Unveiling Its Characteristics and Applications in Tableware, Blister Packaging, Seedling Trays, and Antistatic Sheets

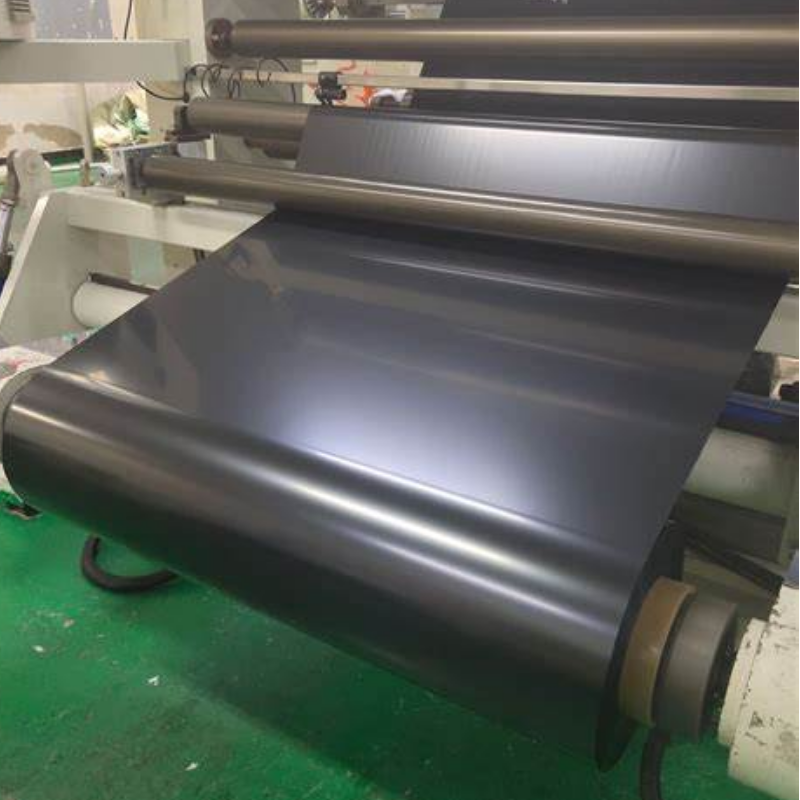

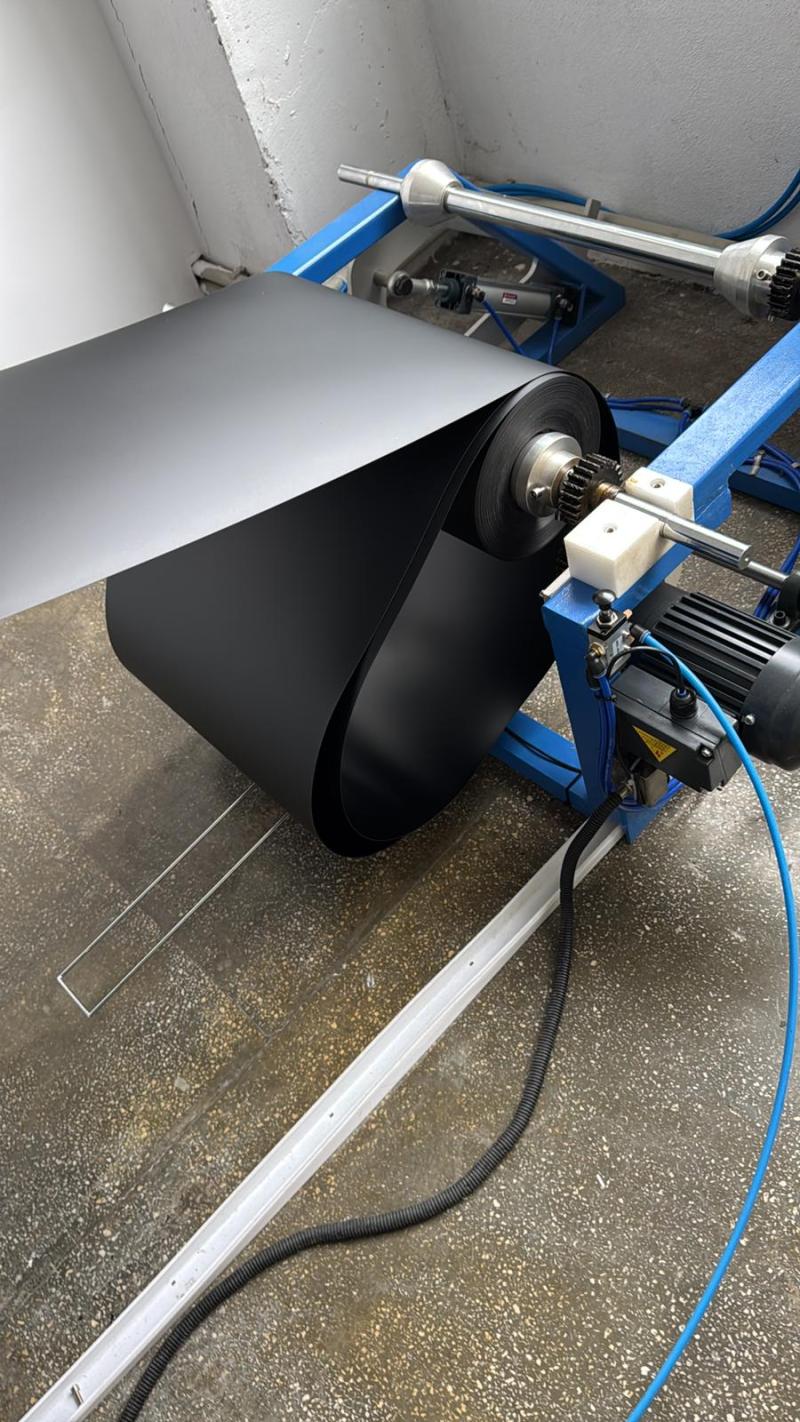

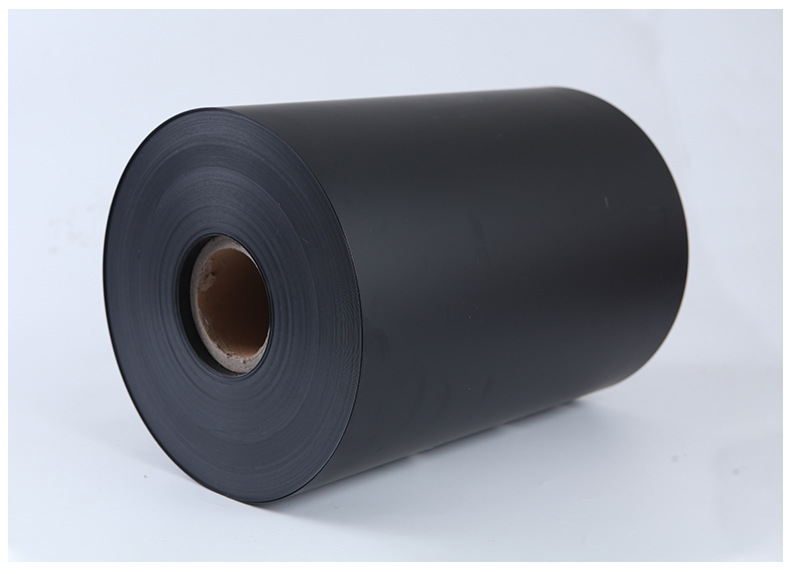

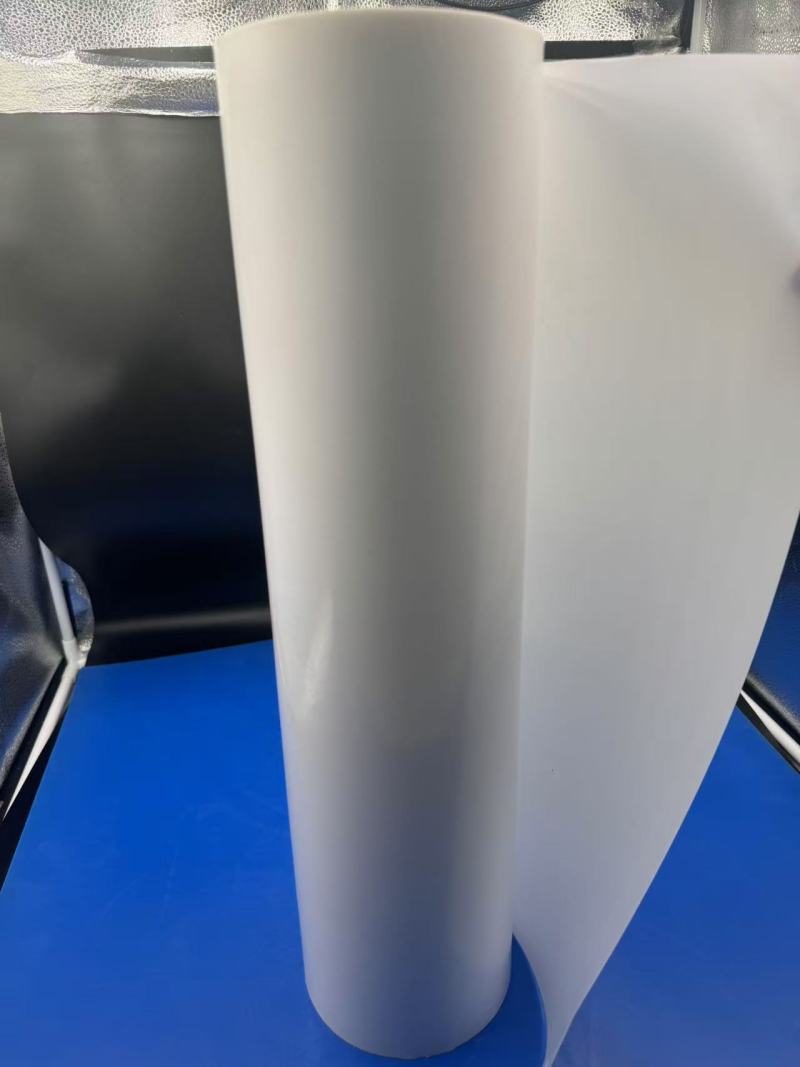

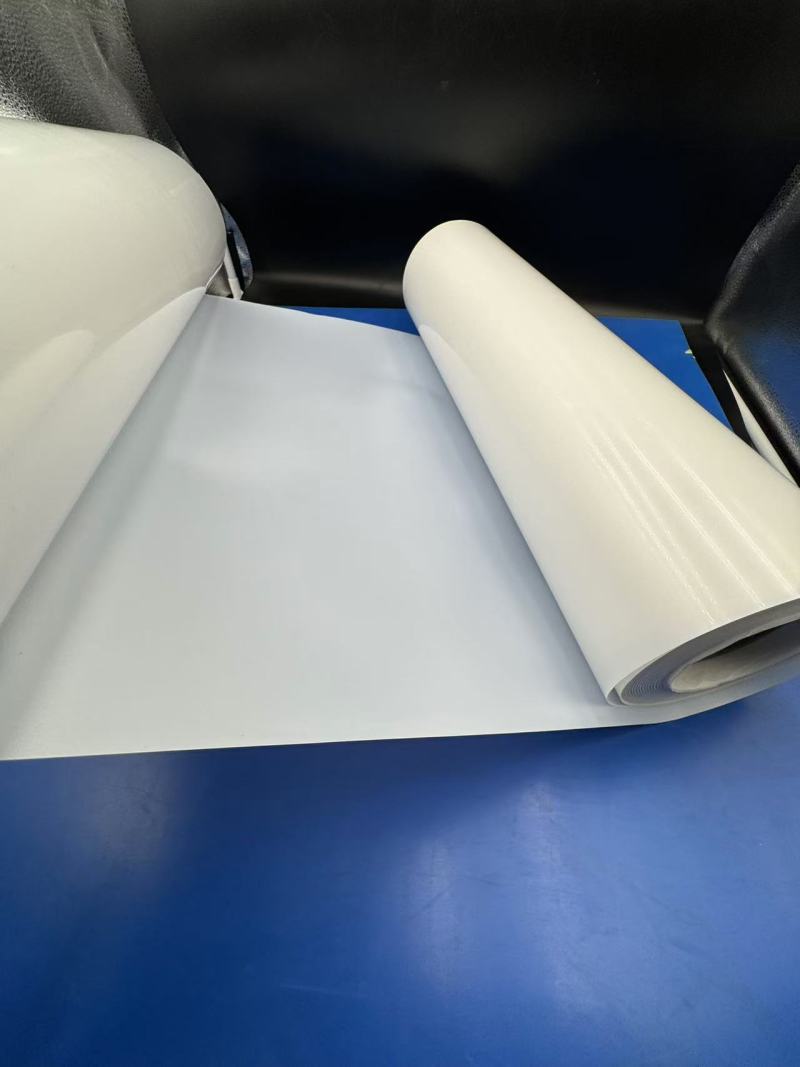

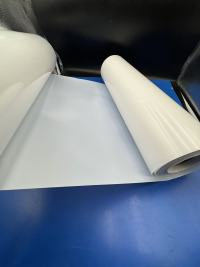

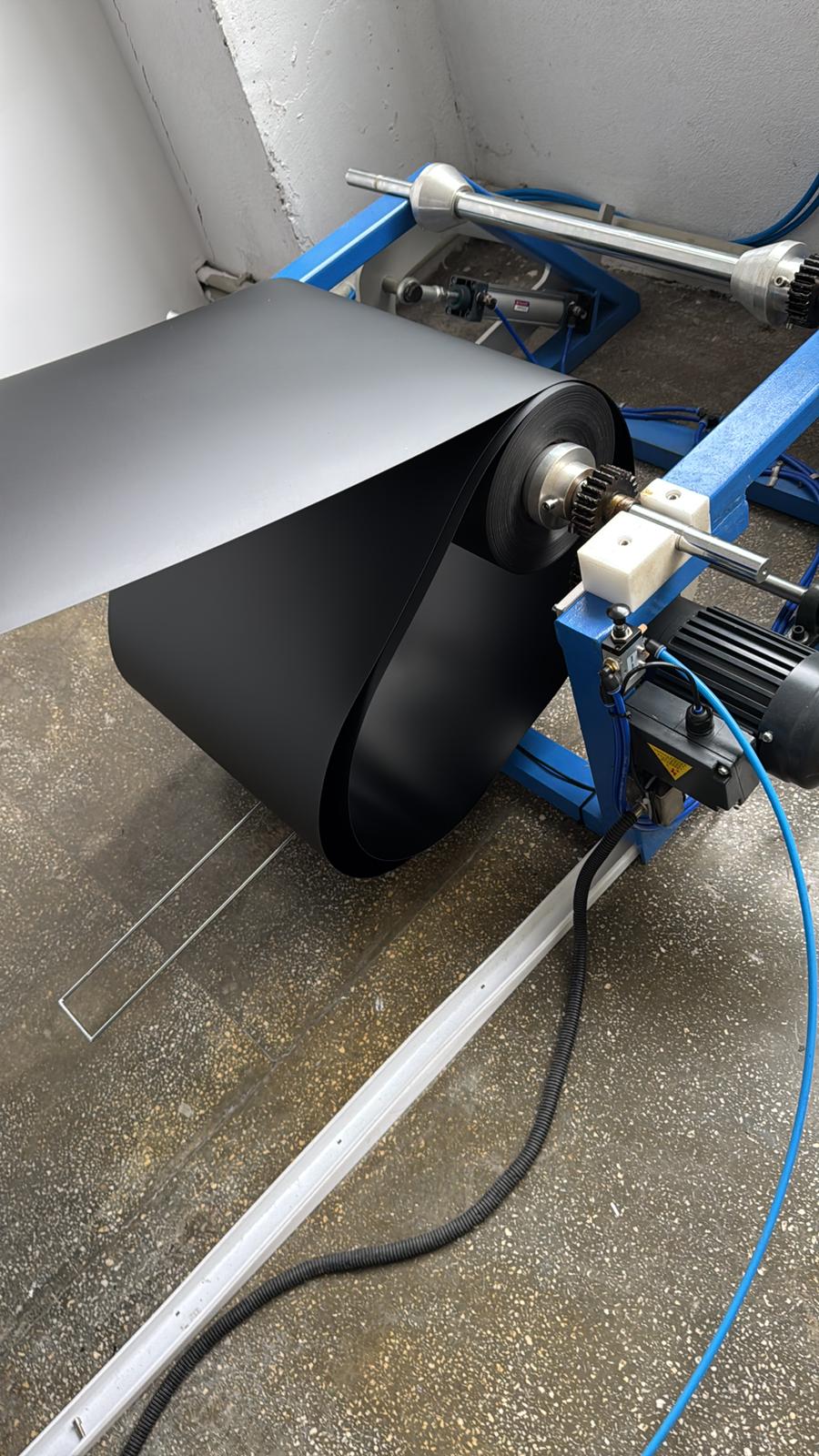

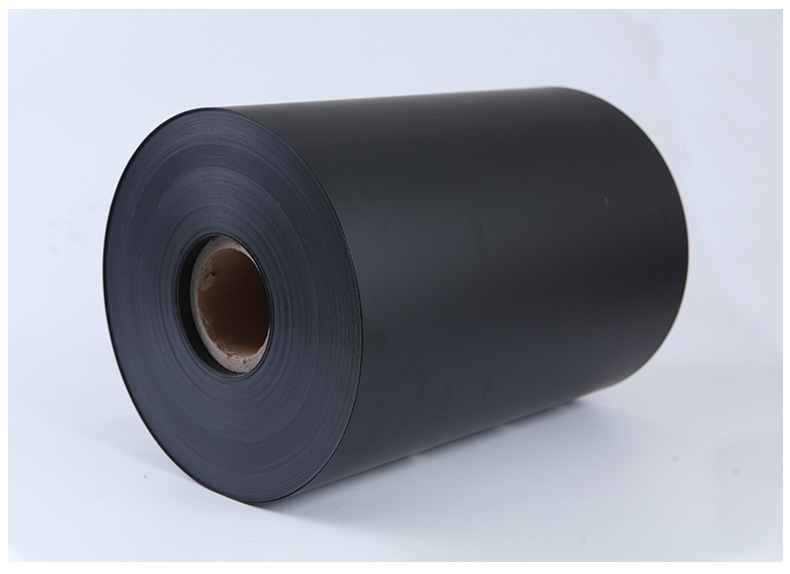

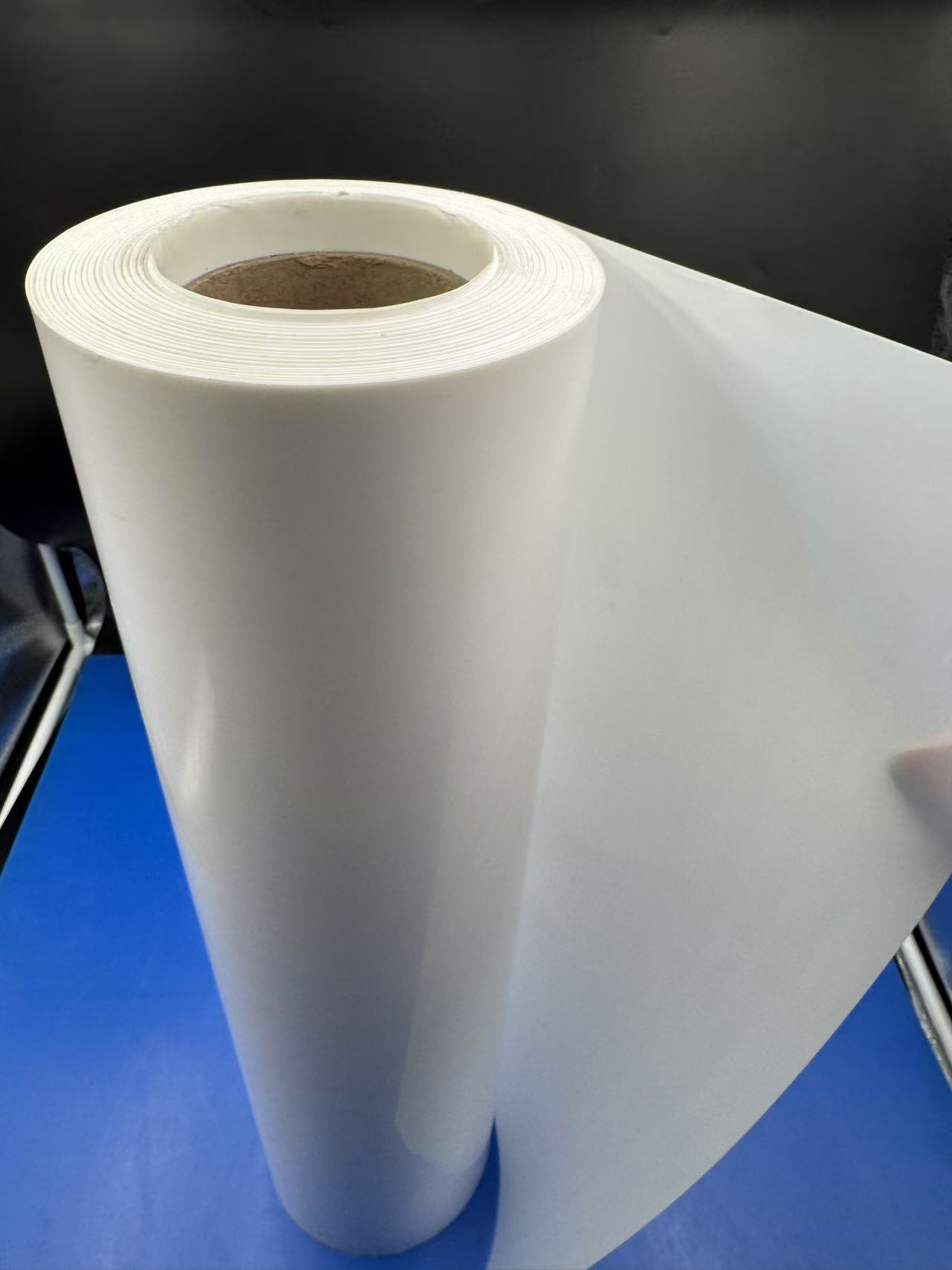

Material: PP Thermal formed sheet

Thickness 0.25-0.9mm/customization

Size: 300mm/Customization

GRADE: Food grade film

color: black/white/ customization

location: china

usage :for food tray ,mircronwave food container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction

