The Versatility and Strength of PE Stretch Film in Modern Packaging Solutions

2025-06-13 13:49In the fast-paced world of logistics, manufacturing, and electronics, effective packaging solutions are critical to ensuring product safety, operational efficiency, and cost-effectiveness.  Among the myriad of packaging materials available, PE stretch film (polyethylene stretch film) stands out as a versatile, durable, and cost-efficient option. Known for its elasticity, strength, and adaptability, PE stretch film has become a cornerstone in industries ranging from warehousing to electronics. This article explores the characteristics of PE stretch film and its applications in bundling, cargo packaging, and electronic packaging, highlighting its unique advantages with vivid examples and data-driven insights.

Among the myriad of packaging materials available, PE stretch film (polyethylene stretch film) stands out as a versatile, durable, and cost-efficient option. Known for its elasticity, strength, and adaptability, PE stretch film has become a cornerstone in industries ranging from warehousing to electronics. This article explores the characteristics of PE stretch film and its applications in bundling, cargo packaging, and electronic packaging, highlighting its unique advantages with vivid examples and data-driven insights.

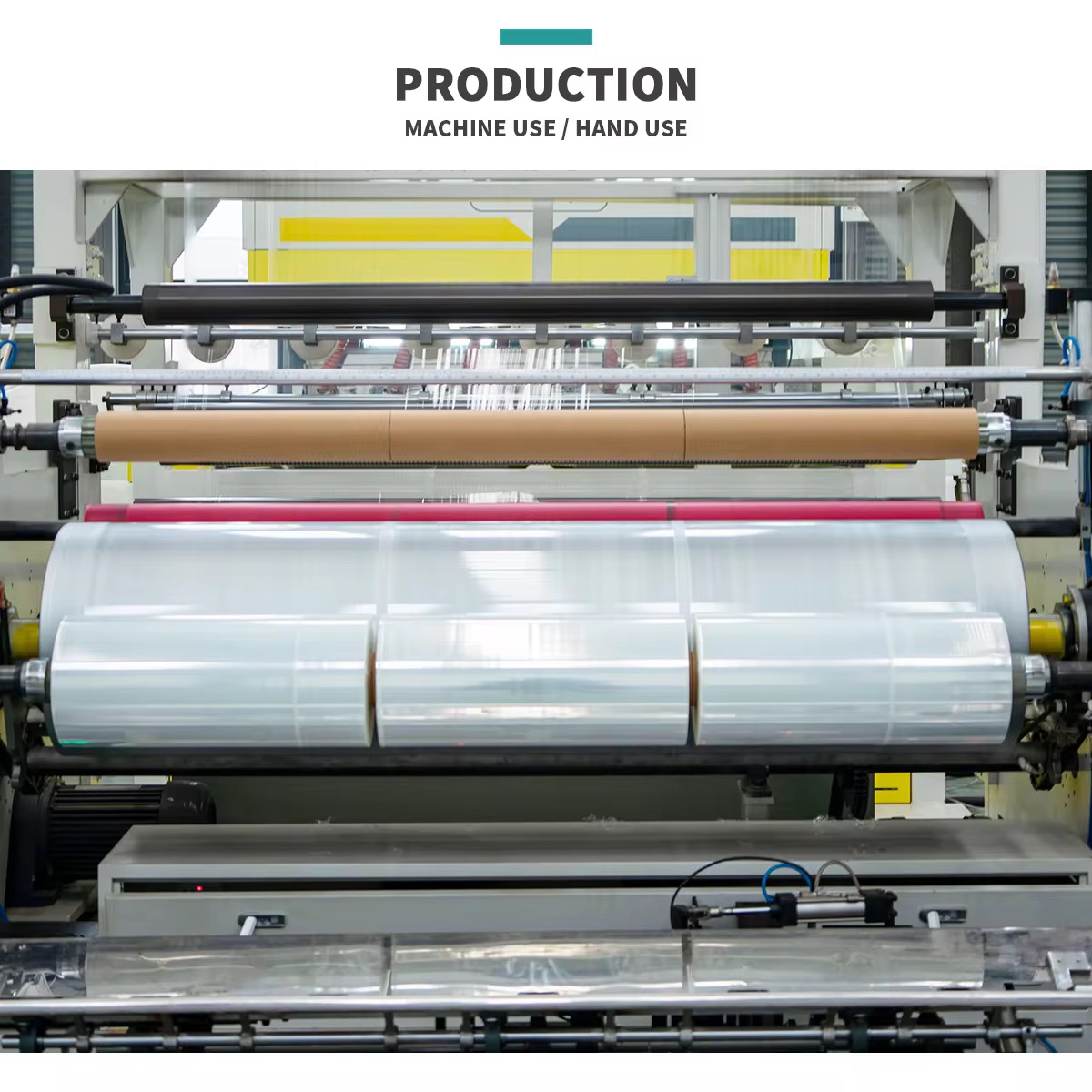

Characteristics of PE Stretch Film

PE stretch film is a thin, flexible plastic film made from linear low-density polyethylene (LLDPE) or other polyethylene-based materials. Its defining feature is its ability to stretch significantly—often up to 200–300% of its original length—while maintaining structural integrity. This elasticity, combined with other properties, makes it an ideal choice for a wide range of packaging applications. Below are the key characteristics that set PE stretch film apart:

High Elasticity and Cling:

PE stretch film is engineered to stretch tightly around objects, creating a secure hold without the need for additional adhesives. Its natural cling properties ensure that the film adheres to itself, forming a tight seal that prevents slippage. For instance, when wrapping a pallet of goods, the film’s cling ensures that boxes remain firmly in place, even during turbulent transportation.

Durability and Puncture Resistance:

The film’s robust composition allows it to withstand punctures, tears, and abrasions. This is particularly crucial in cargo packaging, where sharp edges or rough surfaces could compromise weaker materials. Tests conducted by packaging industry standards (e.g., ASTM D882) show that high-quality PE stretch film can resist punctures from loads up to 2,500 pounds without tearing.

