The Characteristics and Versatile Applications of Transparent PE Film

2024-12-25 16:21The Characteristics and Versatile Applications of Transparent PE Film

Ⅰ. Introduction to Transparent PE Film

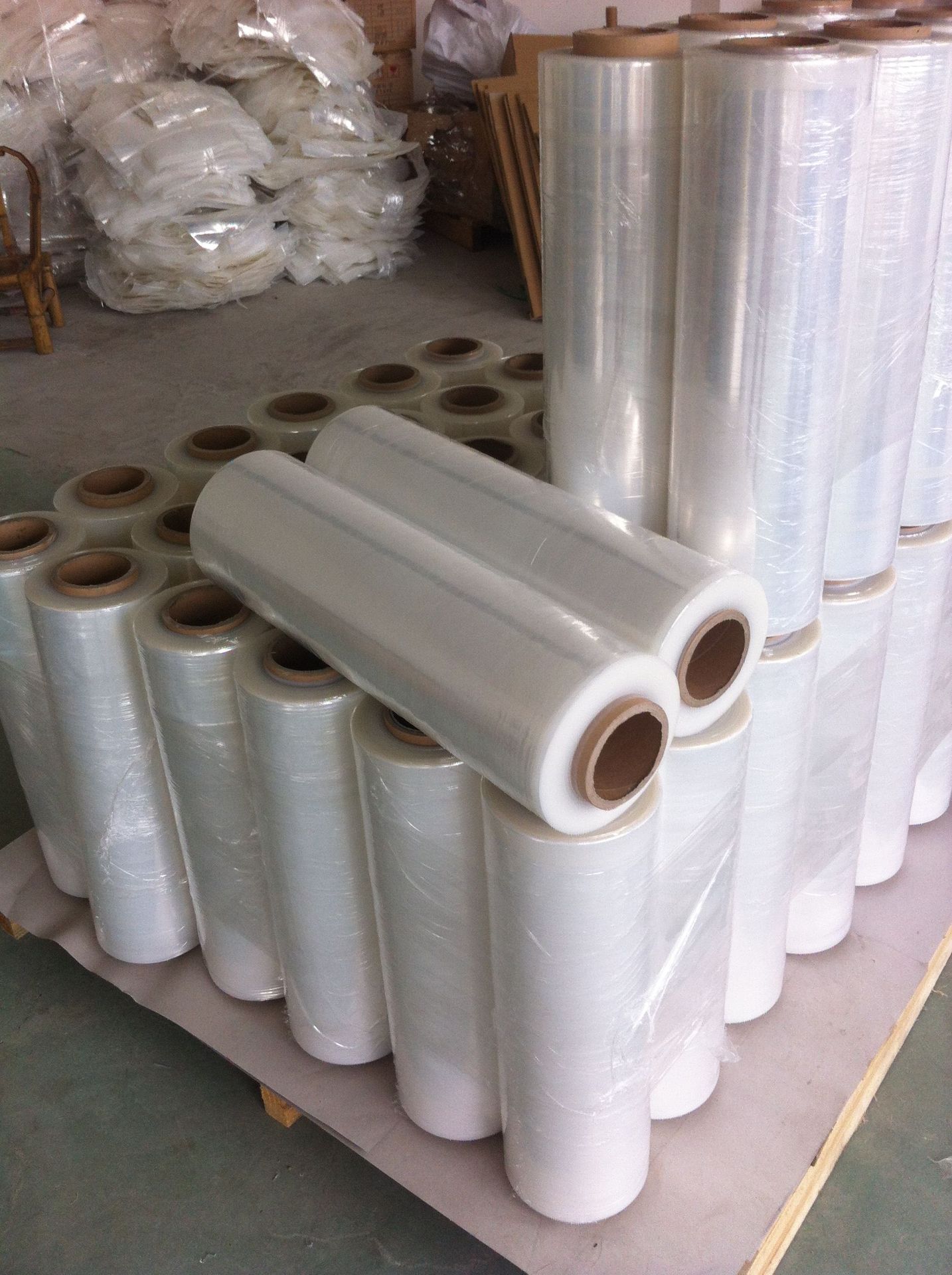

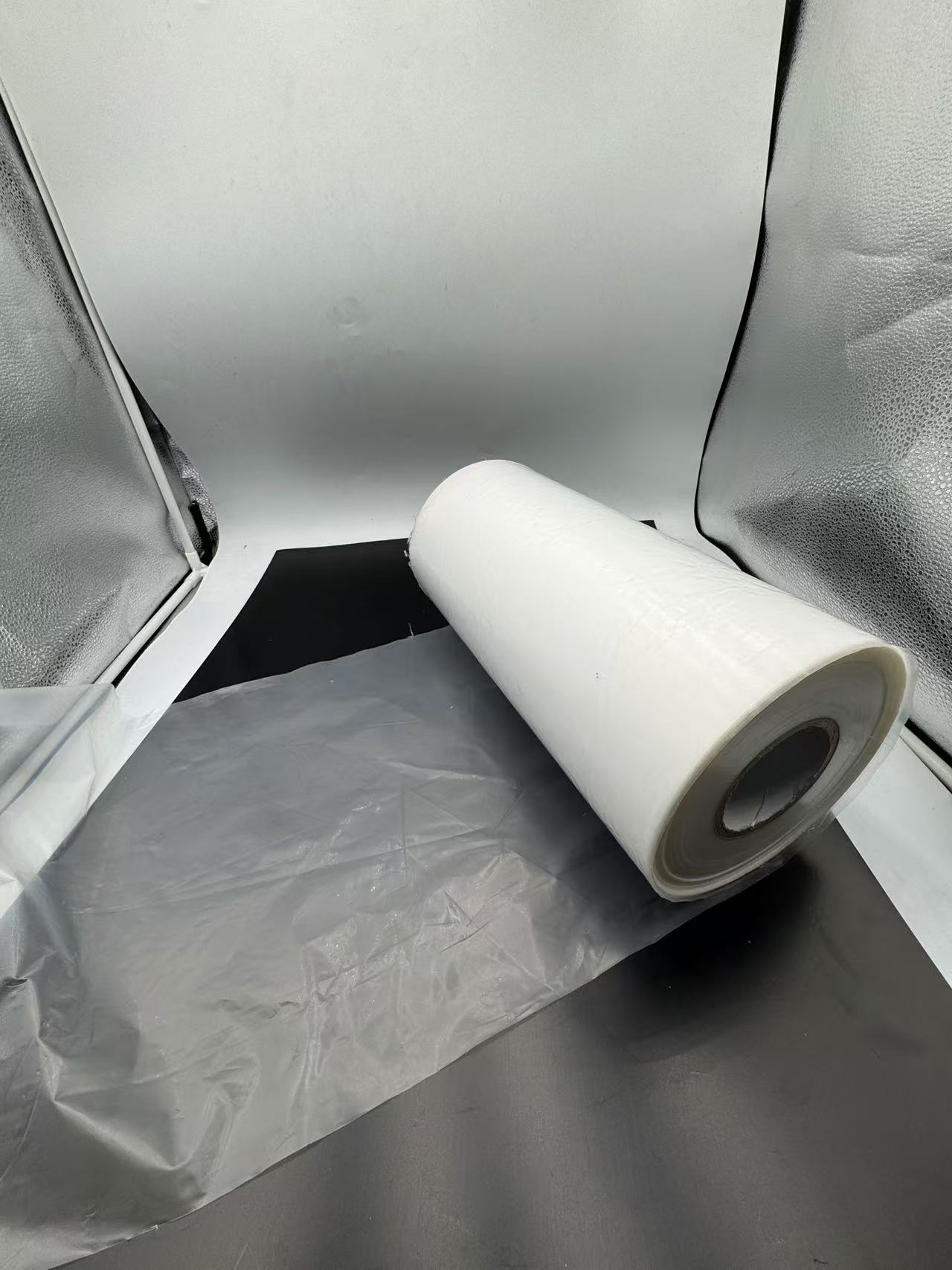

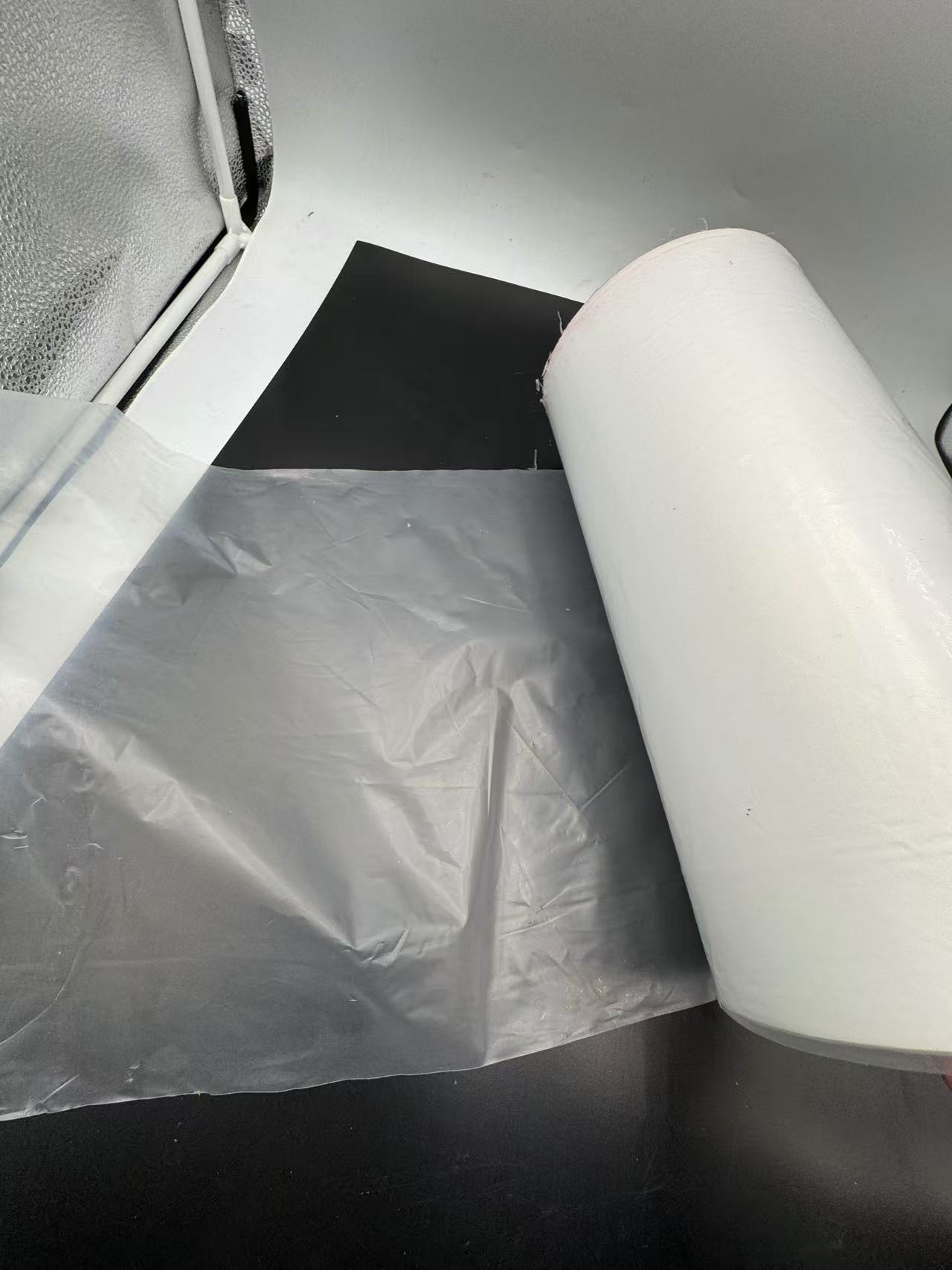

Transparent PE (Polyethylene) film is a ubiquitous material that plays a significant role in various aspects of our daily lives. It is a type of plastic film made from polyethylene resin,

which is known for its versatility and cost-effectiveness. This film is often characterized by its high transparency, allowing clear visibility of the contents it encloses or protects. In our day-to-day encounters, we can find transparent PE film in numerous forms. It is commonly used as a food wrapper, such as the thin, clear film that covers sandwiches, fruits, and baked goods in grocery stores or delis. You might also notice it as the protective covering on electronic devices like smartphones, tablets, and computer monitors during transportation and storage, preventing scratches and damage while still allowing the product's features to be visible. Additionally, it is widely employed in the packaging of various consumer products, from cosmetics and toiletries to stationery and toys, enhancing the visual appeal of the items on the shelves and providing a barrier against dust, moisture, and other contaminants.

