Unveiling the Properties and Applications of Transparent BOP Film in Modern Packaging

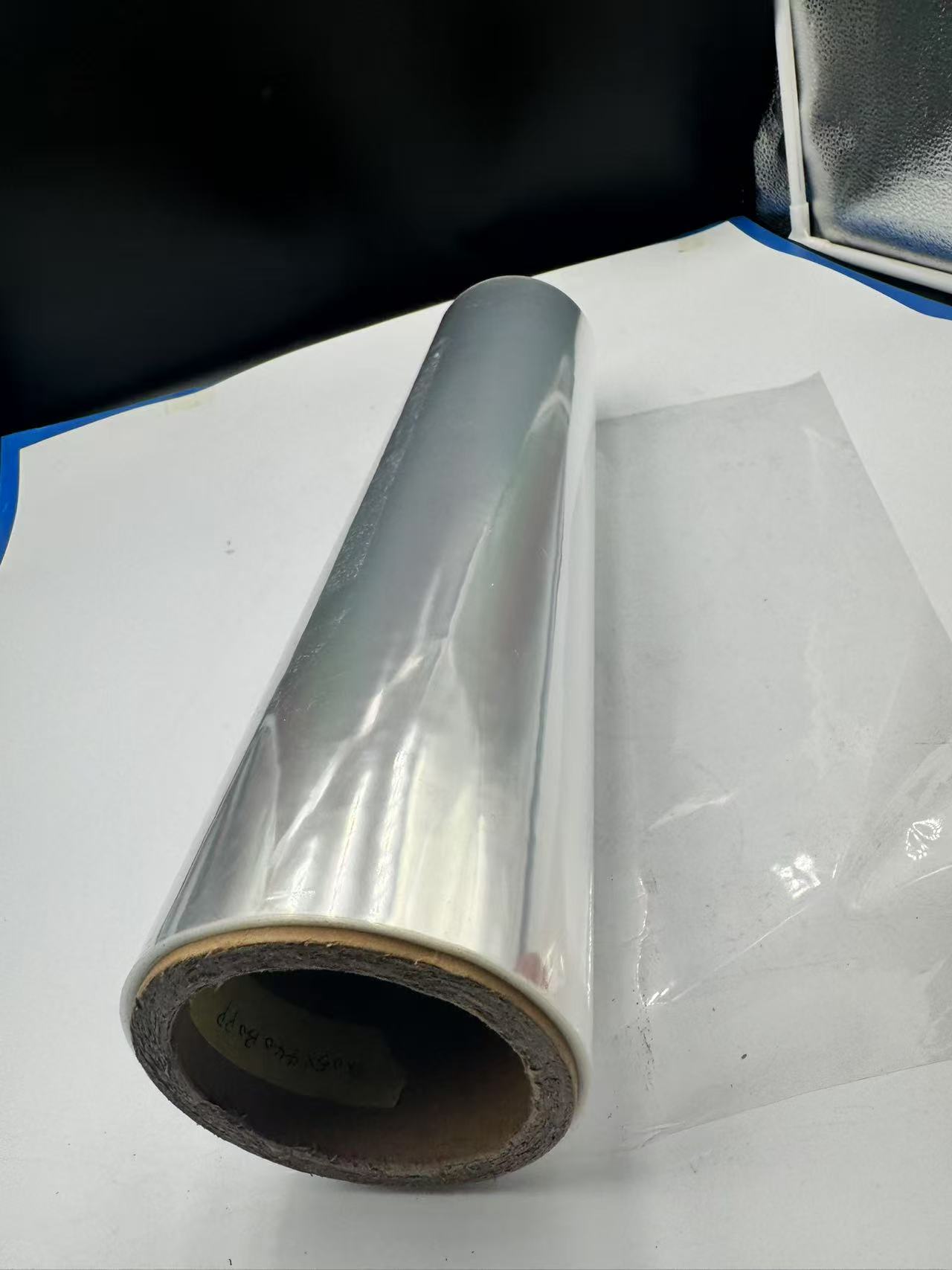

2025-08-06 17:27Biaxially Oriented Polyethylene Terephthalate (BOPET) film, commonly referred to as transparent BOP film, is a high-performance polyester material renowned for its exceptional clarity, strength, and versatility. Produced through a process of biaxial stretching—both longitudinally and transversely—BOPET film achieves superior mechanical and barrier properties,  making it a preferred choice across industries such as food packaging, medical packaging, and industrial applications. This article explores the defining characteristics of transparent BOPET film and its practical uses, supported by vivid examples and evidence of its impact on functionality, aesthetics, and sustainability.Characteristics of Transparent BOPET FilmTransparent BOPET film is a thin, flexible, and robust material that owes its unique properties to the biaxial orientation process. This process aligns the molecular structure of PET, enhancing its strength, clarity, and barrier performance. Below are the key characteristics that make BOPET film indispensable in various

