0081PVC In-depth Analysis of the Characteristics and Multifaceted Applications of Blue Static Protective Film

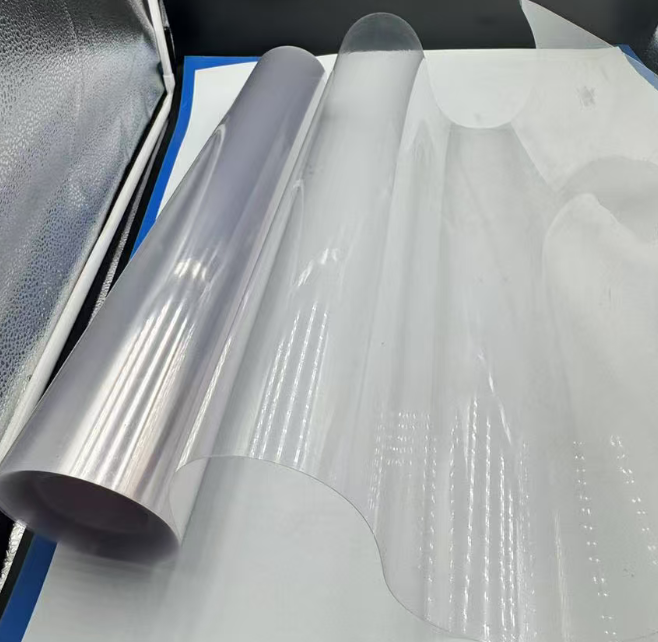

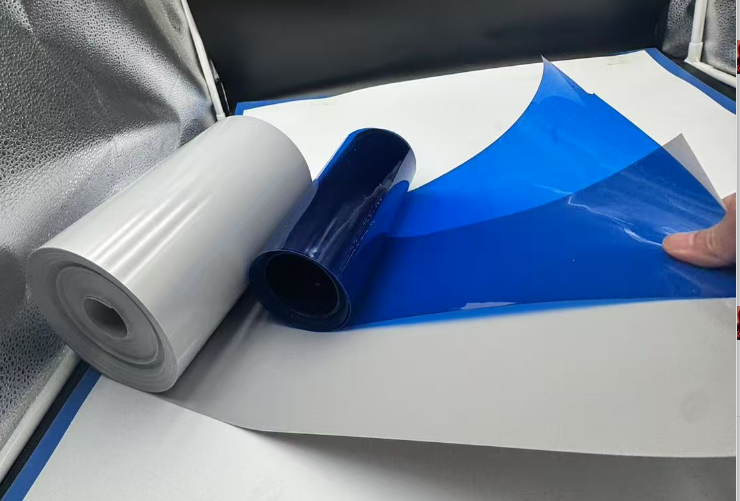

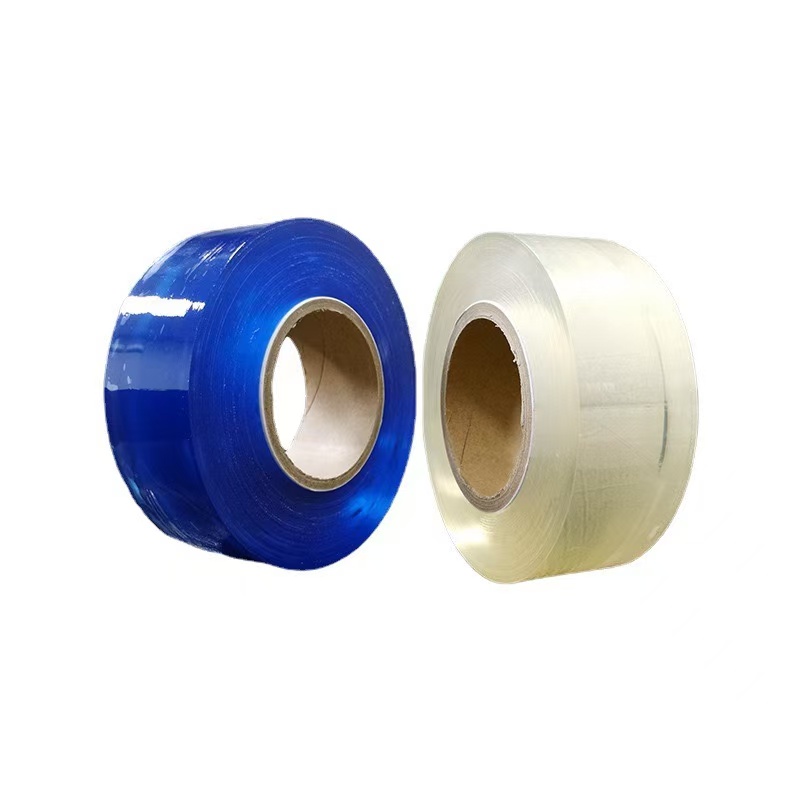

Material: PVC membrane

Thickness 0.45-0.010mm-customization

Size: 100mm-Customization

