Characteristics and Applications of Metalized PET Film in Packaging

2025-03-20 15:28Characteristics and Applications of Metalized PET Film in Packaging

Unveiling the Power of Metalized PET Film: A Packaging Marvel

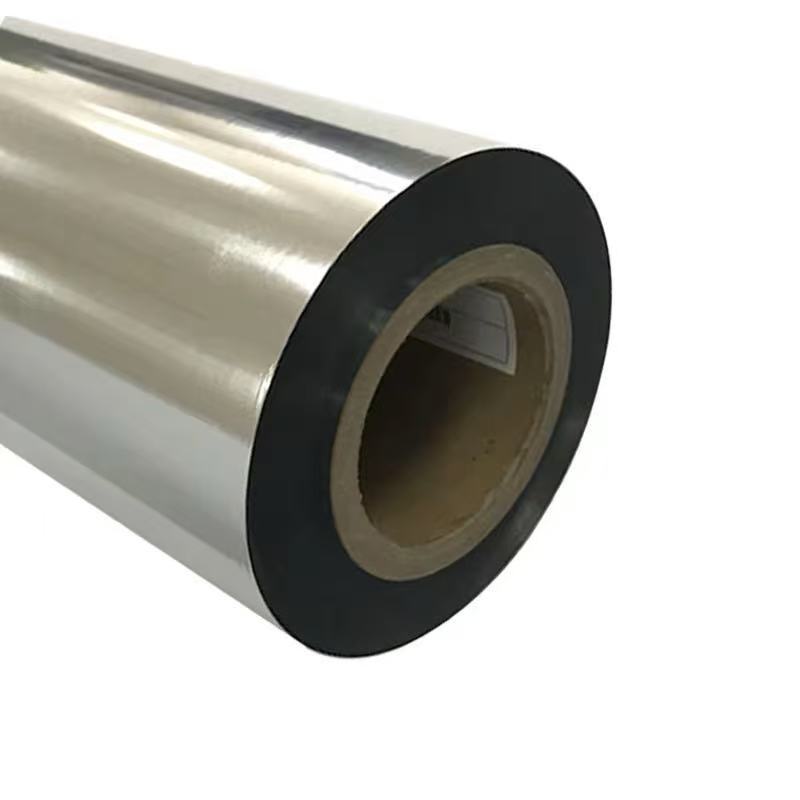

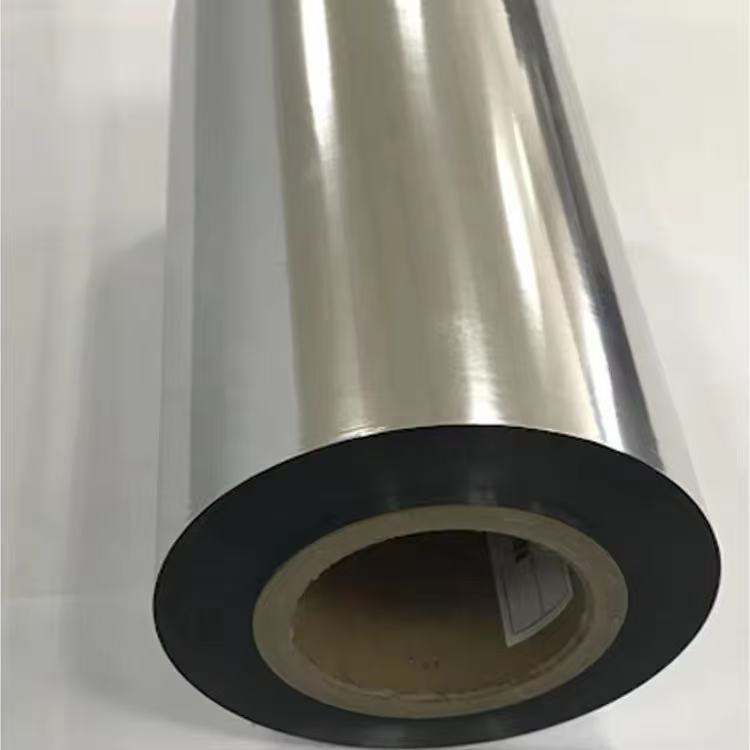

Metalized PET film, a remarkable innovation in the world of materials science, has transformed the packaging industry with its unique blend of aesthetic appeal and functional prowess. This thin layer of polyethylene terephthalate (PET) coated with a metallic layer—typically aluminum—offers a versatile solution that balances performance, cost, and sustainability. By depositing aluminum atoms onto the PET substrate through a vacuum metallization process, this film acquires properties that make it indispensable across various packaging applications. In this article, we’ll dive into the defining characteristics of Metalized PET film and explore its widespread use in food, pharmaceutical, cosmetic, and industrial packaging, supported by vivid examples and compelling evidence.

