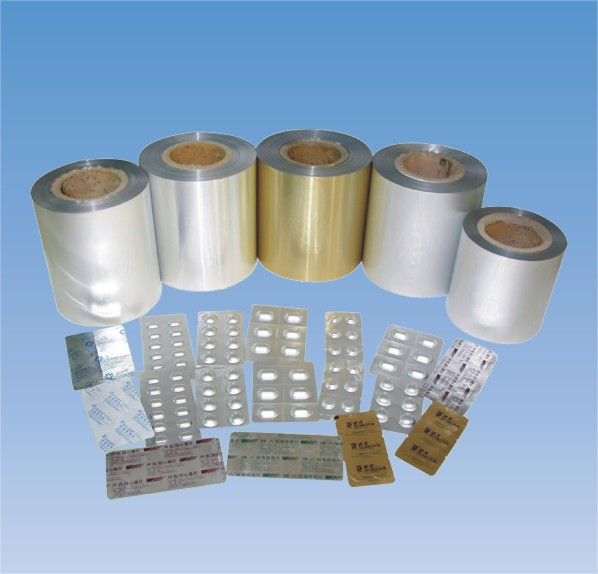

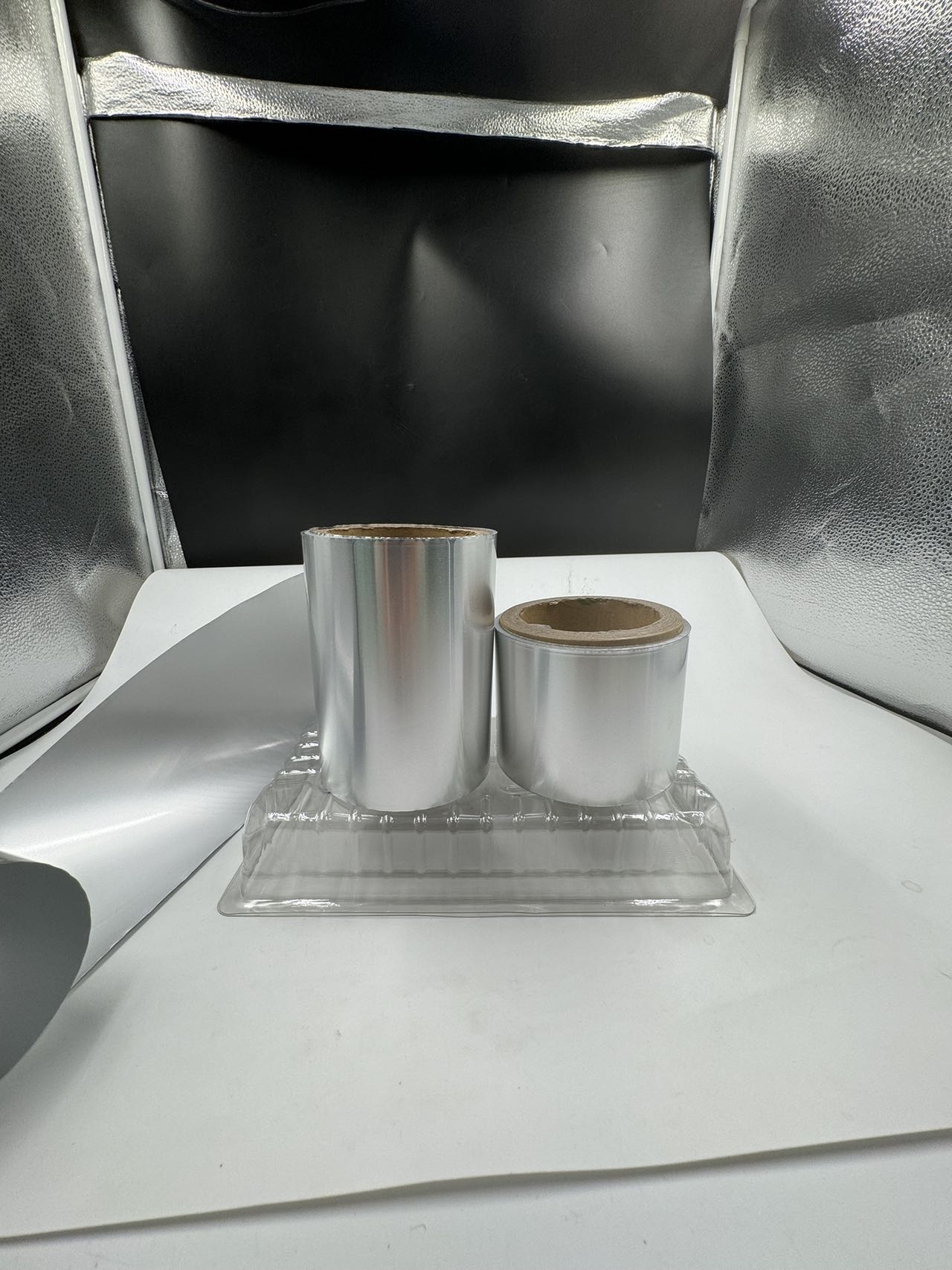

TL-AL-900 THE Aluminum foil for heat sealing packaging

MATERIAL: ALUMINUM roll

THICKNESS:0.04MM-customization

COLORE: Aluminum-customization

SIZE:80MM-customization

GRADE:FOOD GRADE

- TOPLEADER

- CHINA

- 15WORKING DAYS

- 5000T/M

- Information

- Download

Title: The Versatile Applications of Aluminum Films as Heat-Sealing Films in Pharmaceutical and Food Packaging

Introduction

In the modern world, packaging plays a crucial role in ensuring the safety, quality, and integrity of products. Among the various packaging materials available, aluminum films have emerged as a highly reliable and versatile option for both pharmaceutical and food packaging. With their unique properties