GRADE: food grade film

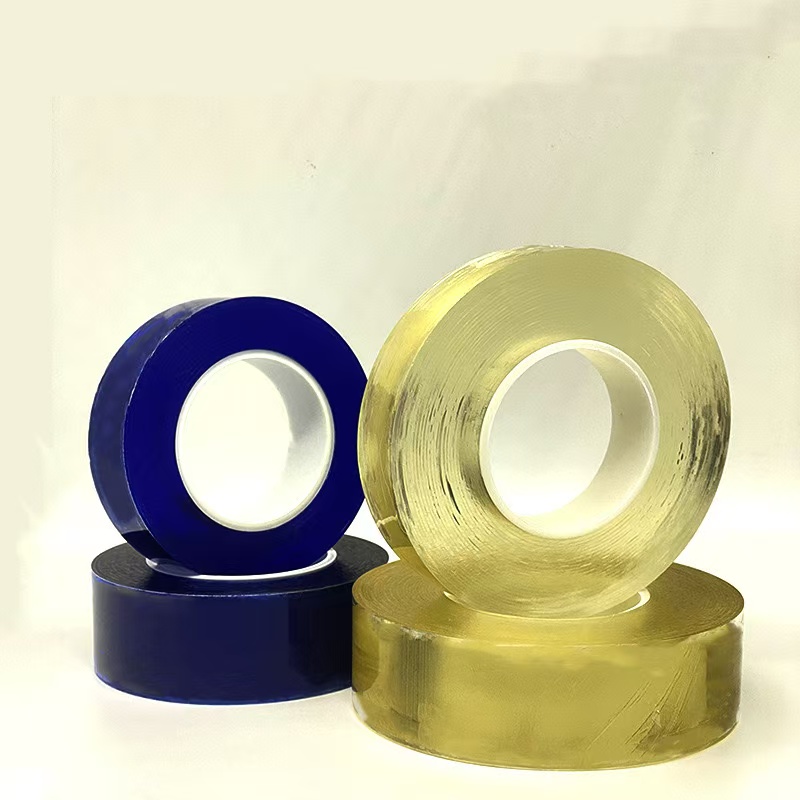

color: transparent customization

location: china

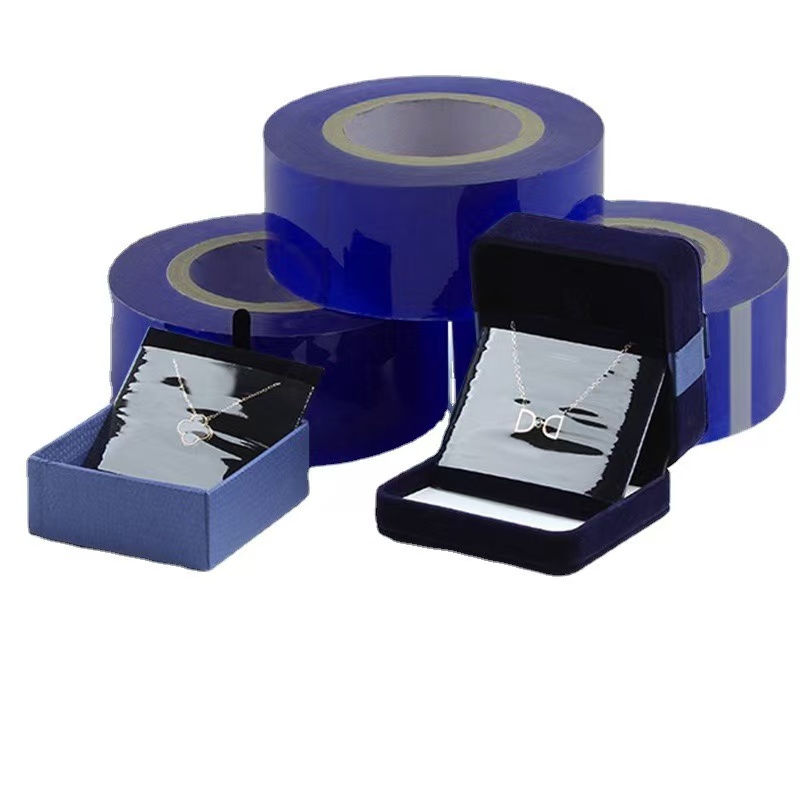

Usage:food packing

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Deep Analysis of the Characteristics and Multifaceted Applications of Blue Static Protective Film