PS film is versatile and economical, hence finding its place in almost all industries due to a unique combination of properties. This article will discuss some of the characteristics of the PS film and its applications in tableware, blister packaging, seedling trays, and antistatic sheets, among others, to give an overview of how the material shapes our daily lives.

Characteristics of PS Film

Transparency and Gloss:

PS film is reputed for crystal clarity, hence ideal for applications where aesthetics are a major factor. Its high gloss and sparkle offer an aesthetic advantage in packaging, among other applications.

Strength and Durability:

PS film has high moisture vapor, oxygen, and CO2 transmission rates, useful in packaging fresh foods where respiration is required but also limit utility of the film in barrier applications.

Printability:

The surface of the film itself is typically printable. It provides good bright graphics and branding, hence being one of the favorites for packaging solutions where print aesthetics are relevant.

Antistatic Properties:

Treated or modified PS may exhibit antistatic properties that are very essential in the packaging and handling of electronic components, preventing static electricity damage.

Tableware Applications

In tableware applications, high clarity and good printability in PS film have been employed to make disposable cups, plates, and food containers. Low in cost and amenable to various shapes by thermoforming, the material is useful for:

Yogurt Cups and Food Trays: PS can present fresh food in clear packaging, which adds to its consumer appeal.

Disposable Cutlery and Containers: The strength in the film provides the structural integrity needed in these products to withstand normal use.

