Unveiling the Crystal Clear World of Transparent CPP Film: Properties and Versatile Applications

2025-09-15 16:25Introduction

EImagine walking down a supermarket aisle, your eyes drawn to a vibrant package of fresh strawberries, their ruby-red hue gleaming through a flawless, crystal-clear layer. Or picture a sleek electronic gadget arriving at your doorstep, cocooned in a protective sheath that shields it from the elements while allowing you to admire its design. This invisible hero in both scenarios?

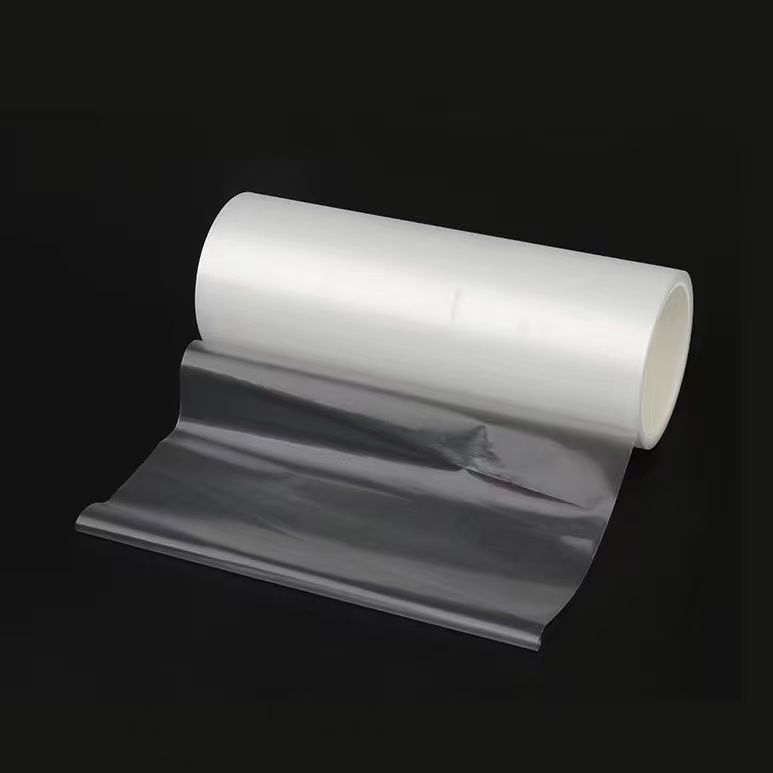

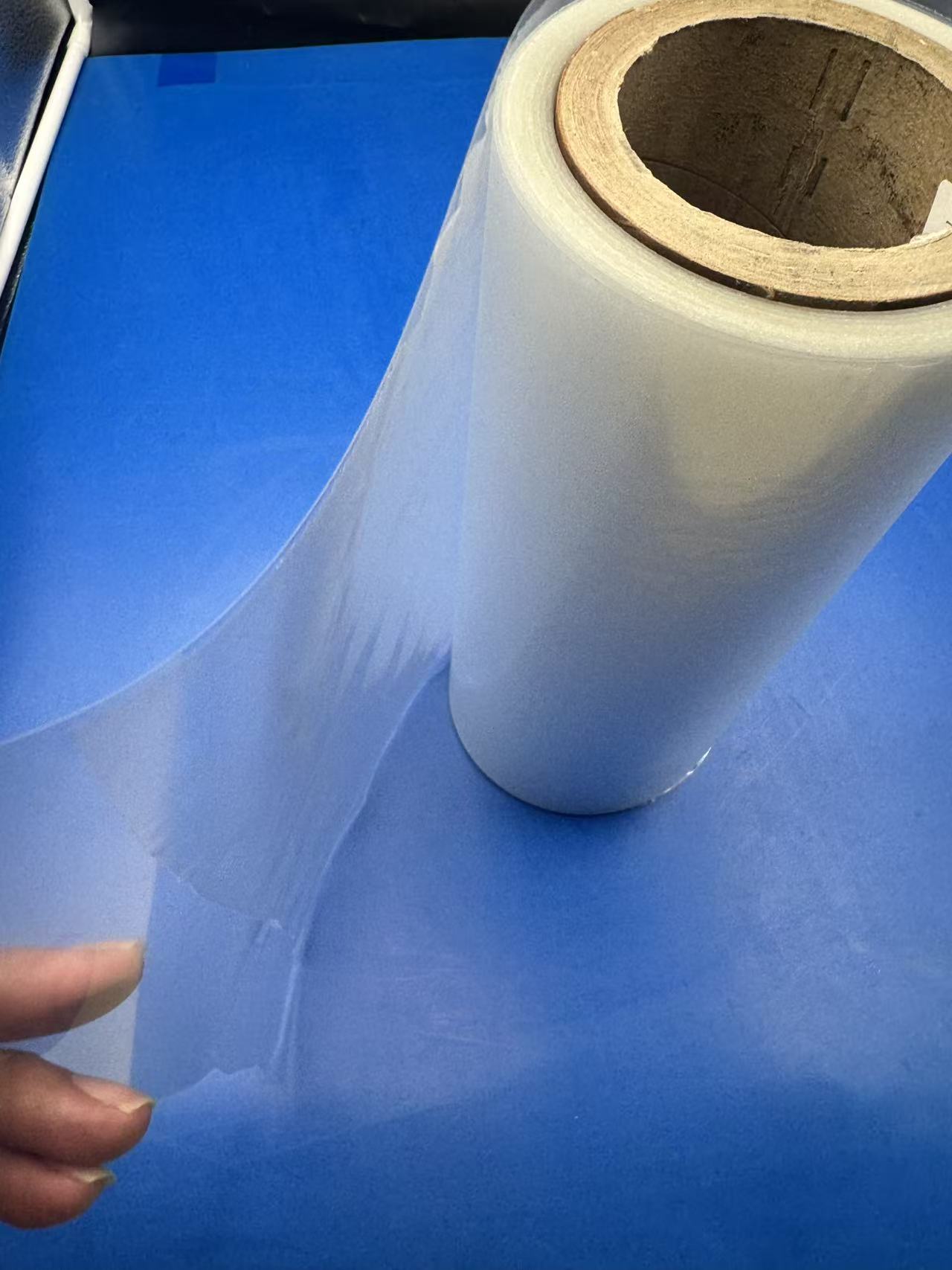

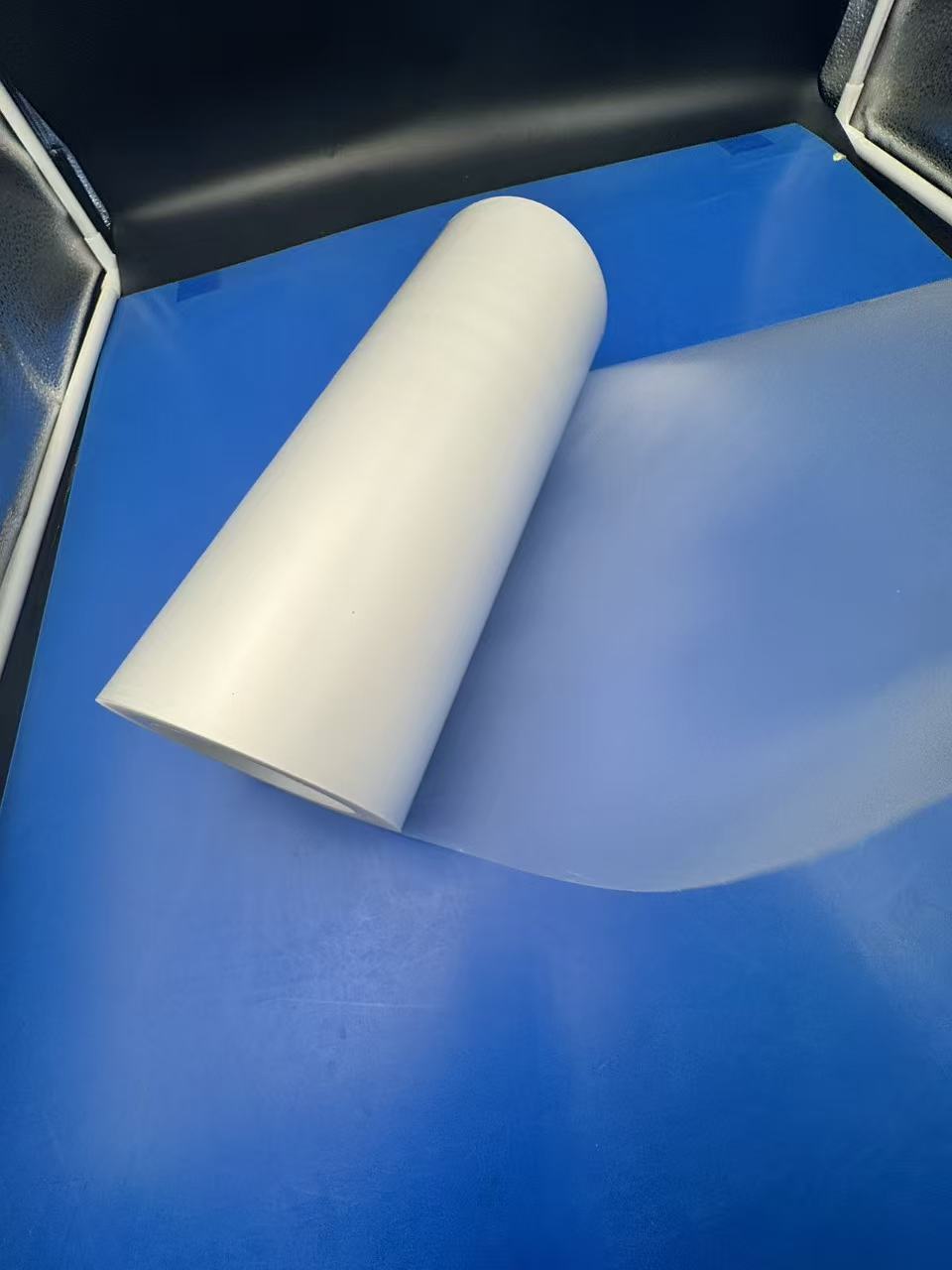

Transparent CPP film. Short for Cast Polypropylene film, this remarkable material is produced through a meticulous cast extrusion process, where molten polypropylene resin is poured onto a chilled roller to form a thin, non-stretched