This thin layer of polyethylene terephthalate (PET) coated with a metallic layer—typically aluminum—offers a versatile solution that balances performance, cost, and sustainability. By depositing aluminum atoms onto the PET substrate through a vacuum metallization process, this film acquires properties that make it indispensable across various packaging applications. In this article, we’ll dive into the defining characteristics of Metalized PET film and explore its widespread use in food, pharmaceutical, cosmetic, and industrial packaging, supported by vivid examples and compelling evidence.

Key Characteristics of Metalized PET Film

Metalized PET film stands out due to its multifaceted properties, which cater to the diverse needs of modern packaging. Let’s break down its key attributes:

Barrier Properties

One of the standout features of Metalized PET film is its ability to act as a robust barrier against moisture, oxygen, light, and UV radiation. The aluminum layer, though only a few nanometers thick (typically 20–50 nm), significantly reduces the permeability of gases and water vapor. For instance, studies indicate that Metalized PET film can achieve oxygen transmission rates as low as 0.5 cm³/m²/day and water vapor transmission rates below 0.3 g/m²/day at a thickness of just 10 µm. This makes it a lightweight yet effective alternative to traditional aluminum foil, which offers absolute diffusion density but is heavier and less flexible.Optical Appeal

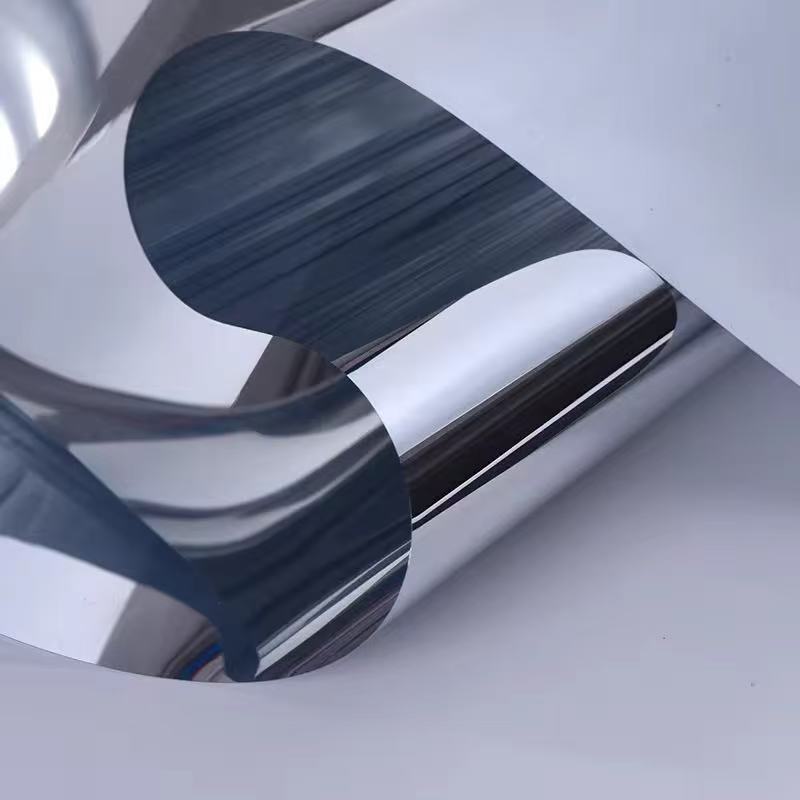

The shiny, reflective surface of Metalized PET film lends a premium, metallic sheen to packaging, enhancing visual appeal. Its high reflectivity—often exceeding 85% across the visible spectrum—creates a mirror-like effect that rivals the gloss of pure aluminum foil. This optical property not only elevates brand perception but also serves functional purposes, such as reflecting heat and light to protect sensitive contents.Mechanical Strength

PET itself is renowned for its tensile strength and dimensional stability, and metallization enhances these traits further. Metalized PET film exhibits excellent tear resistance and durability, maintaining its integrity under external forces. Research has shown that its yield strength remains robust even at elevated temperatures, though it decreases slightly as heat increases—a trait that packaging designers must consider for specific applications.Thermal Stability

With good thermal resistance, Metalized PET film can withstand high temperatures without deforming, making it suitable for processes like heat sealing and sterilization. Its low thermal conductivity also provides insulation, a feature that proves invaluable in applications requiring temperature regulation.Lightweight and Cost-Effective

Compared to aluminum foil or glass, Metalized PET film is significantly lighter, reducing shipping costs and carbon footprints. Its production process, involving vacuum deposition of a thin metal layer, is more economical than manufacturing thick metal foils, offering a glossy finish at a fraction of the weight and expense.

These characteristics collectively position Metalized PET film as a versatile material, bridging the gap between functionality and aesthetics in packaging solutions.

Applications of Metalized PET Film in Packaging

The unique properties of Metalized PET film make it a go-to choice across a range of packaging sectors. Let’s explore how it shines in specific applications, with real-world examples to illustrate its impact.