In the time when materials science and industrial manufacturing go hand in hand, the blue static protective film is one of the brightest stars among many other varieties of protective film products. It is not just a film but a remarkable crystallization of the ingenious combination of technology and craftsmanship, playing an indispensable and crucial role in various fields.

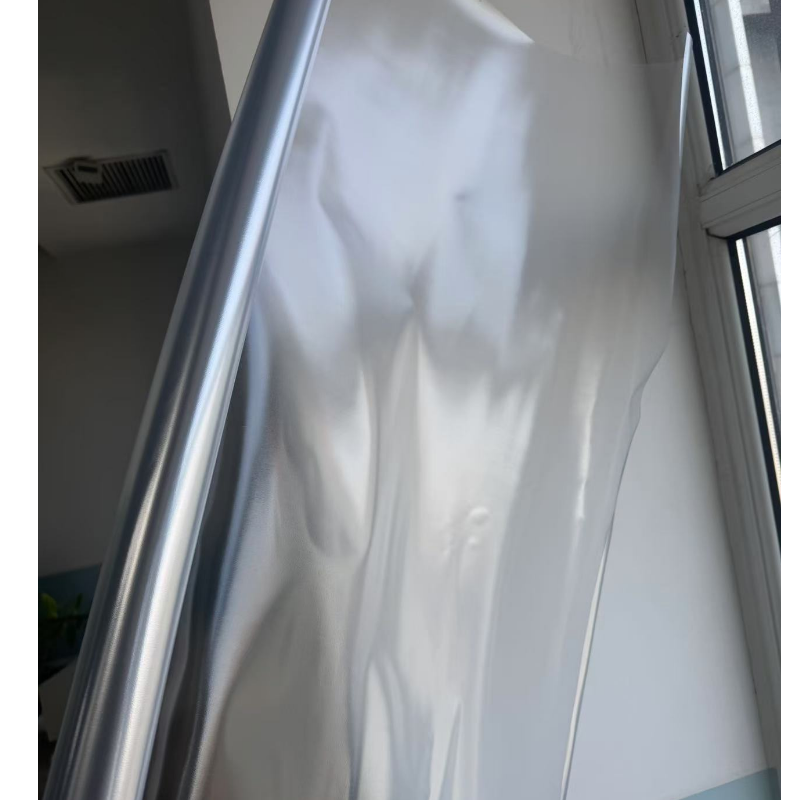

I. Appearance and Basic Characteristics of the Blue Static Protective Film

The blue static protective film gives people an intuitive feeling of freshness and professionalism in an instant with its deep and charming blue hue. The choice and formulation of this blue color are very deliberate. Not only does it have a certain degree of distinctiveness, but it also does not cause any interference or visual conflict with the appearance of the protected items. Its color is consistent, and it can reflect different light with a stable and soft luster to dress up the protected items with an elegant coat. In terms of touching, when we stroke the blue static protective film gently, we can feel its delicate and smooth surface. The present smoothness is not perfectly of the mirror-like texture, though having some soft grain, enabling a good contact between fingers and the surface of the film upon operation and making it difficult to leave fingerprints or stains on it. Even after the actions of touching for long times or after frequent operations, the surface of the film can remain relatively clean and fresh. This is of great significance for some products with extremely high requirements for appearance, such as the screen protection of high-end electronic products.