sheet. Unlike its biaxially oriented cousin, BOPP, which is pulled in multiple directions for added strength, transparent CPP film retains a soft, flexible nature that makes it a standout in the world of packaging and protective solutions.What sets transparent CPP film apart is its innate ability to balance visibility with protection. With thicknesses ranging from a mere 20 microns to 150 microns, it can be customized to fit diverse needs, from delicate food wrappers to robust industrial covers. Globally, the CPP film market has surged, valued at over $4.3 billion in 2022 and projected to climb steadily, driven by its eco-friendly recyclability and superior performance.

This article delves into the captivating properties of transparent CPP film and explores its multifaceted applications across industries, backed by scientific insights and real-world examples. From enhancing shelf appeal in grocery stores to safeguarding sensitive electronics, transparent CPP film is more than a material—it's a silent innovator shaping our daily lives.Key Properties: The Science Behind the SheenAt the heart of transparent CPP film's appeal lies a symphony of physical and chemical properties, each honed through precise molecular engineering. Let's start with its optical prowess. Boasting exceptional clarity and gloss, this film achieves haze levels as low as 2-3%, far surpassing many alternatives like polyethylene.

This means light passes through almost unimpeded, creating a window-like effect that lets consumers inspect products without peeling back layers. In lab tests, transparent CPP film's light transmission rate often exceeds 90%, making it ideal for visual merchandising where first impressions count.

