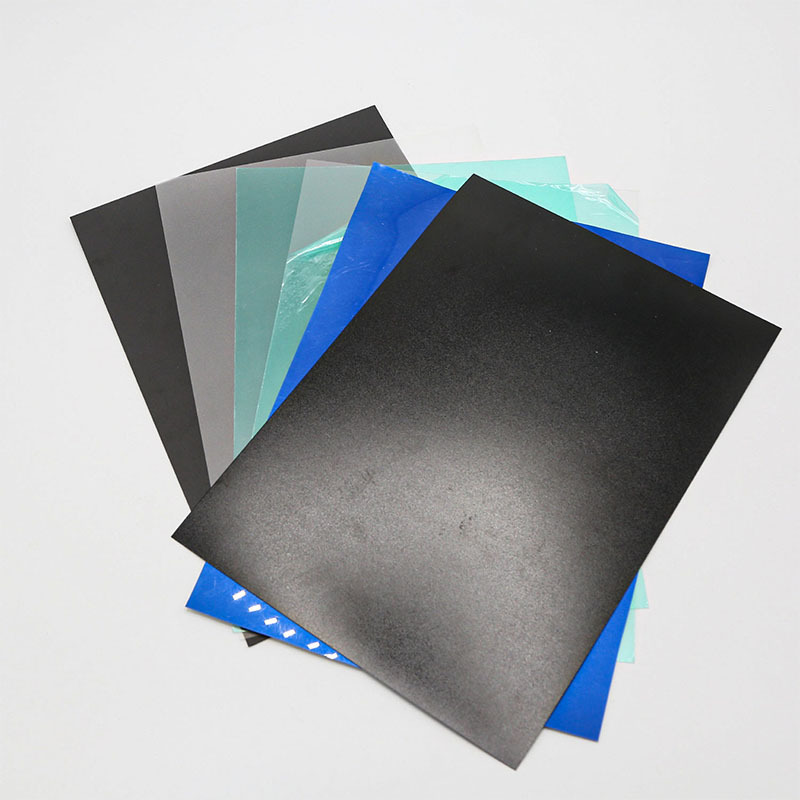

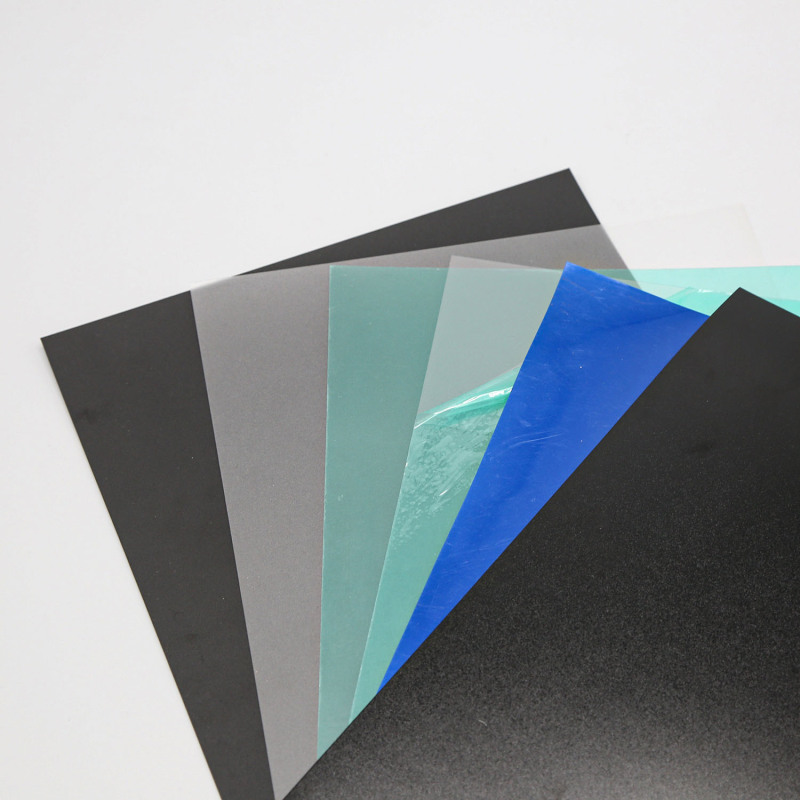

Anti Static Thermoforming Matte PC Polycarbonate Films

Anti-static thermoforming matte PC polycarbonate films are a type of film made from polycarbonate material that is specifically designed to be static dissipative. These films are used in various applications where static electricity can be a problem, such as electronic packaging, automotive parts, and medical devices.