Transparency and Barcode Readability:

Transparent PE stretch film allows for easy identification of packaged goods, including the scanning of barcodes without unwrapping. This feature is invaluable in warehouses where quick inventory checks are essential. For example, a logistics company can scan barcodes on pallets wrapped in transparent PE stretch film, reducing handling time by up to 30%, according to industry case studies.

Cost-Effectiveness and Lightweight Nature:

Compared to alternatives like strapping or corrugated boxes, PE stretch film is lightweight and requires less material to achieve secure packaging. This reduces shipping costs and minimizes environmental impact. A single roll of PE stretch film can wrap multiple pallets, offering significant savings over heavier or bulkier materials.

Weather and Dust Resistance:

PE stretch film provides a protective barrier against moisture, dust, and other environmental factors. This is particularly beneficial for outdoor storage or long-distance shipping, where exposure to rain or humidity could damage goods. For instance, a shipment of electronics wrapped in PE stretch film remains shielded from water ingress during a cross-country journey.

Recyclability and Sustainability:

Modern PE stretch films are often recyclable, aligning with global sustainability goals. Many manufacturers produce films with recycled content or bio-based polyethylene, reducing the carbon footprint of packaging operations. According to a 2023 report by the Ellen MacArthur Foundation, recyclable PE stretch films can reduce plastic waste by up to 40% in industrial settings.

Applications of PE Stretch Film

The versatility of PE stretch film makes it indispensable across multiple industries. Below, we explore its applications in bundling, cargo packaging, and electronic packaging, with real-world examples to illustrate its effectiveness.

1. Bundling with PE Stretch Film

Bundling refers to the process of grouping smaller items together to create a single, manageable unit. PE stretch film excels in this application due to its elasticity and cling, which ensure that bundled items remain tightly secured.

Application Example: In the beverage industry, PE stretch film is used to bundle cans or bottles into packs of 12 or 24. For instance, a soda manufacturer wraps stacks of aluminum cans with PE stretch film to create stable, easy-to-handle units for retail distribution. The film’s elasticity prevents cans from shifting during transport, reducing the risk of dents or damage. A study by the Packaging Machinery Manufacturers Institute (PMMI) found that PE stretch film reduces product loss in beverage bundling by 15% compared to traditional strapping methods.

