Exploring the Printable, Auto-Positioning, and Heat-Sealable Properties of PET Film

2025-04-02 12:02Polyethylene Terephthalate (PET) heat-sealable film has emerged as a cornerstone in modern packaging and labeling solutions, particularly in the food industry. Renowned for its unique combination of properties—printability, auto-positioning capabilities, and heat-sealability—this material offers a versatile, reliable, and visually appealing option for manufacturers and consumers alike. In this article, we’ll dive into the specifics of these characteristics, explore how they enhance the functionality of PET heat-sealable film, and illustrate their practical applications in food outer packaging and labeling with vivid examples and evidence-based insights.

The Core Properties of PET Heat-Sealable Film

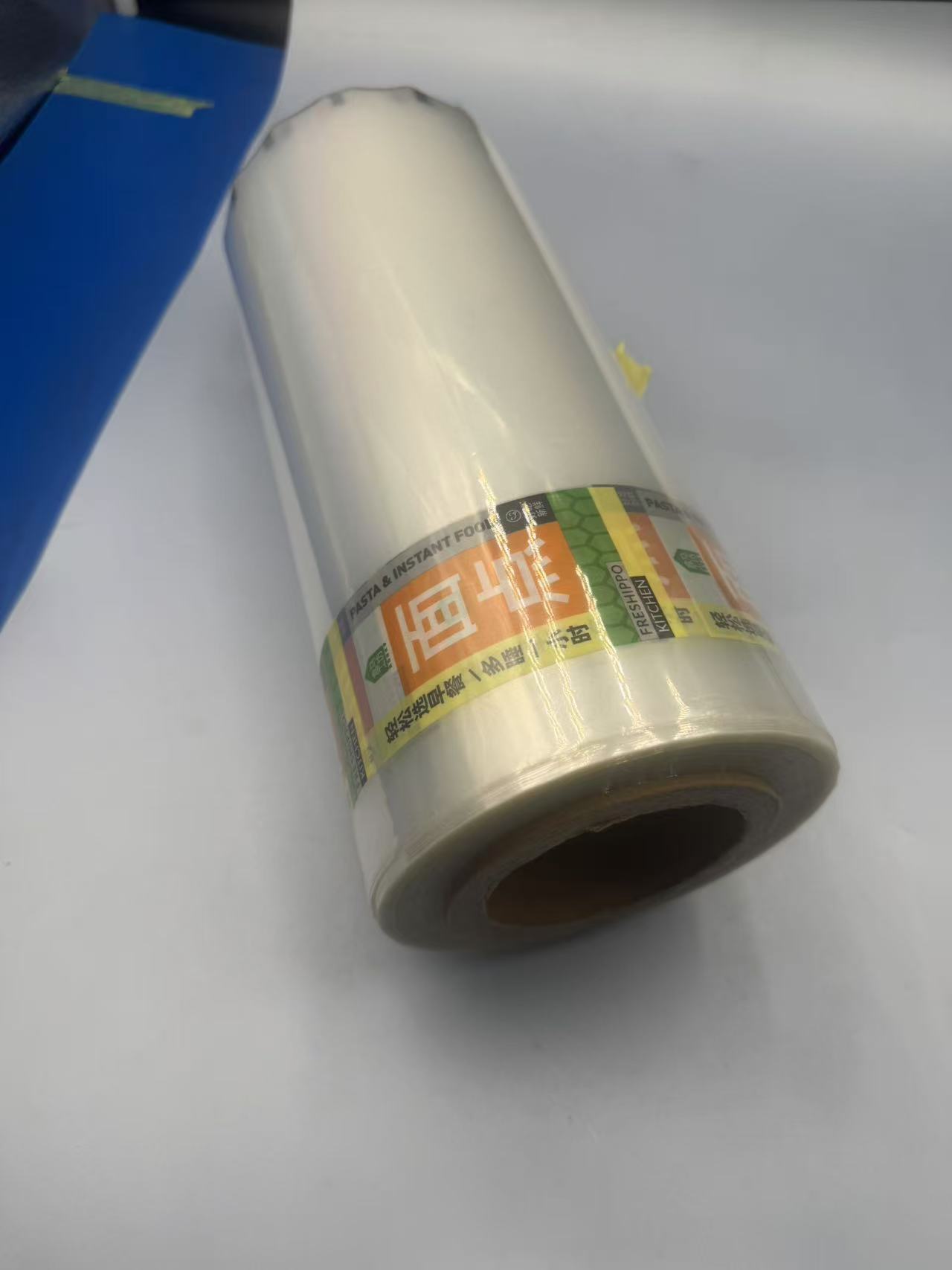

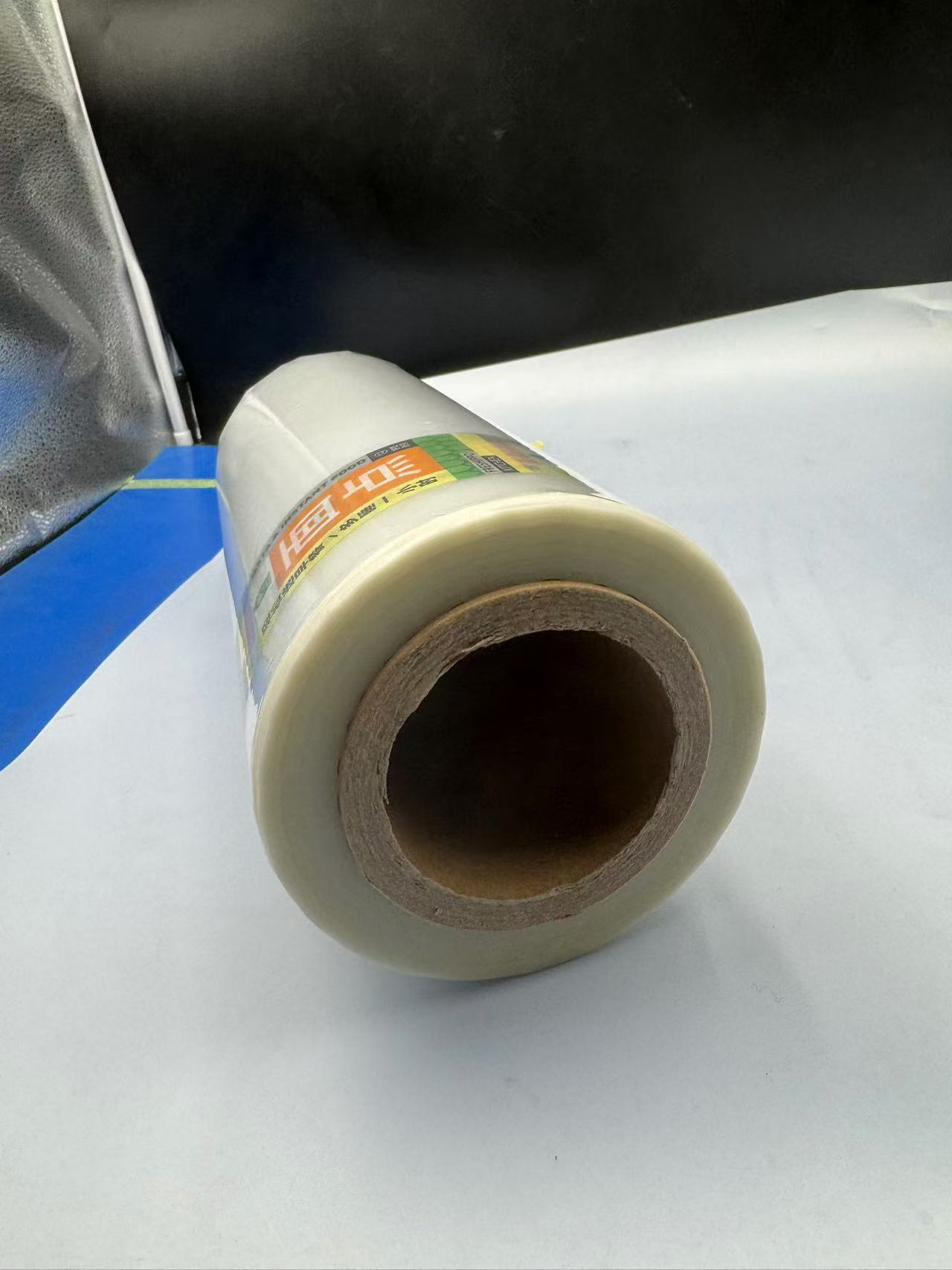

PET heat-sealable film is a biaxially oriented polyester film engineered with a heat-sealable layer, typically achieved through co-extrusion or coating with polymers like LDPE or EVA. This design allows the film to bond securely under heat and pressure, creating airtight and watertight seals. Beyond this fundamental trait, its printability and auto-positioning features elevate its utility, making it a standout choice in the competitive world of packaging materials.