Blister Packaging

Blister packaging employs PS film because of its very good thermoforming capability, which provides tight, protective packaging for such consumer products as pharmaceuticals, electronics, and small hardware:

Pharmaceuticals: The clarity of PS enables the easy inspection of medication, while barrier properties, in modified forms, maintain product integrity.

Electronics: Antistatic variants of PS film find a very specific application in this industry by protecting sensitive components from static discharge.

Seedling Trays

In agriculture, PS films are made into seedling trays because of the following reasons:

Durability: These can withstand the rigors of handling and the variable conditions of nurseries.

Light Transmission: Since PS is translucent, light transmits through, promoting plant growth.

Reusability: Most seedling trays made from PS can be thoroughly cleaned and used again, so reusing instead of disposing saves resources.

Antistatic Sheets

PS usage in antistatic sheets plays a critical role in electronics production:

Electronic Packaging: PS films, modified with antistatic properties, safeguard against static electricity that would otherwise destroy electronic circuits.

Clean Room Applications: Here, surface resistance of the material is optimized to avoid a buildup of static to ensure safety where electronics assembly occurs.

Environmental Considerations

Although PS offers considerable utility, it cannot afford to neglect environmental issues. Improvements in:

Recycling: Though difficult, PS recycling becomes increasingly practiced as countries develop modern waste management infrastructures.

Biodegradable Analogs: Also being researched is the development of biopolymers that approximate PS properties with enhanced degradability.

Conclusion

The properties of PS film make it very versatile for applications, from everyday items like tableware to specialized uses such as antistatic packaging. Its ability to be molded into complex shapes, along with its optical clarity and mechanical strength, continues to make PS a material of choice. However, in the move to more sustainable materials, the industry is challenged to innovate while still leveraging the beneficial properties of PS.

The exploration of PS film manufacturing further points out not only its utility but also the ongoing need for innovation that will make it environmentally friendly, with a view to this material continuing into our future as well as forming part of our present.

Within 15-20 days after received payment...more