Advantages in Bundling:

Stability: The film’s tight wrap prevents items from shifting, even under high-speed conveyor systems.

Efficiency: Automated stretch-wrapping machines can apply PE stretch film at rates of up to 100 pallets per hour, streamlining operations.

Cost Savings: Bundling with PE stretch film eliminates the need for additional fasteners or tapes, reducing material costs by up to 20%, as reported by packaging industry analysts.

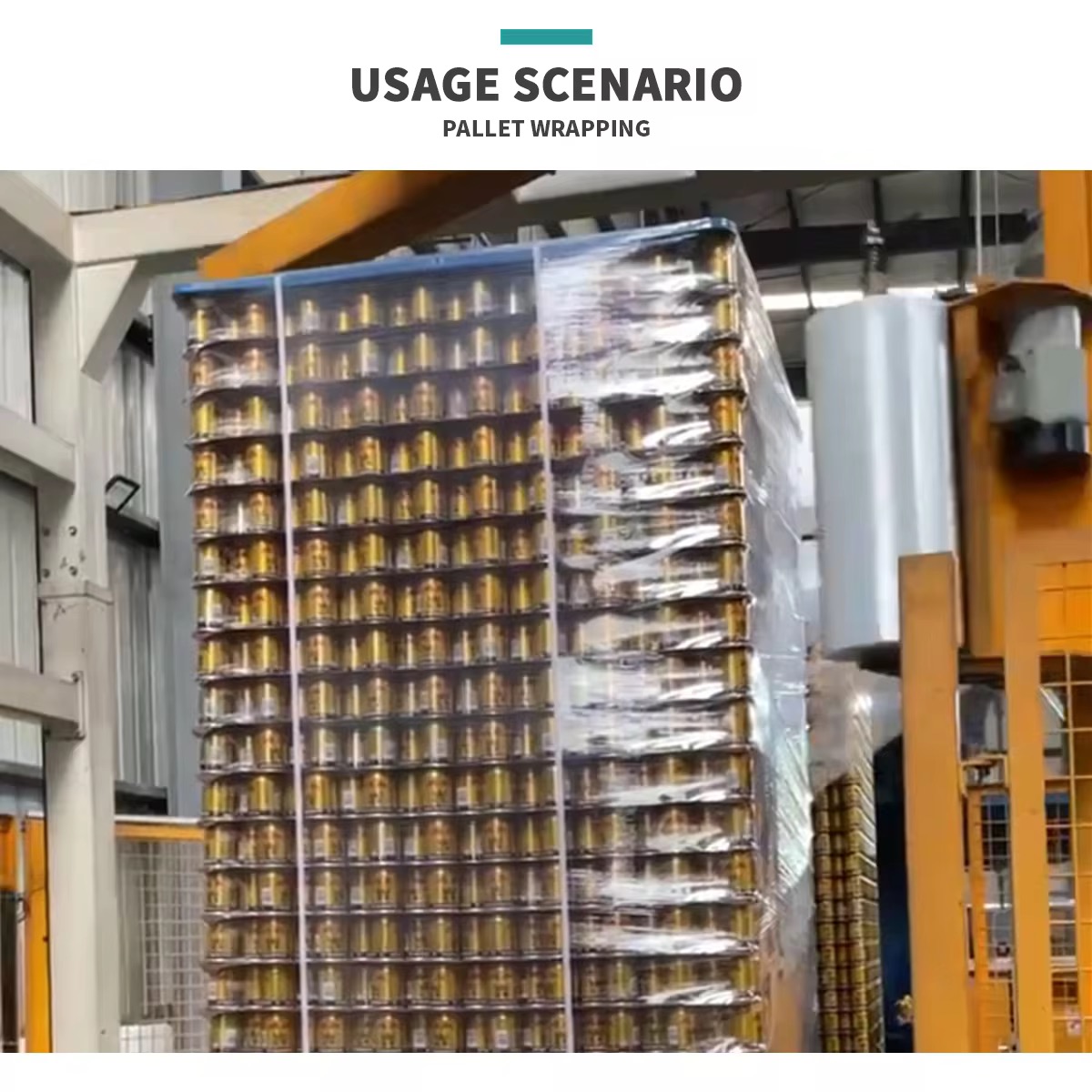

2. Cargo Packaging with PE Stretch Film

In logistics, PE stretch film is widely used to secure cargo on pallets for transportation and storage. Its ability to stabilize heavy loads and protect against environmental hazards makes it a go-to solution for warehouses and shipping companies.

Application Example: A global e-commerce company uses PE stretch film to wrap pallets of consumer goods, such as electronics, clothing, and household items. During a peak holiday season, the company reported that pallets wrapped with PE stretch film experienced a 98% success rate in arriving undamaged, compared to 85% for pallets secured with metal straps. The film’s transparency also allowed warehouse staff to quickly verify contents, reducing processing time.

Advantages in Cargo Packaging:

Load Stability: PE stretch film’s high stretchability ensures that pallets remain stable, even when stacked or tilted during transport. This reduces the risk of toppling, which can cause costly damage.

Protection: The film shields cargo from dust, dirt, and moisture, ensuring goods arrive in pristine condition. For example, a shipment of furniture wrapped in PE stretch film remained free of scratches and water damage during a rainy transatlantic voyage.

Flexibility: PE stretch film can accommodate irregularly shaped loads, unlike rigid packaging materials. This is particularly useful for mixed pallets containing items of varying sizes.

3. Electronic Packaging with PE Stretch Film

The electronics industry demands packaging solutions that protect sensitive components from static electricity, dust, and physical damage. PE stretch film, particularly anti-static variants, is increasingly used in this sector for its protective qualities and adaptability.

