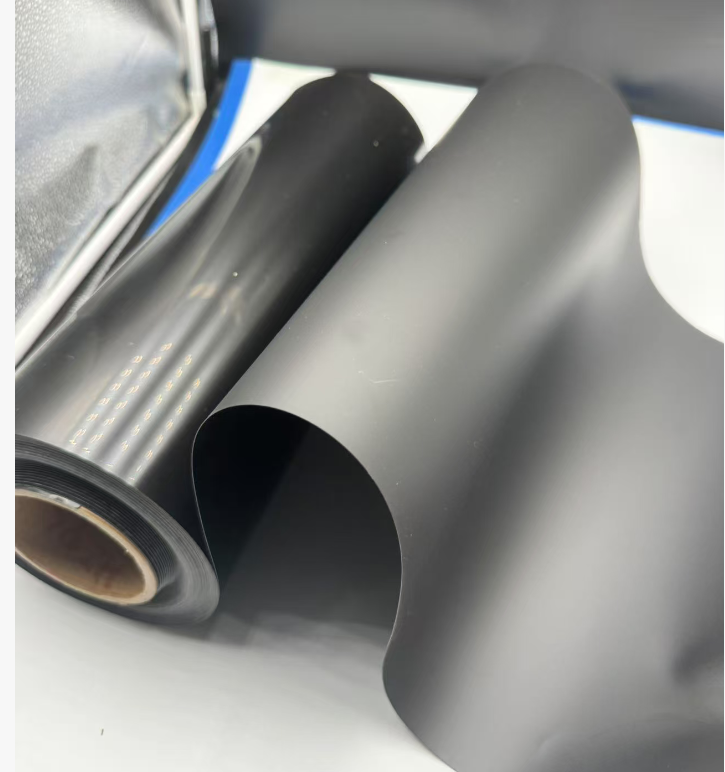

HIPS static dissipative sheet for electronic product protection

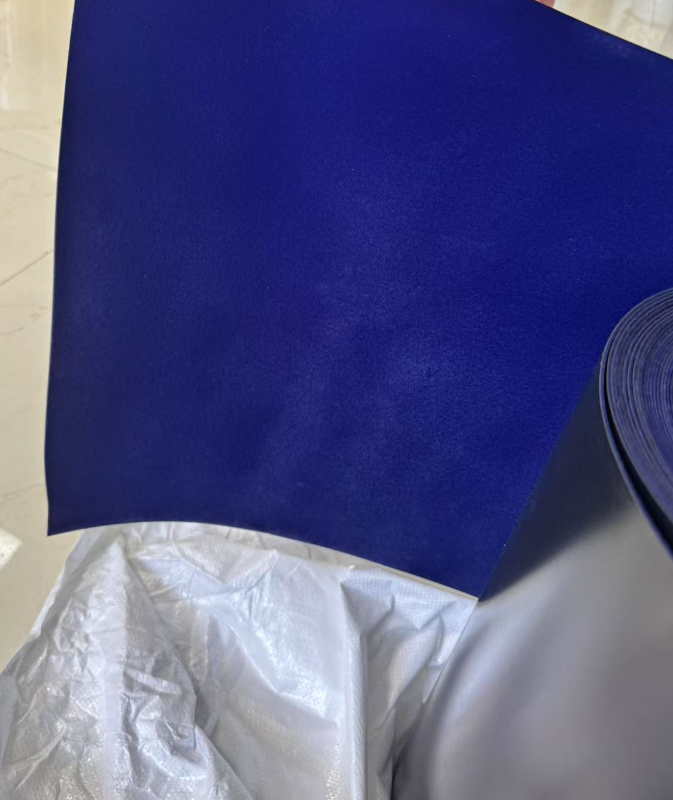

Blue PS antistatic thermoforming sheet

HIPS static dissipative sheet for electronic product protection

Long-lasting conductive blue PS sheet

- top leader plastic

- China

- 19 business days

- 1500 tons/month

- Information

Blue PS antistatic thermoforming sheet

HIPS is modified by adding rubber to ordinary PS (polystyrene), improving its impact resistance (3-5 times higher than regular PS) while retaining PS's ease of processing. This prevents sheet breakage caused by collisions during transportation and assembly of electronic products, ensuring that protection is maintained. Its easy processing makes it suitable for complex protective structures (such as shaped gaskets and grooved trays).

With a surface resistivity between 10⁶ and 10¹¹Ω (meeting standards for electrostatic dissipative materials), it slowly discharges static charge (rather than conducting it away or accumulating it), preventing static sparks. This prevents static electricity from damaging delicate electronic components (such as chips and capacitors) and also prevents static electricity from attracting dust, which can affect component heat dissipation and performance. HIPS can be processed into any shape (such as trays, blister packing, gaskets, and covers) through heating, pressurizing, and cooling processes. This allows for customized protective packaging for electronic products of varying sizes and shapes (such as mobile phone motherboards, computer graphics cards, and automotive chips).

Blue is the industry's default "anti-static material identification color," allowing workers to quickly distinguish between "normal sheet" and "anti-static" materials. Anti-static sheeting prevents the use of non-anti-static materials for delicate component packaging (e.g., accidentally placing chips in ordinary PS trays, which can cause static damage).

1. Electronic Component Transfer: Trays and Liners

This is the most common application scenario. Sheet material is thermoformed into grooved transfer trays or partitioned liners:

Chip/Connector Trays: Used for transferring small components such as IC chips, USB connectors, resistors, and capacitors. The grooves on the trays perfectly match the component dimensions, securing the components and preventing collisions while also providing static dissipation to prevent damage.

Motherboard/Graphics Card Liners: Placed inside motherboard and graphics card transfer boxes, the raised ridges isolate the components from the box walls, preventing pin deformation caused by bumps during transportation.

HIPS static dissipative sheet for electronic product protection

Long-lasting conductive blue PS sheet

Within 15-20 days after received payment...more