Transparent PVC/PVDC Film: Characteristics and Applications in Food and Pharmaceutical Packaging

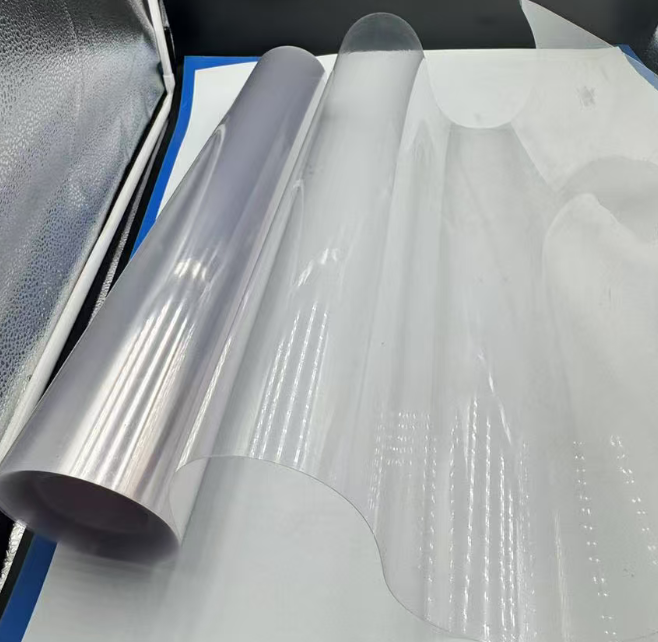

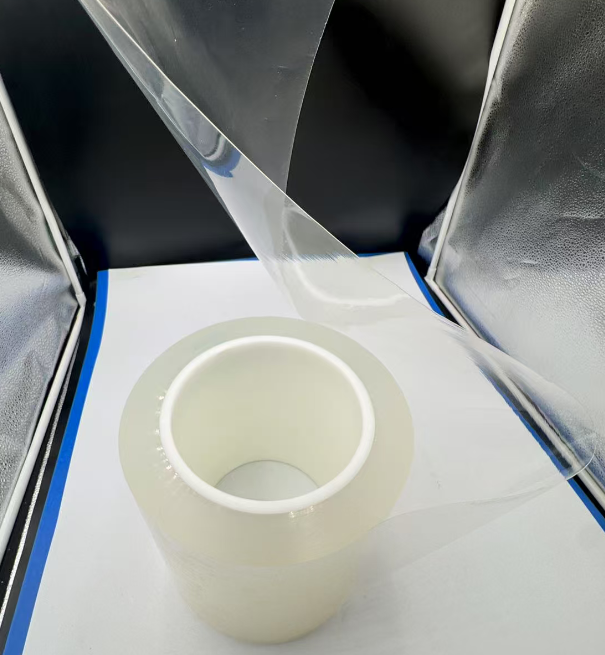

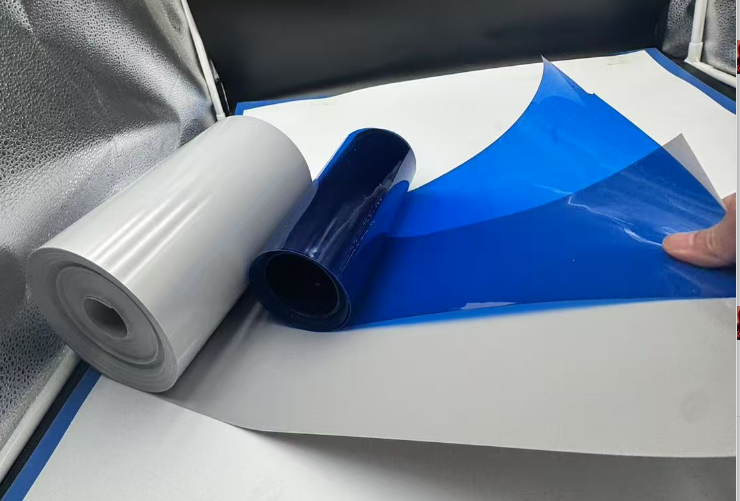

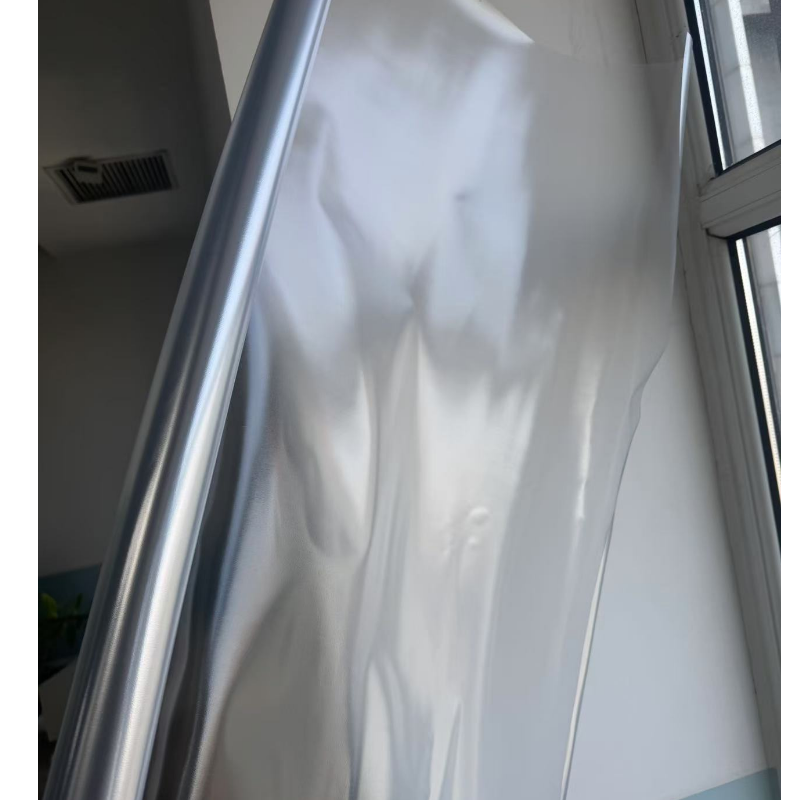

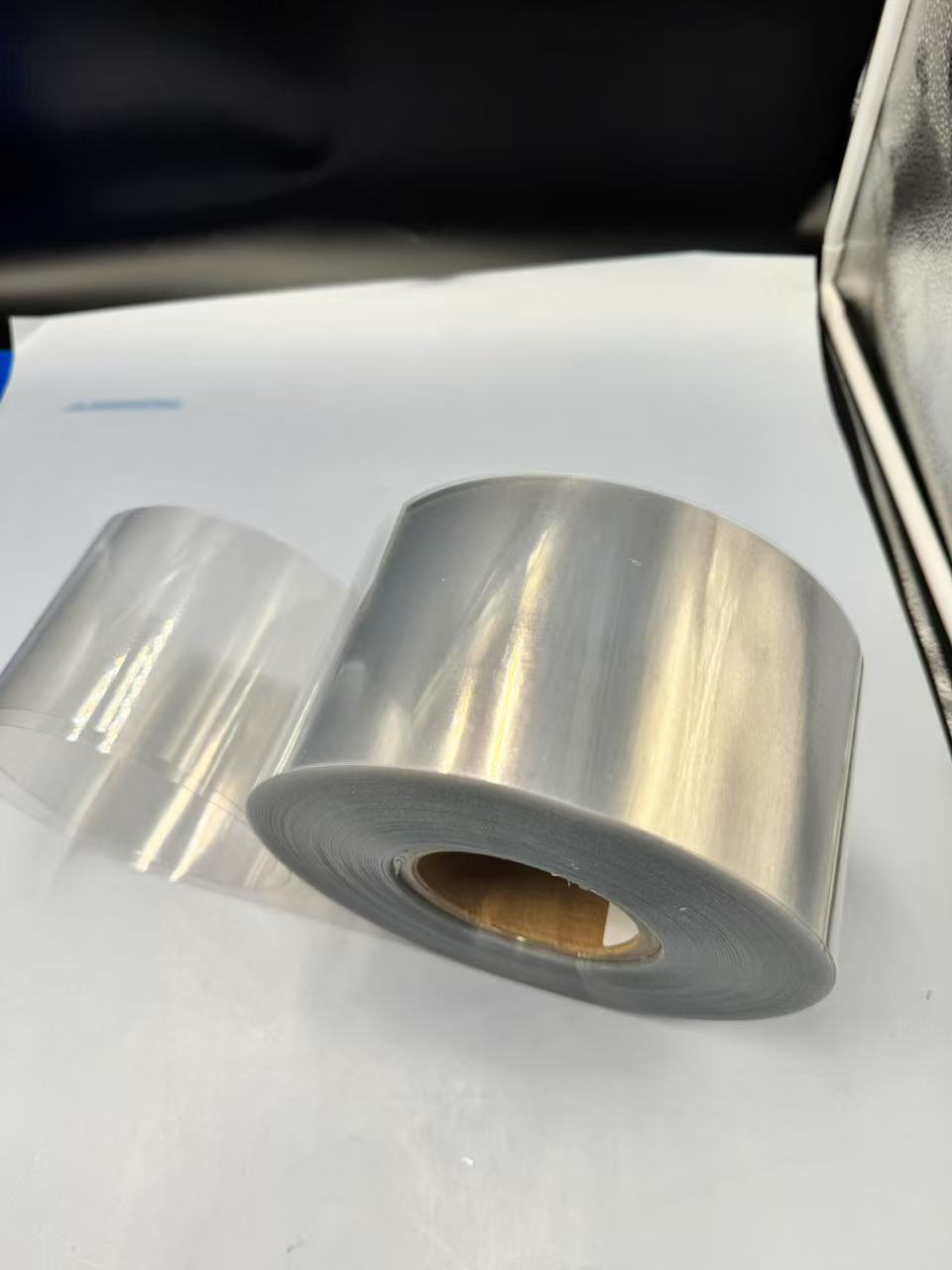

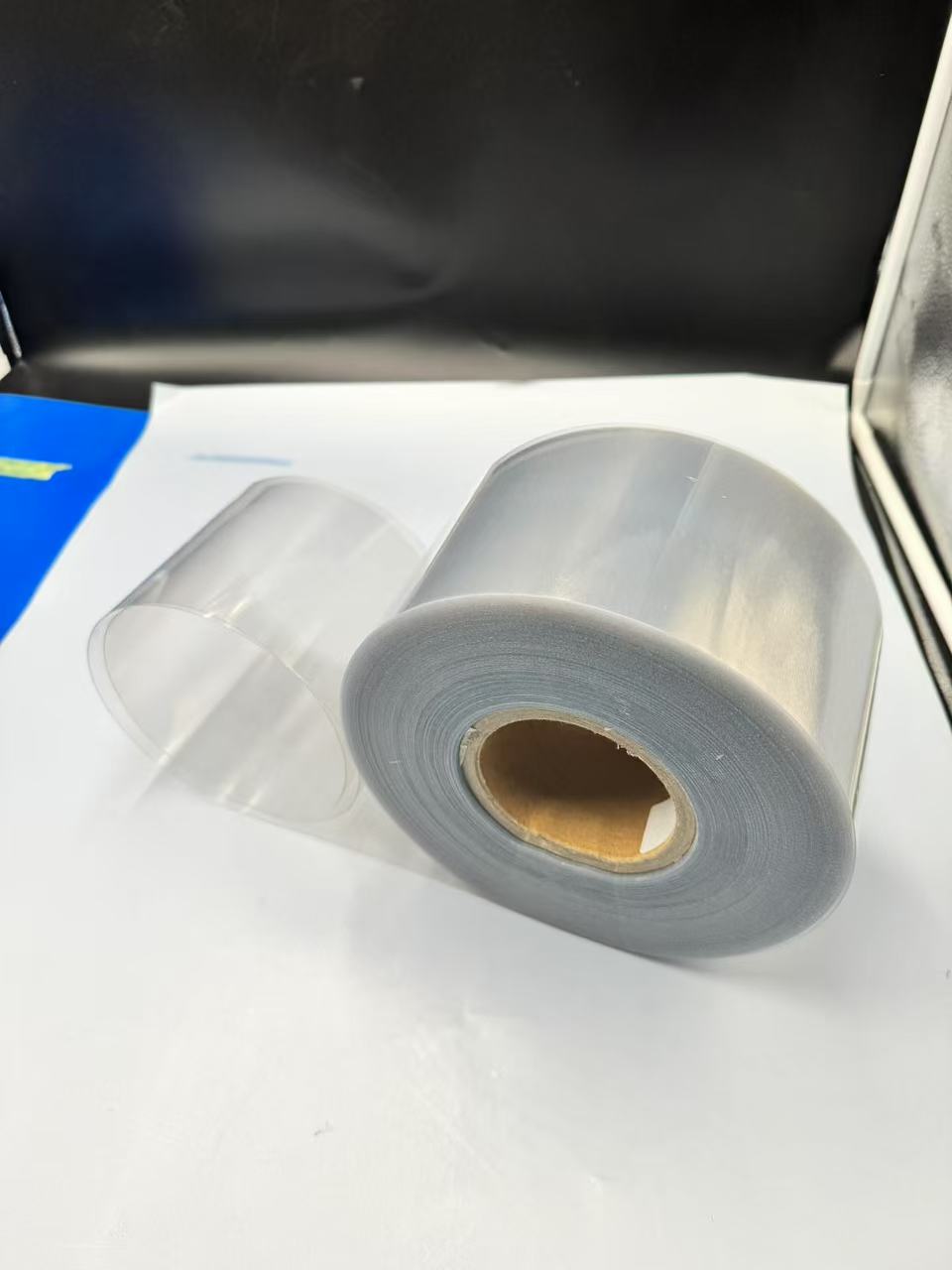

NamePVC/PVDC film roll

SizeTk:0.01-3mm, h100-1200mm

MaterialPET/PP/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

