern printing, driving creativity and innovation across industries.