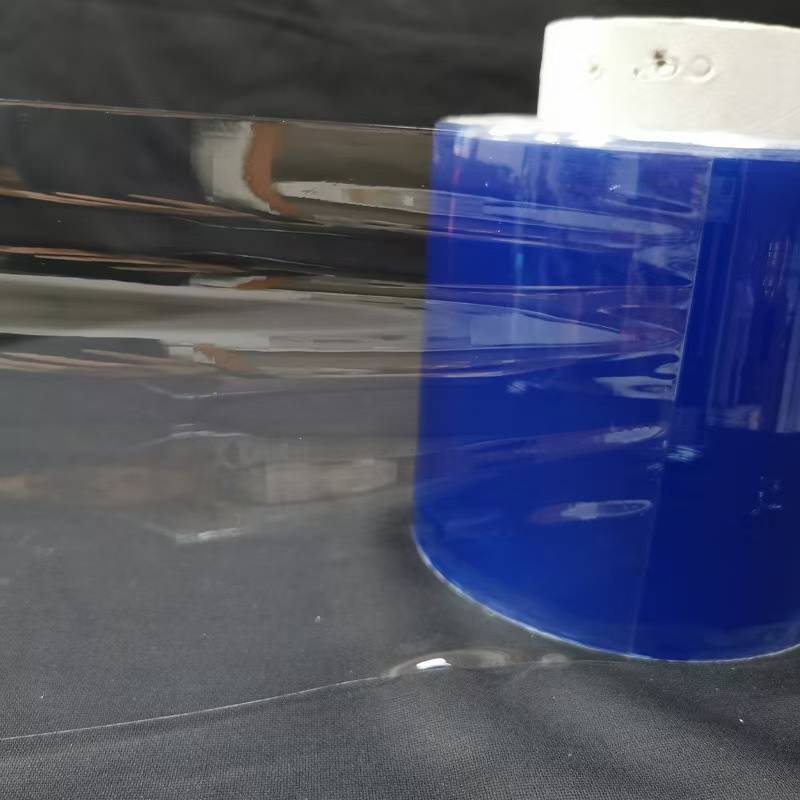

As for thickness, the blue static protective film normally has specifications such as 3 mils, 5 mils, and 8 mils. The 3-mil film is as thin as a cicada wing, applicable in the conditions that are extremely sensitive to the increase in the overall product thickness where the fitting precision requirements are very high. For example, the 3-mil blue static protective film used in the temporary protection of precision electronic components can cling closely to the surface of small components and provide effective protection without causing any hindrance to the subsequent installation or use of the components. The 5-mil thickness is a good balance between thinness and toughness. It has certain resistance to stretching and puncturing and can handle some relatively common usage scenarios. It is widely used in protecting the back of mobile phone cases and tablet computers. This 8-mil blue static protective film is thicker, like a solid shield. It can be used for the protection of products that require higher protection levels and may face harsh environments or greater external impact forces, such as the control panels of industrial equipment and the display screens of outdoor instruments and meters.

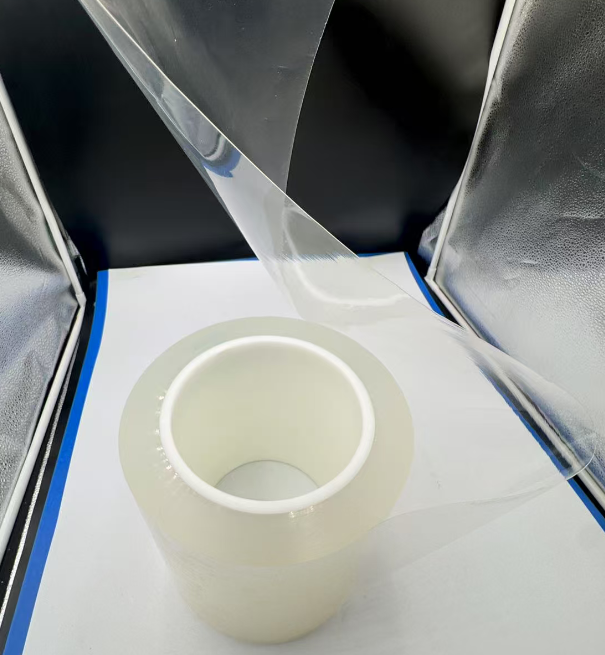

II. Unique Physical Properties of the Blue Static Protective Film

One of the most prominent features of the blue static protective film is its "firm but not fixed" adhesion performance. The moment it comes into contact with various substrate surfaces, it seems to instantly establish a close and special connection. From the hard, smooth surface of metal, to the slightly elastic and textured plastic material, and down to the cold and crystal-clear plane of glass, this blue static protective film can stick to them all with just about the right amount of adhesion force. This adhesion is based not on the sticky nature of glue but on the marvelous principle of electrostatic adsorption.

