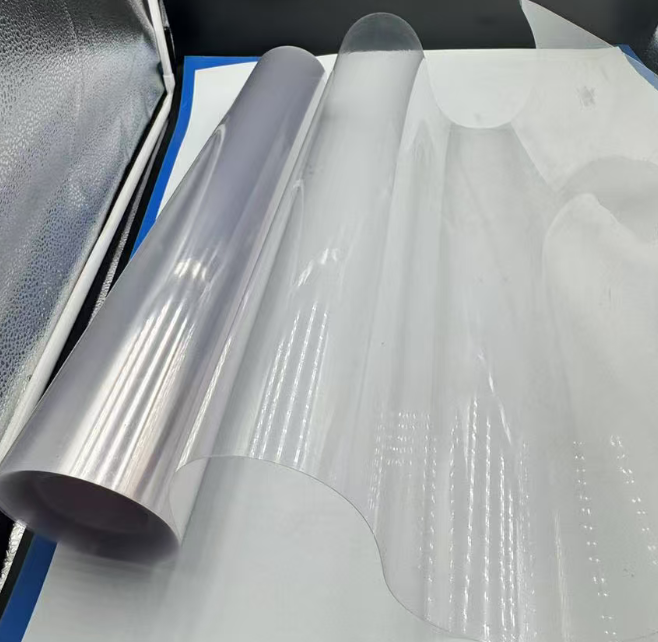

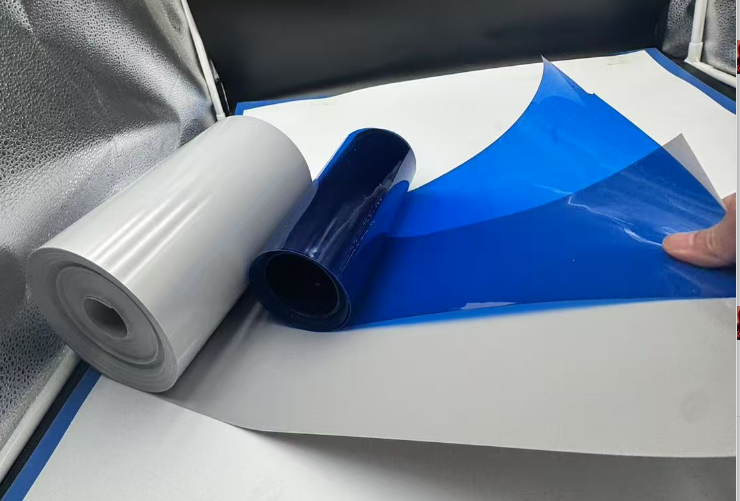

Dark brown opaque PVC sheet and film 0.3MM

Dark brown opaque PVC sheet and film

Coffee-colored PVC pharmaceutical rigid roll for light-resistant pharmaceutical packaging

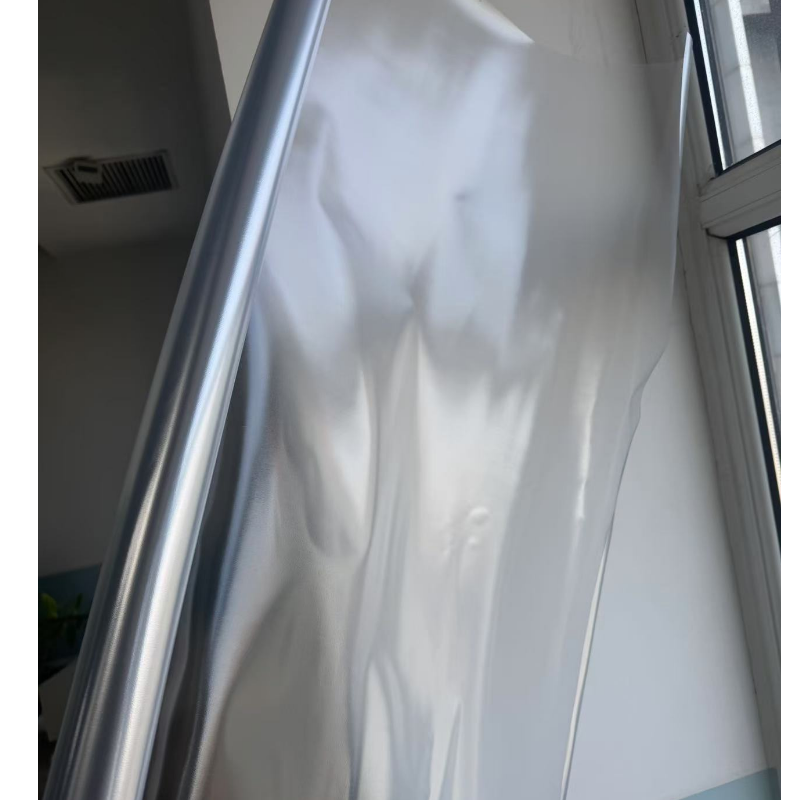

Excellent light-blocking properties: The dark brown opaque material effectively blocks light, protecting packaged items from the effects of light and preventing deterioration and discoloration caused by light.