Printable PET Film: A Canvas for Branding and Information

One of the most compelling attributes of PET heat-sealable film is its exceptional printability. The smooth, uniform surface of PET film serves as an ideal substrate for high-quality printing, accommodating a range of techniques such as flexographic, rotogravure, and digital printing. This capability allows manufacturers to transform the film into a vibrant canvas for branding, nutritional information, and eye-catching designs.

For instance, imagine a bag of frozen berries on a supermarket shelf. The PET heat-sealable film encasing the berries features a glossy, transparent finish with a printed label showcasing a vivid image of ripe strawberries, a bold brand logo, and a nutritional breakdown. The clarity of the film ensures the product remains visible, while the printed elements enhance its marketability. Studies have shown that packaging with high-quality graphics can increase consumer purchase intent by up to 30%, underscoring the value of printable PET film in driving sales.

Moreover, the film’s chemical resistance ensures that inks adhere well without smudging or fading, even under challenging conditions like refrigeration or exposure to moisture. This durability is critical for food packaging, where labels must remain legible throughout the product’s shelf life.Auto-Positioning PET Film: Precision in Production

The auto-positioning capability of PET heat-sealable film refers to its ability to align accurately during automated packaging processes. This property stems from the film’s dimensional stability and uniform thickness, which allow it to be fed seamlessly through high-speed machinery like Vertical Form Fill Seal (VFFS) or Horizontal Form Fill Seal (HFFS) systems.

Consider a production line churning out snack pouches. The PET heat-sealable film, pre-printed with a repeating pattern of logos and designs, moves through the machine with precision. Sensors detect registration marks on the film, ensuring that each pouch is cut and sealed at the exact point where the design aligns perfectly—no misalignment, no wasted material. This efficiency not only reduces production costs but also enhances the aesthetic consistency of the final product. In an industry where speed and accuracy are paramount, the auto-positioning feature of PET film is a game-changer, enabling manufacturers to meet tight deadlines without compromising quality.

