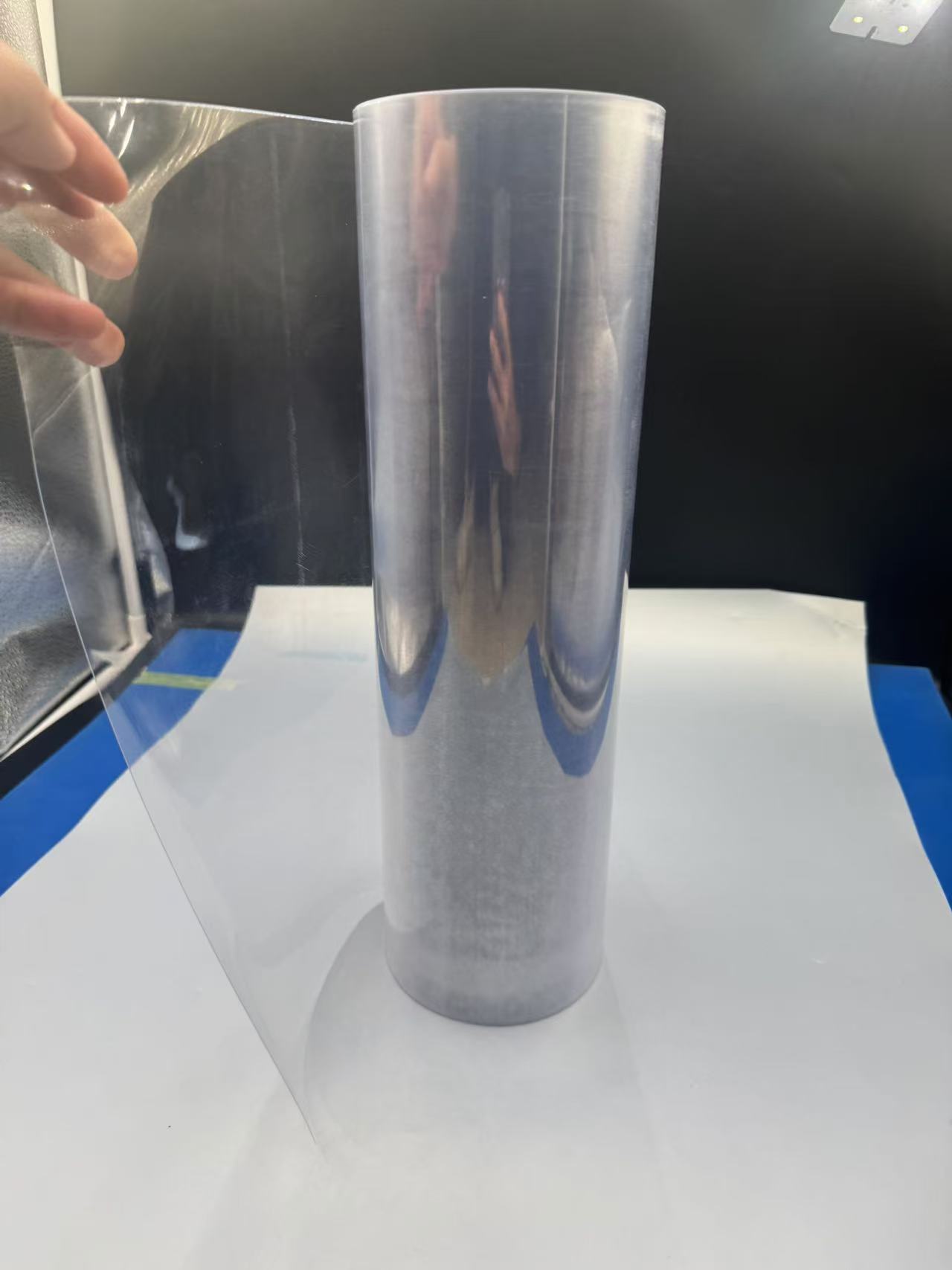

Unveiling the Potential of Transparent BOPS Film in Packaging Solutions

2025-03-12 11:22Section 1: Understanding Transparent BOPS Film – Properties and Composition

BOPS film is crafted from polystyrene resin that undergoes biaxial orientation—stretching in both the machine and transverse directions—during production. This process aligns the polymer chains, transforming a brittle material into a strong, transparent film tailored for demanding applications. Its unique characteristics make it suitable for a range of blister packaging needs, from perishable foods to sensitive pharmaceuticals.

