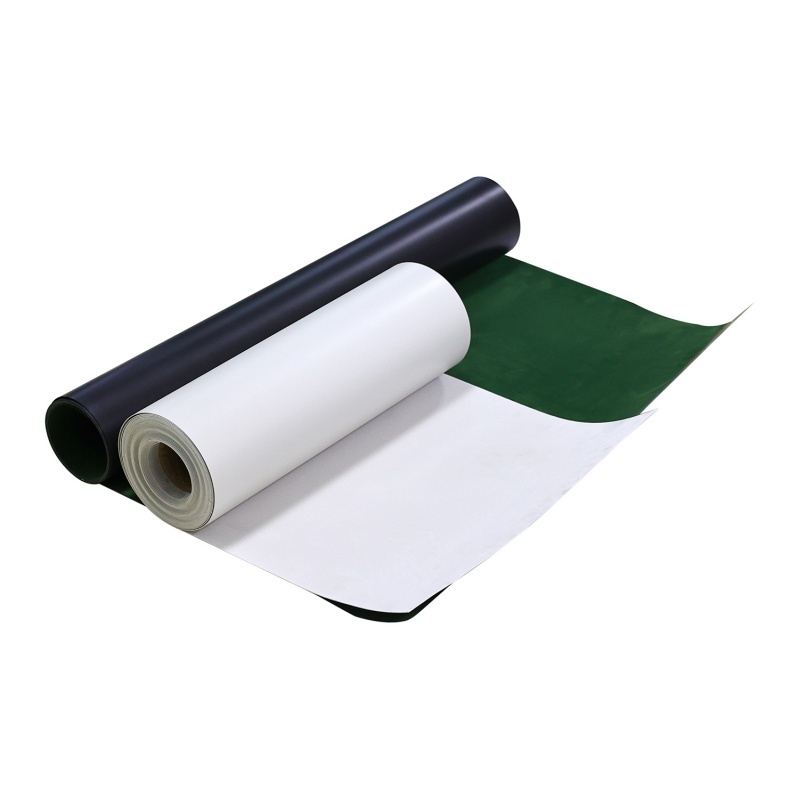

one side glossy one side coated with velvet black PS flocking sheet

one side glossy one side coated with velvet grey PS flocking sheet

1mm thickness flocked PS sheet, customized color and dimensions

- top leader plastic

- China

- 16 business days

- 150 tons/month

- Information

About this gray PS flocked sheet (1mm thick, available in optional colors, for thermoforming) with a smooth one-side and velvet-coated one-side:

Appearance and feel: One side features a smooth surface, facilitating lamination with other components or secondary processing such as printing. The other side is covered with velvet, creating a soft gray texture that enhances the product's aesthetics and tactile comfort, enhancing its quality and added value.

Material properties: PS offers excellent toughness and rigidity. The 1mm thickness ensures stability during the thermoforming process while also providing a certain degree of impact resistance, making it less susceptible to cracking or deformation. PS also offers good insulation and chemical stability.

Thermoformability: Suitable for thermoforming processes, it can be easily formed into various shapes under heating to meet the design requirements of diverse products, such as blister packaging, automotive interiors, and electronic product casings.

Applications

Packaging: It can be used in high-end gift boxes, cosmetic packaging, and electronic product packaging. The velvet-coated side protects the product surface from scratches and enhances the overall packaging quality. Automotive interiors: These products, such as dashboards and door trims, provide a pleasant touch while also providing sound and heat insulation.

Home decoration: They can be used in furniture veneers, decorative moldings, and photo frames, adding a warm and comfortable atmosphere to any home.

Other applications: They can also be used in the production of display stands, billboards, toys, and other products.

Production Process

Flocking: Electrostatic flocking is typically used. Under the influence of an electrostatic field, the flocking fibers are evenly adsorbed onto the adhesive layer on the surface of the PS sheet, forming a strong, firm covering. The choice of adhesive and control of flocking process parameters play a key role in the flocking effect and the strength of the fibers.

Thermoforming: Based on the required shape and size of the product, the PS flocking sheet is placed in a thermoforming machine. Through heating, stretching, and forming processes, it is conformed to the mold shape. After cooling, the desired thermoformed product is obtained. During the thermoforming process, parameters such as heating temperature, time, and stretching speed must be precisely controlled to ensure product quality and dimensional accuracy.

Within 15-20 days after received payment...more