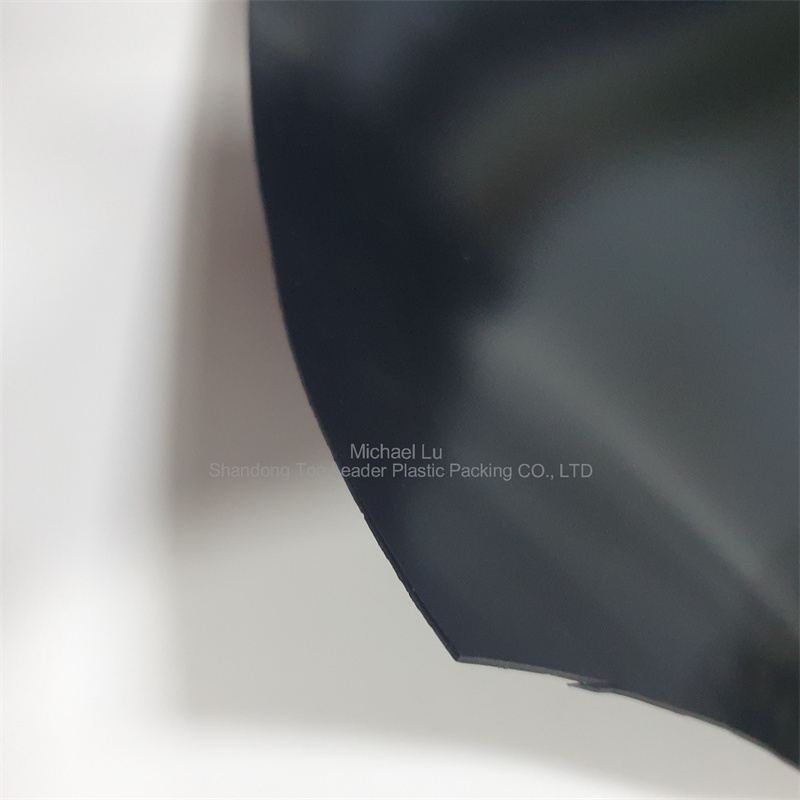

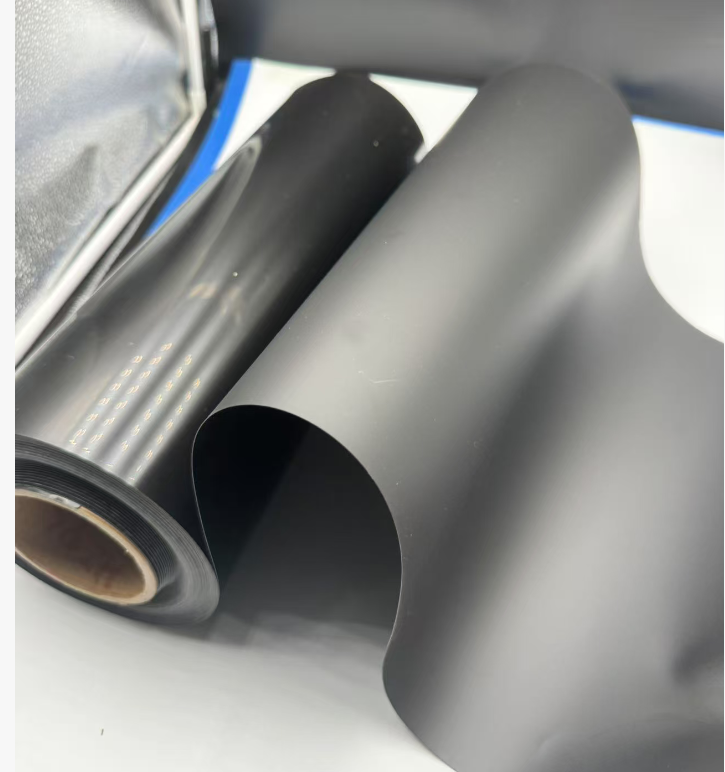

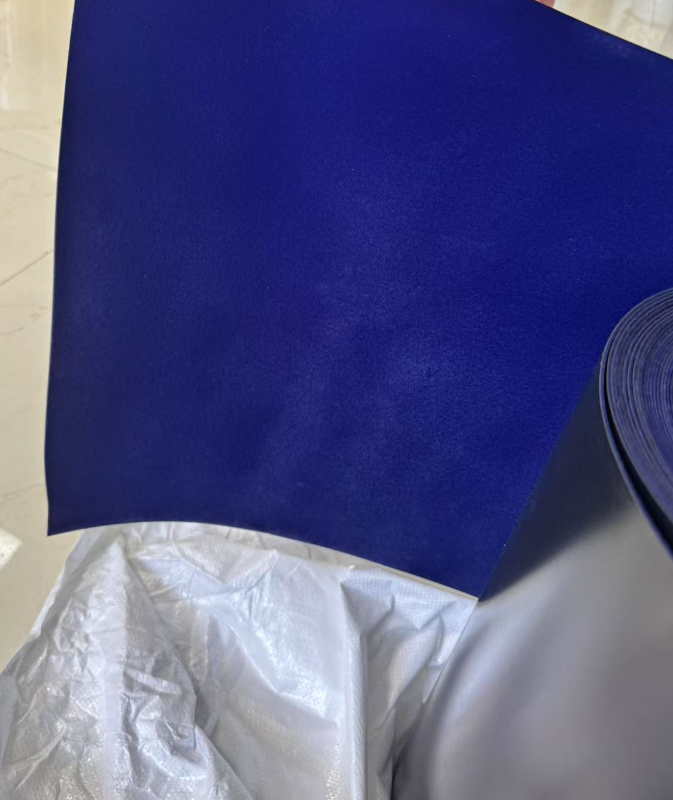

GPPS/HIPS white blister sheets glossy

HIPS stands out in the field of thermoforming for its ease of molding, cost-effectiveness, compliance with food and health safety standards, and its environmentally friendly properties. While rigid PVC film and rigid PVC sheet remain relevant in specific packaging sectors, especially for their durability and barrier properties, HIPS is the material of choice for a wide array of packaging applications, satisfying both manufacturers' and consumers' needs.

- top leader plastic

- China

- customized

- 1500 tons/month

- Information

- Video

High-impact polystyrene (HIPS) serves a significant role in the manufacturing industry, particularly in the realms of packaging and disposable materials. Its widespread use is seen in the containment and protection of various products, most notably food items and health-related products.

One of the fundamental reasons for the choice of HIPS in these applications is its superior performance in thermoforming processes. When heated, HIPS becomes pliable, allowing it to be easily molded into the desired shapes, which solidify upon cooling to form sturdy and reliable packaging solutions. This thermoforming advantage is particularly beneficial when compared to other materials, such as rigid PVC film or rigid PVC sheet, which are also used in packaging applications.

The HIPS sheet utilized for food-related purposes is of the food-grade variety, ensuring safety and compliance with health standards. This quality of the material allows direct contact with consumable products without risking contamination or adverse chemical reactions. It is not only used for the production of yogurt cups but also for assorted food packaging trays, which are central to the presentation and preservation of many perishable items on shelves.

Performance characteristics

Good processing performance: good fluidity, can adapt to various processing methods such as injection molding, extrusion, thermoforming, etc. The processing temperature is usually 190°C-240°C, which can meet the requirements of rapid molding of yogurt cups and improve production efficiency.

High mechanical properties: tensile strength is generally 20-35MPa, elongation at break is usually 15%-50%, impact strength is 2-6kJ/m² (tested according to ISO 179 standard), with good toughness and impact resistance, can prevent yogurt cups from breaking due to collision and extrusion during transportation and use.

Suitable thermal properties: melting temperature range is 220°C-260°C, glass transition temperature is about 90°C-100°C, thermal stability is good below 250°C, suitable for yogurt cup processing technology and low-temperature storage environment.

Within 15-20 days after received payment...more