making it a preferred choice across industries such as food packaging, medical packaging, and industrial applications. This article explores the defining characteristics of transparent BOPET film and its practical uses, supported by vivid examples and evidence of its impact on functionality, aesthetics, and sustainability.Characteristics of Transparent BOPET FilmTransparent BOPET film is a thin, flexible, and robust material that owes its unique properties to the biaxial orientation process. This process aligns the molecular structure of PET, enhancing its strength, clarity, and barrier performance. Below are the key characteristics that make BOPET film indispensable in various applications:Exceptional Transparency and Optical Clarity

applications:Exceptional Transparency and Optical Clarity

BOPET film boasts outstanding transparency, with light transmission rates often exceeding 90%. This crystal-clear appearance enhances the visual appeal of packaged products, making it ideal for applications where product visibility is crucial. Its glossy finish also adds a premium aesthetic, elevating brand perception in competitive markets.

Superior Barrier Properties

BOPET film provides excellent resistance to moisture, gases (such as oxygen and carbon dioxide), and UV light. These barrier properties are critical for preserving the freshness, flavor, and quality of perishable goods, particularly in food and pharmaceutical packaging. For instance, BOPET films can reduce oxygen permeability to as low as 80–120 cm³/m²/day, significantly extending shelf life compared to other plastics like polyethylene.

High Tensile Strength and Durability

The biaxial orientation process imparts remarkable tensile strength and tear resistance to BOPET film, allowing it to withstand mechanical stress during handling, transportation, and storage. Despite its thin gauge (typically 12–50 microns), BOPET film is robust enough to protect contents from punctures and abrasions, making it suitable for both lightweight and heavy-duty applications.

Thermal Stability and Versatility

BOPET film exhibits excellent thermal stability, withstanding temperatures from -70°C to 150°C in some grades. This makes it suitable for applications ranging from frozen food packaging to high-temperature sterilization processes in medical packaging. Its ability to maintain structural integrity under varying conditions enhances its versatility.

Chemical Resistance and Food Safety

BOPET film is chemically inert, non-toxic, and compliant with stringent food safety regulations, such as those set by the FDA and EFSA. It does not react with packaged contents, ensuring the safety and integrity of food, pharmaceuticals, and other sensitive products. This chemical stability also makes it resistant to oils, greases, and mild acids, broadening its applicability.

Printability and Customizability

BOPET film’s smooth surface is ideal for high-quality printing, enabling vibrant graphics, logos, and product information to be displayed. It can also be metallized, laminated, or coated to enhance barrier properties or add functionalities like antistatic or anti-fog features. This customizability allows manufacturers to tailor BOPET film to specific branding or performance needs.

Recyclability and Sustainability

BOPET film is fully recyclable, and advancements in recycling technologies have increased the use of recycled PET (R-PET) in its production. This aligns with global sustainability goals, reducing reliance on virgin materials and minimizing waste. Some BOPET films are also being developed with biodegradable additives, further enhancing their environmental credentials.

Lightweight and Cost-Effective

BOPET film’s high strength-to-weight ratio makes it an economical choice, as thinner films can achieve the same performance as thicker alternatives. Its lightweight nature reduces transportation costs and carbon emissions, while its efficient production process ensures cost-effectiveness for large-scale manufacturing.

Applications of Transparent BOPET FilmThe unique properties of transparent BOPET film make it a versatile material across multiple industries. Below, we explore its applications in food packaging, medical packaging, and industrial uses, with specific examples to illustrate its benefits.1. Food PackagingTransparent BOPET film is widely used in food packaging due to its ability to balance product protection, visual appeal, and consumer convenience. Its barrier properties, clarity, and compliance with food safety standards make it ideal for a variety of food products, from snacks to frozen goods.Preservation and Shelf Life Extension

BOPET film’s excellent barrier properties protect food from moisture, oxygen, and light, which can degrade quality and lead to spoilage. For example, in snack packaging, such as potato chips or dried fruits, laminated BOPET films create a robust barrier that maintains crispness and flavor for months. A study by the Packaging Technology and Science journal notes that BOPET-based laminates can reduce oxygen transmission rates by up to 90% compared to non-oriented films, significantly extending shelf life.