Heat-Sealable PET Film: Securing Freshness and Safety

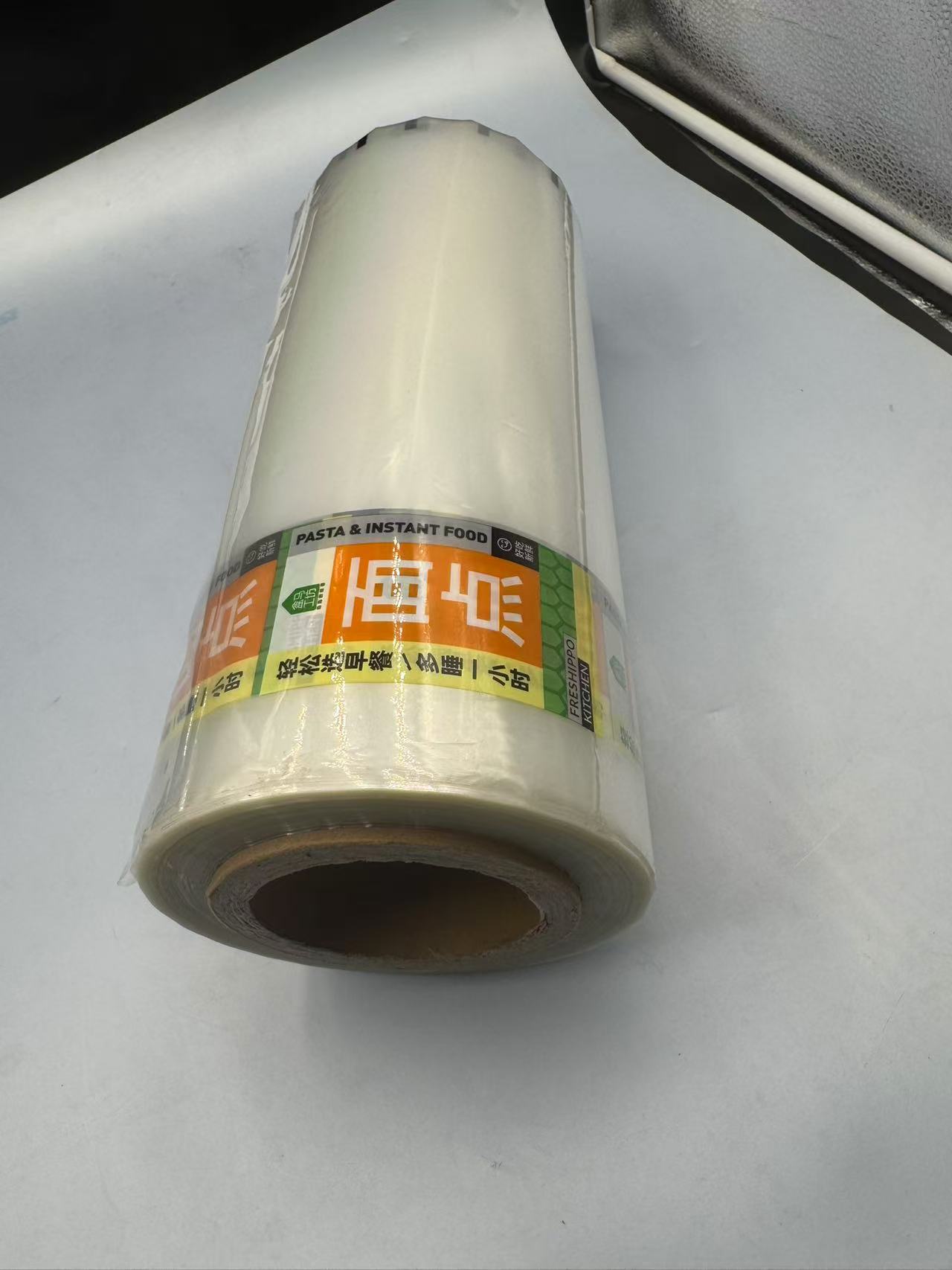

The defining characteristic of PET heat-sealable film is its ability to form strong, reliable seals when subjected to heat and pressure. This property is achieved through a specialized layer that bonds to itself or compatible substrates like APET or CPET trays, creating a barrier against moisture, oxygen, and contaminants.

Picture a ready-to-eat meal tray sealed with PET heat-sealable film. The film locks in the aroma of a freshly cooked lasagna, preventing air from seeping in and spoiling the dish. Tests have demonstrated that PET film can achieve oxygen transmission rates as low as 6 cc/m²/day, far surpassing many traditional packaging materials. This superior barrier performance extends shelf life, reduces food waste, and ensures that consumers enjoy products at their peak freshness.

