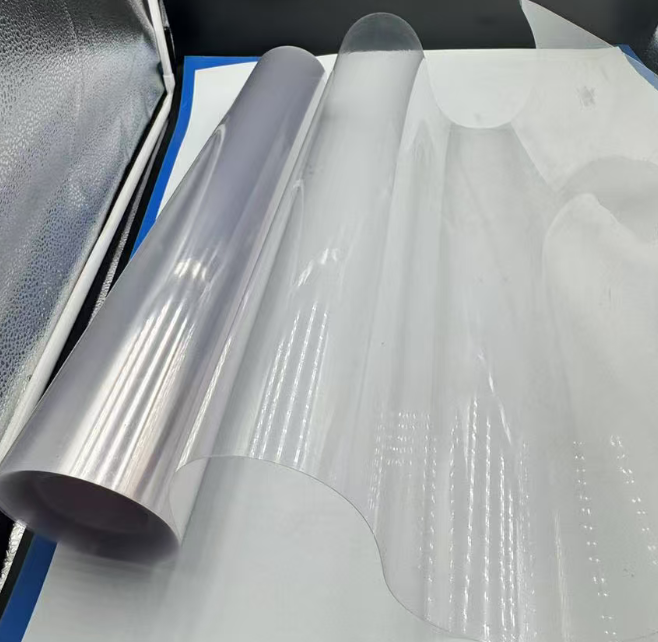

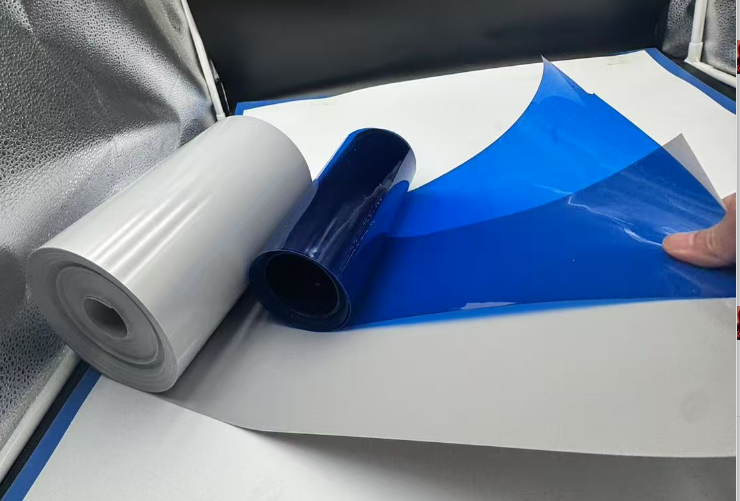

pharmaceutical packaging pvc film opaque white 250 microns

Characteristics of Opaque White Rigid PVC Film for PTP Blister Pharmaceutical Packaging

opaque white rigid pvc film for PTP Blister pharmaceutical packaging

- top leader plastic

- China

- 15 business days

- 350 tons/month

- Information

Characteristics of Opaque White Rigid PVC Film for PTP Blister Pharmaceutical Packaging

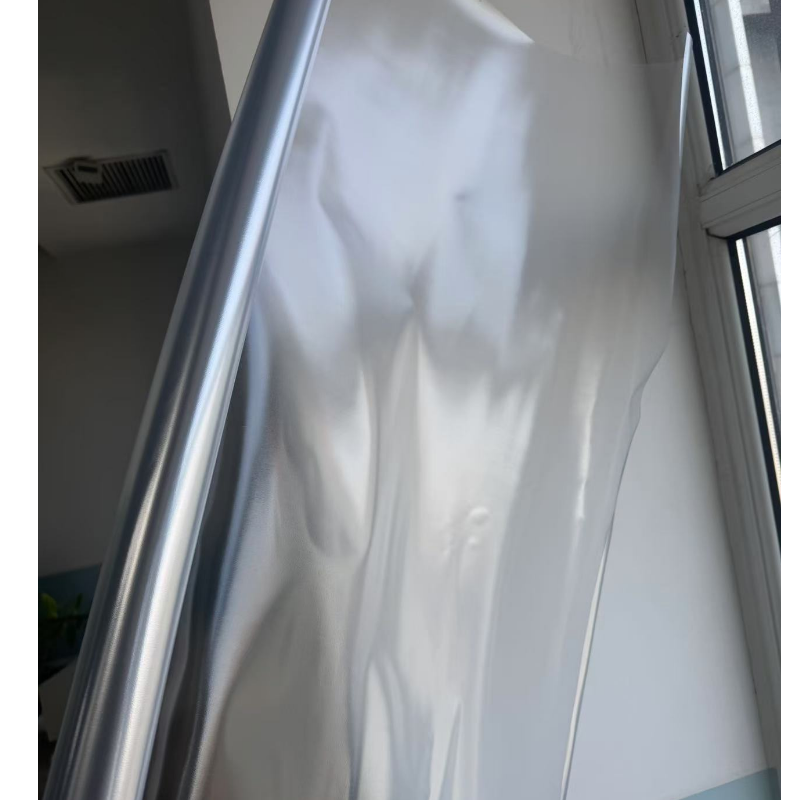

Excellent Mechanical Properties: High hardness and strength make it resistant to cracking and damage, effectively protecting pharmaceuticals from external impact during storage, transportation, and use, ensuring their integrity.