The electrostatic adsorption allows the blue static protective film to stick without any auxiliary adhesives during the bonding process and avoids leaving glue residue. This characteristic is critical in the manufacturing process of electronic products. In such conditions, for example, there is a need for temporary protection of many precision components such as camera modules and fingerprint recognition modules on the smartphone production line from dust and scratch during assembly. The blue static protecting film will firmly attach to their surfaces and can be removed easily after the assembly is completed, without leaving a single trace of glue on their surface. This ensures that the product's cleanliness and performance won't be affected in the least bit. In the processing and transporting of optical lenses, too, this characteristic of electrostatic adsorption in the blue static protective film is irreplaceable. The film can be closely stuck to the lens surface, preventing scratches caused by friction between the lenses, and will be removed without leaving any residue when the lens has reached the final stage of use, guaranteeing the optical clarity and quality of the lenses.

Besides the unique adhesion brought by electrostatic adsorption, the blue static protective film also has excellent anti-static performance. In this modern society filled with electronic devices, static electricity is always around, an omnipresent factor that could easily cause problems. These tiny static charges may break down integrated circuits and interfere with signal transmission in your electronic components. The blue static protective film can effectively dissipate and shield static electricity, just like putting an anti-static protective suit on electronic devices. In the production workshop of computer motherboards, the blue static protective film is widely used to protect various parts of the motherboard. It not only avoids damaging the motherboard caused by the static electricity during the process generated by personnel operation and operation of equipment but also continues the role in static protection for transportation and storage of the motherboard to guarantee that the performance will remain untouched when it reaches users.

Its anti-fingerprint function can also be viewed as an important highlight of the blue color static protection film. In daily use, our fingers often leave fingerprints on the surface of an object every time we touch it. These fingerprints not only affect the appearance but may also attract dust, oil stains, and other impurities, which may then erode the object's surface or affect its normal use. The surface of the blue static protective film has undergone special treatment and has a microscopic texture structure with low surface energy characteristics. When fingers touch it, the oil and moisture in the fingerprints are difficult to adhere substantially to the film surface. Even if there are a few fingerprint residues, they can be easily wiped clean, and the protected items will always be as clean as new. Taking a tablet computer as an example, in work and life, users are frequently operating the screen of a tablet computer. The blue static protective film can effectively reduce fingerprint residue, keeping the screen clear and bright at all times, allowing users to have a better visual experience and operational feeling. III. Chemical Stability and Durability of the Blue Static Protective Film On the chemical stability of the membrane, the blue static protective film tolerance is outstanding. Whether it is in contact with common acid-base solutions or under different humidity and temperature conditions, it can resist the attack and protect the substrates covered from erosion. In the chemical laboratory, the surface of various chemical reagent bottles is often covered with blue static protective films. When a small amount of acid-base solution accidentally splashes onto the film surface, it can effectively block the contact between the solution and the bottle body surface, preventing the bottle body from being corroded. In the car manufacturing industry, before painting, the car body needs to go through many pretreatment processes. It can avoid erosion by chemical cleaning agents, rust remover, and other chemical substances in this process, which ensures that the car body paint has good adhesion and gloss after spraying. Other important performance indices of the blue static protective film are moisture resistance and aging resistance. Different varieties of blue static protective film may vary slightly in this regard, but generally speaking, they can maintain stable performance in humid environments. During the plum rain season in the south, when the air humidity is often as high as over 80%, electronic devices and metal products are prone to rust or damage due to moisture. It is used to provide reliable protection for items in such an environment and prevent moisture from penetrating into the protected substrates. If it is for long-term outdoor use, the blue static protective film should be resistant to the harsh environment of sunlight ultraviolet radiation, wind, and rain. The blue static protective film, after special formulation design and process treatment, can well resist the aging effect brought about by ultraviolet rays and thus slows down the speed of degradation and discoloration of the body of the film. For example, it is used in outdoor billboards or solar panels where exposure to the outdoors is direct, the blue static protective film maintains performance for a long period of time and extends the life of the facilities being protected.

IV. Deeply Apply Blue Static Protective Film in the Electronic Field

In the electronic field, the blue static protective film is everywhere, and its application runs through the whole life cycle from the manufacturing of electronic components to the assembly of electronic products and finally to the end use of the products.