Additionally, the heat-sealability of PET film supports a wide sealing temperature range (typically 110-190°C), making it adaptable to various packaging equipment and product types, from chilled salads to ovenable meals. Its dual-ovenable nature—capable of withstanding temperatures up to 220°C—further broadens its appeal for convenience foods.

Applications in Food Outer Packaging

The food industry has embraced PET heat-sealable film for its ability to balance functionality, safety, and aesthetics in outer packaging. Here are some specific applications where its properties shine:

Snack Packaging

Take the example of a bag of potato chips. The PET heat-sealable film forms a tight seal at the top and bottom, protecting the chips from moisture and crushing during transport. Its printable surface displays a bold brand name and a mouthwatering image of golden chips, while the auto-positioning feature ensures each bag is uniformly shaped and sealed. The film’s strength and flexibility allow it to withstand the rigors of stacking and shipping, delivering an intact product to the consumer.

Frozen Food Packaging

For frozen goods like fish fillets, PET heat-sealable film offers a robust solution. The film’s heat-sealed edges prevent freezer burn by blocking air and moisture, while its transparency—enhanced by anti-fog coatings—lets consumers inspect the product’s quality. The printable layer provides cooking instructions and a UPC code, seamlessly integrated into the design. The auto-positioning capability ensures that high-speed freezing and packaging lines operate without hiccups, maintaining efficiency in large-scale production.

Ready-Meal Trays

In the realm of convenience foods, PET heat-sealable film serves as a lidding material for trays. A tray of chicken curry, for example, is topped with a film that seals hermetically to the tray’s edges, preserving the dish’s flavor and nutrients. The film’s heat resistance allows it to go straight from the fridge to the oven, while its printable surface offers a recipe suggestion or a promotional message. The precision of auto-positioning ensures that the film aligns perfectly with the tray, avoiding leaks or weak spots in the seal.

Applications in Food Labeling

Beyond outer packaging, PET heat-sealable film plays a pivotal role in food labeling, where its printability and durability are particularly valuable:

