What Is the Difference Between Ps Material and Pet Material

2023-07-27 17:30Ps Material:

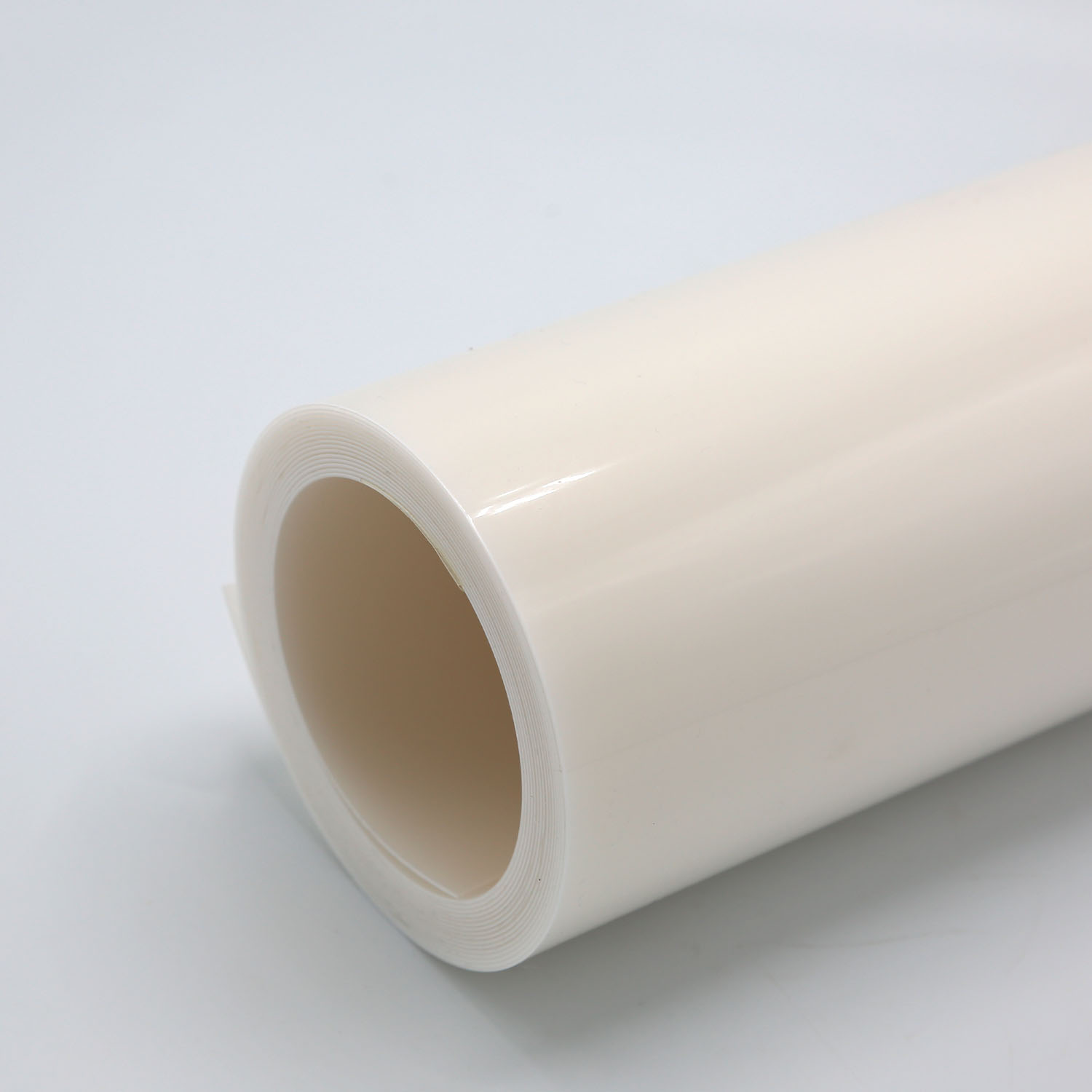

PS is widely used in the optical industry because of its good light transmittance. It can be used to manufacture optical glass and optical instruments, as well as transparent or bright colors, such as lampshades, lighting appliances, etc. PS can also produce many electrical components and instruments that work in high-frequency environments. Since PS plastic is a difficult-to-inert surface material, it is necessary to use professional PS glue for bonding in the industry.

Using PS alone as a product has high brittleness. Adding a small amount of other substances to PS, such as butadiene, can significantly reduce brittleness and improve impact toughness. This plastic is called impact-resistant PS, and its mechanical properties are greatly improved. Many mechanical parts and components with excellent performance are made from plastic.