Application Example: A semiconductor manufacturer uses anti-static PE stretch film to wrap trays of microchips before shipping. The film’s anti-static properties prevent electrostatic discharge (ESD), which could damage delicate circuits. In a 2024 case study, the manufacturer reported a 25% reduction in ESD-related defects after switching to anti-static PE stretch film from traditional bubble wrap. Additionally, the film’s transparency allowed for quick visual inspections without unwrapping.

Advantages in Electronic Packaging:

Anti-Static Protection: Anti-static PE stretch film dissipates static charges, safeguarding sensitive electronics. This is critical for components like circuit boards, where ESD can cause failures costing thousands of dollars.

Compactness: The thin profile of PE stretch film reduces packaging bulk, allowing more products to fit in a single shipment. For example, a laptop manufacturer saved 10% on shipping costs by using PE stretch film instead of bulkier foam packaging.

Cleanroom Compatibility: Many PE stretch films are designed for use in cleanroom environments, ensuring no contamination of sensitive electronic components.

Comparative Advantages Over Other Packaging Materials

While alternatives like strapping, shrink film, and corrugated boxes have their uses, PE stretch film offers unique advantages:

Vs. Strapping: Strapping requires additional tools and fasteners, increasing labor costs. PE stretch film, applied manually or via automated systems, is faster and more cost-effective.

Vs. Shrink Film: Shrink film requires heat to conform to goods, adding energy costs and complexity. PE stretch film achieves similar results without heat, making it more environmentally friendly.

Vs. Corrugated Boxes: Boxes are bulkier and less flexible, increasing shipping weight and costs. PE stretch film’s lightweight nature reduces freight expenses while maintaining protection.

Conclusion

PE stretch film is a game-changer in modern packaging, offering unmatched versatility, durability, and cost-effectiveness. Its applications in bundling, cargo packaging, and electronic packaging demonstrate its ability to meet diverse industry needs. From securing pallets of consumer goods to protecting sensitive electronics, PE stretch film delivers reliable performance backed by its unique characteristics. As industries continue to prioritize efficiency and sustainability, the role of PE stretch film will only grow, solidifying its place as an essential tool in the global supply chain.