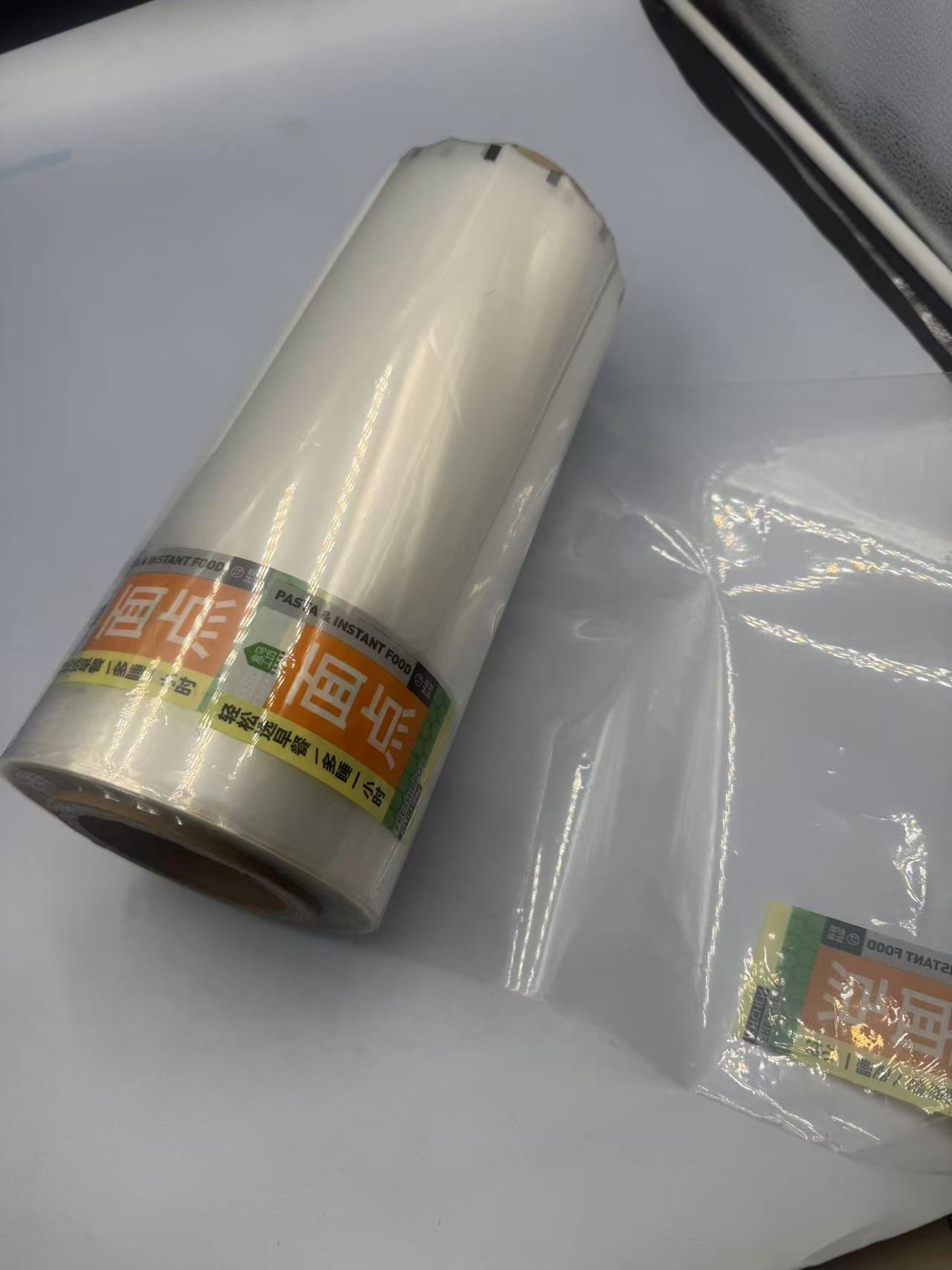

Shelf-Stable Product Labels

Consider a jar of pasta sauce with a wraparound label made from PET heat-sealable film. The film’s printable surface showcases a rich red tomato graphic and a list of ingredients, printed in crisp detail. Its heat-sealable layer adheres securely to the jar, resisting peeling even when exposed to condensation in a refrigerator. The auto-positioning feature ensures that the label aligns perfectly around the jar’s curvature, creating a polished, professional look that enhances brand recognition.

Fresh Produce Labels

For items like pre-cut fruit trays, PET heat-sealable film doubles as both a lid and a label. The film seals the tray while displaying a printed “Best By” date and a colorful fruit medley image. Its clarity allows shoppers to see the contents, while the heat-sealed bond keeps the fruit fresh. The auto-positioning capability ensures that the label’s text and graphics are consistently placed, avoiding overlaps or misprints that could confuse consumers.Promotional Sleeves

PET heat-sealable film is also used for shrink sleeves on beverage bottles. Imagine a bottle of juice wrapped in a full-body sleeve made from PET film. The printable surface bursts with a tropical fruit design and a limited-time offer, while the heat-sealable property ensures the sleeve shrinks tightly around the bottle when heated, conforming to its shape. The auto-positioning feature guarantees that the design aligns with the bottle’s contours, creating a seamless, eye-catching presentation.

Benefits and Broader Implications

The integration of printable, auto-positioning, and heat-sealable properties in PET film offers tangible benefits for manufacturers, retailers, and consumers. For manufacturers, the film’s versatility streamlines production, reduces material waste, and supports high-quality branding. Retailers benefit from extended shelf life and attractive packaging that drives sales, while consumers enjoy fresher, safer food with clear, informative labels.

Moreover, PET heat-sealable film aligns with sustainability goals. Its recyclability—capable of incorporating up to 90% post-consumer waste—makes it an eco-friendly choice in an era where environmental concerns are paramount. The film’s lightweight nature also reduces transportation emissions, further enhancing its green credentials.