and advantages, aluminum films have become an integral part of the packaging industry, providing an effective barrier against external factors and enhancing the shelf life of products.

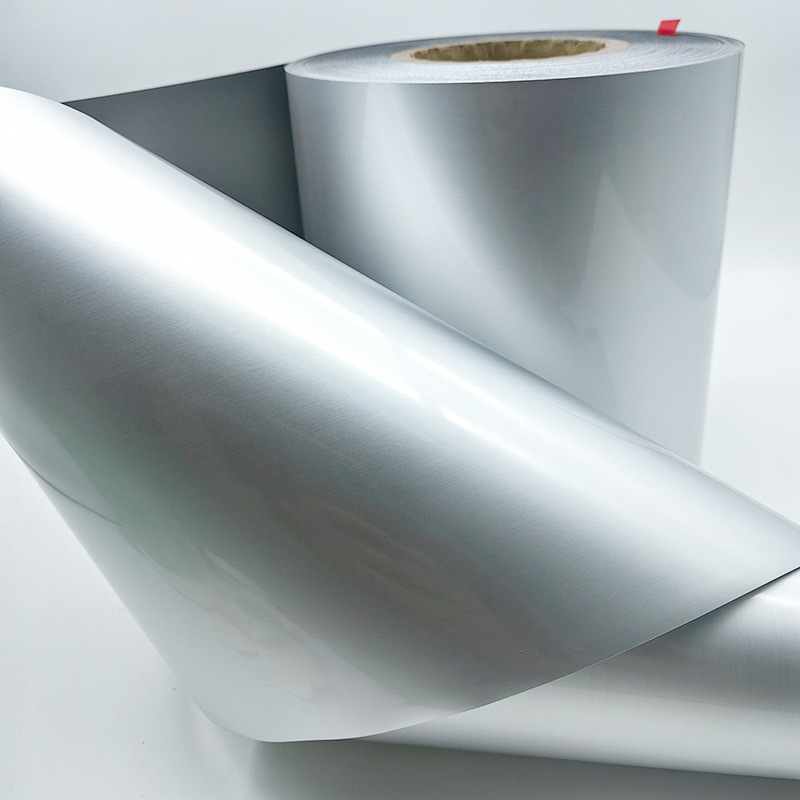

The Properties of Aluminum Films

Aluminum films are known for their excellent barrier properties. They are highly impermeable to moisture, oxygen, light, and other gases, which helps in protecting the contents of the package from degradation. This is particularly important for pharmaceutical products, where moisture and oxygen can cause the degradation of active ingredients and reduce the efficacy of the drug. In food packaging, aluminum films help in preserving the freshness and flavor of the product by preventing the entry of air and moisture.