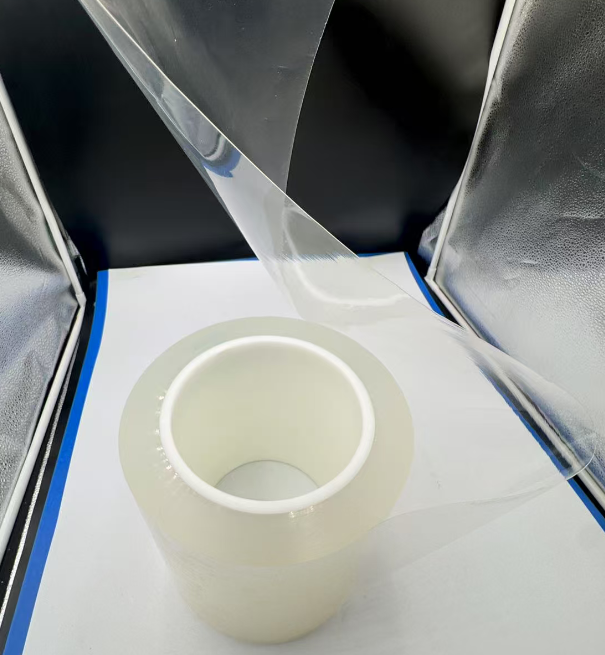

Excellent Formability: Through thermoforming processes such as blister molding, it can be easily formed into blisters of various shapes and sizes to suit different pharmaceutical packaging needs, demonstrating excellent process adaptability.

Production Process

Raw Material Preparation: Polyvinyl chloride (PVC) resin granules that meet pharmaceutical standards are selected, along with appropriate amounts of additives such as plasticizers, stabilizers, lubricants, and opacifiers. These additives improve the properties of the PVC film, such as increasing flexibility, enhancing thermal stability, improving processing performance, and achieving an opaque white finish.

Mixing: The PVC resin granules and additives are added to a high-speed mixer in a specific ratio and thoroughly stirred to evenly disperse the additives throughout the PVC resin, forming a homogeneous mixture. Extrusion: The mixed material is added to an extruder, heated and pressurized to melt it, and extruded through a die into a sheet. Extruder parameters such as temperature, pressure, and screw speed must be precisely adjusted according to the characteristics of the PVC resin and product requirements to ensure the extruded film has uniform thickness and a smooth surface.

Calendering: Extruded PVC sheets typically undergo further calendering to improve the film's flatness and thickness uniformity, achieving the desired thickness and surface quality. During the calendering process, parameters such as the temperature, pressure, and speed of the calendering rolls can be adjusted to control the film's physical properties and appearance.

Cooling and Setting: The calendered PVC film is cooled and set in a cooling device, solidifying it into a film with a certain hardness and strength. Cooling methods typically include water cooling and air cooling. The appropriate cooling method should be selected based on actual production conditions to ensure the film's dimensional stability and performance. Cutting and Rewinding: After cooling and setting, the PVC film is cut to the appropriate length and width according to packaging specifications and then rolled into finished rolls for subsequent packaging and use.

Excellent heat-sealing properties: It can achieve excellent heat-sealing properties with materials such as pharmaceutical aluminum foil under specific temperature, pressure, and time conditions, forming a sealed package that prevents moisture, contamination, and leakage, ensuring the sealing and safety of the drug.

Applications: Tablet packaging: Blister packaging made of opaque white rigid PVC film can be used to package various tablets, such as cold medicines, antipyretics, and antibiotics, to individually package each tablet, making it convenient for patients to take the correct dosage while protecting the tablets from moisture, oxidation, and breakage.

Capsule packaging: This film can also be used for blister packaging of capsules, protecting the capsules from external environmental influences, ensuring the integrity of the capsule shell, and the stability of the drug ingredients.

Pill packaging: PTP blister packaging is also commonly used for various pills. The opaque white rigid PVC film provides excellent protection for the pills, preventing them from sticking and deteriorating.

Within 15-20 days after received payment...more