Ⅱ. Physical Characteristics of Transparent PE Film

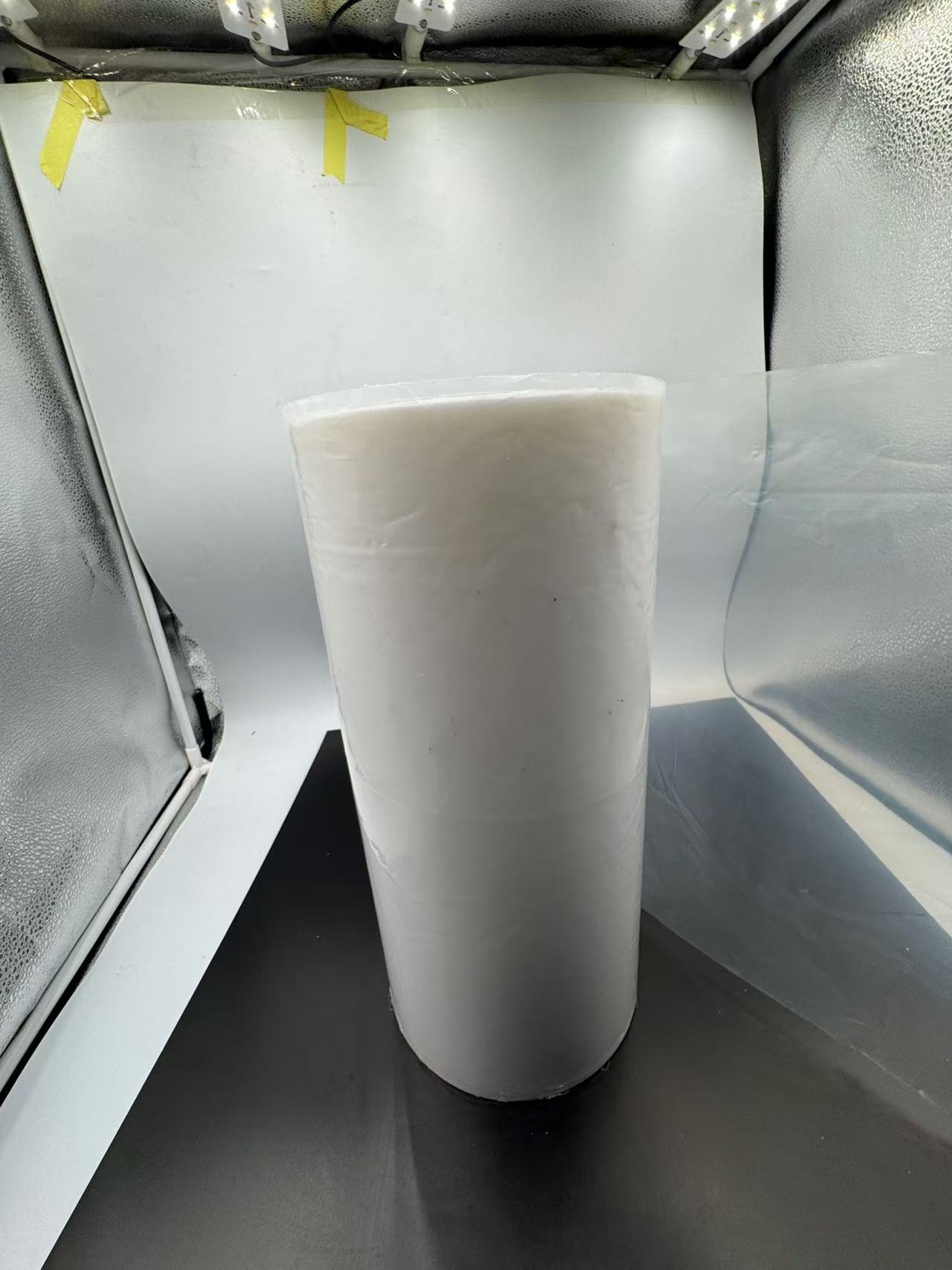

1. Appearance and Transparency

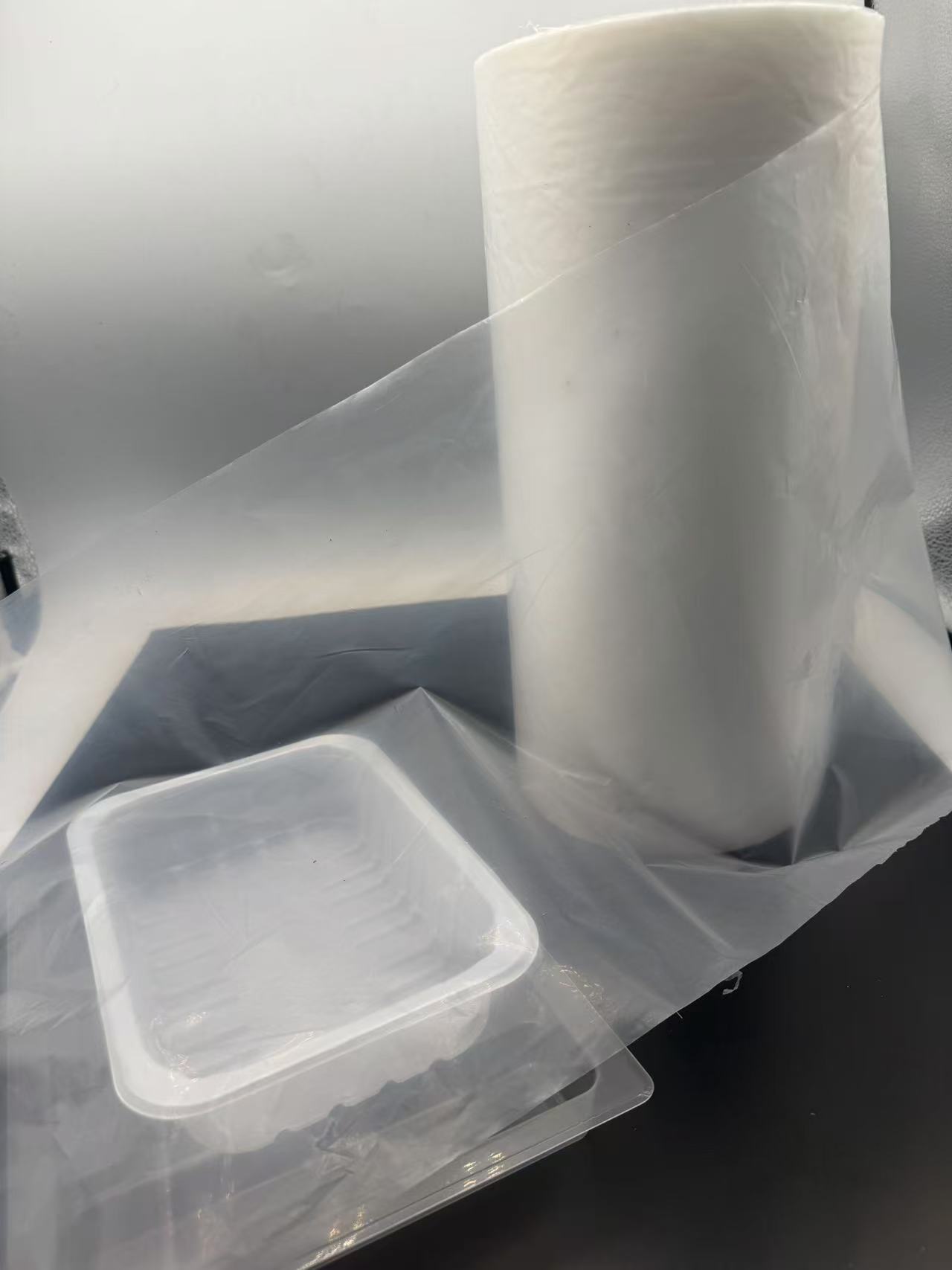

Transparent PE film exhibits a smooth and clear surface, often with a lustrous sheen that gives it an appealing visual quality. Its transparency is remarkable, allowing for a high degree of visibility through the film. When held up to the light, objects on the other side can be seen with great clarity, almost as if there were no barrier present. In comparison to other common films like PVC or PP, transparent PE film offers a more natural and distortion-free view. For instance, when used as a food wrapper, it enables consumers to easily identify the contents inside, enhancing the product's presentation. In the case of packaging delicate items such as jewelry or electronic components, the high transparency of the PE film ensures that the product's details and quality are fully visible, which can be crucial for marketing and quality inspection purposes.

2. Texture and Flexibility

The texture of transparent PE film is typically smooth to the touch, with a certain degree of softness that gives it a pleasant tactile feel. It is not overly rigid or brittle, which contributes to its excellent flexibility. This film can be effortlessly bent, folded, or wrapped around various objects without cracking or breaking. Its flexibility makes it highly adaptable for use in a wide range of applications. For example, in the packaging of irregularly shaped products like toys or sports equipment, the film can conform snugly to the contours of the item, providing a secure and protective covering. In the manufacturing of flexible packaging for liquids, such as pouches for shampoo or sauce, the flexibility of the PE film allows it to withstand the stresses of handling and transportation while maintaining its integrity and preventing leaks.

