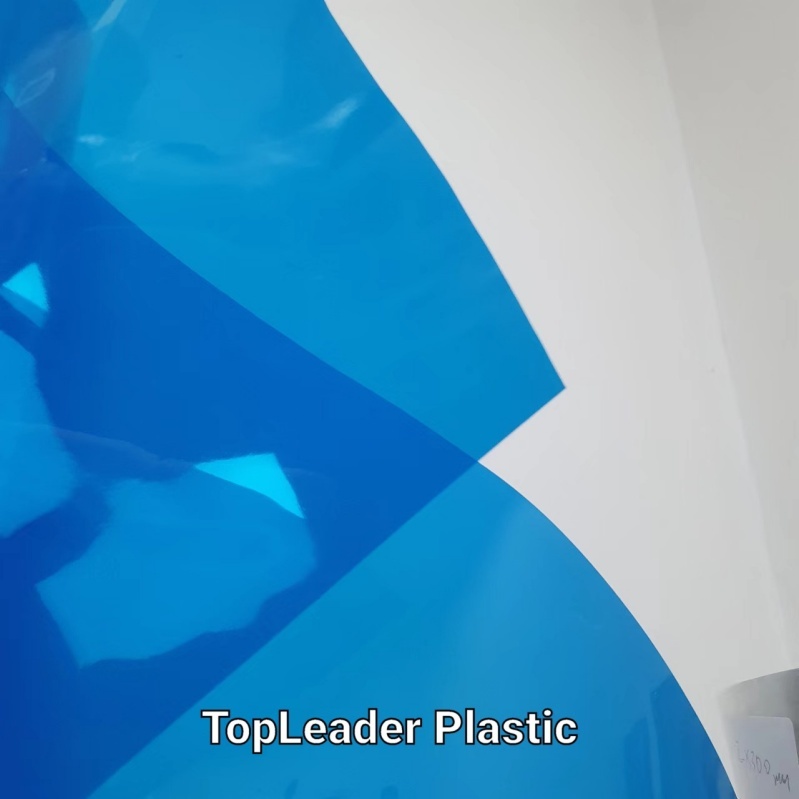

translucent blue pvc film for pharma blister pack

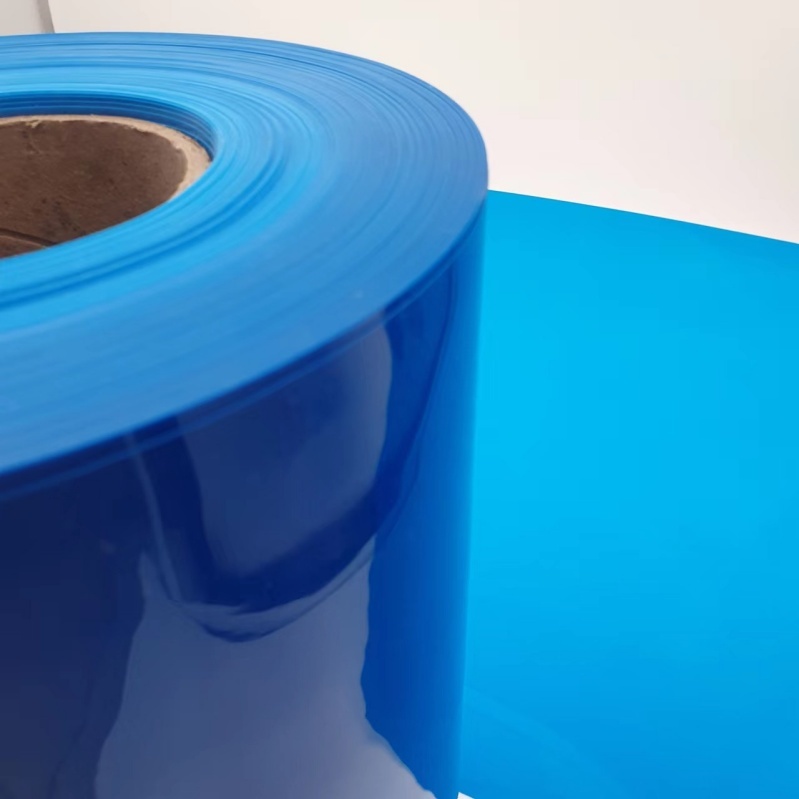

Translucent Blue PVC 0.25mm for Pharma Blister Packaging – High-Quality, Reliable, and Compliant Solution Pharma Blister PVC in translucent blue color, specifically 0.25mm (250 microns) thickness