In the production process of electronic components, such as in the manufacture of semiconductor chips, every small chip bears a complicated structure of the circuit, and its requirements on manufacturing precision are very high. The blue static protective film can protect the chip surface in the processes like lithography, etching, and packaging from pollution and damage caused by dust particles, impurity ions, and other factors. During the process of transportation and storage,

In the production process of electronic components, such as in the manufacture of semiconductor chips, every small chip bears a complicated structure of the circuit, and its requirements on manufacturing precision are very high. The blue static protective film can protect the chip surface in the processes like lithography, etching, and packaging from pollution and damage caused by dust particles, impurity ions, and other factors. During the process of transportation and storage,

it can also prevent chips from performance degradation or damage due to collisions and static electricity. In the manufacturing process of liquid crystal display screens (LCD) and organic light-emitting diode display screens (OLED), the blue static protective film also plays a very important role. In processes like glass substrates processing, thin-film deposition, and pixel point production for display screens, it can prevent scratches, fingerprints, and static electricity from affecting the optical and electrical properties of the display screens. For instance, during the evaporation process in an OLED display screen, a blue static protective film ensures the cleanliness of the surface of the glass substrate before it goes into the evaporation equipment, so the organic material deposited by evaporation is evenly distributed to form a high-quality light-emitting layer to meet the high brightness, high contrast, and high color saturation requirements of the display screen.

In the assembly stage of electronic products, during the assembly workshops of various electronic devices such as mobile phones, tablet computers, and laptops, the blue static protective film is widely used for protection against various components and assembly assistance. During the assembly process of mobile phones, components such as motherboards, cameras, and batteries need to be protected when they are transferred between different workstations. The various chips and circuit elements on the motherboard need to be protected from static interference and collision damage, the lenses of cameras need to be protected from scratches and dust pollution, and the electrode surfaces of batteries need to be kept clean to ensure good electrical conductivity. These versatile needs can be satisfied by the blue static protective film, which can be easily removed after the components are assembled without leaving any residue that might affect the quality and performance of the products.

In the final use stage of electronic products, the blue static protective film provides additional protection for the users. Many consumers choose to stick blue static protective films on the screen and outer case of newly purchased electronic devices such as mobile phones and tablet computers. In daily use, screens are easily affected by finger touches, scratches from keys, and dust contamination. The blue static protective film can effectively reduce those damages. For instance,

In the final use stage of electronic products, the blue static protective film provides additional protection for the users. Many consumers choose to stick blue static protective films on the screen and outer case of newly purchased electronic devices such as mobile phones and tablet computers. In daily use, screens are easily affected by finger touches, scratches from keys, and dust contamination. The blue static protective film can effectively reduce those damages. For instance,

when the mobile phone is accidentally dropped, the blue static protective film can buffer the impact in some degree, reducing the risk of screen cracking. At the same time, its anti-fingerprint and anti-static functions can also improve the usage experience for the user by keeping the screen clear and sensitive all the time.

when the mobile phone is accidentally dropped, the blue static protective film can buffer the impact in some degree, reducing the risk of screen cracking. At the same time, its anti-fingerprint and anti-static functions can also improve the usage experience for the user by keeping the screen clear and sensitive all the time.

V. Key Role of the Blue Static Protective Film in the Optical Field

In the optical field, the purity of the product surface and optical performance has exceptionally high requirements; in that respect, the blue static protective film has an essential and important role to play. In a production process from grinding, polishing to coating of an optical lens, blue static protective films act like a loyal guard to each inch of the surface. The friction between the lens and grinding equipment during grinding easily leads to scratches and debris. In that, the blue static protective film can effectively insulate the grinding tool from the lens to avoid scratch damage to the surface of the lens. In addition, during polishing,

it can avoid the residue of the polishing agent on the lens and adsorption of impurities to keep the surface of the lens smooth. The blue static protective film can prevent the pollution of the lens surface before coating when the lens is coated. For example, during the manufacturing of high-end camera lenses, multi-layer coating technology is widely used to improve the light transmittance of the lens and reduce reflection and chromatic aberration. Therefore, the blue static protective film provides a clean surface environment for the lens during the coating process,

enabling the coating layer to be precisely deposited onto the surface of the lens so that the excellent optical performance of the lens can be assured, and clear and realistic photographs can be taken with high color reproduction.

In the use and maintenance of optical instruments, the blue static protective film also plays an irreplaceable role. During use, the lenses and optical elements of optical instruments such as microscopes, telescopes, and theodolites are easily contaminated by dust, water vapor, fingerprints, and other factors, which will seriously affect the imaging quality and observation accuracy of the instruments. The blue static protective film can protect the lens when the instrument is not used, avoiding dust and water vapor intrusion. When use is needed, just gently remove the protection film to ensure that the lens is in good working condition. During the course of transport and storage of optical instruments, the blue static protective film is even more indispensable. It can avoid scratches or damage caused by collisions between optical elements, ensuring that the instruments can maintain good performance after long-distance transportation and long-term storage.