3. Density and Thickness Varieties

Transparent PE film is available in different densities, namely low-density (LDPE), medium-density (MDPE), and high-density (HDPE). LDPE is known for its excellent transparency and flexibility, making it suitable for applications where a soft and pliable film is required, such as in food packaging for items like bread or fresh produce. MDPE offers a balance between the properties of LDPE and HDPE,

with moderate strength and flexibility, and is often used in applications where a slightly more durable film is needed, such as in the packaging of heavier consumer goods. HDPE, on the other hand, has a higher density and greater mechanical strength, which makes it ideal for applications that demand robustness and resistance to puncture and tearing, such as in the packaging of industrial products or

Ⅲ. Chemical Properties of Transparent PE Film

1. Chemical Stability

2. Non-toxic and Safe Nature

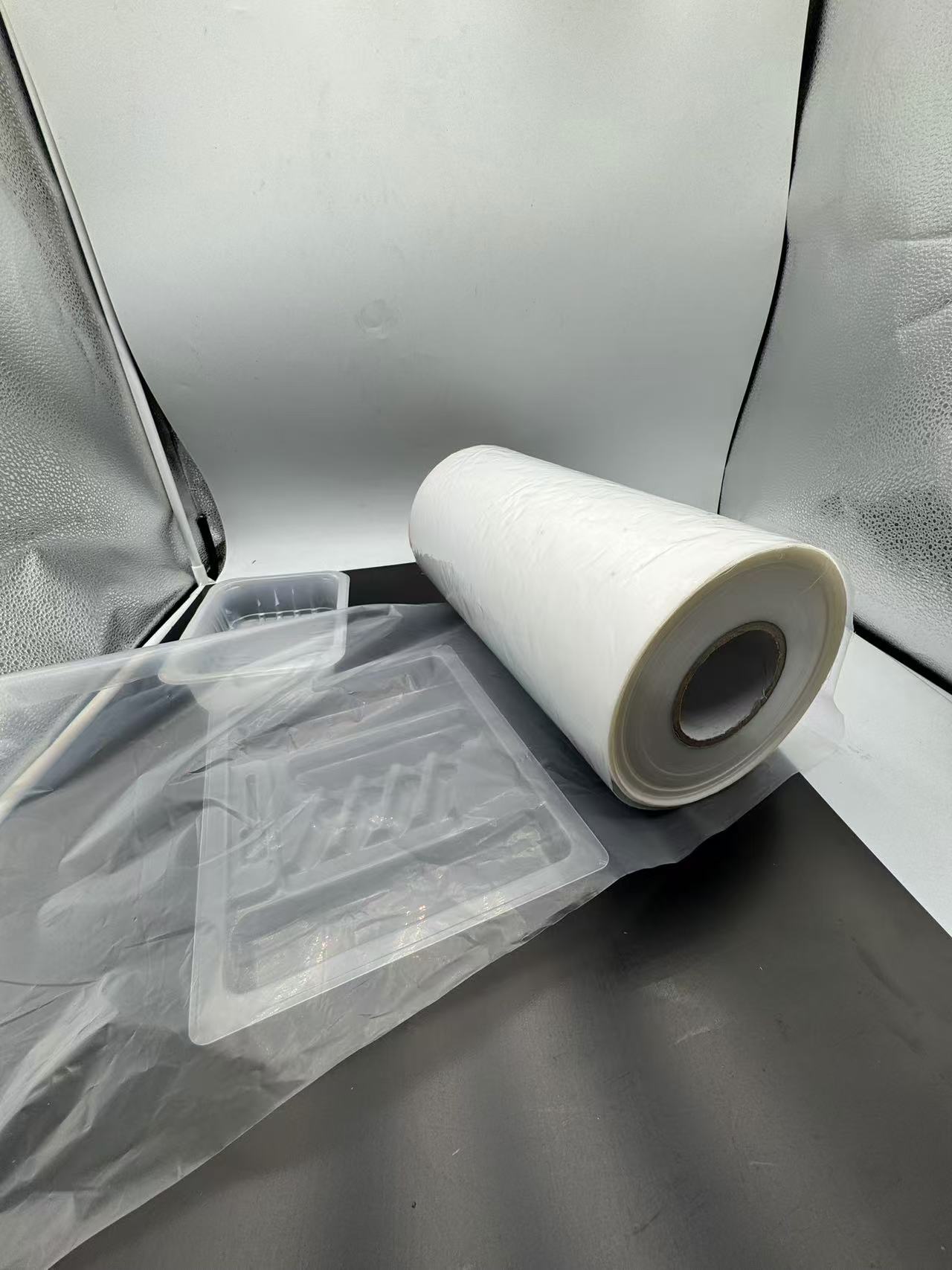

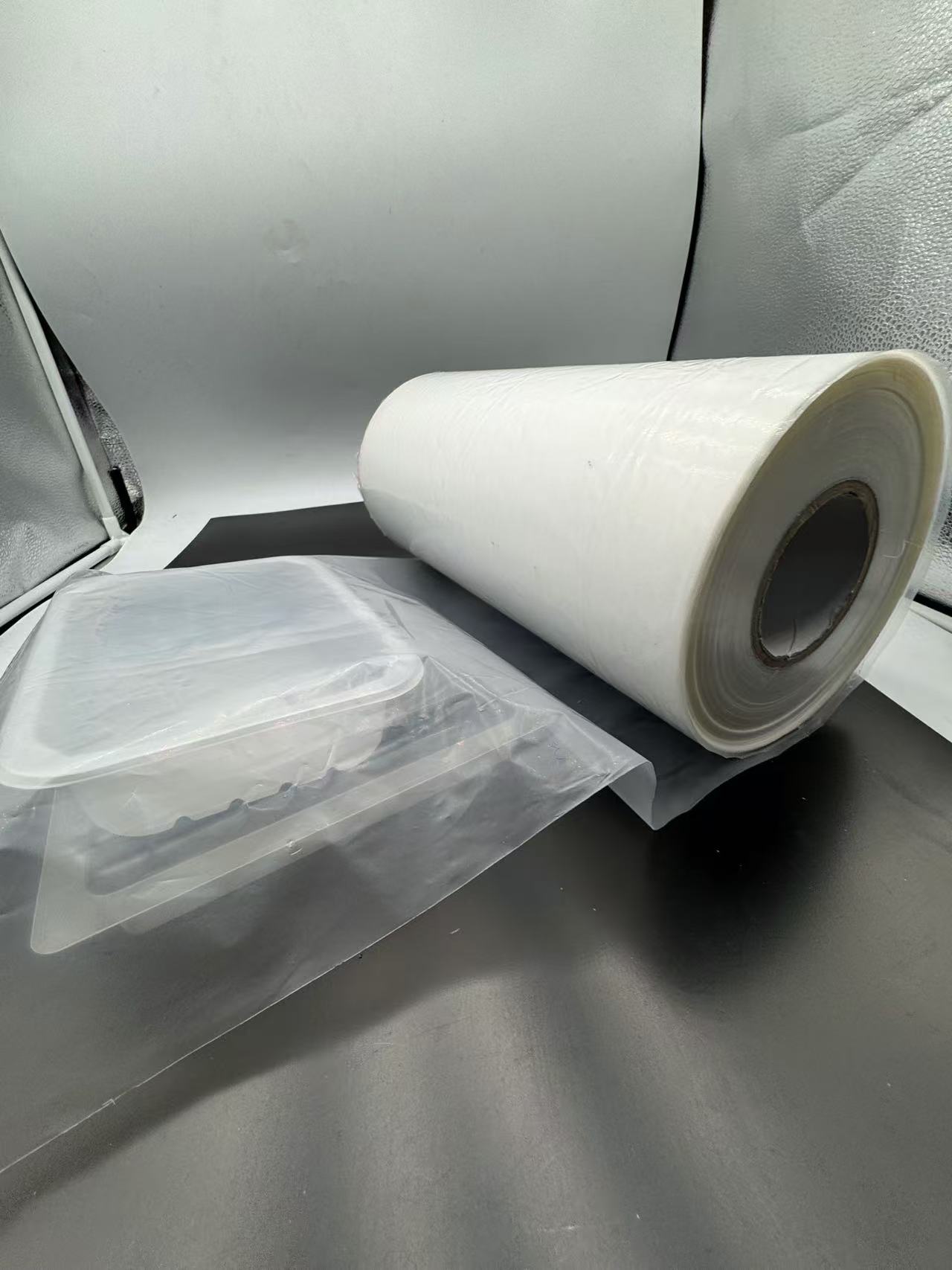

2. Pharmaceutical and Cosmetic Packaging

Transparent PE film is a preferred choice for packaging pharmaceuticals and cosmetics due to its ability to protect the products from contamination and light damage. In the pharmaceutical industry, it ensures the integrity of medications during storage and transportation. For example, tablets and capsules are often packaged in blister packs made of transparent PE film, which provides a barrier against moisture, air, and microorganisms, preventing degradation of the active ingredients. In the cosmetic sector, it is used for packaging products like creams, lotions, and lipsticks. The film protects the delicate formulations from oxidation and contamination, maintaining their efficacy and quality. Some well-known pharmaceutical and cosmetic brands that utilize this film for their packaging include Johnson & Johnson for their over-the-counter medications and L'Oréal for their various cosmetic products. These brands rely on the film's properties to enhance the shelf life and safety of their products, while also presenting them in an attractive and hygienic manner to consumers.

3. Industrial Product Packaging

2. Protecting Furniture and Home Appliances