- top leader plastic

- China

- 19 business days

- 1500 tons/month

- Information

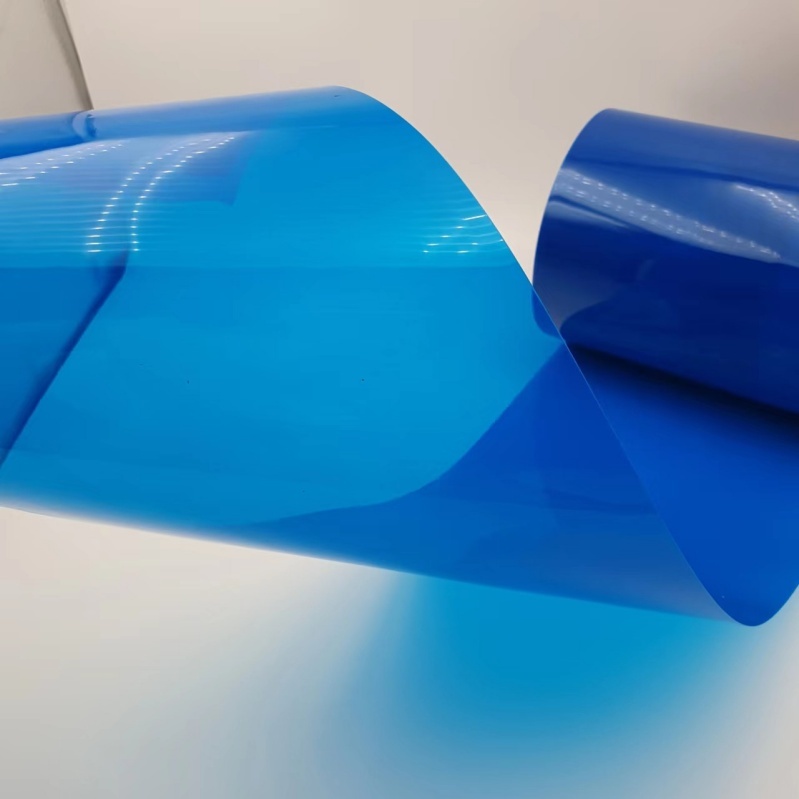

Translucent Blue PVC 0.25mm for Pharma Blister Packaging – High-Quality, Reliable, and Compliant Solution Pharma Blister PVC in translucent blue color, specifically 0.25mm (250 microns) thickness, offers an optimal balance between flexibility, durability, and clarity for pharmaceutical blister packaging applications. This specialized transparent polymer film is engineered to meet global regulatory standards for drug safety, tamper resistance, and product integrity while maintaining visual appeal for end users. Designed with precision for the healthcare and pharmaceutical industries, this material ensures consistent performance across diverse climates and storage conditions. Key Features: - Translucent blue appearance enhances product visibility while providing a professional aesthetic - 0.25mm (250 microns) thickness ensures robust mechanical strength without compromising formability - Excellent barrier properties against moisture, oxygen, and light—critical for preserving drug efficacy - Chemically inert and compliant with USP Class VI and ISO 10993 biocompatibility standards - Easy to thermoform, seal, and process using standard blister packaging machinery - Suitable for cold flow, hot stamping, and lamination techniques Detailed Description: The translucent blue PVC 0.25mm film represents a premium choice for blister packaging in the pharmaceutical sector. Unlike opaque or fully transparent alternatives, this specific shade of blue provides a visually distinct product identity that aids in brand recognition and consumer trust. Its semi-translucent nature allows for clear visibility of tablets or capsules inside the blister pocket while offering subtle branding opportunities through color differentiation. The precise 250-micron thickness delivers enhanced puncture resistance compared to thinner films, reducing the risk of damage during handling, transportation, and storage. It also maintains excellent thermal stability during heat sealing processes, ensuring strong, uniform seals that prevent contamination or exposure to environmental factors. Additionally, this material supports sustainable practices by enabling efficient use of raw materials and minimizing waste in high-speed packaging lines. Use Cases: Ideal for primary packaging of oral solid dosage forms such as tablets, capsules, and lozenges across global markets. Commonly used in over-the-counter medications, prescription drugs, vitamins, and dietary supplements. Particularly suited for manufacturers seeking compliance with EU Falsified Medicines Directive (FMD), FDA 21 CFR Part 11, and other international pharmacovigilance requirements. Also applicable in clinical trial packaging where traceability and batch consistency are critical. Compatible with both manual and automated blister packing systems, making it versatile for small-scale laboratories and large-scale production facilities alike. Customer Feedback: Users consistently highlight the film’s reliability under varying temperature and humidity conditions. One manufacturer noted improved sealing consistency after switching from standard PVC to this translucent blue variant, resulting in fewer rejected packs. Another praised its non-reactive surface, which prevented any chemical interaction with active pharmaceutical ingredients (APIs). A third user appreciated how the blue hue differentiated their product on pharmacy shelves, enhancing customer recall and perceived quality. Frequently Asked Questions: What makes translucent blue PVC 0.25mm different from regular PVC? This formulation includes additives that enhance clarity, UV resistance, and mechanical strength while achieving a unique blue tint that improves product differentiation without compromising transparency. Is this material suitable for medical devices as well? Yes, when certified to relevant biocompatibility standards, it can be used for packaging medical devices classified as Class II or III, provided proper validation protocols are followed. How does the 250-micron thickness affect processing speed? The 0.25mm thickness allows for faster cycle times in thermoforming machines due to improved dimensional stability, reducing downtime and increasing overall throughput. Can it be recycled or disposed of safely? While not universally recyclable, it can be processed through dedicated plastic recycling streams for PVC, and its composition supports safer disposal methods compared to some alternative polymers.

Within 15-20 days after received payment...more