- top leader plastic

- China

- 15 business days

- 550 tons/month

- Information

Dark brown opaque PVC sheets, PVC films, and brown PVC pharmaceutical rigid coils are used for light-shielding pharmaceutical packaging.

Excellent light-blocking properties: The dark brown opaque material effectively blocks light, protecting packaged items from the effects of light and preventing deterioration and discoloration caused by light.

High chemical stability: It exhibits excellent chemical resistance, resisting corrosion from a variety of chemicals and resisting chemical reactions with other substances, ensuring the stability of the packaged contents.

Excellent mechanical properties: It possesses sufficient strength and toughness, resisting cracking or tearing, and can withstand a certain degree of external forces such as compression and impact, thus protecting the packaged contents.

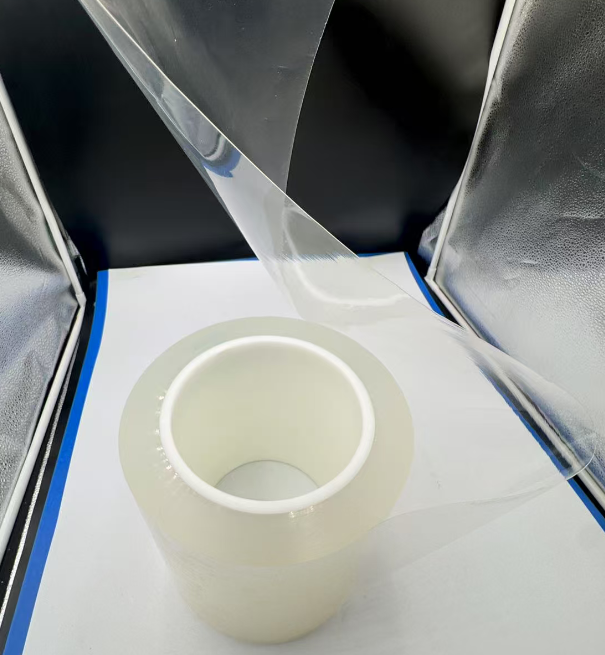

Excellent formability: It can be formed into various shapes and sizes through various processing methods, including thermoforming, molding, and cutting, to meet diverse packaging needs.

Applications:

Packaging: Commonly used in the packaging of electronic products, cosmetics, food, and pharmaceuticals, it protects products from light damage while enhancing their appearance. Architectural Decoration: Can be used as decorative panels for walls, ceilings, floors, and other structures, creating a unique dark brown opaque effect and enhancing the building's aesthetic appeal.

Advertising: Suitable for signage, display boards, posters, and other advertising materials, attracting attention and enhancing advertising effectiveness.

Coffee-colored PVC pharmaceutical rigid membrane for light-shielding pharmaceutical packaging

Features: Excellent light-shielding properties: By adding special colorants and additives, the membrane possesses excellent light-shielding properties, effectively blocking UV and visible light, preventing drug decomposition and deterioration due to light exposure, thereby ensuring drug quality and efficacy.

Compliant with pharmaceutical standards: The production process strictly adheres to pharmaceutical packaging material standards. The raw materials selected meet pharmaceutical requirements and do not contain harmful substances, thus ensuring drug safety.

Excellent barrier properties: In addition to light-shielding properties, it also exhibits excellent oxygen and water vapor barrier properties, preventing external oxygen and moisture from entering the packaging, protecting drugs from moisture and oxidation, and extending their shelf life. Easy Forming and Heat Sealability: This product can be easily thermoformed into various shapes of blisters or containers to meet diverse pharmaceutical packaging requirements. It also exhibits excellent heat-sealing properties, allowing it to securely seal with materials such as PTP aluminum foil, creating airtight packaging and ensuring drug stability during storage and transportation.

Production Process

Raw Material Preparation: High-grade, sanitary polyvinyl chloride resin is used as the primary raw material, along with imported, high-grade auxiliary materials such as stabilizers, plasticizers, lubricants, and colorants to meet the performance requirements of pharmaceutical rigid coils.

Mixing: The raw materials are added to a high-speed kneader in the specified proportions and thoroughly mixed to evenly disperse them, forming a premix.

Plasticizing and Extrusion: The premix enters the extruder for plasticizing and extrusion. Heating and screw rotation melt and plasticize the raw materials, and extrudes them into sheets or coils of a specific shape and size. Calendering: After plasticizing in the extruder, the sheet or coil enters the calender for calendering. The squeezing and stretching action of multiple rollers creates a more uniform thickness and smoother surface, while also further improving its physical properties.

Cooling and Rewinding: After calendering, the brown PVC medical rigid coil passes through a cooling device to cool and set its shape, then is reeled into the finished coil.

Within 15-20 days after received payment...more