BOPA film is much more than just a packaging material; it plays a strategic role in modern packaging solutions

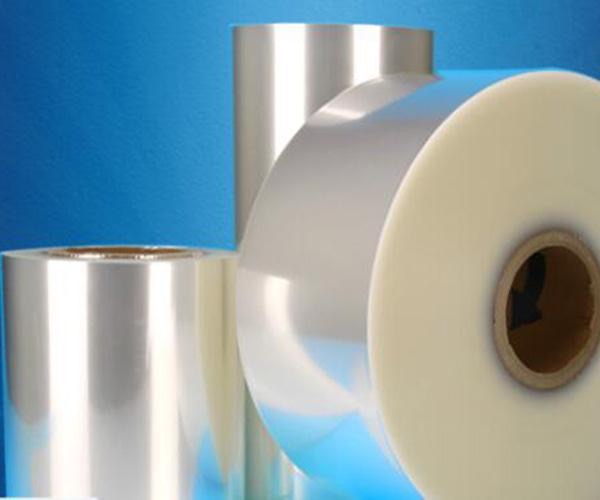

Material: bopa film roll

Thickness 0.012mm/customization

Size: 100mm customization

GRADE: Food grade film

color: white/fog/matt/ clear customization

location: china

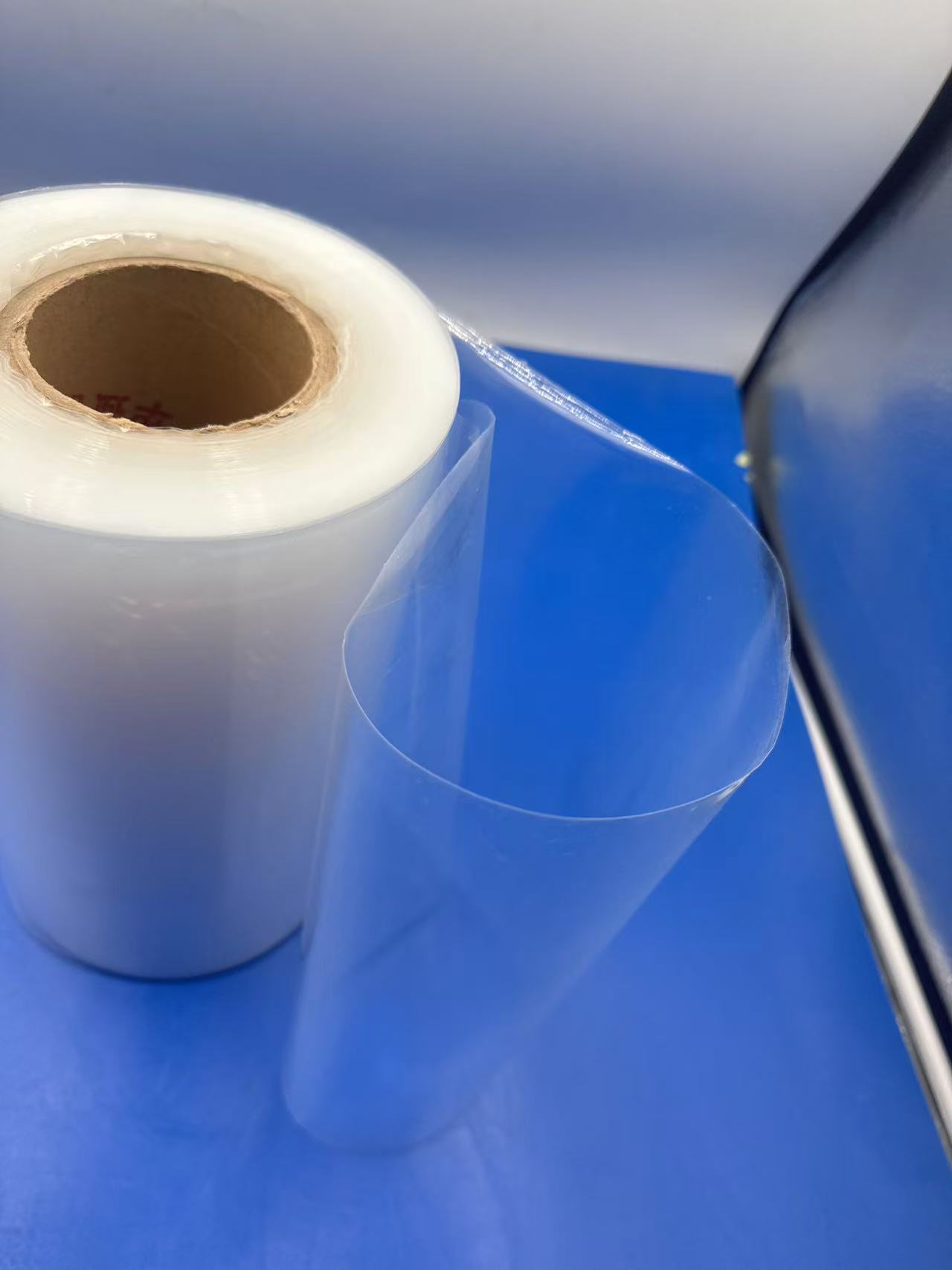

usage: for food protection, vacuum packing food heat-sealing box,lamination

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction to BOPA Film

BOPA stands for Biaxially Oriented Polyamide (Nylon) Film. As a value-added packaging material with superior mechanical properties and barrier characteristics,

it has been gaining paramount importance in food processing, pharmaceuticals, chemical products, and many other fields. BOPA film is specially noted for its resistance to break, impact, and puncture, with capabilities in aroma barrier, which makes it suitable for applications involving frozen, vacuum, and retort packaging where food freshness and flavor are important to be preserved. Characteristics of BOPA Film

Mechanical Properties: The biaxial orientation that aligns the polymer chains confers a superlative tensile, toughness, and puncture to the BOPA films hence a strong material with unrivaled mechanical strengths.

Barrier Properties:

One Side: Oxygen barrier properties because the OTR for BOPA is considered relatively low and thereby an extension in the life on the shelf for such commodities against oxidations.

The second one should concern Aroma.

Thermal Stability: This film retains its properties over a wide temperature range, suitable for both freezing and high-temperature applications like retort packaging. Chemical Resistance: BOPA is resistant to many chemicals, further enhancing its utility in packaging where products may come into contact with a variety of substances.

Transparency and Appearance: It can be made quite transparent, which is necessary for some packages where product visibility is wanted. Besides that, it can either be matte or glossy, whichever the application may require.

Environmental Impact: The BOPA films are also generally considered more environmentally friendly in comparison to several other plastics owing to their high resistance and being potentially recyclable, though recycling nylon films is not easy.

Applications of BOPA Film

Food Industry:

Freshness Preservation: BOPA highly contributes to the prolonging of foodstuffs' shelf life, especially in e-commerce where it is very hard to keep the integrity during transportation.

Vacuum and Retort Packaging: The product is applied to meats, snacks, ready-to-eat meals enabling it to maintain flavor and nutritional values for a certain period of time.