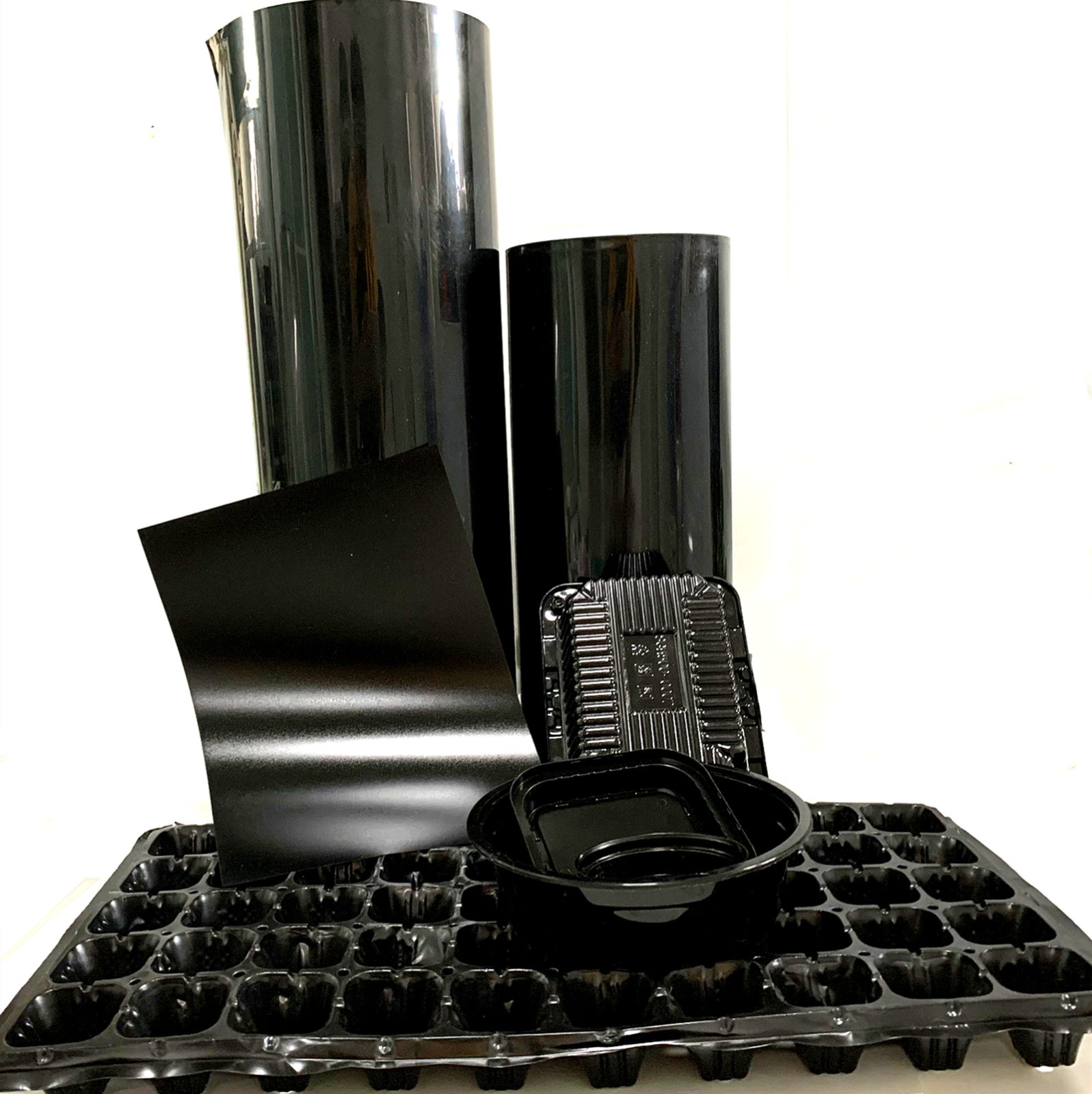

Pet Material:

Glass fiber reinforced PET is suitable for electronic, electrical and automotive industries, and is used in various coil bobbins, transformers, televisions, tape recorder parts and shells, automotive lamp holders, lampshades, incandescent lamp holders, relays, selenium rectifiers, etc. The current consumption ratio of PET engineering plastics in several application fields is: electrical and electronic 26%, automobiles 22%, machinery 19%, appliances 10%, consumer goods 10%, and others 13%. At present, the total consumption of PET engineering plastics is not large, accounting for only 1.6% of the total PET.