Usage PVC film, PHARMACEUTICAL PACKING , corrosion resistance, fireproofing, waterproofing, anti-static

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- 中国

- 15 WORKINGDAYS

- 5000T/M

- Information

- Download

Introduction

In the intricate world of food and pharmaceutical packaging, where safety, shelf life, and compliance with stringent regulations are non-negotiable, transparent Polyvinyl Chloride (PVC) coated with Polyvinylidene Chloride (PVDC) film stands out as a trusted solution. Renowned for its exceptional barrier properties, clarity, and versatility, PVC/PVDC film ensures that perishable foods and sensitive medications remain protected while maintaining an appealing presentation. From blister packs for tablets to vacuum-sealed meat trays, this advanced material has become indispensable in modern packaging. This article explores the key characteristics of transparent PVC/PVDC film and its critical applications in food and pharmaceutical packaging, highlighting its role in safeguarding quality and consumer trust.

Renowned for its exceptional barrier properties, clarity, and versatility, PVC/PVDC film ensures that perishable foods and sensitive medications remain protected while maintaining an appealing presentation. From blister packs for tablets to vacuum-sealed meat trays, this advanced material has become indispensable in modern packaging. This article explores the key characteristics of transparent PVC/PVDC film and its critical applications in food and pharmaceutical packaging, highlighting its role in safeguarding quality and consumer trust.