1.1 Physical Properties

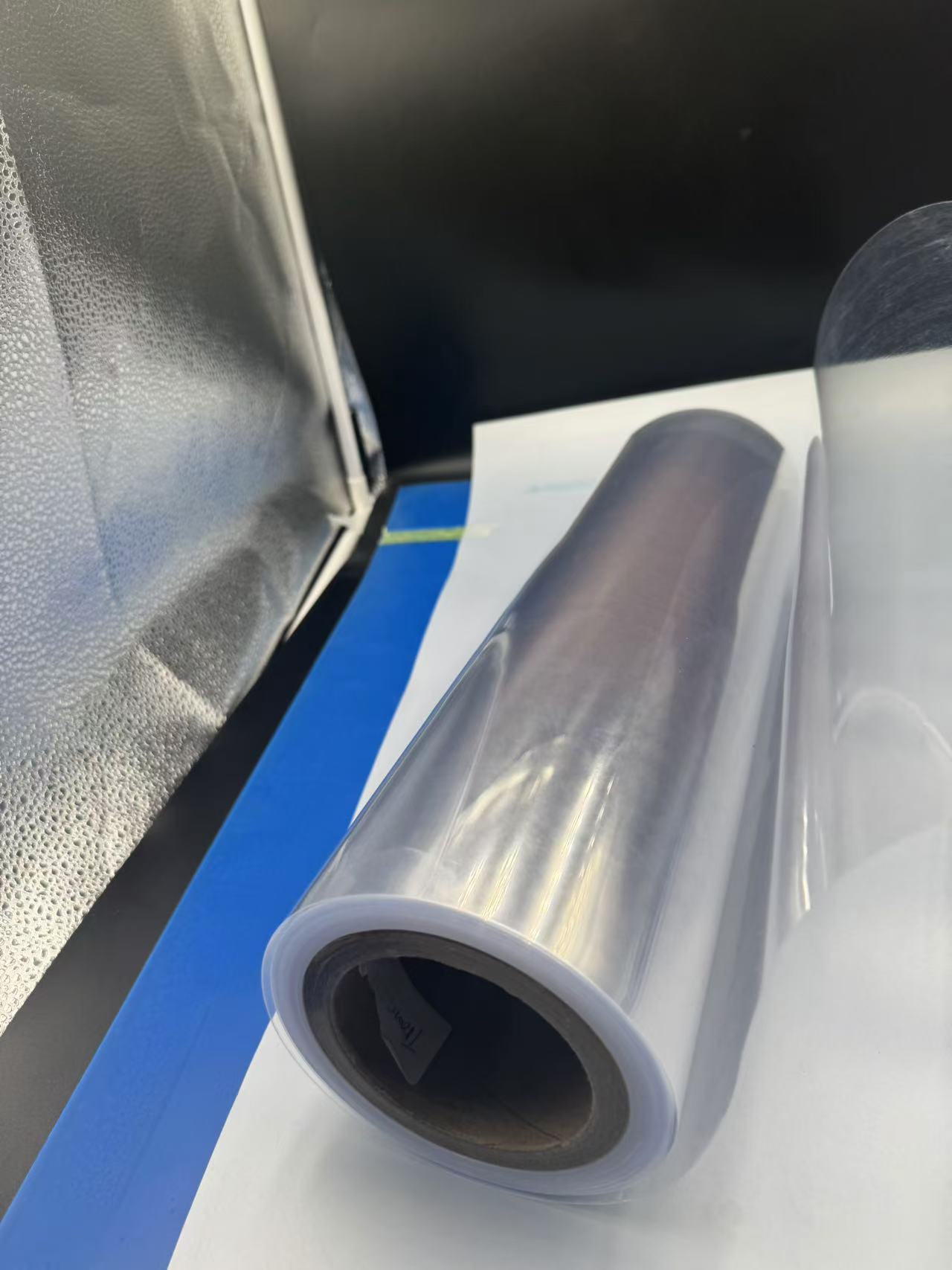

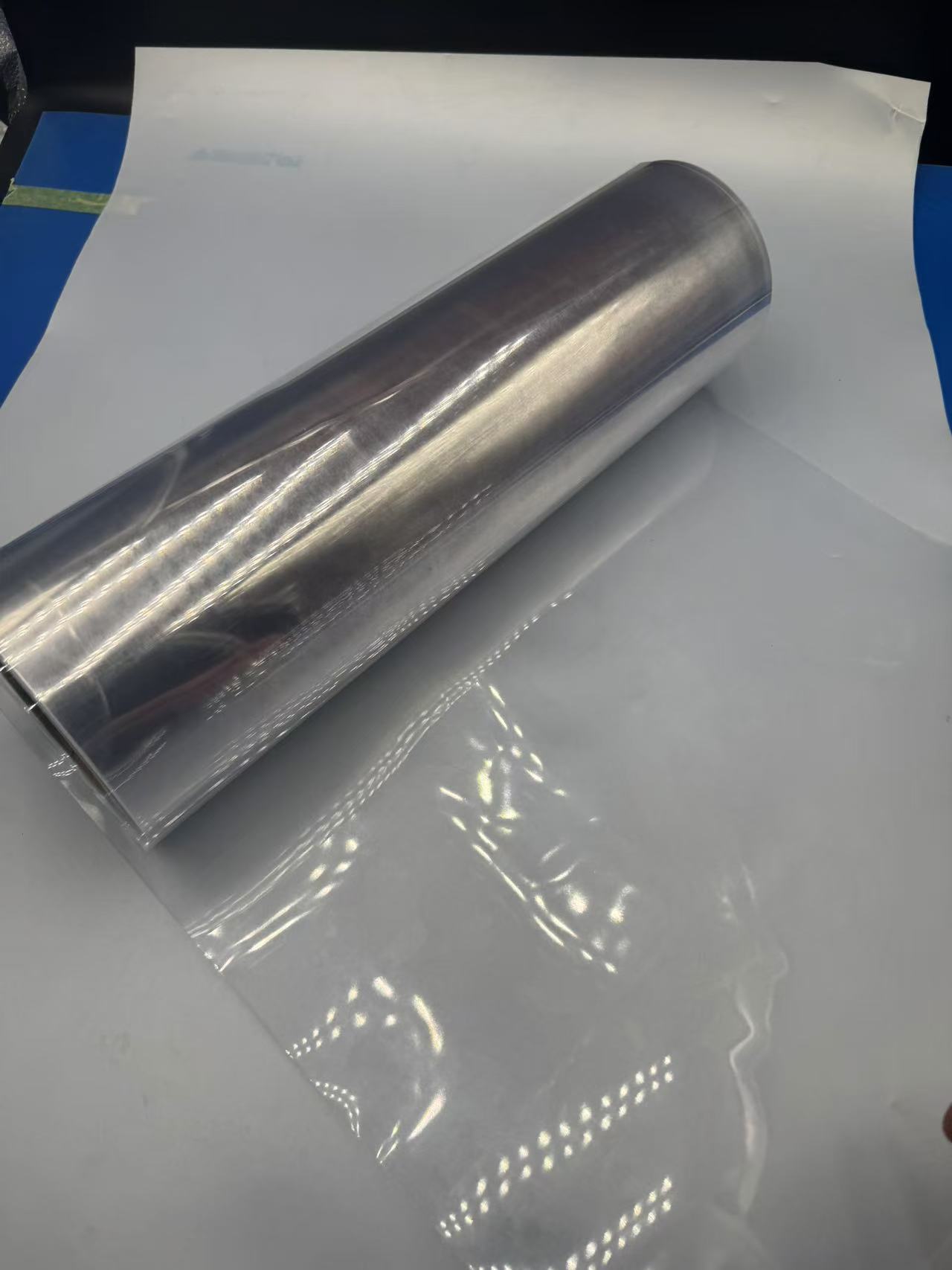

The defining feature of BOPS film is its exceptional clarity, with light transmittance exceeding 90%. This transparency rivals glass, allowing consumers to inspect contents with ease—whether it’s the vibrant red of a strawberry or the pristine white of a tablet. Its tensile strength, ranging from 50 to 70 MPa, ensures durability, resisting tears and punctures during handling. With a density of approximately 1.05 g/cm³, BOPS film is lightweight yet robust, reducing shipping costs without compromising protection.