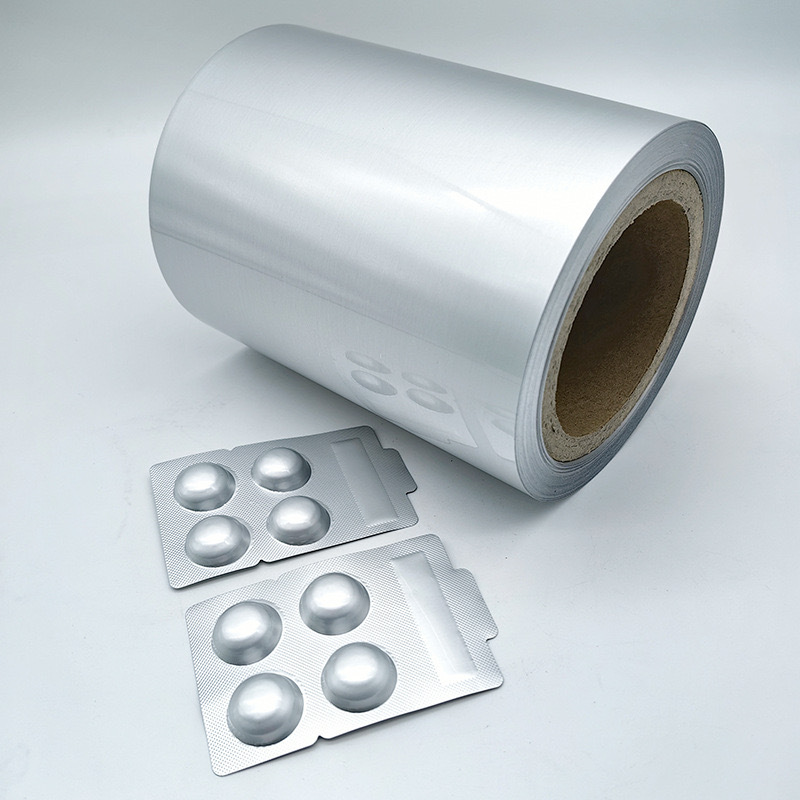

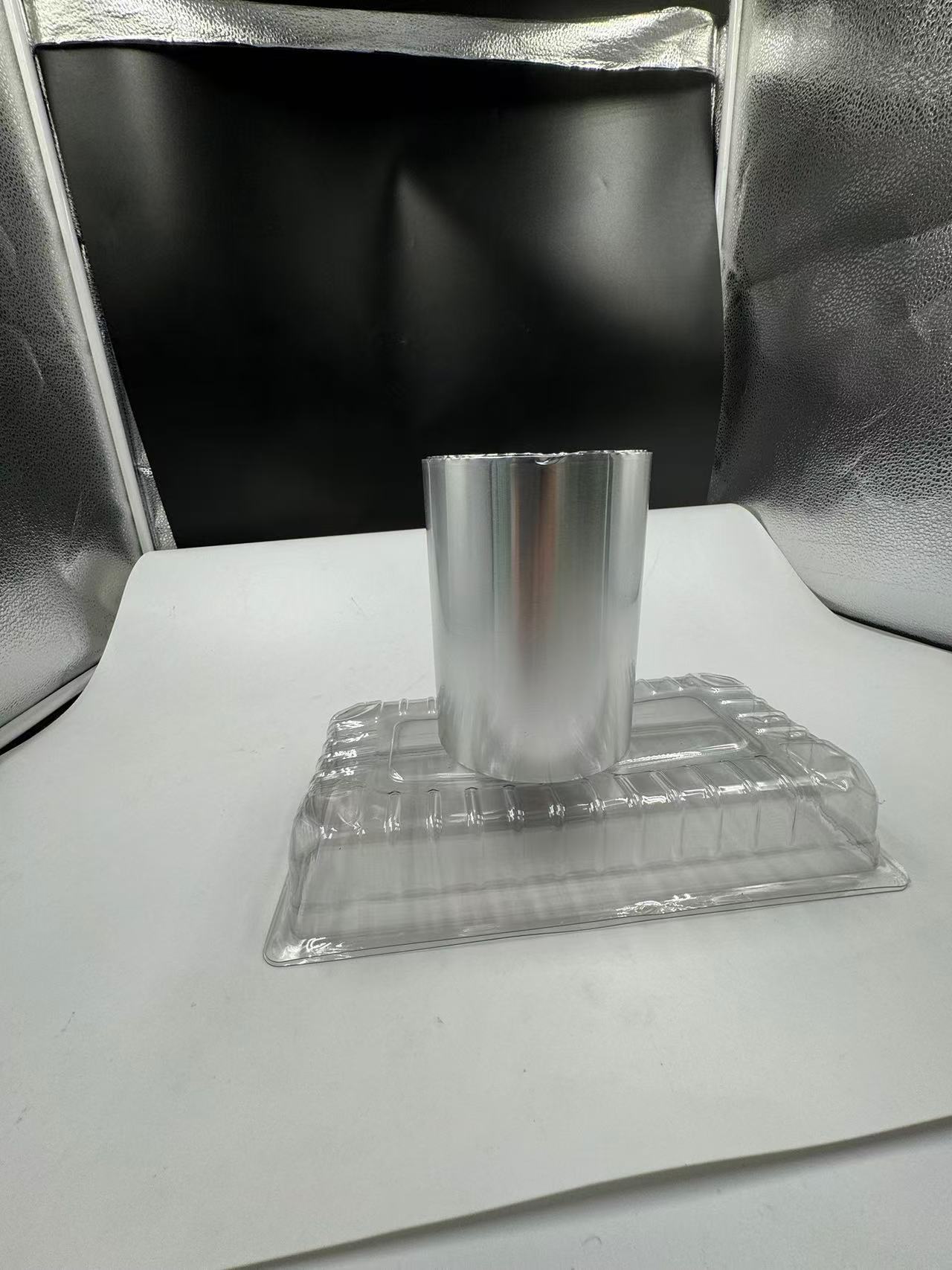

Another important property of aluminum films is their heat-sealability. Aluminum films can be easily heat-sealed to various substrates, such as plastic films, paperboard, and laminates. This allows for the creation of tight seals that prevent the leakage of the product and ensure the integrity of the package. The heat-sealing process is also relatively quick and efficient, making it suitable for high-speed packaging lines.

Aluminum films are also lightweight and flexible, which makes them easy to handle and process. They can be easily formed into various shapes and sizes, making them suitable for a wide range of packaging applications. Additionally, aluminum films have a high tensile strength and puncture resistance, which helps in protecting the package from physical damage during transportation and handling.