- top leader

- china

- 7 days

- 5000 tons per month

- Information

- Video

Anti Static Thermoforming Matte PC Polycarbonate Films:

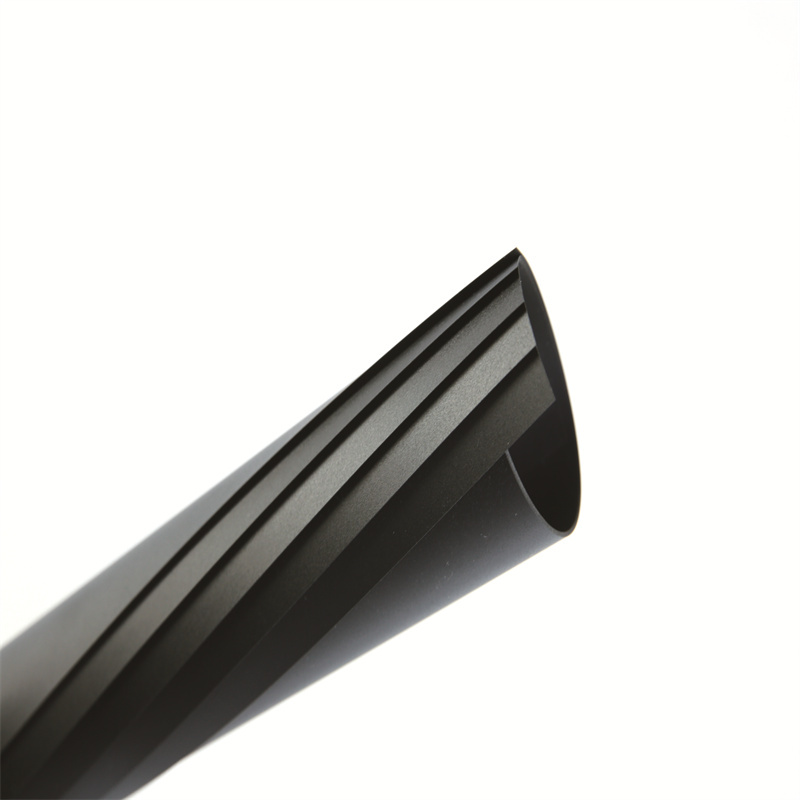

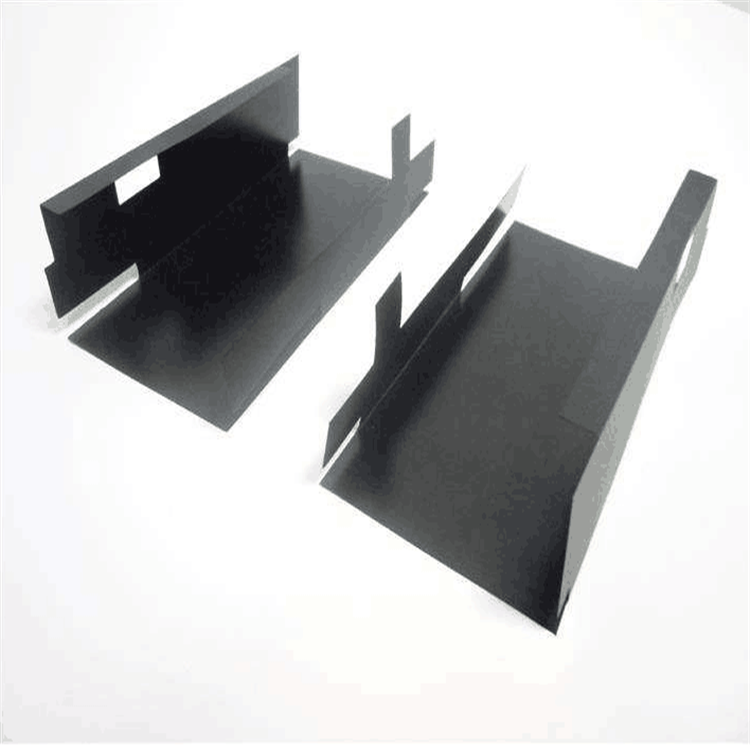

The matte finish on these films helps to reduce glare and improve visibility, making them suitable for applications where optical clarity is important. The thermoforming property of these films allows them to be easily molded into various shapes and sizes, making them versatile for different manufacturing processes.

The anti-static properties of these films help to prevent the buildup of static electricity, which can cause damage to sensitive electronic components or attract dust and dirt. This makes them ideal for use in environments where static electricity can be a concern, such as cleanrooms or manufacturing facilities.