VI. Application Examples of the Blue Static Protective Film in the Automotive Manufacturing and Decoration Field

In the automotive manufacturing field, the blue static protective film is an indispensable material in the production and assembly process of automobile bodies. After the car body has been stamped and formed, its surface needs to be treated with many processes such as rust removal, phosphating, and electrophoretic coating. The blue static protective film can protect the car body surface from impurity pollution and scratches between these processes. In the car painting workshop, the car body surface should be strictly cleaned and pretreated before painting. The blue static protective film prevents the car body surface from being scratched or contaminated by dust during the pretreatment process, ensuring that the painted surface is flat, smooth,

and flawless. In the automobile manufacturing process, the doors, engine hood, and trunk lid also need protection by the blue static protective film before installation to avoid collision damage and surface pollution during handling and assembly. In automotive decoration, the blue static protective film also has a wide range of applications. The blue static protective films can cover plastic parts, metal parts, and leather parts in auto interiors during production and transportation. For instance, sticking one blue static protective film on the plastic panel before installing it into the car can avoid scratches by tools and contamination by dust during the assembling operation.

and flawless. In the automobile manufacturing process, the doors, engine hood, and trunk lid also need protection by the blue static protective film before installation to avoid collision damage and surface pollution during handling and assembly. In automotive decoration, the blue static protective film also has a wide range of applications. The blue static protective films can cover plastic parts, metal parts, and leather parts in auto interiors during production and transportation. For instance, sticking one blue static protective film on the plastic panel before installing it into the car can avoid scratches by tools and contamination by dust during the assembling operation.

After the car wheels are manufactured and before they are installed on the car, they can also be protected by blue static protective films to prevent the wheel surfaces from being oxidized or scratched. Besides, some car modification enthusiasts will choose blue static protective films when modifying the appearance of their cars by pasting films. It can not only provide a certain decorative effect but also protect the original paint of the car. When restoration to the original state is needed, just remove the protective film without causing any damage to the car paint.

After the car wheels are manufactured and before they are installed on the car, they can also be protected by blue static protective films to prevent the wheel surfaces from being oxidized or scratched. Besides, some car modification enthusiasts will choose blue static protective films when modifying the appearance of their cars by pasting films. It can not only provide a certain decorative effect but also protect the original paint of the car. When restoration to the original state is needed, just remove the protective film without causing any damage to the car paint.

VII. High-end Applications of the Blue Static Protective Film in the Aerospace and High-end Manufacturing Industries

In the aerospace field, every component is related to flight safety and mission success, and the quality and reliability requirements have reached the extreme. The blue static protective film plays an important role in the manufacturing, assembly, and storage of aerospace components. In the manufacturing process of aircraft engine blades, the blades need to undergo precise processing, heat treatment, coating treatment, and so on. During these processes, the blue static protective film can protect the blade surfaces from scratches, oxidation, and impurity pollution. The surface precision and smoothness of engine blades are related to the performance and reliability of the engine. The electrostatic adsorption characteristic of the blue static protective film can ensure that it closely adheres to the blade surfaces without affecting the precision of the blades at all.

In the manufacturing and assembly process of aircraft fuselage structural parts, the blue static protective film can protect the surface from scratch and corrosion for aluminum alloy, titanium alloy, and other materials to ensure the connection precision and strength of the structural parts. During storage of aerospace components, this blue static protective film can effectively avoid the damaging effects caused by humidity, temperature, and static electricity within the environment to the component; hence, allowing the parts to be suitable for flight requirements even after a long storage period.

In the manufacturing and assembly process of aircraft fuselage structural parts, the blue static protective film can protect the surface from scratch and corrosion for aluminum alloy, titanium alloy, and other materials to ensure the connection precision and strength of the structural parts. During storage of aerospace components, this blue static protective film can effectively avoid the damaging effects caused by humidity, temperature, and static electricity within the environment to the component; hence, allowing the parts to be suitable for flight requirements even after a long storage period.