Characteristics of Transparent PVC/PVDC Film

Transparent PVC/PVDC film is a composite material that combines the flexibility and clarity of PVC with the superior barrier properties of PVDC coating. Its unique attributes make it ideal for demanding packaging applications. Below are the key characteristics that define this material:

1. Outstanding Barrier Properties

The PVDC coating on PVC film provides exceptional protection against oxygen, moisture, and gases, significantly extending the shelf life of packaged products. PVDC is one of the most effective barrier materials, with an oxygen transmission rate (OTR) as low as 0.5–2 cm³/m²/day at 23°C and a water vapor transmission rate (WVTR) of 0.5–3 g/m²/day. This makes PVC/PVDC film ideal for oxygen-sensitive foods like meats or moisture-sensitive pharmaceuticals like tablets, ensuring product stability and freshness.

2. High Transparency and Aesthetic Appeal

Transparent PVC/PVDC film offers excellent optical clarity, allowing consumers to view the packaged product in vivid detail. The glossy surface enhances visual appeal, making it a preferred choice for food items like cheeses or pharmaceuticals in blister packs, where product visibility builds trust. The clarity of PVC/PVDC film rivals that of PET films, but its superior barrier properties give it an edge in high-protection applications.

3. Strong Heat-Sealing Capabilities

PVC/PVDC film is designed for reliable heat sealing, forming airtight and tamper-evident seals when paired with substrates like PVC trays, aluminum foils, or other plastics. The PVDC layer maintains its integrity at sealing temperatures (typically 120–160°C), ensuring secure closure for pouches, trays, or blister packs. This property is critical for maintaining product safety and preventing contamination in both food and pharmaceutical packaging.

4. Mechanical Strength and Flexibility

PVC/PVDC film combines the toughness of PVC with the flexibility needed for various packaging formats. With a tensile strength of approximately 50–80 MPa, the film resists punctures and tears, protecting contents during handling and transportation. Its flexibility allows it to conform to complex shapes, such as deep-drawn blister packs for capsules or vacuum-formed trays for deli meats, without compromising barrier performance.

5. Chemical Resistance and Stability

The PVDC coating enhances the film’s resistance to chemicals, oils, and grease, making it suitable for packaging fatty or acidic foods like sausages or sauces. In pharmaceuticals, this resistance prevents interactions between the film and active ingredients, ensuring drug stability. The film’s stability under varying temperatures (from -20°C for frozen foods to 70°C for ambient storage) further broadens its applicability.

6. Regulatory Compliance for Food and Drug Safety

Transparent PVC/PVDC film is manufactured to meet rigorous global standards, including those set by the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and China’s National Medical Products Administration (NMPA). The film is certified for direct food contact and pharmaceutical use, free from harmful substances like phthalates or heavy metals. Migration tests confirm that no harmful compounds leach into food or drugs, ensuring consumer safety.

7. Customizable Thickness and Coating Options

PVC/PVDC film is available in various thicknesses (typically 200–350 microns for blister packs and 15–100 microns for flexible films) and PVDC coating weights (e.g., 40, 60, or 90 g/m²). Higher PVDC coating levels enhance barrier properties but increase costs, allowing manufacturers to tailor the film to specific needs. This customization ensures cost-effective solutions for both high-barrier pharmaceutical blister packs and moderate-barrier food pouches.

Applications of Transparent PVC/PVDC Film in Food and Pharmaceutical Packaging

The superior properties of transparent PVC/PVDC film make it a versatile material for food and pharmaceutical packaging, balancing protection, aesthetics, and compliance. Below are its key applications in these industries:

1. Blister Packaging for Pharmaceuticals

In pharmaceutical packaging, transparent PVC/PVDC film is the backbone of blister packs for tablets, capsules, and other solid-dose medications. The film’s clarity allows patients to see the medication, while its high barrier properties protect against moisture and oxygen, which can degrade active ingredients. For example, a PVDC-coated PVC film with a 60 g/m² coating might be used to package antibiotics, ensuring a shelf life of 2–3 years. The film’s heat-sealing compatibility with aluminum foil creates tamper-evident packs, enhancing patient safety and regulatory compliance.