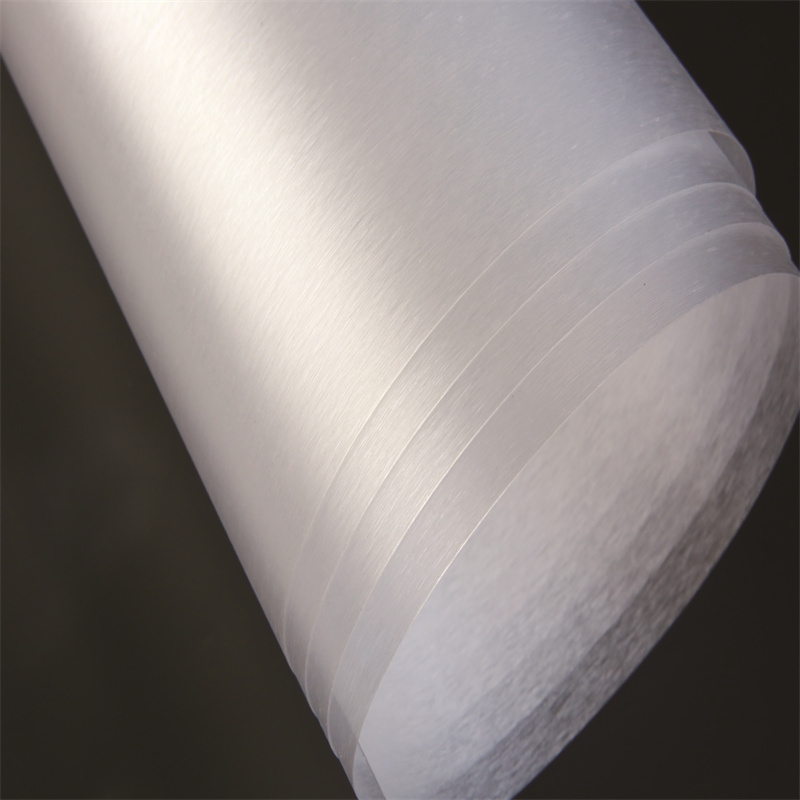

High Quality 0.125mm PC Film Roll Clear Polycarbonate Film for print

Features

1. PC Thickness Range: 0.07mm-10mm

2. Size: 915X1220mm, 1220x2440mm, 700x1000mm, 915x1830mm, 600x600mm or Other customized size

3. Application: Vacuum forming /Thermoforming/Screen Printing/Offset Printing/Folding Box/Bending/Binding Covers

4. Shape: PC Sheet or PC Roll

polycarbonate sheet roll,polycarbonate rolling,polycarbonate film:

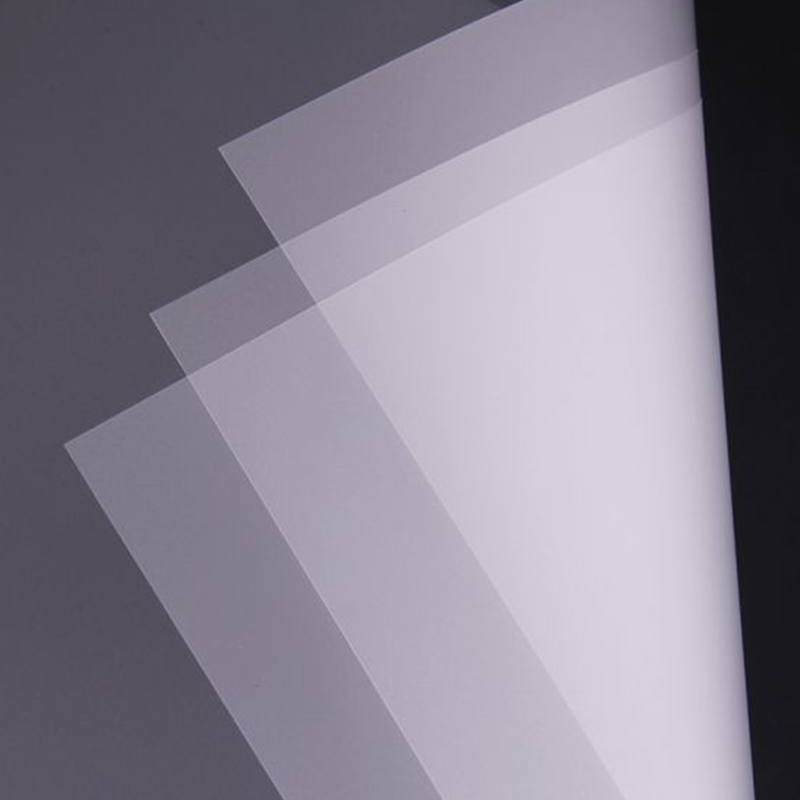

1) Impact strength: 850J/m.The impact resistance of polycarbonate solid sheet is about 200 times of common glass,20 times of acrylic sheets.