1. Food Packaging: Preserving Freshness with Flair

In the food industry, maintaining product freshness while catching the consumer’s eye is paramount. Metalized PET film excels here, offering excellent barrier properties that extend shelf life. For instance, snack foods like potato chips and biscuits are often packaged in Metalized PET film due to its ability to block moisture and oxygen, preventing staleness and rancidity. The film’s reflective surface also shields light-sensitive products like coffee and tea from UV degradation, preserving flavor and aroma.

Picture a bag of premium coffee beans on a supermarket shelf: its sleek, silver packaging glints under the lights, promising quality even before the consumer reads the label. This is Metalized PET film at work—its metallic luster not only enhances brand appeal but also ensures the beans remain fresh for months. In microwaveable popcorn bags, the film acts as a susceptor, absorbing microwave energy to pop the kernels efficiently, showcasing its adaptability beyond mere protection.

2. Pharmaceutical Packaging: Safeguarding Sensitive Medications

Pharmaceuticals demand packaging that protects against environmental factors like light and moisture, which can degrade active ingredients. Metalized PET film meets these stringent requirements with its low transmittance and high barrier capabilities. It’s commonly used for blister packs and pouches containing light-sensitive drugs, such as vitamins or antibiotics.

Consider a packet of vitamin C tablets: exposure to sunlight could diminish their potency over time. Encased in Metalized PET film, the tablets are shielded from UV rays, ensuring they retain efficacy until the expiration date. The film’s flexibility also allows it to be laminated with other materials, creating multi-layer structures that enhance protection while remaining lightweight—a critical factor in pharmaceutical logistics.

3. Cosmetic Packaging: Elevating Aesthetics and Performance

In the cosmetics industry, packaging is as much about allure as it is about preservation. Metalized PET film delivers both, with its luxurious appearance and protective qualities. Skincare products like creams and serums often come in pouches or tubes lined with this film, which prevents oxidation and maintains product integrity.

Imagine a high-end moisturizer in a stand-up pouch: the shimmering Metalized PET exterior exudes sophistication, appealing to discerning buyers, while its barrier properties keep the formula stable, free from air or moisture intrusion. The film’s ability to be molded into creative shapes also allows brands to experiment with innovative designs, setting their products apart in a crowded market.

4. Industrial and Specialty Packaging: Beyond the Everyday

Metalized PET film isn’t limited to consumer goods—it shines in industrial and specialty applications too. Its thermal insulation properties make it ideal for packaging materials that require temperature control, such as cryogenic components or satellite parts. In fact, NASA uses Metalized PET film in spacesuits and emergency blankets to reflect heat radiation, a testament to its reliability in extreme conditions.

Closer to everyday life, the film is used in insulation wraps for cables and wires, protecting them from environmental damage while maintaining flexibility. For industrial food packaging, such as large bags for frozen meat exports, Metalized PET film provides a controlled permeation layer that extends shelf life during long-distance shipping.

5. Decorative and Promotional Packaging: A Visual Statement

Beyond protection, Metalized PET film is a favorite for decorative purposes, especially in seasonal or promotional packaging. Its high gloss and reflectivity make it perfect for gift wraps, labels, and holiday-themed products like Christmas candy wrappers. The film’s ability to be printed with vibrant colors—where yellow ink shimmers like gold without a primer—adds a festive touch that printed paper or plain polymers can’t match.

Imagine a chocolate box wrapped in Metalized PET film for Valentine’s Day: the reflective surface catches the light, making the package a standout gift, while its barrier properties keep the chocolates fresh. This dual role of aesthetics and functionality underscores the film’s versatility.

Advantages and Challenges in Perspective

The advantages of Metalized PET film are clear: it combines the strength of PET with the protective and visual benefits of metal, all at a lower cost and weight than alternatives like aluminum foil. Its recyclability, though challenging due to the metal-plastic composite, is improving with advances in separation technologies, aligning it with sustainable packaging trends.

However, it’s not without limitations. Compared to pure aluminum foil, Metalized PET film offers weaker gas tightness and opacity, making it less suitable for products requiring absolute diffusion barriers or extended shelf life. Its thinner metal layer also means it can’t match foil’s dead-fold ability, which is crucial for twist-closure packaging like candy wrappers. Packaging designers must weigh these trade-offs against the film’s benefits for each use case.

Conclusion: A Bright Future for Metalized PET Film

Metalized PET film is more than just a packaging material—it’s a fusion of science and creativity that meets the demands of modern industries. Its exceptional barrier properties, mechanical strength, thermal stability, and eye-catching appeal make it a cornerstone of food, pharmaceutical, cosmetic, and industrial packaging. From preserving the crunch of a potato chip to protecting a life-saving drug, this film proves its worth time and again.

As technology advances, so too will the capabilities of Metalized PET film. Innovations in thinner metal layers and biodegradable substrates promise to enhance its sustainability, ensuring it remains a vital player in the packaging world. Whether it’s a shimmering coffee pouch or a heat-reflective space blanket, Metalized PET film continues to shape how we protect, present, and preserve the products that define our lives.