When it comes to furniture, transparent PE film finds extensive use in safeguarding various surfaces. On wooden tables, it provides a protective barrier against scratches caused by daily activities such as placing objects on the table, writing, or moving things around. For instance, in a busy household with children, the use of a PE film on the dining table can prevent scratches from toys, cutlery, and other items, preserving the table's finish and appearance. Glass cabinets are also protected by the film, which

Similarly, the front panels and control areas of washing machines are protected from scuffs and scratches, ensuring that the appliance remains in good condition and functions properly.

3. Protecting Building Materials

During the construction process, building materials are vulnerable to damage. Stainless steel panels, which are commonly used in modern architecture for their sleek appearance and durability, can be scratched or dented during transportation and installation. Transparent PE film provides a protective layer that absorbs the impact of minor collisions and prevents scratches, ensuring that the panels arrive at the construction site in pristine condition. Aluminum curtain walls, another popular building material, are also protected by the film. It shields the aluminum surface from scratches and exposure to harsh environmental conditions such as dust, rain, and UV radiation during the construction period. Ceramic tiles, whether they are used for flooring or wall cladding, are protected from chipping and scratching. This is especially important during the installation process when the tiles are being handled and cut. The film can be easily removed after the installation is complete, leaving the tiles with a flawless finish.

Ⅵ. Agricultural Applications of Transparent PE Film

1. Crop Protection

2. Soil and Water Conservation

For example, in a region with intensive vegetable cultivation, the use of the film reduced the amount of nitrate and pesticide residues in the groundwater by approximately 50%, ensuring the safety of the water supply for both humans and livestock. When used as a mulch film, it helps to conserve water by reducing evaporation from the soil surface. The film forms a sealed