2) Light weight: polycarbopnate film is About 1/2 times of glass

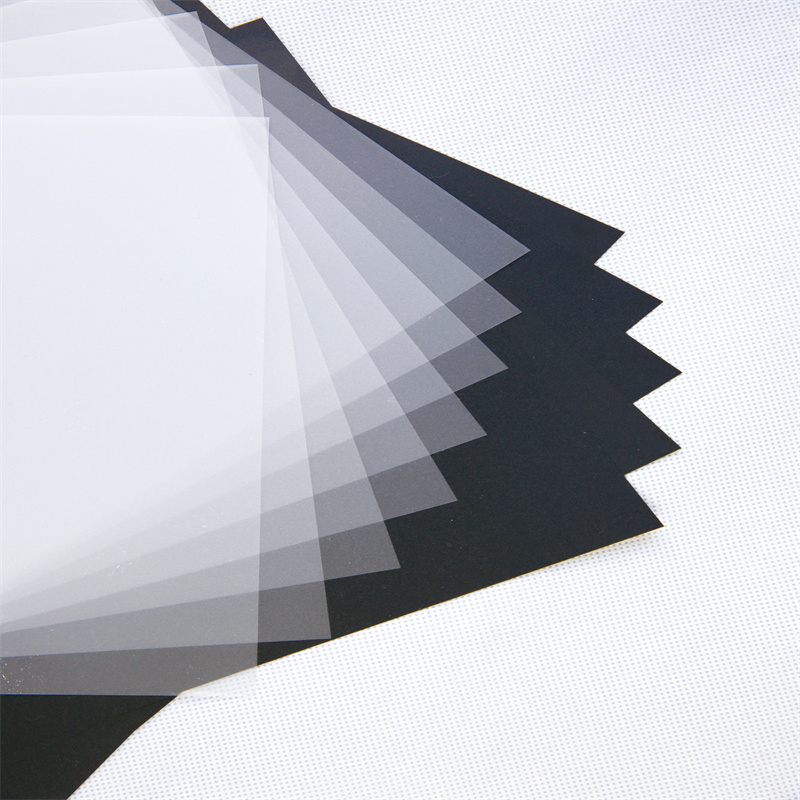

3) Transmission: good light transmission of PC film(clear color)80%--90% for different thickness

4) Wide service temperature range: -40°Cto 120°C,good weather resistance and UV protection

5) Specific gravity: 1.2 g/cm

6) Coefficient of thermal expansion: 0.065 mm/m°C

7) Tensile strength: >60N/mm2

8) Flexural strength: 100N/mm2

9) Modulus of elasticity: 2,400mPa

10) Tensile street at break: >65mPa

11) Elongation at break: >100%

12) Specific heat: 1.16J/kgk

13) Heat deflection temperature: 140°C

14) Heat conductivity: 2.3-3.9 W/m2°C

Polycarbonate Film:

Being a good electrical insulator and having heat-resistant and flame-retardant properties, it is used in various products associated with electrical and telecommunications hardware.

It can also serve as a dielectric in high-stability capacitors.

PP insulation Mylar sheets

2. Fire, flame, shock buffer, dustproof, anti-skid.

3. Backlit, high temperature, corrosion, sealing, protection

4. Spraying shelter, insulation, noise, filtering.

5. Customers may require professional precision die-processed into a variety of shapes.

Application:

About US:

Our company: embedded 14 calender lines, 10 printing machines, 10 lamination and emboss machines to supplyproducts of common transparent film, super transparent film, electrostatic protective film, inkjet advertising film, trademark film, protective film gum paste, electricians film, grainy film, sound film, steel film, furniture membranepressing film, etc. Totally 64 production lines, and the production of PLA sheet ,PVC sheet, PET sheet, PETG sheet, GAG sheet,PP sheet, PS sheet ,PC sheet widely used in food packaging, pharmaceutical packaging, electronic tray, metal packaging,Handicraft packaging and other fields.

Within 15-20 days after received payment...more