2. Vacuum and Modified Atmosphere Packaging for Foods

For perishable foods like fresh meats, seafood, or cheeses, transparent PVC/PVDC film is used in vacuum or modified atmosphere packaging (MAP). The film’s low OTR and WVTR maintain low oxygen levels, slowing microbial growth and oxidation. Its puncture resistance ensures that vacuum-sealed packages remain intact, even for sharp products like bone-in poultry. A supermarket might use PVC/PVDC film to package sliced ham, offering a clear view of the product while ensuring a shelf life of 30–60 days under refrigeration.

3. Lidding Films for Dairy and Ready Meals

Transparent PVC/PVDC film serves as a lidding material for dairy products (e.g., yogurt, cream cheese) and ready-to-eat meals in trays. The film’s clarity showcases the product, while its heat-sealing properties create a secure, peelable seal that preserves freshness. For instance, a yogurt brand might use PVC/PVDC film with a 40 g/m² coating to seal PET trays, protecting against moisture and extending shelf life. The film’s resistance to acidic dairy contents ensures product safety and quality.

4. Flexible Pouches for Snacks and Condiments

In food packaging, transparent PVC/PVDC film is used for flexible pouches containing snacks, sauces, or condiments. The film’s barrier properties protect against moisture and air, maintaining the crispness of snacks or the flavor of sauces. Its chemical resistance is particularly valuable for oily or acidic contents, such as salad dressings. A brand might use PVC/PVDC film to package ketchup sachets, combining visual appeal with a shelf life of 6–12 months.

5. Overwraps for Frozen and Perishable Foods

Transparent PVC/PVDC film is ideal for overwrapping frozen foods like vegetables, seafood, or baked goods. The film’s low-temperature flexibility (-20°C) prevents cracking, while its barrier properties protect against freezer burn and moisture loss. For example, a frozen shrimp package might use PVC/PVDC film to maintain product quality during storage, with the film’s clarity highlighting the shrimp’s fresh appearance.

6. Child-Resistant and Senior-Friendly Pharmaceutical Packaging

In pharmaceuticals, PVC/PVDC film is used in blister packs designed for child resistance and senior accessibility. The film’s strength prevents children from tearing the pack, while peel-push or peelable designs allow seniors to access medications easily. For instance, a PVDC-coated PVC film might be used for antihypertensive drugs, ensuring both safety and convenience for elderly patients.

7. Sustainability Considerations

While PVC/PVDC film is less recyclable than PET due to the chlorine content in PVC, advancements in recycling technologies and the development of PVC-free alternatives are improving its environmental profile. Manufacturers can reduce material usage by opting for thinner films or integrating post-consumer recycled (PCR) content where regulations allow. For example, a food brand might use a thinner PVC/PVDC film for cheese packaging, minimizing waste while maintaining barrier performance.

Practical Considerations for Using Transparent PVC/PVDC Film

To maximize the benefits of transparent PVC/PVDC film in food and pharmaceutical packaging, manufacturers must address several practical aspects:

1. Selecting the Appropriate Film Specification

The choice of PVC/PVDC film depends on the product’s sensitivity, packaging format, and shelf-life requirements. For moisture-sensitive drugs, a film with a 90 g/m² PVDC coating is ideal, while a 40 g/m² coating suffices for short-shelf-life foods. Manufacturers should consult suppliers to select films with the right thickness and barrier properties.

2. Optimizing Heat-Sealing Parameters

Effective heat sealing requires precise control of temperature (120–160°C), pressure, and dwell time (0.5–2 seconds). Testing on production equipment ensures strong, leak-proof seals. For blister packs, compatibility with aluminum foil or other lidding materials must be verified to prevent seal failures.

3. Ensuring Regulatory Compliance

Manufacturers must confirm that PVC/PVDC films meet food and drug safety standards, obtaining certificates of compliance and migration test reports. Films should be stored in clean, dry conditions (15–25°C, 40–60% RH) to prevent contamination or degradation.

Within 15-20 days after received payment...more