Thermoformability is a key asset. BOPS film softens at 100–120°C, enabling it to be molded into precise cavities that snugly fit products of varying shapes—be it a plump grape or a cylindrical capsule. This adaptability is critical for blister packaging, where consistency and fit are paramount.

1.2 Barrier Properties

BOPS film offers moderate barrier protection, with a water vapor transmission rate (WVTR) of 50–70 g/m²/day at 38°C and 90% relative humidity, and an oxygen transmission rate of 1,000–1,500 cm³/m²/day. While not as impermeable as materials like aluminum foil, it suffices for many applications, particularly when paired with coatings or laminates. For instance, a PVDC (polyvinylidene chloride) layer can reduce WVTR to below 10 g/m²/day, enhancing its suitability for moisture-sensitive items.

1.3 Chemical and Thermal Stability

Chemically inert, BOPS film resists acids, alkalis, and most organic solvents, ensuring compatibility with food and drugs. It remains stable from -20°C to 80°C, accommodating diverse storage conditions—from refrigerated fruit displays to room-temperature medicine cabinets. This stability prevents unwanted interactions, preserving the freshness of a cherry or the potency of an analgesic.

1.4 Economic and Environmental Benefits

BOPS film is cost-competitive, leveraging efficient production processes to balance quality and affordability. It’s also recyclable, aligning with sustainability trends. While polystyrene recycling varies by region, advancements in mechanical recycling are making BOPS film an eco-friendlier option, appealing to industries seeking greener solutions.

Section 2: BOPS Film in Food Blister Packaging

Blister packaging is increasingly popular for food items, offering portion control, hygiene, and visual appeal. Transparent BOPS film excels in this role, protecting edibles while showcasing their quality.

2.1 Preserving Freshness and Safety

For processed foods like cheese cubes or deli meats, BOPS film provides a hygienic barrier against dust and microbes. Its moderate moisture resistance prevents sogginess, while its clarity highlights the product’s texture and color. Imagine a pack of sliced ham in a supermarket—through the BOPS film, consumers can see the pink freshness, confident in its quality.

The film’s rigidity ensures structural integrity, preventing crushing during stacking or transport. For delicate items like crackers, this strength is a game-changer, delivering an intact product to the table.

2.2 Portion Control and Convenience

BOPS film blisters enable single-serve packaging, a boon for on-the-go snacks like nuts or dried fruits. Each cavity, molded to fit a handful of almonds, keeps portions consistent and mess-free. The transparency enhances appeal—picture a traveler selecting a pack of golden raisins, drawn by the visible plumpness through the BOPS film.

2.3 Tamper Evidence

Food safety hinges on integrity, and BOPS film delivers. Once sealed with foil or plastic lids, any tampering—such as a puncture or tear—is immediately visible. This feature is vital for high-value items like gourmet chocolates, reassuring buyers of authenticity in a market wary of counterfeits.

Section 3: BOPS Film in Vegetable and Fruit Blister Packaging

Fresh produce benefits immensely from BOPS film’s properties, balancing preservation with presentation in blister packs designed for retail and consumer convenience.

3.1 Extending Shelf Life

Vegetables like cherry tomatoes or fruits like berries are prone to bruising and spoilage. BOPS film’s rigid cavities cradle each piece, reducing physical damage. Its moderate barrier properties slow moisture loss, keeping grapes plump or mushrooms firm. In a grocery store, a clamshell-style blister pack of strawberries in BOPS film reveals their ruby glow, enticing shoppers while protecting them from handling.

For longer shelf life, perforations can be added to BOPS film, allowing controlled airflow to prevent rot—a practical solution for breathable produce like blueberries.

