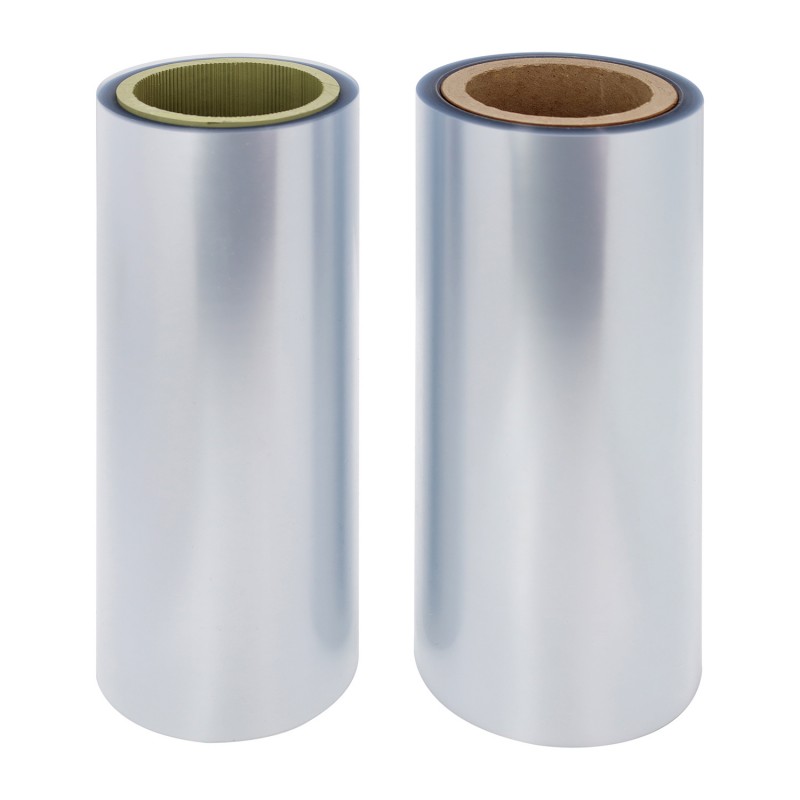

white PET sealing film, heat-sealing film, printable

White opaque PET composite film, cover film

PET sealing film, heat-sealing film, printable

- top leader plastic

- China

- 15 business days

- 150 tons/month

- Information

A "sealing expert" for food packaging: White opaque PET composite cover film, adapting to diverse needs with its heat-sealing and printability.

In food packaging, the cover film is the "last line of defense" protecting food freshness. Whether sealing the top of a bucket of instant noodles, the lid of a boxed cake, or sealing a cup of yogurt, the cover film requires a strong seal, heat resistance, and a high-quality appearance. White opaque PET composite cover film (also known as PET sealing film or heat-sealing film) combines the toughness of PET with the heat-sealing properties of the composite layer and the light-blocking properties of its opaque white color. It also supports custom printing, making it a versatile performer in the food packaging industry. Today, we'll take a look at this cover film to see how it balances sealing protection with brand presentation.

1. First, understand: What is white opaque PET composite cover film?

This cover film isn't made solely of PET. Instead, it's a multi-layered structure using PET (polyethylene terephthalate) as its base material, combined with a heat-seal layer and a light-blocking layer through lamination processes (such as dry lamination and extrusion lamination). Its design focuses on the core requirements of a cover film: secure heat sealing to containers (such as plastic cups, cartons, and metal cans), light-blocking properties, puncture resistance, and the ability to carry printed information.

Strong heat-sealing performance: Leak-proof, compatible with a wide range of containers.

The core value of lidding film is "sealing." The heat-sealing advantages of this PET composite lidding film lie in its wide compatibility, high strength, and stable weather resistance.

Compatible with a variety of container materials: The inner PE heat-sealing layer can be heat-sealed with PP cups, PS boxes, and paper containers (such as instant noodle buckets and cake boxes); the PP heat-sealing layer can be heat-sealed with PET bottles and aluminum cans (such as nut jars and protein powder jars). This eliminates the need to change lidding films for different containers, reducing procurement costs.

High heat-sealing strength and leak resistance: The post-heat-sealing peel strength is ≥3.0N/15mm. Even with liquids (such as yogurt and juice) or greasy foods (such as biscuits and nuts), there's no seal cracking or leakage. Tests by a dairy customer showed that yogurt cups sealed with this lidding film remained leak-free even when inverted for 24 hours, far superior to standard PE lidding films.

Wide heat-sealing temperature range: The PE heat-sealing layer is compatible with The PP heat seal layer is suitable for temperatures between 120-150°C and 150-180°C. It is compatible with both small manual heat sealers and large assembly line heat seal equipment. It offers low operational requirements and is less susceptible to seal failure due to temperature fluctuations.

Typical Applications: These Food Applications Are Essential

White opaque PET composite cover films are specifically targeted at food packaging requiring both sealing and light protection, covering a wide range of applications, from ready-to-eat foods to dry snacks:

1. Ready-to-eat foods: Sealed to lock in freshness and easy to open

Cup/boxed ready-to-eat foods: Such as instant noodle buckets, instant soup containers, boxed cakes, and yogurt cups – The heat-sealed cover film locks in the aroma of the food (such as the seasoning aroma of instant noodles) and prevents moisture during transportation. The opaque white design conceals visual imperfections in the food (such as slight dents on a cake), while also allowing for printed nutrition information and directions for enhanced practicality.

Disposable lunch box cover films: Suitable for disposable takeout containers, heat-sealed to prevent leaks and spills. The white printed version can be printed with a business logo for enhanced brand exposure. 2. Dry Goods and Powdered Foods: Blocking Light and Moisture to Extend Shelf Life

Canned dry goods/powdered foods: such as nut jars, protein powder jars, coffee powder jars, and milk powder jars – Heat-sealing the lid film to the aluminum can, combined with a desiccant inside the can, provides dual protection: blocking light and moisture, preventing oxidation and clumping of dry goods and powdered foods. The opaque white design blocks direct sunlight, making it particularly suitable for long-term storage.

Sealing bagged foods: For example, the "secondary seal" of potato chip and biscuit bags (some bagged foods use a lid film as an inner seal) enhances the packaging's barrier properties and extends the shelf life after opening.

Within 15-20 days after received payment...more