layer, preventing water vapor from escaping into the atmosphere. This is beneficial in arid and semi-arid regions where water is a scarce resource. In a cornfield in a dry area, the use of the mulch film reduced water evaporation by about 30%, allowing the plants to access more water for growth. This not only increased the crop yield but also reduced the frequency of irrigation, saving water and energy. Additionally, the film helps to maintain soil fertility by reducing the loss of nutrients through leaching. The sealed environment under the film promotes the activity of beneficial soil microorganisms, which in turn aids in the decomposition of organic matter and the release of nutrients for plant uptake. Overall, the use of transparent PE film in soil and water conservation measures contributes to sustainable agricultural practices and the long-term productivity of the land.

Ⅶ. Other Special Applications of Transparent PE Film

1. Use in Arts and Crafts

2. Educational and Laboratory Uses

3. Decorative Applications

Ⅷ. Comparison with Other Similar Films

In conclusion, the choice between transparent PE film and other similar films depends on the specific requirements of the application.

Ⅸ. Future Trends and Innovations of Transparent PE Film

Ⅹ. Conclusion

When compared to other films, it offers distinct advantages in terms of cost-effectiveness, flexibility, and chemical resistance, although the choice depends on specific application requirements. Looking ahead, the future of transparent PE film holds great promise, with ongoing research and development focused on improving its properties, making it more environmentally friendly, and exploring innovative applications in smart packaging, medicine, and energy.

Overall, the importance of transparent PE film in our daily lives and industries cannot be overstated. It continues to evolve and adapt, opening up new possibilities and opportunities for its utilization, and is likely to remain a staple material for many years to come. We encourage readers to further explore the potential of this versatile material in their respective fields or daily life, whether it be in product packaging, protection, or creative projects, and discover the many benefits it can offer.