3.2 Visual Appeal and Consumer Trust

The transparency of BOPS film transforms produce packaging into a marketing tool. A pack of mixed bell peppers—red, yellow, and green—shines through the film, inviting purchase with its vivid palette. This visibility builds trust, as consumers can assess freshness without opening the pack, reducing waste and returns.

3.3 Sustainability Edge

Unlike opaque plastics, BOPS film’s recyclability appeals to eco-conscious buyers. A farmer’s market vendor using BOPS film blisters for raspberries not only showcases their product but also signals environmental responsibility, aligning with modern consumer values.

Section 4: BOPS Film in Pharmaceutical Blister Packaging

In pharmaceuticals, where safety and stability are non-negotiable, BOPS film offers a transparent, reliable solution for blister packaging tablets, capsules, and more.

4.1 Drug Protection and Stability

BOPS film shields medications from light, dust, and moderate humidity. For over-the-counter drugs like paracetamol, its barrier properties maintain efficacy throughout a typical shelf life. The film’s clarity allows pharmacists to verify contents—a critical step for antibiotics like amoxicillin, where each capsule’s integrity is visible through the pack.

For moisture-sensitive drugs, such as effervescent vitamin C tablets, a PVDC-coated BOPS film prevents premature fizzing, ensuring the product performs as intended when dissolved.

4.2 Patient Safety and Compliance

Individual cavities in BOPS film blisters isolate doses, reducing contamination risks—a vital feature for drugs like warfarin with narrow therapeutic windows. The transparency aids compliance; a patient managing diabetes can see their metformin tablets clearly, paired with foil markings for daily tracking, simplifying complex regimens.

4.3 Tamper Evidence and Security

In a world of counterfeit medicines, BOPS film’s tamper-evident design is a safeguard. A breached blister—whether for antimalarials or painkillers—shows visible damage, protecting patients and reinforcing trust in the supply chain.

Section 5: Manufacturing and Customization of BOPS Film

The production of BOPS film for blister packaging is a precise process, tailored to meet the needs of food, produce, and pharmaceuticals.

5.1 Thermoforming Process

BOPS film is extruded into sheets, biaxially oriented, and thermoformed into cavities at 100–120°C. Whether shaping a shallow pocket for a blueberry or a deeper one for a capsule, the process ensures uniformity. High-speed machines churn out thousands of blisters hourly, meeting demand across industries.

5.2 Coating and Enhancement

To boost barrier performance, BOPS film can be coated with PVDC or laminated with metallized layers. For fruits needing UV protection—like apples—or drugs like doxycycline, these customizations extend shelf life. Perforated variants cater to vegetables, balancing humidity and freshness.

5.3 Regulatory and Quality Standards

For food and pharmaceuticals, BOPS film complies with standards like FDA and EU regulations. Testing for extractables ensures safety—whether it’s a grape or a tablet, no harmful substances leach into the product, a guarantee upheld by rigorous quality controls.

Section 6: Advantages and Limitations of BOPS Film

BOPS film’s strengths and challenges shape its role across these applications.

6.1 Key Advantages

Clarity: Its transparency enhances visibility, critical for quality assurance and appeal.

Strength: High tensile strength protects delicate items, from berries to tablets.

Cost-Effectiveness: Affordable production makes it viable for mass markets.

Recyclability: Supports sustainable packaging initiatives.

6.2 Limitations and Solutions

Its moderate barrier properties limit use for highly sensitive items unless enhanced with coatings. Thermal stability caps at 80°C, excluding high-heat processes, though this rarely affects blister applications. Public perception of polystyrene as less eco-friendly persists, but recycling advancements counter this narrative.

Conclusion

Transparent BOPS film is a packaging powerhouse, bridging food, vegetables, fruits, and pharmaceuticals with its clarity, strength, and versatility. From showcasing a ripe tomato to protecting a life-saving drug, it meets diverse needs with finesse. While its barrier properties require tailoring for some uses, its advantages—visibility, durability, and sustainability—ensure its place in modern blister packaging. As industries evolve, BOPS film stands ready to adapt, offering a clear, reliable solution for the future.