Applications in Pharmaceutical Packaging

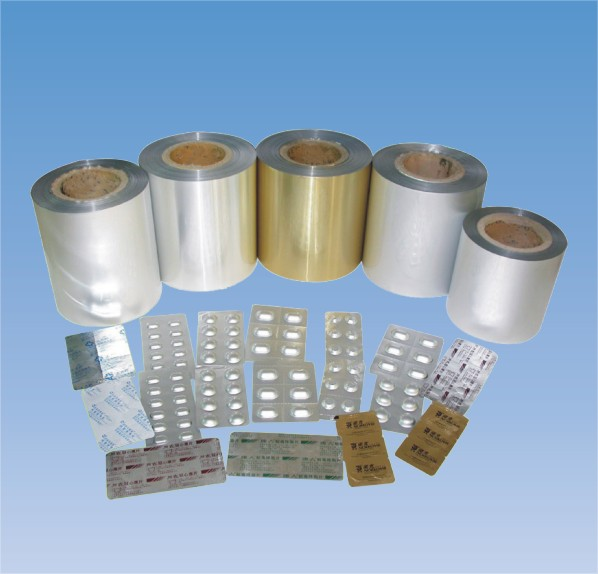

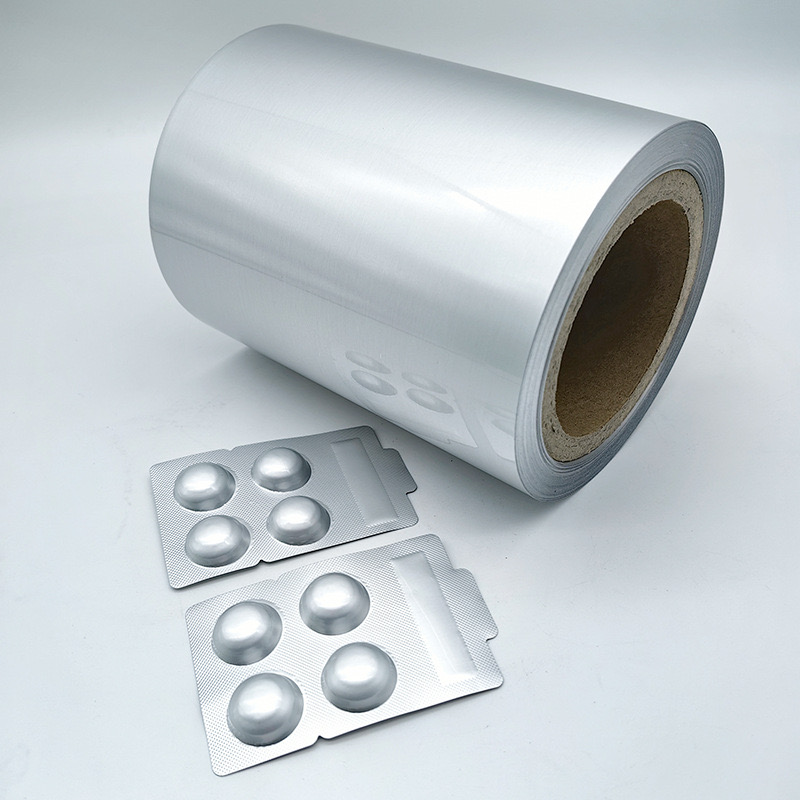

In the pharmaceutical industry, aluminum films are widely used as heat-sealing films for blister packaging. Blister packaging is a popular packaging format for solid oral dosage forms, such as tablets and capsules. The aluminum film is heat-sealed to a plastic blister tray, creating a protective barrier around the drug product. The blister packaging provides several advantages, including protection from moisture and oxygen, ease of handling and dispensing, and tamper-evident features.

Aluminum films are also used in the packaging of liquid and semi-solid pharmaceutical products. In these applications, the aluminum film is often combined with other materials, such as plastic films or laminates, to create a multi-layer packaging structure. The aluminum film provides an effective barrier against moisture and oxygen, while the other materials provide additional properties such as flexibility and printability.

In addition to blister packaging and liquid/semi-solid packaging, aluminum films are also used in the packaging of injectable drugs. Injectable drugs require sterile packaging to ensure the safety and efficacy of the product. Aluminum films can be used in combination with other sterile packaging materials, such as glass vials and rubber stoppers, to create a sterile barrier. The aluminum film provides an additional layer of protection against external contaminants and helps in maintaining the sterility of the product.

Applications in Food Packaging

Aluminum films are also widely used in food packaging due to their excellent barrier properties and heat-sealability. In the food industry, aluminum films are used for packaging a wide range of products, including snacks, beverages, dairy products, and frozen foods.