Daily Chemicals:

Light-weighted and convenient packaging: Due to the support of BOPA, the shift from rigid to soft packaging contributes to portability and user-friendliness in product packaging.

Aesthetic appeal: Printability imparting good visibility to brands effective consumer acceptance, which is of great importance in today's market competition .

Lithium-ion Battery Industry:

Aluminum Laminated Film: In the case of aluminum laminated films used in soft-pack lithium-ion batteries, BOPA is the main component to provide mechanical strength, insulation, and resistance to battery electrolytes.

Medical Field:

Pharmaceutical Packaging: The barrier properties preserve the integrity of drugs against moisture, oxygen, and light that might degrade pharmaceuticals.

Market Trends and Development

Market Growth: The demand for BOPA films in the world market has grown from 271,300 tons in 2016 to 381,600 tons in 2020 at a compound annual growth rate of 8.91%. In comparison, the demand in China surged at an even higher growth rate of 13.53% annually, reflecting its robust growth in the industry.

Geographical Distribution: The Asia-Pacific region, especially China and Japan, is dominant in the consumption of BOPA films, accounting for about 80% of the global market in 2020.

Future Outlook: Demand for BOPA is very likely to grow further, considering that global demand by 2025 will be about 579,000 tons, driven by demands for high-barrier, sustainable, and customer-specific packaging. The technologies being used are as follows. Manufacturing Process The evolution of manufacturing processes-from the simple flat-film stretching technique to the state-of-the-art sequential biaxial stretching, simultaneous stretching, and magnetic levitation linear synchronous motor technology-in this industry is really marching ahead on efficiency, quality, and customer customization.

Future Manufacturing Trends:

Sustainability: Trend to reduce energy consumption and material usage in production.

Smart Manufacturing: Incorporating IoT, AI, and big data towards more intelligent and efficient lines of production.

Conclusion

BOPA film is much more than just a packaging material; it plays a strategic role in modern packaging solutions due to its unique combination of properties. The growth in demand and new technological advances in production ensure that it will be an indispensable part of sustainable, high-performance packaging for the foreseeable future. As consumer awareness and regulatory pressure for sustainability intensify, so will the use of BOPA in eco-friendly packaging solutions to respond to the evolution of various industry needs.

Within 15-20 days after received payment...more