Highly precision-related and high-end manufacturing sectors, including precision machining and medical equipment manufacturing, are other relevant application fields where the blue static protective film is highly applied. In precision machinery, some parts, such as the spindles and guiding rails of the cutting tools on CNC machine tools, require very accurate protection during processing and in their assembly. The blue protective film

can protect these high accuracies from contamination by cutting fluid and metal chips in service, ensuring the assembly precisions of the parts. In the manufacturing of medical devices, surgical instruments, optical components of medical equipment, and electronic sensors are all in need of strict protection. The blue static protective film is sterile, residue-free, anti-static, and thus quite ideal for the protection of medical devices. For instance, the lens of a surgical microscope requires a highly clean and optically sensitive environment before use. The blue static protective film can protect all lenses in every aspect during transport, storage, and preoperative preparation to ensure smooth progress in surgeries and the safety of patients.

can protect these high accuracies from contamination by cutting fluid and metal chips in service, ensuring the assembly precisions of the parts. In the manufacturing of medical devices, surgical instruments, optical components of medical equipment, and electronic sensors are all in need of strict protection. The blue static protective film is sterile, residue-free, anti-static, and thus quite ideal for the protection of medical devices. For instance, the lens of a surgical microscope requires a highly clean and optically sensitive environment before use. The blue static protective film can protect all lenses in every aspect during transport, storage, and preoperative preparation to ensure smooth progress in surgeries and the safety of patients.

VIII. Future Development Trend and Prospect of the Blue Static Protective Film

Along with the continuous progress of science and technology and the continuous improvement of the industrial manufacturing level, there will also be broader development prospects for the blue static protective film.

In the future, blue static protective films will be made from advanced polymer material formulations. It will introduce new functional additives, such as anti-static agents, anti-aging agents, and antibacterial agents, that will further enhance the performance of the protective film. For example, developing blue static protective films with stronger anti-static capabilities will meet the extremely high requirement of static protection in fields such as ultra-large-scale integrated circuit manufacturing. While improving the molecular structure of materials, the temperature resistance, chemical corrosion resistance, and other properties of the protective film will be improved, enabling it to be used in harsher environments, such as in deep-sea exploration equipment and high-temperature smelting equipment. In terms of process improvement, manufacturing will be more refined and intelligent. By adopting new technologies like advanced nanotechnology, microfluidic technology, and so on, these parameters can be precisely regulated, such as the thickness and surface roughness of the protective film and the magnitude of an electrostatic adsorption force. For instance, by using advanced nanotechnology, blue static protective films with nanometer-scale thickness can be prepared, with ultra-smooth surfaces. Without affecting either the appearance or performance, they can provide more outstanding protection effects. The intelligent production process will be enabled to monitor and adjust the production process in real-time, and improve the consistency and stability of products. Based on big data analysis and artificial intelligence algorithms, the parameters of the production process can be automatically optimized according to different application requirements and production conditions to manufacture customized blue static protective film.

In the future, blue static protective films will be made from advanced polymer material formulations. It will introduce new functional additives, such as anti-static agents, anti-aging agents, and antibacterial agents, that will further enhance the performance of the protective film. For example, developing blue static protective films with stronger anti-static capabilities will meet the extremely high requirement of static protection in fields such as ultra-large-scale integrated circuit manufacturing. While improving the molecular structure of materials, the temperature resistance, chemical corrosion resistance, and other properties of the protective film will be improved, enabling it to be used in harsher environments, such as in deep-sea exploration equipment and high-temperature smelting equipment. In terms of process improvement, manufacturing will be more refined and intelligent. By adopting new technologies like advanced nanotechnology, microfluidic technology, and so on, these parameters can be precisely regulated, such as the thickness and surface roughness of the protective film and the magnitude of an electrostatic adsorption force. For instance, by using advanced nanotechnology, blue static protective films with nanometer-scale thickness can be prepared, with ultra-smooth surfaces. Without affecting either the appearance or performance, they can provide more outstanding protection effects. The intelligent production process will be enabled to monitor and adjust the production process in real-time, and improve the consistency and stability of products. Based on big data analysis and artificial intelligence algorithms, the parameters of the production process can be automatically optimized according to different application requirements and production conditions to manufacture customized blue static protective film.

In terms of the expansion of application fields, the blue static protective film will not be limited to existing fields and will continue its expansion in emerging fields: the new energy field, for example, manufactures and protects lithium-ion batteries and fuel cells. The blue static protective film will be able to fully exert its functions of anti-static and anti-pollution in improving battery performance and safety. With the rapid development of foldable mobile phones, flexible display screens, and wearable devices, there is an urgent need in the field of flexible electronics to make the blue static protective film have better flexibility, foldability, and anti-bending performance to meet the needs of these new types of electronic products. In the smart home field, the blue static protective film can be used for the surface protection of smart home appliances to prevent scratches, fingerprint pollution and other problems during transportation, installation, and use. At the same

Within 15-20 days after received payment...more