For snacks and dry foods, aluminum films are often used as stand-up pouches or laminated films. The aluminum film provides an effective barrier against moisture and oxygen, which helps in preserving the freshness and crunchiness of the product. The stand-up pouch format is also convenient for consumers, as it allows for easy storage and dispensing of the product.

In beverage packaging, aluminum films are used for packaging cans and bottles. The aluminum can is a popular packaging format for carbonated beverages, as it provides an excellent barrier against oxygen and carbon dioxide. The aluminum film is also used as a label or decoration on beverage bottles, providing a high-quality finish and enhancing the visual appeal of the product.

For dairy products and frozen foods, aluminum films are often used in combination with other materials, such as plastic films or laminates. The aluminum film provides an effective barrier against moisture and oxygen, while the other materials provide additional properties such as flexibility and heat-sealability. This multi-layer packaging structure helps in preserving the freshness and quality of the product and extending its shelf life.

Advantages of Aluminum Films in Packaging

The use of aluminum films in packaging offers several advantages over other packaging materials. Some of the key advantages include:

1. Excellent barrier properties: Aluminum films are highly impermeable to moisture, oxygen, light, and other gases, which helps in protecting the contents of the package from degradation.

2. Heat-sealability: Aluminum films can be easily heat-sealed to various substrates, creating tight seals that prevent the leakage of the product and ensure the integrity of the package.

3. Lightweight and flexible: Aluminum films are lightweight and flexible, making them easy to handle and process. They can be easily formed into various shapes and sizes, making them suitable for a wide range of packaging applications.

4. High tensile strength and puncture resistance: Aluminum films have a high tensile strength and puncture resistance, which helps in protecting the package from physical damage during transportation and handling.

5. Tamper-evident features: Aluminum films can be designed with tamper-evident features, such as tear strips or holographic labels, to ensure the integrity of the package and protect consumers from counterfeit products.

6. Recyclability: Aluminum films are highly recyclable, which makes them an environmentally friendly packaging option.

Challenges and Future Trends

Despite their many advantages, aluminum films also face some challenges in packaging applications. One of the main challenges is the cost of aluminum, which can be relatively high compared to other packaging materials. Additionally, the production of aluminum films requires significant energy consumption, which can have an impact on the environment.

To address these challenges, the packaging industry is constantly exploring new technologies and materials to improve the performance and sustainability of aluminum films. Some of the future trends in aluminum film packaging include:

1. Thinner films: The development of thinner aluminum films can help reduce material costs and energy consumption. Thinner films can also provide better flexibility and heat-sealability, making them suitable for a wider range of packaging applications.

2. Multilayer films: The combination of aluminum films with other materials, such as plastic films or laminates, can create multi-layer packaging structures with enhanced barrier properties and functionality. Multilayer films can also help reduce the amount of aluminum used, making the packaging more sustainable.

3. Sustainable production: The packaging industry is increasingly focusing on sustainable production methods, such as the use of renewable energy sources and recycled materials. The development of sustainable production methods for aluminum films can help reduce the environmental impact of packaging and meet the growing demand for sustainable products.

4. Intelligent packaging: The integration of intelligent packaging technologies, such as sensors and indicators, can provide real-time information about the condition of the product and enhance the safety and quality of packaging. Aluminum films can be used as a substrate for intelligent packaging technologies, providing an effective barrier and enhancing the functionality of the package.

Conclusion

Aluminum films have emerged as a highly reliable and versatile packaging material for both pharmaceutical and food packaging. With their excellent barrier properties, heat-sealability, lightweight and flexible nature, and high tensile strength and puncture resistance, aluminum films offer several advantages over other packaging materials. However, the packaging industry also needs to address the challenges associated with aluminum films, such as cost and environmental impact. By exploring new technologies and materials and focusing on sustainable production methods, the packaging industry can continue to improve the performance and sustainability of aluminum films and meet the growing demand for high-quality packaging solutions.

Within 15-20 days after received payment...more