Picture a bag of gourmet cookies: the film's high gloss—measured at over 85% reflectance—gives it a premium, jewel-like finish, turning a simple snack into a luxurious treat.But beauty isn't just skin deep; durability is woven into its structure. Transparent CPP film exhibits impressive mechanical strength, with tensile strength values around 20-30 MPa in both machine and transverse directions, thanks to its isotropic (uniform) molecular alignment.

This translates to excellent puncture resistance—up to 50% higher than oriented films—preventing tears during handling or transport. In a vivid example, during drop-impact tests at -5°C, samples withstand falls from heights equivalent to a meter without cracking, a boon for frozen goods packaging.

Its flexibility shines in low-temperature environments, maintaining pliability down to -20°C, where brittle alternatives might shatter like glass.Heat-sealing prowess is another cornerstone. Transparent CPP film seals at temperatures as low as 100°C, forming hermetic bonds with hot-tack strength exceeding 5 N/15mm, ensuring pouches don't burst under pressure.

This low seal initiation temperature (SIT) allows for energy-efficient production on high-speed lines, processing up to 300 meters per minute without compromising integrity. Chemically, it's a fortress: resistant to acids, alkalis, and fats, with a water vapor transmission rate (WVTR) below 5 g/m²/day, blocking moisture ingress that could spoil contents.

Oxygen barrier properties, with transmission rates under 1000 cc/m²/day, further extend shelf life by curbing oxidation—vital for oxygen-sensitive items like cheeses or nuts.Sustainability adds a modern twist. Being 100% polypropylene, transparent CPP film is fully recyclable, aligning with circular economy goals. It requires no additional coatings for printability, reducing waste, and its low density (0.91 g/cm³) means lighter shipments, slashing carbon footprints by up to 20% compared to glass or metal alternatives.

Anti-fog variants, modified with surfactants, prevent condensation droplets, keeping views clear in refrigerated displays—a simple yet ingenious tweak born from polymer chemistry.These properties aren't abstract; they're battle-tested. In a comparative study, transparent CPP film outperformed PVC in flexibility and recyclability for garment bags, while edging out PET in heat-seal speed for food trays.

This blend of optics, strength, and eco-friendliness positions it as a versatile workhorse.Applications in Food Packaging: Preserving Freshness with FlairFood packaging is where transparent CPP film truly feasts, transforming mundane wrappers into vibrant showcases. In snack foods, its clarity lets colorful chips or chocolates pop, boosting impulse buys by 15-20% in retail studies.

For instance, a major brand uses 30-micron transparent CPP film for potato chip bags, where the film's grease resistance (contact angle >90°) prevents oil stains, and its aroma barrier locks in flavors for months.

The result? Crisps that crunch as fresh as the day they were packed.Frozen foods owe their integrity to the film's deep-freeze resilience. Co-extruded variants with modified POE (polyolefin elastomer) endure -40°C without brittleness, ideal for ice cream tubs or veggie pouches.

Envision a family dinner: steam rises from microwaved vegetables, the film sealing intact post-thaw, thanks to hot-tack properties that reform bonds at 120°C. In bakery applications, like bread wraps, its anti-stick surface (COF <0.3) eases unwrapping, while puncture resistance handles jagged crusts.Fresh produce benefits from anti-fog transparent CPP film, where hydrophilic additives scatter water into sheets rather than beads, maintaining visibility in chillers.

A salad mix in a supermarket case stays temptingly green, not obscured by mist, extending appeal by days. For retort pouches—those ready-meals heated to 135°C—the film's thermal stability ensures seals hold, preventing leaks in high-pressure sterilization.

A steaming pouch of curry arrives unspoiled, flavors intact, demonstrating how this film turns convenience into reliability.Beyond basics, metallized versions amplify barriers for dry goods like pasta, reflecting light to deter rancidity.

In all, food applications leverage transparent CPP film's printability—accepting flexo inks with 95% adhesion—for eye-catching labels that narrate brand stories.Applications in Electronics: Shielding InnovationShift to the electronics realm, and transparent CPP film becomes a guardian angel for gadgets in a dust-prone world. Its electrostatic dissipation (surface resistivity <10^10 Ω) prevents static buildup, crucial for circuit boards during shipping.