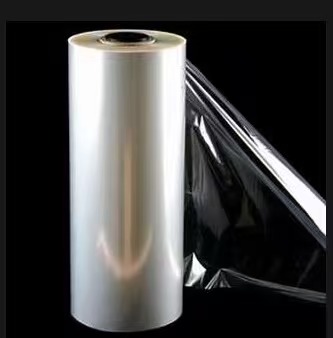

The Versatile Marvel of Transparent BOPET Film: Properties and Applications Across Industries

2025-08-07 17:14Introduction

Transparent BOPET (Biaxially Oriented Polyethylene Terephthalate) film is a high-performance polyester film renowned for its exceptional combination of mechanical, optical, and chemical properties. Manufactured through a meticulous process of extruding and stretching polyethylene terephthalate (PET) in both machine and transverse directions, BOPET film achieves a tightly ordered molecular structure that imparts remarkable strength, clarity, and versatility. Since its development in the mid-20th century by companies like TOPLEADER

and Imperial Chemical Industries, BOPET film has evolved from a niche material to a cornerstone of industries ranging from packaging to electronics, medical applications, and even aerospace. This article explores the unique characteristics of transparent BOPET film and its diverse applications, highlighting its pivotal role in modern technology and sustainable innovation.Characteristics of Transparent BOPET FilmTransparent BOPET film is distinguished by a suite of properties that make it a preferred material across multiple sectors. Below are its key characteristics, each contributing to its widespread utility:High Tensile Strength and Durability

BOPET film exhibits exceptional mechanical strength, with a tensile strength often exceeding 200 MPa. This robustness allows it to withstand physical stress, making it ideal for applications requiring durability, such as packaging and industrial laminates. Its ability to resist tearing and puncturing ensures that products remain protected during handling and transportation.

Optical Clarity and Low Haze

The film’s transparency, characterized by low haze and high gloss, makes it an excellent choice for applications where visual appeal is critical. With light transmission rates often exceeding 90%, BOPET film ensures that packaged contents are clearly visible, enhancing product presentation in retail environments. Its glossy surface also supports high-quality printing, enabling vibrant designs and branding.

Chemical and Thermal Stability

BOPET film is highly resistant to most chemicals, including oils, greases, and solvents, making it suitable for harsh environments. It maintains its integrity at temperatures ranging from -60°C to 150°C, allowing it to perform reliably in both high-temperature processing and cold storage applications. However, prolonged exposure to hot water or steam can cause brittleness, a consideration for specific use cases.

Barrier Properties

When metallized, BOPET film offers excellent gas and moisture barrier properties, significantly extending the shelf life of perishable goods. Even in its transparent form, it provides moderate moisture resistance, making it suitable for food and pharmaceutical packaging where protection from environmental factors is essential.

Electrical Insulation

With a high dielectric constant and low dielectric loss, BOPET film is an outstanding insulator. Its ability to withstand high voltages and resist electrical breakdown makes it a staple in the electronics industry for applications like capacitors and cable insulation.

Dimensional Stability

The biaxial orientation process ensures that BOPET film maintains its shape and size under varying conditions, such as temperature fluctuations or mechanical stress. This stability is crucial for applications requiring precision, such as in electronic displays or medical imaging.

Eco-Friendly Potential

BOPET film is recyclable, aligning with growing demands for sustainable materials. Advances in recycling technologies allow it to be reprocessed into new polyester products, reducing environmental impact. Additionally, its lightweight nature contributes to lower transportation emissions compared to heavier alternatives.

Applications of Transparent BOPET FilmThe unique properties of transparent BOPET film have led to its adoption across a wide array of industries. Below, we explore its applications in detail, illustrating how its characteristics translate into real-world utility.1. Flexible PackagingTransparent BOPET film is a cornerstone of the packaging industry, particularly for food, beverages, and consumer goods. Its high clarity allows consumers to see the product inside, enhancing appeal for items like snacks, confectionery, and fresh produce. For example, a 12-micron BOPET film laminated with a polyethylene (PE) layer is commonly used for snack pouches, providing both visual clarity and a robust barrier against moisture and oxygen. This combination ensures that products like potato chips remain fresh and crisp for months.

In pharmaceutical packaging, BOPET film is used in blister packs and sachets, where its clarity allows for easy dosage visibility, and its chemical stability ensures sterility. For instance, blister packs for tablets often use a BOPET layer to protect medications from light and moisture while maintaining a clear view of the contents. Its compatibility with printing processes like flexography and gravure also makes it ideal for branding and labeling, with vibrant designs that attract consumers.

2. Electronics and Electrical InsulationThe electronics industry relies heavily on BOPET film for its excellent electrical insulation properties. It is widely used in the production of film capacitors, where its high dielectric strength and low dielectric loss ensure reliable performance in electronic circuits. For example, in compact devices like smartphones, BOPET-based capacitors help manage power efficiently, contributing to device longevity.

Additionally, BOPET film serves as an insulating layer in wires, cables, and transformers, preventing electrical shorts and enhancing safety. Its dimensional stability ensures that it maintains its insulating properties even under high temperatures or mechanical stress, making it a critical component in motors and generators.

3. Medical and Imaging ApplicationsIn the medical field, transparent BOPET film is used for its clarity and chemical inertness. It serves as a base material for X-ray films and other medical imaging applications, where its high transparency ensures sharp, accurate images. In CT scanners, BOPET film acts as a physical barrier between the X-ray tube and the patient, allowing negligible attenuation of the X-ray beam while maintaining safety.

BOPET film is also used in pharmaceutical packaging, such as pouches for medical devices, where its purity and barrier properties protect sensitive contents. For example, IV fluid bags often incorporate BOPET layers to ensure sterility and durability during storage and transport.